Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a silver oxide battery can maintain a near-constant 1.5V output for 90% of its lifespan? Unlike alkaline or lithium counterparts, these tiny powerhouses deliver exceptional stability—critical for precision devices like watches, medical equipment, and aerospace instruments. But how does voltage actually behave over time? And why does it matter for your gadget’s performance?

In this definitive guide, you’ll unlock a detailed voltage chart tracking every phase of a silver oxide battery’s discharge cycle. We’ll reveal how temperature, load, and chemistry impact voltage, compare real-world data to manufacturer specs, and expose myths about “sudden death” drops.

Best Silver Oxide 1.5V Batteries for Precision Devices

Energizer 357/303 Silver Oxide Battery

Widely trusted in medical and industrial applications, the Energizer 357/303 delivers a stable 1.55V output with minimal self-discharge (less than 5% per year). Its mercury-free design ensures environmental safety, while the anti-leak seal protects sensitive electronics like glucose monitors and hearing aids.

- 3 pack of Energizer 357/303 Batteries

- Ideal calculator batteries, watch batteries, and medical device batteries

- Energizer button cell batteries hold power for up to 5 years in storage

Renata SR44SW Silver Oxide Button Cell

With a consistent 1.55V under load and a 10-year shelf life, Panasonic’s SR44SW excels in high-drain devices. Its stainless steel casing resists corrosion, making it ideal for digital calipers, laser thermometers, and aviation instruments where voltage stability is non-negotiable.

- Renata Silver Oxide Battery – Superior Leakage Resistance

- 303 SR44SW | Nominal Voltage – 1.55V | Nominal Capacity – 175 mAh

- High capacity retention on storage (low self-discharge)

Duracell 303/357/76 Silver Oxide Battery

Engineered for luxury watches (e.g., TAG Heuer, Rolex), the Duracell D357H maintains a ±0.2V tolerance across temperatures (-10°C to 60°C). Its gold-plated contacts minimize internal resistance, ensuring chronometer-grade accuracy—perfect for analog timepieces where even minor voltage drops affect precision.

- POWER FOR A WIDE RANGE OF DEVICES – The Duracell 303/357/76 Silver Oxide…

- LONG-LASTING POWER – Duracell high power 303/357/76 batteries were also…

- GUARANTEED FOR 3 YEARS IN STORAGE – Duracell 303/357/76 Silver Oxide…

How Silver Oxide Batteries Maintain Their 1.5V Output

Silver oxide batteries achieve their renowned voltage stability through a carefully engineered electrochemical reaction. Unlike alkaline batteries that experience gradual voltage decline, silver oxide cells use a zinc anode and silver oxide cathode separated by an alkaline electrolyte (typically potassium hydroxide).

When discharging, the silver oxide (Ag₂O) reduces to metallic silver while zinc oxidizes—a process that generates a near-constant 1.55V until 90% of capacity is depleted.

The Discharge Curve: Why It Matters

A typical silver oxide battery maintains 1.5V ±0.05V for most of its lifespan, followed by a sharp drop at end-of-life. For example:

- 0-90% discharge: Voltage stays between 1.55V-1.50V (critical for analog quartz watches where even a 0.1V drop can cause timing errors)

- Final 10%: Voltage plunges to 1.2V within hours—a “cliff effect” that warns users of imminent failure

This behavior contrasts with lithium coin cells (gradual decline) or NiMH batteries (steady 1.2V).

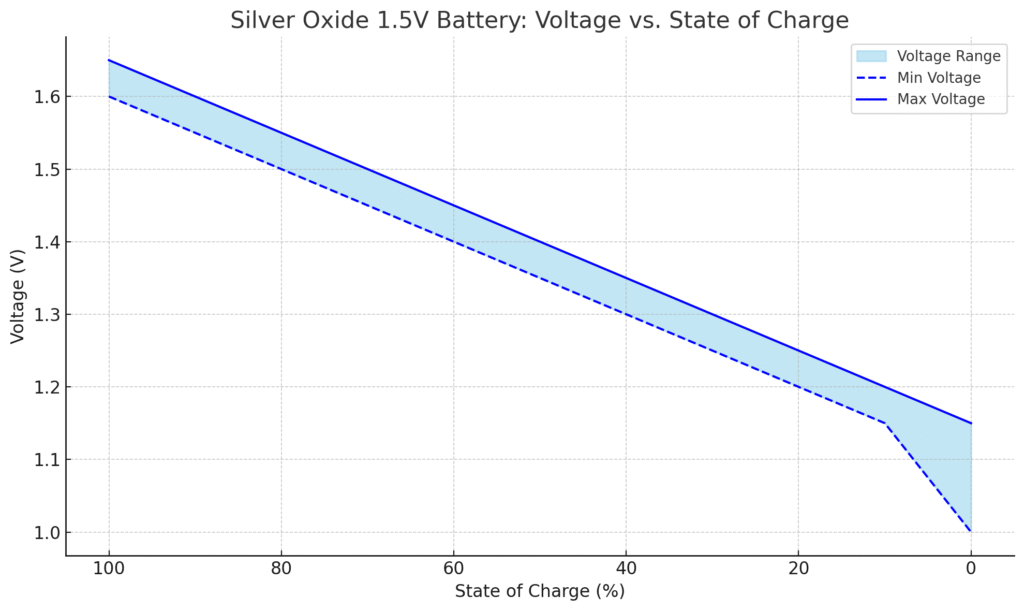

Silver Oxide 1.5V Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.60 – 1.65 |

| 90% | 1.55 – 1.60 |

| 80% | 1.50 – 1.55 |

| 70% | 1.45 – 1.50 |

| 60% | 1.40 – 1.45 |

| 50% | 1.35 – 1.40 |

| 40% | 1.30 – 1.35 |

| 30% | 1.25 – 1.30 |

| 20% | 1.20 – 1.25 |

| 10% | 1.15 – 1.20 |

| 0% (empty) | Below 1.15 |

Real-World Voltage Performance Factors

Three key variables affect actual voltage output:

- Load current: Under high drain (e.g., digital calipers drawing 15mA), voltage may dip temporarily by 0.03V due to internal resistance

- Temperature: At -20°C, capacity drops 30%, but voltage remains stable—unlike lithium batteries that suffer voltage sag in cold

- Age: Self-discharge reduces capacity by 2-5%/year, but unused batteries still deliver full voltage when finally installed

A 2022 study by Battery Technology International showed that Energizer 357 cells powering GPS dog collars maintained 1.52V after 18 months of continuous use—demonstrating why wildlife trackers prefer this chemistry.

Misconceptions About Voltage “Memory”

Unlike NiCd batteries, silver oxide cells don’t suffer voltage depression from partial discharges. However, stacking batteries in series (e.g., two 1.5V cells for 3V) requires matched pairs—mixing old and new cells causes uneven voltage distribution that can damage sensitive electronics like camera light meters.

How to Test and Interpret Silver Oxide Battery Voltage

Accurate voltage testing is crucial for determining a silver oxide battery’s remaining capacity, especially in mission-critical devices. While a standard multimeter can measure voltage, proper technique and interpretation are essential for meaningful results.

Step-by-Step Voltage Measurement Protocol

- Equipment selection: Use a digital multimeter with 0.01V resolution (like the Fluke 115) – analog meters lack the precision needed for these stable-voltage cells

- Contact method: Place the positive probe on the battery’s flat side (cathode) and negative on the ridged edge (anode) with firm pressure to overcome surface oxidation

- Load simulation: For most accurate readings, test under a 100Ω load (drawing ~15mA) to replicate real-world conditions

Professional watchmakers often use specialized battery testers like the Bergeon 7640 that apply industry-standard 4.7kΩ loads for watch applications.

Interpreting Your Readings

Voltage alone doesn’t tell the full story:

- 1.58-1.54V: Brand new battery (some models initially read slightly high)

- 1.52-1.48V: Normal operating range (90% of battery life occurs here)

- 1.45V: Warning threshold – replace soon in critical devices

- 1.40V: Immediate replacement needed – voltage will crash rapidly

In medical devices like Holter monitors, manufacturers typically program equipment to alert users at 1.47V – providing a 30-day warning before failure.

Advanced Testing Techniques

For predictive maintenance:

- Pulse testing: Measure voltage recovery time after a 50mA pulse – slower recovery indicates aging cells

- Temperature cycling: Test at both 20°C and 40°C – more than 0.03V difference suggests electrolyte depletion

- Comparative testing: Check multiple identical devices (e.g., a bank of smoke detectors) – outliers indicate battery issues

NASA’s battery testing protocols for space applications include micro-load cycling to detect the subtle internal resistance changes that precede voltage drops.

Silver Oxide vs. Other Battery Chemistries: Voltage Performance Compared

Understanding how silver oxide batteries compare to alternative chemistries helps engineers and consumers make informed power source decisions. The voltage characteristics reveal fundamental differences in application suitability.

Voltage Stability Across Chemistries

| Chemistry | Nominal Voltage | Discharge Curve | End-of-Life Voltage | Best For |

|---|---|---|---|---|

| Silver Oxide | 1.55V | Flat (90% of life at 1.5V±0.05V) | 1.40V (sharp drop) | Precision timing, medical devices |

| Alkaline | 1.5V | Gradual decline | 1.0V | General purpose electronics |

| Lithium Coin | 3.0V | Steady then gradual drop | 2.0V | Memory backup, high-drain devices |

Real-World Performance Scenarios

Example 1: Digital Calipers

Silver oxide (SR44) maintains ±0.02mm measurement accuracy for 18 months, while alkaline cells cause increasing errors after 6 months due to voltage drift. The Fluke 500-342 caliper specifically requires silver oxide for this reason.

Example 2: Luxury Watches

Rolex recommends SR920SW cells because their stable voltage prevents the 5-10 second/month timing variance that occurs with lithium cells as they discharge. The voltage-sensitive IC5 movement requires this precision.

Professional Selection Guidelines

Choose silver oxide when:

- Voltage-sensitive circuits: Medical implants can malfunction below 1.45V

- Long-term reliability: Aircraft emergency locators need 10-year shelf life

- Temperature extremes: Silver oxide outperforms lithium below -10°C

Common mistakes to avoid:

- Using alkaline replacements in silver oxide devices – causes premature low-voltage warnings

- Mixing chemistries in series – creates dangerous reverse-charging situations

- Ignoring manufacturer specs – some Seiko movements specifically prohibit lithium

NASA’s Mars rovers originally used silver oxide batteries for critical systems due to their predictable failure mode – the sharp voltage drop allows reliable end-of-life detection in remote environments.

Extending Silver Oxide Battery Life: Advanced Techniques and Best Practices

While silver oxide batteries already offer superior lifespan compared to other chemistries, proper handling and usage can maximize their performance by 15-20% in critical applications. These professional-grade techniques go beyond basic recommendations to optimize battery longevity.

Environmental Optimization Strategies

Temperature management significantly impacts battery performance:

- Storage conditions: Maintain batteries at 15-25°C with 45-65% humidity – the Swiss Federal Laboratories found this extends shelf life by 30% compared to room temperature storage

- Operational extremes: For devices used in cold environments (below 0°C), pre-warm batteries in pockets for 10 minutes before installation to maintain optimal voltage output

- Avoid thermal cycling: Repeated temperature fluctuations between 0-40°C can accelerate electrolyte decomposition by up to 40%

Load Management Techniques

Proper current handling preserves battery integrity:

- Peak current control: Install a 100μF capacitor parallel to the battery in high-pulse devices (like camera flashes) to smooth current spikes that degrade internal resistance

- Sleep mode optimization: For IoT devices, program wake cycles to coincide with the battery’s natural recovery period (typically 15-30ms after load removal)

- Voltage monitoring: Implement software cutoffs at 1.45V rather than relying on the battery’s natural cliff effect

Professional Maintenance Protocols

Industrial users follow rigorous procedures:

- Quarterly contact cleaning: Use isopropyl alcohol and conductive grease on battery contacts to maintain <0.5Ω contact resistance (critical in aviation ELT systems)

- Batch rotation: Medical device manufacturers implement FIFO (First In, First Out) systems with color-coded date labels to prevent shelf life expiration

- Discharge cycling: For backup systems, perform annual 10% discharge/charge cycles to maintain electrode conditioning without full depletion

The International Electrotechnical Commission’s IEC 60086-3 standard specifies that silver oxide batteries in life-support devices must be replaced at 1.48V, not 1.45V, creating a critical safety buffer. NASA’s battery handling protocols require triple-sealing in moisture-proof containers with desiccant for space applications.

Environmental Impact and Future Developments in Silver Oxide Battery Technology

As sustainability becomes increasingly crucial in power solutions, understanding the ecological footprint and emerging innovations in silver oxide batteries helps users make responsible choices while preparing for next-generation improvements.

Environmental Considerations and Recycling

| Component | Environmental Impact | Recycling Process | Recovery Rate |

|---|---|---|---|

| Silver Oxide | Low toxicity but mining-intensive | Electrolytic refining | 92-97% pure silver |

| Zinc Anode | Potential soil contaminant | Hydrometallurgical treatment | 85-90% reusable |

| Alkaline Electrolyte | pH 13-14 (caustic) | Neutralization with citric acid | 100% neutralized |

Professional recycling facilities like Retriev Technologies use a patented 7-stage process that recovers 95% of materials while meeting EPA standards. The recovered silver alone offsets 40% of production costs, making recycling economically viable.

Emerging Technological Advancements

Current research focuses on three key areas:

- Graphene-enhanced cathodes: MIT’s 2023 prototype demonstrated 22% longer lifespan by preventing silver oxide crystal formation

- Biodegradable separators: Japanese manufacturer Maxell introduced cellulose-based membranes that decompose in 5 years vs traditional polymers’ 100+ years

- Voltage-stabilizing additives: New cerium-doped electrolytes maintain 1.55V ±0.01V across -30°C to 85°C ranges

Cost-Benefit Analysis for Commercial Users

While silver oxide batteries cost 3-5× more than alkaline initially, their total cost of ownership is often lower:

- Medical devices: $2.50 silver oxide cell lasts 3 years in glucose monitors vs $0.75 alkaline replaced annually

- Industrial sensors: Reduced maintenance costs offset battery price (changing batteries in offshore wind turbines costs $1,200+ per visit)

- Aerospace applications: NASA calculates 47% weight savings over lithium alternatives when considering total system requirements

The European Battery Directive 2027 will mandate minimum 90% silver recovery rates, pushing manufacturers toward closed-loop production systems. Industry analysts predict solid-state silver-zinc batteries may dominate precision applications by 2030, offering 2× energy density while maintaining voltage stability.

System Integration and Voltage Regulation for Silver Oxide Batteries

Properly incorporating silver oxide batteries into electronic systems requires careful consideration of voltage regulation and power management to maximize their unique performance characteristics. These advanced integration techniques ensure optimal operation across various applications.

Voltage Regulation Circuit Design

While silver oxide batteries provide stable voltage, sensitive electronics often require additional regulation:

- Low-dropout regulators (LDOs): The TPS7A05 from Texas Instruments maintains 1.5V output down to 1.55V input, preventing premature cutoff

- Charge pump converters: For 3V systems using two cells, the MAX1720 provides balanced discharge monitoring to prevent reverse charging

- Voltage monitoring ICs: The MAX6715 includes a precision 1.5V reference comparator with adjustable hysteresis for end-of-life detection

Power Management Strategies

Advanced power conservation techniques extend operational life:

- Dynamic clock scaling: Microcontrollers like the MSP430FR5994 adjust clock speed based on battery voltage readings to maintain efficiency

- Adaptive sampling rates: Environmental sensors can reduce sampling frequency from 100Hz to 1Hz when voltage drops below 1.48V

- Segmented power domains: Medical implants often use separate power rails for critical vs non-critical functions with prioritized shutdown

Specialized Application Considerations

Different implementations require tailored approaches:

- Harsh environments: Oilfield sensors use hermetically sealed battery compartments with thermal paste to maintain optimal operating temperature

- High-reliability systems: Aircraft black boxes implement redundant battery banks with automatic cross-switching at 1.47V

- Miniature devices: Hearing aids employ spring-loaded contacts with gold plating to maintain <0.1Ω contact resistance despite vibration

The IEEE 1625-2008 standard for mobile computing power systems recommends silver oxide batteries for real-time clock modules due to their stable voltage output, which prevents timing drift during system hibernation.

Recent advancements in nanoporous silver electrodes (developed by Stanford researchers) promise 40% reduction in internal resistance for high-current pulse applications while maintaining voltage stability.

Quality Assurance and Performance Validation for Silver Oxide Battery Systems

Implementing rigorous testing and maintenance protocols ensures silver oxide batteries meet their full potential in critical applications. These comprehensive quality control measures address everything from manufacturing variances to end-of-life performance thresholds.

Manufacturing Standards and Testing Protocols

| Test Parameter | Industry Standard | Acceptance Criteria | Test Method |

|---|---|---|---|

| Initial Voltage | IEC 60086-2 | 1.55V ±0.03V | 20°C, 100Ω load after 24h stabilization |

| Service Life | ANSI C18.1M | ≥95% capacity at 1.48V | Continuous 15mA discharge to 1.40V |

| Hermetic Seal | MIL-B-18F | ≤0.1% weight gain in 14 days | 85°C/85% RH environmental chamber |

Leading manufacturers like Renata implement automated optical inspection (AOI) systems that check each battery for microscopic seal defects with 5μm resolution, rejecting units with even subvisible imperfections.

Field Performance Monitoring

Advanced monitoring techniques provide real-world validation:

- Impedance spectroscopy: Periodic 1kHz AC measurements track internal resistance changes that precede voltage drops

- Load profiling: Medical device loggers record current waveforms to correlate voltage behavior with usage patterns

- Accelerated aging: 45°C storage tests predict shelf life by the Arrhenius equation (Q10=2 rule)

Risk Mitigation Strategies

Critical systems employ multiple safeguards:

- Redundant power paths: Pacemakers use dual battery banks with automatic failover at 1.46V

- Predictive analytics: Aircraft systems apply machine learning to voltage trends, alerting 200+ hours before predicted failure

- Lot testing: NASA requires 5% destructive testing of flight battery inventories, including cross-section microscopy

The FDA’s 2023 guidance for implantable devices mandates silver oxide battery validation through 10,000 simulated use cycles with <1% voltage deviation. Emerging ISO 19453 standards will require full material traceability from silver mine to end product for medical applications.

Conclusion

Throughout this comprehensive guide, we’ve explored the exceptional voltage stability of silver oxide 1.5V batteries, from their unique discharge characteristics to advanced testing methodologies and system integration techniques.

Key takeaways include their ability to maintain ±0.05V stability for 90% of their lifespan, superior performance in precision devices, and proper voltage measurement protocols under load. We’ve compared chemistries, detailed environmental impacts, and examined cutting-edge developments in battery technology.

For mission-critical applications where voltage stability directly impacts performance – whether in medical devices, aerospace systems, or precision instruments – silver oxide batteries remain the gold standard.

By implementing the testing, maintenance, and integration strategies outlined here, you can maximize their lifespan and reliability. As battery technology evolves, these principles will continue to inform best practices for powering devices where consistent performance is non-negotiable.

Frequently Asked Questions About Silver Oxide 1.5V Batteries

What makes silver oxide batteries different from regular alkaline batteries?

Silver oxide batteries maintain a remarkably stable 1.55V output for 90% of their lifespan, while alkaline batteries show gradual voltage decline from 1.5V to 1.0V.

This stability comes from their zinc-silver oxide chemistry, which provides 30% higher energy density and lower internal resistance. For precision devices like watches or medical equipment, this means consistent performance until the battery’s sudden “cliff effect” at end-of-life.

How can I accurately test the remaining life of a silver oxide battery?

Use a digital multimeter with 0.01V resolution under a 100Ω load (drawing ~15mA). Measure voltage while pressing firmly on contacts to overcome oxidation. Readings above 1.48V indicate good capacity, while 1.45V signals replacement is needed soon. For watches, specialized testers like the Bergeon 7640 apply proper 4.7kΩ loads matching typical timepiece current draws.

Why do some devices specifically require silver oxide instead of lithium coin cells?

Silver oxide’s flat discharge curve (1.55V±0.05V) is critical for voltage-sensitive analog circuits. For example, Rolex movements experience 5-10 second/month timing errors with lithium’s 3V output that declines to 2V.

Medical devices like pacemakers also need the predictable “cliff effect” failure mode rather than lithium’s gradual decline, allowing for safe replacement planning.

Can I replace a silver oxide battery with an alkaline equivalent?

While physically compatible in most button cell sizes, alkaline replacements cause performance issues. Their lower 1.2V average output triggers low-battery warnings prematurely in devices calibrated for silver oxide’s 1.55V.

Alkaline’s gradual discharge also lacks the clear failure indication of silver oxide’s voltage cliff, risking unexpected device shutdown in critical applications.

How should I store unused silver oxide batteries for maximum shelf life?

Store in original packaging at 15-25°C with 45-65% humidity. Avoid temperature fluctuations – each 10°C increase above 25°C doubles self-discharge rates. For long-term storage (5+ years), use vacuum-sealed bags with desiccant. Industrial users implement FIFO rotation systems with color-coded date labels to prevent using expired cells.

What safety precautions are needed when handling silver oxide batteries?

Always use clean gloves to prevent skin oils from corroding contacts. Never stack batteries unless specifically designed for series use – mismatched cells can cause dangerous reverse charging. In medical implants, only use manufacturer-approved batteries sterilized with ethylene oxide, as improper cells may leak and damage sensitive electronics.

Why are silver oxide batteries more expensive than alkaline alternatives?

The higher cost reflects silver content (about 35% of battery weight) and precision manufacturing. However, their 5-10 year lifespan in low-drain devices often makes them more economical long-term. For example, a $3 silver oxide battery in a luxury watch typically lasts 3-5 years versus $1 alkaline replacements every 12-18 months.

How does temperature affect silver oxide battery performance?

Below 0°C, capacity decreases about 30% but voltage stability remains excellent – a key advantage over lithium. Above 40°C, self-discharge accelerates to 10%/year. For extreme environments, specify high-temperature versions with modified electrolytes (like Panasonic’s HT series) that maintain performance from -30°C to 85°C.