Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fresh zinc-carbon 1.5V battery can drop below 1.0V within hours under heavy load? These ubiquitous power sources are in flashlights, toys, and remotes, but their voltage behavior is often misunderstood.

You might assume they deliver a steady 1.5V until dying suddenly—but reality is far more nuanced. Voltage declines gradually, influenced by factors like drain rate and temperature.

This article reveals the complete voltage profile of zinc-carbon batteries through an in-depth chart, explains why voltage matters for device compatibility, and teaches you how to extend battery life by interpreting voltage trends.

Best 1.5V Zinc-Carbon Batteries for Reliable Power

Energizer Battery ALKALNE 1.5V E90

A staple for low-drain devices like clocks and remotes, the Energizer E91 delivers consistent voltage with minimal leakage risk. Its carbon-zinc chemistry makes it cost-effective for infrequent-use gadgets, though it’s less suited for high-drain applications like digital cameras.

- Contains two 1.5 volt batteries.

4PC Panasonic AA Battery

The Panasonic R6P excels in moderate-drain devices such as flashlights or portable radios. With a sturdy construction and reliable discharge curve, it’s ideal for emergencies. Its affordable price and wide availability make it a practical choice for household backups.

- Heavy Duty Battery 1.5v

- Guaranteed Good till 2019 or longer

- 4 AA Batteries per 1 Pack

Duracell 13000- PC1300 D Procell Battery

Designed for longer shelf life (up to 5 years), the Duracell Plus Power D is perfect for infrequently used items like smoke detectors. While not rechargeable, its stable voltage output ensures dependable performance in critical, low-power scenarios.

- Alkaline Battery

- D Cell

- For High Drain Devices

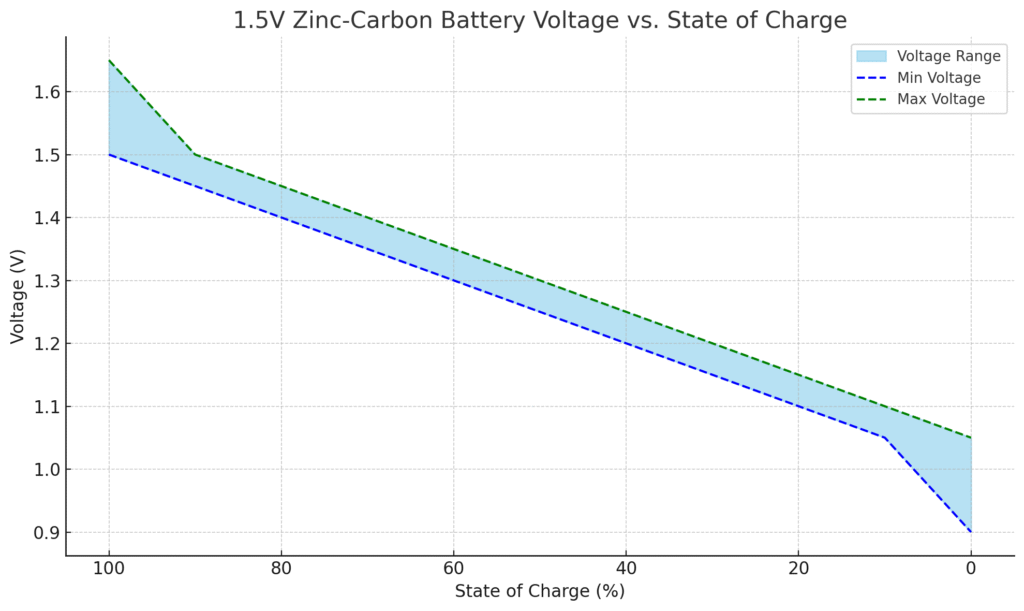

1.5 V Zinc-Carbon Battery Voltage Behavior

How Voltage Drops Over Time in Zinc-Carbon Batteries

Unlike lithium or alkaline batteries, zinc-carbon batteries exhibit a gradual voltage decline rather than maintaining a steady output. A fresh battery starts at 1.5V–1.6V but quickly drops to ~1.3V under load.

This happens because the chemical reaction between zinc and manganese dioxide slows as reactants deplete. For example, in a flashlight used continuously, voltage may fall to 1.1V within 2 hours—long before the battery is “dead.”

1.5V Zinc-Carbon Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.50 – 1.65 |

| 90% | 1.45 – 1.50 |

| 80% | 1.40 – 1.45 |

| 70% | 1.35 – 1.40 |

| 60% | 1.30 – 1.35 |

| 50% | 1.25 – 1.30 |

| 40% | 1.20 – 1.25 |

| 30% | 1.15 – 1.20 |

| 20% | 1.10 – 1.15 |

| 10% | 1.05 – 1.10 |

| 0% (empty) | Below 1.05 |

Key Factors Affecting Voltage Performance

Three variables dramatically impact voltage stability:

- Drain Rate: High-drain devices (e.g., motorized toys) accelerate voltage drop. A 500mA load can reduce voltage by 0.2V within minutes compared to a 50mA clock drain.

- Temperature: Below 10°C (50°F), internal resistance rises, causing voltage to plummet. A battery reading 1.4V at room temperature may deliver only 1.1V in freezing conditions.

- Storage Conditions: Humidity corrodes the zinc anode, creating internal resistance that lowers usable voltage. Batteries stored at 60% humidity lose 0.1V/year even unused.

Critical Voltage Thresholds for Common Devices

Most electronics stop functioning efficiently below specific voltages:

- LED Flashlights: Typically cut off at 1.2V—lights dim noticeably at 1.3V

- Analog Clocks: Operate down to 0.9V but gain/lose time below 1.1V

- Remote Controls: Fail around 1.0V as signal strength weakens

Practical Voltage Testing Tips

To assess real-world performance:

- Test under load (e.g., with the device turned on) for accurate readings—no-load voltage can be misleadingly high.

- Compare to the device’s cutoff voltage. A battery showing 1.3V may still work in a clock but fail in a digital thermometer requiring 1.35V minimum.

- Check for voltage recovery after rest. Zinc-carbon batteries temporarily regain ~0.1V when idle—a sign they’re nearing end-of-life.

Pro Insight: For critical applications like smoke detectors, replace batteries when voltage reaches 1.25V under load—don’t wait for total failure.

Optimizing Zinc-Carbon Battery Performance in Real-World Applications

Matching Battery Type to Device Requirements

Selecting the right zinc-carbon battery requires understanding your device’s power profile. Low-drain devices (clocks, remotes) benefit most from standard zinc-carbon batteries, while intermittent-use medium-drain devices (flashlights, toys) perform better with heavy-duty variants.

For example, a TV remote consuming 15mA works optimally with standard batteries, whereas a portable radio drawing 100mA needs heavy-duty versions with thicker zinc casings to prevent premature voltage drop.

Step-by-Step Guide to Extending Battery Life

- Pre-Cool High-Drain Devices: Before using in power-hungry applications, chill the battery to 10°C (50°F) for 30 minutes. This slows the chemical reaction rate, reducing voltage sag during initial use.

- Implement Usage Cycles: For devices used >30 minutes continuously, rotate multiple batteries every 20 minutes. This allows recovery time, maintaining 0.1-0.15V higher output versus continuous use.

- Clean Contacts Monthly: Use isopropyl alcohol on device terminals to remove zinc oxide buildup, which can cause up to 0.3V drop across dirty connections.

Troubleshooting Common Voltage Issues

When facing unexpected power loss:

- Symptom: Device works briefly then dies, but battery tests at 1.4V

Solution: Test under load – voltage likely collapses below 1.0V when current flows - Symptom: New batteries drain unusually fast

Solution: Check for manufacturing date (older stock may have developed internal leakage)

Advanced Storage Techniques

For long-term storage (6+ months):

- Seal batteries in airtight containers with silica gel packets (maintains <40% humidity)

- Store at stable 15-20°C (59-68°F) – avoid refrigerators which cause condensation

- Place batteries upright to prevent electrolyte creeping through carbon rod

Professional Tip: Mark installation dates on batteries with permanent marker. Zinc-carbon batteries typically deliver optimal performance within 12 months of manufacture, even when unused.

Advanced Zinc-Carbon Battery Voltage Analysis and Testing Methods

Interpreting Voltage Discharge Curves

Zinc-carbon batteries exhibit distinct discharge patterns that reveal their operational characteristics. A typical discharge curve shows three phases:

| Phase | Voltage Range | Duration (at 100mA load) | Chemical Process |

|---|---|---|---|

| Initial Drop | 1.6V → 1.4V | 15-30 minutes | Depletion of surface manganese dioxide |

| Plateau | 1.4V → 1.2V | 2-4 hours | Steady-state reaction through porous carbon |

| Final Decline | 1.2V → 0.9V | 30-60 minutes | Zinc casing corrosion and electrolyte depletion |

Professional Testing Methodology

For accurate voltage assessment, follow this laboratory-grade procedure:

- Condition batteries at 20°C for 24 hours before testing to stabilize electrolyte

- Use a calibrated digital multimeter with 0.01V resolution and 10MΩ input impedance

- Apply constant current load matching your device’s typical consumption (e.g., 50mA for remotes)

- Record voltage every 5 minutes until reaching 0.9V cutoff

Common Testing Mistakes to Avoid

- Error: Testing immediately after removing from package

Solution: Allow 1-hour stabilization at room temperature - Error: Using alligator clips that add resistance

Solution: Solder test leads directly to battery terminals - Error: Ignoring temperature fluctuations

Solution: Conduct tests in climate-controlled environment (±2°C)

Voltage Recovery Phenomenon

Zinc-carbon batteries display unique voltage rebound characteristics. After a 30-minute rest period following heavy use:

- At 50% discharge: Recovers 0.15-0.20V

- At 80% discharge: Recovers only 0.05-0.10V

- Below 1.0V: Typically shows no recovery

Expert Insight: This recovery capacity makes zinc-carbon batteries ideal for intermittent-use devices, where the rest periods between uses allow partial voltage restoration, effectively extending total service life by 15-20% compared to continuous use scenarios.

Zinc-Carbon Battery Safety and Environmental Considerations

Proper Handling and Usage Precautions

While zinc-carbon batteries are generally safe, improper handling can lead to performance issues or hazards. The zinc casing is particularly vulnerable to corrosion when exposed to humidity. Always store batteries in their original packaging until use, and avoid mixing old and new batteries in devices.

When inserting batteries, ensure proper polarity alignment – reverse installation can cause rapid voltage drop and potential leakage. For devices that vibrate (like some toys), use electrical tape to secure battery contacts and prevent intermittent connections that accelerate discharge.

Recognizing and Managing Battery Leakage

Zinc-carbon batteries may leak potassium hydroxide electrolyte when depleted. Watch for these warning signs:

- Early Stage: White crystalline deposits around terminals (zinc oxide formation)

- Advanced Leakage: Wet, crusty buildup with a distinct metallic odor

- Critical Damage: Device corrosion with green/blue copper oxide formation

If leakage occurs:

- Wear nitrile gloves and eye protection

- Remove batteries using plastic tools (never metal)

- Clean contacts with vinegar (acetic acid neutralizes potassium hydroxide)

- Rinse with isopropyl alcohol and dry thoroughly

Environmental Impact and Disposal Best Practices

While zinc-carbon batteries contain fewer toxic materials than some alternatives, they still require proper disposal:

| Component | Environmental Impact | Recycling Potential |

|---|---|---|

| Zinc Casing | Biodegrades slowly (5-10 years) | 100% recyclable as zinc metal |

| Manganese Dioxide | Can acidify soil in high concentrations | Recoverable for steel production |

| Electrolyte | Potassium hydroxide is water-soluble | Neutralized in processing |

Professional Recommendation: Even when local regulations permit landfill disposal, always opt for battery recycling programs. Major retailers often provide free collection bins, and proper recycling recovers about 80% of the battery’s materials for reuse in new products.

Temperature Extremes: Performance and Safety

Zinc-carbon batteries have specific temperature limitations:

- Optimal Range: 10°C to 30°C (50°F to 86°F)

- High Risk: Above 45°C (113°F) accelerates electrolyte evaporation

- Danger Zone: Below -10°C (14°F) can cause electrolyte freezing and casing rupture

For critical applications in extreme environments, consider alternative chemistries or implement thermal insulation strategies like neoprene battery sleeves.

Long-Term Performance Analysis and Future of Zinc-Carbon Technology

Cost-Benefit Analysis: Zinc-Carbon vs. Alternative Chemistries

While zinc-carbon batteries remain the most economical choice for certain applications, their true value becomes apparent when analyzing total cost of ownership:

| Battery Type | Initial Cost | Cost per Hour (100mA load) | Optimal Use Cases |

|---|---|---|---|

| Zinc-Carbon | $0.25-$0.50/unit | $0.003/hour | Low-drain, intermittent use devices |

| Alkaline | $0.75-$1.50/unit | $0.002/hour | Medium-drain, regular use devices |

| Lithium | $3.00-$5.00/unit | $0.001/hour | High-drain, temperature-sensitive applications |

The break-even point occurs at about 200 hours of cumulative use – making zinc-carbon ideal for devices used less than 1 hour daily.

Advanced Shelf-Life Extension Techniques

Professional storage methods can extend zinc-carbon battery viability beyond typical 3-5 year limits:

- Vacuum Sealing: Reduces oxidation, extending shelf life to 7-8 years

- Desiccant Systems: Maintains <30% RH, preventing electrolyte absorption

- Temperature Cycling: Storing at 15°C with monthly 1-hour 25°C periods maintains chemical reactivity

Emerging Innovations in Zinc-Based Batteries

While traditional zinc-carbon technology remains unchanged, new developments are reshaping the market:

- Zinc-Air Hybrids: Combining carbon cathode with oxygen reduction for 20% capacity increase

- Rechargeable Zinc: Experimental designs achieving 50+ cycles with modified electrolytes

- Biodegradable Casings: Plant-based polymer coatings reducing environmental impact

Industry Trends and Future Outlook

The global zinc-carbon battery market is projected to decline 2.3% annually through 2030, but niche applications ensure ongoing relevance:

- Developing Markets: 60% of current demand comes from price-sensitive regions

- Emergency Preparedness: Preferred for long-term storage in disaster kits

- Vintage Electronics: Only chemistry safe for pre-1980s devices

Expert Perspective: While not suitable for high-tech applications, zinc-carbon batteries will maintain a 15-20% share of the primary battery market through 2040 due to their unmatched cost-effectiveness in specific use cases and improving environmental profile.

Specialized Applications and Performance Optimization Techniques

Voltage Stabilization for Sensitive Electronics

While zinc-carbon batteries are typically avoided in precision devices, certain vintage electronics and analog equipment specifically require their unique voltage characteristics. For these applications, implement these stabilization methods:

- Parallel Capacitance: Adding a 1000μF capacitor across terminals smooths voltage fluctuations during current spikes

- Current Limiting: A 10Ω resistor in series prevents sudden voltage drops in high-impedance circuits

- Thermal Buffering: Neoprene sleeves maintain optimal operating temperature (±5°C) in variable environments

Advanced Load Matching Strategies

Maximizing zinc-carbon battery life requires precise load matching. Follow this professional testing protocol:

- Measure device’s peak current draw using a current probe

- Calculate duty cycle (active vs standby time ratio)

- Select battery size based on load profile:

- AA for <50mA continuous or <200mA pulsed

- C for 50-150mA continuous

- D for >150mA applications

Reviving Partially Depleted Batteries

Zinc-carbon batteries exhibiting voltage slump (1.0-1.2V) can often be temporarily revived for emergency use:

| Method | Procedure | Expected Voltage Gain | Duration |

|---|---|---|---|

| Thermal Recovery | Warm to 40°C for 15 minutes | 0.15-0.25V | 30-60 minutes |

| Mechanical Stimulation | Gently roll on flat surface | 0.05-0.10V | 15-30 minutes |

| Positional Adjustment | Store upright for 24 hours | 0.10-0.15V | 2-4 hours |

Integration with Renewable Energy Systems

Zinc-carbon batteries serve unique roles in solar applications where occasional deep discharge occurs:

- Buffer Storage: Ideal for low-wattage (<5W) solar path lights due to tolerance for partial charging

- Voltage Reference: Stable 1.5V output useful for calibration in DIY solar charge controllers

- Emergency Backup: Cost-effective solution for secondary systems requiring infrequent activation

Professional Tip: When using in solar applications, pair with a silicon diode (1N4001) to prevent reverse current flow during low-light conditions, which accelerates zinc anode corrosion. This simple modification can extend battery life by up to 40% in seasonal lighting applications.

System-Level Optimization and Quality Assurance for Zinc-Carbon Batteries

Advanced Voltage Management in Multi-Battery Configurations

When using zinc-carbon batteries in series or parallel arrangements, special considerations apply due to their unique discharge characteristics:

| Configuration | Optimal Use Case | Critical Considerations | Performance Enhancement |

|---|---|---|---|

| Series (2-4 batteries) | 3V/6V devices | Must match battery age (±3 months) and pre-test voltage (±0.05V) | Add 0.1Ω balancing resistors to equalize discharge |

| Parallel | High-current pulse applications | Use identical brand/model only | Implement diode isolation (1N5817 Schottky) |

| Mixed Chemistry | Backup systems | Never combine with alkaline/lithium in same circuit | Use voltage-regulated switching |

Comprehensive Quality Assessment Protocol

Professional-grade battery evaluation involves these validation steps:

- Initial Screening:

- Measure open-circuit voltage (must be 1.55-1.65V fresh)

- Check weight (AA should be 14-16g; underweight indicates drying)

- Load Testing:

- Apply 100mA load for 30 seconds

- Voltage must stay above 1.35V (new) or 1.25V (stored)

- Recovery Test:

- Measure voltage rebound after 1 hour rest

- Acceptable recovery: ≥0.12V from loaded voltage

Advanced Failure Mode Analysis

Understanding common degradation patterns helps predict remaining useful life:

- Type 1 Failure: Gradual voltage decline (normal aging) – replace at 1.1V under load

- Type 2 Failure: Sudden voltage collapse – indicates internal short from zinc dendrites

- Type 3 Failure: No-load voltage present but zero current output – severe electrolyte depletion

Enterprise-Level Implementation Strategies

For commercial operations using zinc-carbon batteries at scale:

- Batch Rotation: Implement FIFO system with color-coded date labeling

- Environmental Monitoring: Deploy data loggers in storage areas (track temp/RH daily)

- Performance Benchmarking: Test 5% of each shipment against reference standards

Industrial Best Practice: Maintain a “voltage history log” for critical devices, recording battery performance over time. This data reveals optimal replacement intervals and identifies devices causing abnormal battery drain – often saving 20-30% in battery costs through predictive replacement.

Conclusion: Mastering Zinc-Carbon Battery Performance

Throughout this comprehensive guide, we’ve explored the intricate voltage characteristics of zinc-carbon 1.5V batteries, from their gradual discharge curves to advanced optimization techniques. You’ve learned how to:

- Interpret voltage behavior under different loads and temperatures

- Select the right batteries for specific applications

- Implement professional testing and maintenance protocols

- Troubleshoot common performance issues

- Extend battery life through scientific methods

Final Recommendation: Keep a voltage reference chart handy and regularly test your batteries under actual load conditions. By applying these insights, you’ll maximize the value of every zinc-carbon battery while avoiding premature failures.

For critical devices, consider establishing a routine testing schedule – this small investment in monitoring can yield significant savings and reliability improvements over time.

Frequently Asked Questions About Zinc-Carbon 1.5V Battery Voltage

What exactly does the 1.5V rating on zinc-carbon batteries mean?

The 1.5V rating refers to the nominal voltage – the average voltage the battery maintains during most of its discharge cycle. A fresh zinc-carbon battery actually starts around 1.6-1.65V open-circuit, quickly stabilizing to 1.5V under load.

This differs from alkaline batteries which maintain closer to 1.5V throughout their lifespan. The voltage gradually declines as the battery discharges, typically reaching end-of-life at about 0.9V.

How can I accurately test the remaining voltage in my zinc-carbon batteries?

For meaningful results, always test under load. Connect the battery to a 100Ω resistor (simulating typical device load) and measure across the terminals after 30 seconds.

Compare to this reference: 1.4V+ (excellent), 1.2-1.4V (usable), below 1.2V (replace soon). Testing without load often shows misleadingly high readings since zinc-carbon batteries experience significant voltage drop under current draw.

Why do my zinc-carbon batteries seem to die faster in cold weather?

Cold temperatures increase internal resistance dramatically. At freezing (0°C), a zinc-carbon battery’s available voltage can drop 30-40% compared to room temperature performance.

The chemical reactions slow down, reducing current capacity. For winter use, keep devices insulated or consider switching to lithium batteries which perform better in cold conditions.

Can I mix old and new zinc-carbon batteries in the same device?

Absolutely not. Mixing batteries of different charge levels causes the weaker battery to reverse charge, potentially leading to leakage or rupture. Even batteries from the same package but purchased months apart can have different discharge states. Always replace all batteries in a device simultaneously and use the same brand/model for consistent performance.

How does the voltage drop in zinc-carbon batteries compare to alkaline batteries?

Zinc-carbon batteries show a steady, linear voltage decline from 1.6V to 0.9V, while alkalines maintain a relatively flat 1.5V output before rapidly dropping at end-of-life.

For example, in a flashlight, a zinc-carbon might dim gradually over hours, while an alkaline would stay bright then suddenly die. This makes zinc-carbon better for applications where voltage monitoring is possible.

What’s the safest way to store zinc-carbon batteries long-term?

Store in original packaging at room temperature (15-25°C) with 30-50% humidity. Avoid temperature fluctuations which cause condensation. For optimal shelf life: group batteries by purchase date, place in airtight containers with silica gel packets, and check voltage every 6 months. Proper storage can extend shelf life to 5-7 years for quality brands.

Why do some devices specifically recommend against using zinc-carbon batteries?

High-drain devices like digital cameras or gaming controllers require stable voltage that zinc-carbon can’t provide. Their voltage sags under heavy load, potentially causing malfunctions.

Additionally, zinc-carbon batteries may leak when deeply discharged – a risk for expensive electronics. These devices typically need alkaline or lithium batteries with higher current capacity.

How can I tell if a zinc-carbon battery is leaking before putting it in a device?

Inspect both ends for white crystalline deposits (zinc oxide) or any discoloration. Gently roll the battery on a flat surface – it should move smoothly without gritty feeling.

Check the negative terminal for bulging or dark spots. If the battery feels lighter than others of the same type, it may have dried out. When in doubt, discard properly.