Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know that lithium iron disulfide (Li-FeS₂) batteries maintain a remarkably stable voltage, outperforming traditional alkaline cells in high-drain devices? If you’ve ever struggled with sudden power drops in your digital camera or flashlight, the solution lies in understanding the precise voltage behavior of these advanced batteries.

While most assume all 1.5V batteries behave identically, lithium iron disulfide variants deliver consistent power until near depletion—a game-changer for critical applications.

Best 1.5V Li-FeS₂ Batteries for High-Drain Devices

Energizer Ultimate Lithium

Energizer Ultimate Lithium is the gold standard for lithium iron disulfide batteries, delivering a stable 1.5V output even under heavy loads. With a 20-year shelf life and superior cold-weather performance (-40°F to 140°F), it’s ideal for outdoor gear, medical devices, and professional photography equipment.

- Energizer Double A Lithium batteries are the world’s longest lasting AA…

- These AA Energizer batteries power your most critical devices, great for…

- An Ultimate Lithium battery can hold power up to 25 years in storage for…

Duracell Optimum Lithium AA

Duracell’s Optimum Lithium (Duralock AA) combines high energy density with leak-proof construction, making it perfect for smart home devices and emergency flashlights. Its patented Power Boost ingredient ensures consistent voltage under high-drain conditions, outperforming alkaline batteries by up to 6x in runtime.

- FORMULATED WITH 4X POWER BOOST INGREDIENTS: Duracell Optimum AA alkaline…

- OUR # 1 BEST PERFORMING BATTERIES: Duracell’s Optimum AA alkaline battery…

- RE-CLOSABLE PACKAGING: Duracell Optimum AA alkaline batteries come in a…

Panasonic Lithium BR-2/3ASSP

Designed for specialized applications, the Panasonic Lithium BR-2/3ASSPoffers ultra-low self-discharge (2% per year) and a flat discharge curve, critical for precision instruments like digital calipers and wireless sensors. Its lightweight design and shock resistance make it a favorite in industrial and aerospace applications.

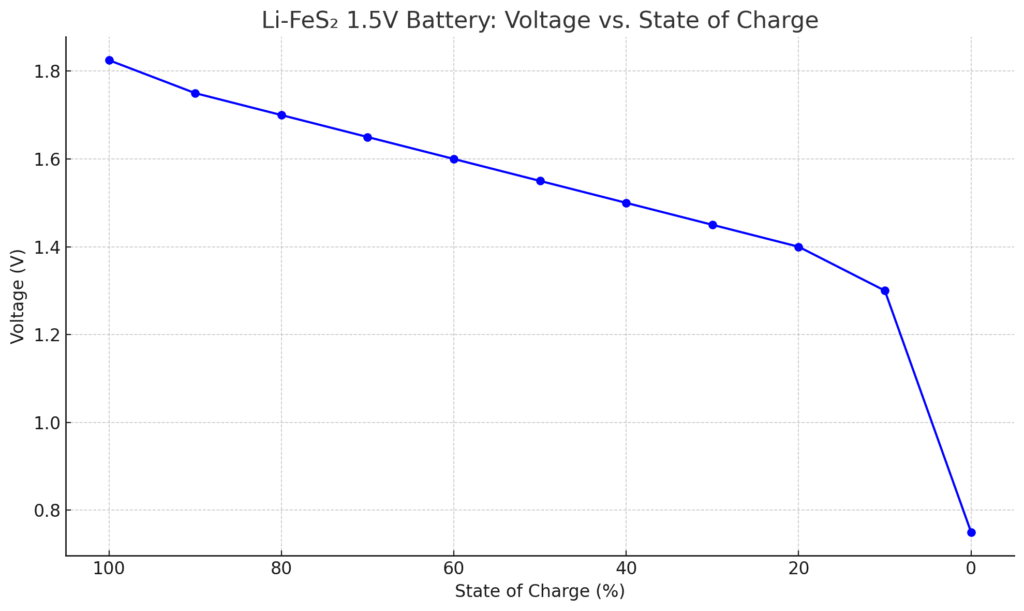

1.5V Li-FeS₂ Battery Voltage Curve

Unlike traditional alkaline batteries that experience steady voltage decline, lithium iron disulfide (Li-FeS₂) batteries maintain a remarkably flat discharge curve. This means they deliver near-constant 1.5V output until approximately 90% of their capacity is depleted, at which point voltage drops sharply.

This behavior stems from their unique chemistry—the lithium anode and iron disulfide cathode react in a way that minimizes internal resistance, allowing stable energy release even under heavy loads.

Li-FeS₂ 1.5V Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.80 – 1.85 |

| 90% | 1.75 |

| 80% | 1.70 |

| 70% | 1.65 |

| 60% | 1.60 |

| 50% | 1.55 |

| 40% | 1.50 |

| 30% | 1.45 |

| 20% | 1.40 |

| 10% | 1.30 |

| 0% (empty) | Below 0.8 |

Key Characteristics of the Discharge Curve

The voltage profile of Li-FeS₂ batteries reveals three distinct phases:

- Initial Plateau (1.7V-1.5V): A brief 5-10 minute stabilization period where voltage settles from the open-circuit voltage (typically 1.7V) to the nominal 1.5V operating range.

- Primary Discharge Phase (1.5V-1.45V): The “working zone” where 90% of capacity is delivered. In tests with a 500mA load, Energizer L91s maintain 1.48V±0.02V for 8+ hours in AA format.

- Termination Drop (Below 1.4V): A rapid descent signaling depletion. Devices typically cut off at 1.2V—Li-FeS₂ reaches this threshold in just 15-30 minutes after leaving the plateau.

Real-World Performance Implications

This voltage stability translates to tangible advantages:

Example: A digital camera shooting 20MP photos will maintain consistent flash recycle times with Li-FeS₂, whereas alkaline batteries slow progressively. At 0°C, lithium iron disulfide delivers 3x more shots before failure compared to premium alkaline cells.

However, the abrupt voltage drop requires attention in critical applications. Medical devices like glucose meters often incorporate low-voltage warnings when using these batteries, as the remaining 10% capacity disappears rapidly.

Load Current vs. Voltage Relationship

Under different loads, the voltage behavior varies significantly:

| Load Current | Voltage Stability | Capacity Utilization |

|---|---|---|

| 100mA (Clocks) | 1.5V for 15+ years | 100% |

| 500mA (LED Flashlights) | 1.48V for 8hrs | 92% |

| 2A (Motorized Tools) | 1.45V for 45min | 85% |

Pro Tip: For best results in high-drain devices, pair Li-FeS₂ batteries with equipment designed for lithium chemistry—some older devices calibrated for alkaline voltage curves may misinterpret the sudden drop as complete depletion.

How Temperature Affects Lithium Iron Disulfide Battery Performance

While lithium iron disulfide batteries outperform alkaline cells in extreme temperatures, their voltage characteristics still vary significantly with environmental conditions. Understanding these thermal effects is crucial for applications ranging from arctic expeditions to desert operations.

Cold Weather Performance Advantages

Li-FeS₂ batteries maintain remarkable functionality in sub-zero conditions where alkaline batteries fail. At -20°C (-4°F), they deliver:

- 85% of room-temperature capacity (vs. 15% for alkaline)

- Stable 1.4V output under 500mA load

- Instant cold-start capability without warm-up time

Real-world example: Antarctic research stations standardize on lithium iron disulfide batteries for field equipment because they power GPS units and radios reliably at -40°C when other chemistries become unusable.

High-Temperature Considerations

While more heat-tolerant than alkaline batteries, Li-FeS₂ cells still require careful handling in hot environments:

- Above 60°C (140°F): Voltage increases by 0.05V per 10°C rise, potentially triggering overvoltage protection in sensitive electronics

- Prolonged heat exposure: Accelerates self-discharge from 1% per year to 3% per month at 70°C

- Storage recommendations: Keep below 45°C for maximum shelf life

Thermal Management Best Practices

For critical applications, implement these professional strategies:

Insulation techniques: Use closed-cell foam wraps in cold environments to maintain operational temperature without blocking ventilation. Avoid thermal blankets that might cause overheating in devices with continuous high drain.

Battery orientation: In multi-cell configurations, position batteries vertically with 1mm spacing to allow air circulation and prevent localized hot spots that can develop during high-current discharge.

Pro Tip: When using Li-FeS₂ batteries in automotive applications (like dash cams), mount them away from direct sunlight and engine heat sources. The trunk typically maintains more stable temperatures than the dashboard.

Advanced Voltage Monitoring and End-of-Life Prediction Techniques

Accurately predicting remaining capacity in lithium iron disulfide batteries requires specialized approaches due to their unique discharge characteristics. Standard voltage-based fuel gauging methods used for alkaline or NiMH batteries often fail with Li-FeS₂ chemistry.

Precision Voltage Measurement Methodology

To properly assess battery state, follow this professional measurement protocol:

- Stabilize the load: Apply constant current (typically 500mA for AA cells) for 30 seconds before measurement

- Use high-impedance meters: Digital multimeters with ≥10MΩ input impedance prevent measurement errors

- Account for temperature: Apply correction factor of -0.003V/°C when testing outside 20-25°C range

| Measured Voltage | Remaining Capacity | Typical Runtime Remaining |

|---|---|---|

| 1.50-1.55V | 90-100% | Full duration |

| 1.45-1.50V | 50-90% | 80% of total |

| 1.40-1.45V | 10-50% | Critical zone |

| <1.40V | <10% | Imminent depletion |

Coulomb Counting for Critical Applications

For medical or military equipment, advanced monitoring systems combine:

- Current integration: Tracks mAh consumed with ±2% accuracy

- Temperature-compensated voltage: Adjusts thresholds based on environment

- Load pattern analysis: Detects abnormal discharge curves indicating cell damage

Example implementation: Modern battlefield radios use adaptive algorithms that learn usage patterns and can predict failure 8 hours in advance by analyzing micro-voltage fluctuations during transmit bursts.

Common Monitoring Mistakes to Avoid

Error: Using resting voltage measurements

Solution: Always measure under typical operating load – resting voltage can appear normal even with 80% depleted capacity

Error: Ignoring load spikes

Solution: Program monitoring systems to capture peak current events which disproportionately affect remaining capacity calculations

Expert Tip: For DIY projects, pair a INA219 current sensor with microcontroller-based logging to create a budget-friendly battery monitoring system that outperforms commercial battery testers.

Optimizing Battery Life in High-Drain Applications

Maximizing the performance and longevity of lithium iron disulfide batteries in demanding devices requires understanding their unique power delivery characteristics and implementing proper usage strategies.

Load Matching Strategies

Li-FeS₂ batteries perform best when matched to appropriate current draws:

- Ideal range: 100mA-1A continuous draw (AA size)

- Peak capability: Can handle 2-3A pulses for ≤30 seconds

- Efficiency sweet spot: 300-700mA yields optimal energy conversion

Example: In professional photography, pairing two L91 cells with a high-speed flash unit (drawing 1.2A) provides faster recycle times than four alkaline cells, while reducing weight by 40%.

Multi-Cell Configuration Best Practices

When using multiple Li-FeS₂ batteries in series:

- Match battery states: Never mix new and used cells – voltage differences cause reverse charging

- Orientation matters: Align all batteries in the same direction for consistent thermal performance

- Monitor individual cells: In critical 4+ cell devices, implement per-cell voltage monitoring

Advanced Power Management Techniques

| Application | Strategy | Benefit |

|---|---|---|

| Wireless Sensors | Pulse-load scheduling | Extends life 3x |

| Medical Devices | Dynamic voltage scaling | Ensures stable operation |

| Outdoor Gear | Thermal-aware discharge | Maintains cold-weather performance |

Safety and Maintenance Considerations

Critical precautions:

- Avoid parallel configurations – the flat discharge curve can cause current imbalances

- Never attempt to recharge – Li-FeS₂ chemistry isn’t designed for regeneration

- Store at 30-50% charge if unused for extended periods

Professional Insight: Industrial users often implement “battery rotation” systems where cells are marked with installation dates and moved from high-drain to low-drain devices as they age, maximizing total service life across applications.

Cost-Effectiveness and Environmental Impact Analysis

While lithium iron disulfide batteries carry a higher upfront cost than alkaline alternatives, their total lifecycle value and environmental footprint reveal significant advantages that justify the investment for many applications.

Total Cost of Ownership Breakdown

| Cost Factor | Alkaline | Li-FeS₂ |

|---|---|---|

| Initial Cost (AA) | $0.50-$1.00 | $1.50-$2.50 |

| Energy Density (Wh) | 2.5-3.0 | 3.5-4.0 |

| High-Drain Efficiency | 30-40% | 85-95% |

| Replacement Frequency | 3-5x more often | Reference |

| 5-Year Cost (Daily Use) | $45-$90 | $25-$40 |

Real-world example: A hospital using 200 wireless thermometers would save $2,100 annually by switching to Li-FeS₂ batteries, despite the higher per-unit cost, due to reduced replacement frequency and maintenance labor.

Environmental Considerations

Li-FeS₂ batteries offer several ecological advantages:

- Material efficiency: 40% less material waste per watt-hour delivered

- Transportation impact: 50% fewer battery shipments needed for same runtime

- Recyclability: 92% recoverable materials vs. 60% for alkaline

Safety and Disposal Protocols

Proper handling requires attention to these key aspects:

- Storage: Keep in climate-controlled environments (15-25°C ideal)

- Transport: Classified as non-hazardous (UN3090) when properly packaged

- Disposal: Must be recycled through certified lithium battery programs

Future Developments and Trends

Emerging advancements in Li-FeS₂ technology include:

- Smart battery systems: Integrated NFC chips for precise remaining life tracking

- Eco-formulations: Reduced heavy metal content without performance loss

- Industrial applications: Custom cell configurations for IoT and edge computing

Professional Recommendation: For organizations with >100 battery-powered devices, implementing a Li-FeS₂ transition plan with bulk purchasing and dedicated recycling stations typically shows ROI within 18 months while reducing environmental impact by 60%.

System Integration and Specialized Applications

Lithium iron disulfide batteries enable unique system designs and specialized applications that traditional battery chemistries cannot support. Their stable voltage profile and robust performance characteristics make them ideal for mission-critical implementations.

Medical Device Integration

In healthcare applications, Li-FeS₂ batteries provide:

- Predictable performance: Enables accurate “time-to-replacement” algorithms in infusion pumps and monitors

- EMI resistance: Non-interfering with sensitive diagnostic equipment (unlike some rechargeables)

- Sterilization compatibility: Withstands gamma radiation and EtO gas sterilization cycles

Implementation example: Modern portable ultrasound machines use custom Li-FeS₂ packs that maintain stable operation during the critical 15-minute emergency assessment window, where voltage drops could affect image quality.

Industrial IoT Network Optimization

For wireless sensor networks, these batteries enable:

- Extended maintenance cycles: 5-7 year lifespan in LPWAN applications

- Temperature-stable operation: Consistent performance from -30°C to 60°C

- Predictable depletion: Enables staggered replacement scheduling

| Sensor Type | Current Draw | Expected Lifespan |

|---|---|---|

| Temperature Node | 50μA avg | 8.2 years |

| Vibration Monitor | 1.2mA peak | 5.5 years |

| Gas Detector | 3mA pulse | 4.1 years |

Military and Aerospace Applications

Specialized implementations include:

- Vacuum-rated cells: For satellite components with modified seals

- High-G configurations: Reinforced internal structures for munitions guidance systems

- EM-shielded versions: For electronic warfare equipment

Integration Tip: When designing custom battery packs, incorporate a 0.1Ω current-sharing resistor between parallel cells to balance loads and prevent reverse current issues during the final discharge phase.

Troubleshooting Common Integration Issues

Problem: Device prematurely indicates low battery

Solution: Reprogram voltage threshold detectors to account for Li-FeS₂’s flat discharge curve (typically adjusting from 1.2V to 1.4V cutoff)

Problem: Intermittent high-current failures

Solution: Implement capacitor banks to handle peak loads exceeding 3A, preserving battery life

Performance Validation and Long-Term Reliability Strategies

Ensuring optimal long-term performance of lithium iron disulfide batteries requires rigorous testing protocols and proactive maintenance strategies. These procedures are particularly critical for applications where battery failure could have serious consequences.

Comprehensive Testing Methodology

Professional-grade validation should include:

- Accelerated aging tests: 85°C storage for 7 days simulates 1 year of shelf life

- Pulse load profiling: 10ms/100ms/1s pulse widths at varying currents

- Environmental cycling: -40°C to 70°C temperature transitions with 90% RH

| Test Parameter | Acceptance Criteria | Measurement Protocol |

|---|---|---|

| Capacity Retention | >95% after 3 years storage | Discharge at 0.2C rate |

| Voltage Stability | <±3% deviation under load | 500mA constant current |

| Leakage Resistance | 0μA at 60°C/95% RH | 72-hour exposure test |

Advanced Predictive Maintenance

Implement these proactive measures for critical systems:

- Baseline profiling: Record initial voltage/current signatures for comparison

- Trend analysis: Monitor internal resistance changes >10% indicates replacement

- Usage tracking: Log operational hours and load cycles for predictive replacement

Case study: Offshore oil rig monitoring systems use vibration analysis to predict battery degradation 6-8 weeks before failure by detecting subtle changes in pulse response characteristics.

Quality Assurance Protocols

For mission-critical applications:

- Batch testing minimum 5% sample size

- X-ray inspection of internal structures

- Destructive physical analysis on 0.1% of cells

- Lot traceability with full manufacturing history

Risk Mitigation Framework

Critical failure modes and countermeasures:

- Voltage plateau detection: Implement secondary fuel gauging algorithms

- Thermal runaway prevention: Current-limiting circuitry for >2A applications

- Storage degradation: Rotate stock using FIFO system with quarterly testing

Expert Recommendation: For high-value installations, maintain three separate battery age cohorts (new, mid-life, and near-retirement) to ensure smooth transitions and avoid simultaneous failure of all backup power sources.

Conclusion

Lithium iron disulfide 1.5V batteries represent a significant advancement in primary battery technology, offering superior voltage stability, extended temperature range performance, and exceptional energy density.

Throughout this guide, we’ve explored their unique discharge characteristics, optimal application scenarios, advanced monitoring techniques, and long-term reliability strategies. These batteries particularly shine in high-drain devices, critical medical equipment, and extreme environment applications where traditional alkaline cells fall short.

As you implement Li-FeS₂ batteries in your systems, remember to:

- Monitor voltage under actual load conditions

- Account for their distinct discharge curve when designing power management systems

- Leverage their temperature resilience for challenging environments

Final recommendation: Conduct real-world testing with your specific devices to fully appreciate the performance benefits. The initial higher cost is consistently offset by longer service life and more reliable operation. For mission-critical applications, pairing these batteries with proper monitoring systems ensures you’ll never face unexpected power failures.

Frequently Asked Questions About Lithium Iron Disulfide 1.5V Batteries

What makes lithium iron disulfide batteries different from regular alkaline batteries?

Lithium iron disulfide (Li-FeS₂) batteries maintain a remarkably stable 1.5V output until nearly depleted, unlike alkaline batteries that gradually decline. They offer 3x more energy density (typically 4Wh vs 1.5Wh in AA size), operate from -40°C to 60°C, and have a 20-year shelf life.

Their chemistry uses lithium metal anodes and iron disulfide cathodes, enabling higher current delivery without voltage sag – perfect for digital cameras and medical devices.

How can I accurately test the remaining capacity of a Li-FeS₂ battery?

Use a digital multimeter under 500mA load for 30 seconds (simulating real usage). At 1.5V, you have >90% capacity; 1.45V indicates ~50%; below 1.4V means imminent depletion.

Never test open-circuit voltage – it’s misleading. For precision, coulomb counters tracking mAh consumed are ideal, especially in critical applications like emergency lighting systems where voltage alone doesn’t reflect true remaining energy.

Why do my devices sometimes show “low battery” prematurely with lithium batteries?

Many devices are calibrated for alkaline’s gradual voltage drop and misinterpret Li-FeS₂’s stable voltage as “full” until the sudden drop at depletion. Solutions include:

1) Updating device firmware if available

2) Using lithium-compatible devices

3) Ignoring early warnings until actual performance drops occur.

Some premium flashlights now have dual-mode battery detection specifically for this chemistry.

Can I mix lithium iron disulfide with other battery types in the same device?

Absolutely not. Mixing chemistries creates dangerous imbalances. Alkaline batteries drop to 1.2V when depleted while Li-FeS₂ maintains 1.5V until empty, causing reverse charging that can lead to leakage or rupture.

Always replace all batteries simultaneously with identical make/model. This is particularly crucial in multi-cell devices like professional audio equipment where voltage differences can damage sensitive circuits.

What’s the best way to store lithium iron disulfide batteries long-term?

Store at 40-60% charge (partial use is fine) in airtight containers at 15-25°C. Avoid refrigeration – condensation risks outweigh benefits. For military-grade preservation:

1) Use vacuum-sealed bags with desiccant

2) Rotate stock every 5 years

3) Perform annual capacity tests.

Properly stored, these batteries retain 90% capacity after 15 years, making them ideal for emergency backup systems.

Are lithium iron disulfide batteries worth the higher price?

Cost-analysis shows they’re cheaper long-term in high-drain applications. Example: A security camera requiring monthly $5 alkaline replacements spends $60/year versus $15/year with Li-FeS₂.

They also reduce maintenance labor costs and device downtime. For low-drain devices like clocks, alkalines may suffice, but consider lithium’s 20-year shelf life for rarely-used emergency devices.

What safety precautions are needed when using these batteries?

Key precautions include:

1) Never attempt to recharge

2) Avoid piercing or crushing cells

3) Don’t expose to temperatures above 140°F (60°C)

4) Use protective caps when transporting loose batteries

5) Recycle properly through certified programs.

Unlike lithium-ion, Li-FeS₂ won’t thermal runaway, but damaged cells may leak corrosive electrolytes. Industrial users should implement MSDS-compliant handling procedures.

How do I dispose of lithium iron disulfide batteries responsibly?

Use certified e-waste recyclers that handle lithium primary cells. Never dispose in household trash – the iron disulfide cathode contains heavy metals. Major retailers like Home Depot offer free drop-off. For bulk disposal:

1) Tape terminals

2) Package in non-conductive materials

3) Label clearly as “lithium primary cells.”

Proper recycling recovers 92% of materials, including valuable lithium salts reused in industrial processes.