Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged AGM 12V battery should read 12.8–13.0V, but most owners never check until it’s too late? Whether you rely on AGM batteries for your solar setup, RV adventures, or marine applications, understanding voltage is the difference between a reliable power source and an unexpected failure.

Many assume these batteries are “maintenance-free,” but neglect can slash their lifespan in half. In this guide, you’ll unlock a comprehensive voltage chart, decode what each reading means, and learn exactly how to act—from charging thresholds to emergency fixes.

Best 12V AGM Batteries for Reliable Power

Renogy Deep Cycle AGM Battery 12V 100Ah

Renogy’s 12V 100Ah AGM battery is a top choice for solar and off-grid setups due to its deep-cycle durability and spill-proof design. With a low self-discharge rate and 10-year lifespan, it handles frequent discharges efficiently. Ideal for RVs, marine, and backup power systems.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

Odyssey Battery

The Odyssey Battery is built for extreme conditions, offering 400+ recharge cycles at 80% depth of discharge. Its military-grade construction resists vibration and high temperatures, making it perfect for heavy-duty applications like trucks, boats, and industrial equipment. Delivers 1200 cranking amps for reliable starts.

- 70% longer cycle life than conventional deep cycle batteries — high…

100Ah 12V Lithium-Ion

While not AGM, Battle Born’s LiFePO4 battery is worth mentioning for its lightweight, 3000–5000 cycle life, and faster recharge. At 12V 100Ah, it outperforms AGM in efficiency and longevity, though at a higher upfront cost. Best for those prioritizing long-term savings and weight reduction.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

12V AGM Battery Voltage Levels and Their Meaning

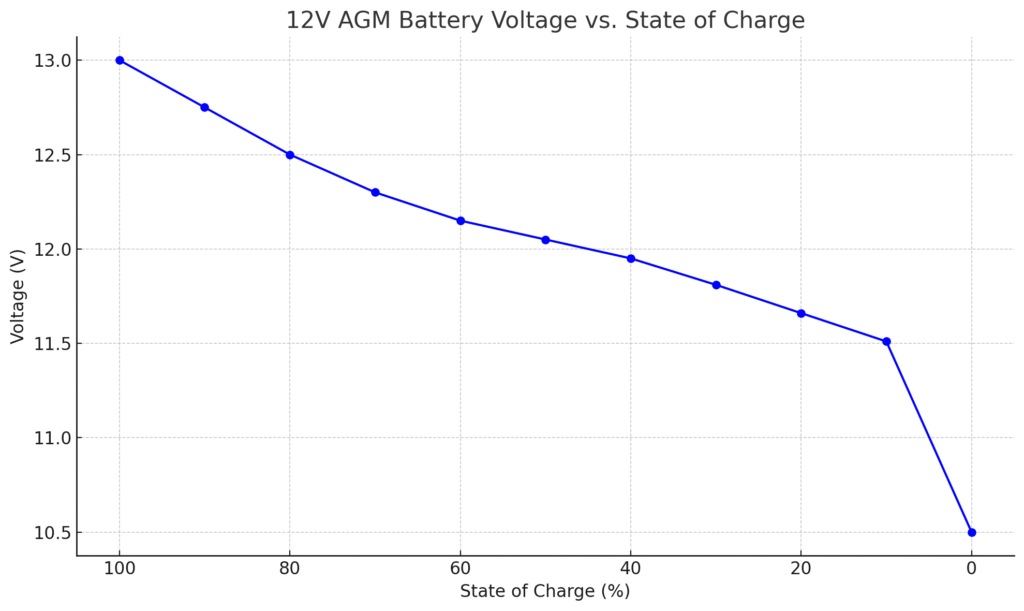

12V AGM Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 13.00 |

| 90% | 12.75 |

| 80% | 12.50 |

| 70% | 12.30 |

| 60% | 12.15 |

| 50% | 12.05 |

| 40% | 11.95 |

| 30% | 11.81 |

| 20% | 11.66 |

| 10% | 11.51 |

| 0% (empty) | 10.50 or lower |

What Voltage Readings Tell You About Battery Health

AGM (Absorbent Glass Mat) batteries operate within specific voltage ranges that indicate their state of charge (SoC) and overall health. Unlike flooded lead-acid batteries, AGM batteries maintain a more stable voltage curve, but interpreting these readings correctly is crucial for proper maintenance. Here’s a breakdown of key voltage thresholds:

- 12.8V–13.0V (100% Charged): A resting voltage in this range means your AGM battery is fully charged. For example, if you measure 12.9V after the battery has sat unused for 12 hours, it’s ready for optimal performance.

- 12.4V–12.7V (50–75% Charged): This is the typical range for a battery in regular use. Dropping below 12.4V frequently (e.g., in an RV fridge cycling overnight) signals excessive discharge, which can shorten lifespan.

- 12.0V–12.3V (25–50% Charged): At this stage, the battery needs immediate recharge. Prolonged use in this range (common in solar systems during cloudy days) causes sulfation, reducing capacity.

- Below 11.8V (0% Charged): A reading this low risks permanent damage. AGM batteries discharged beyond 50% regularly (e.g., in trolling motors) may lose up to 30% of their cycle life.

Why Temperature and Load Affect Voltage Readings

Voltage measurements must account for temperature and active loads to avoid false diagnoses. A battery showing 12.2V at 32°F (0°C) may actually be at 50% charge, not 25%, due to temperature-induced voltage depression.

Similarly, checking voltage while a load is applied (like an inverter running) will show a temporary dip—a 12V AGM battery powering a 100W light might read 11.7V, rebounding to 12.5V once the load is removed.

Real-World Application: Solar Power Systems

Consider a 200W solar panel charging a Renogy 12V 100Ah AGM battery. On a sunny day, the charge controller may push voltage to 14.4V (absorption phase), then taper to 13.6V (float). At night, a healthy system shouldn’t drop below 12.4V. If it hits 11.9V by dawn, your panel array or battery capacity is undersized—a common issue in off-grid cabins.

Pro Tip: Always measure voltage at rest (no charge/discharge for 2+ hours) for accurate SoC assessment. For dynamic systems, use a shunt monitor (like Victron BMV-712) to track real-time amp-hour consumption.

How to Properly Charge and Maintain AGM 12V Batteries

Optimal Charging Parameters for Maximum Lifespan

AGM batteries require specific charging voltages that differ from other lead-acid types. Using incorrect settings can reduce capacity by up to 40% over time. The ideal charging process occurs in three distinct phases:

- Bulk Phase (14.4–14.8V): Delivers 80% charge at maximum current. For a 100Ah battery, this means ~25A until voltage reaches 14.6V. Example: A NOCO Genius 10 charger maintains precise 14.7V during this critical stage.

- Absorption Phase (14.2–14.6V): Holds voltage steady while current tapers. This completes the final 15% charge over 2–4 hours, crucial for preventing stratification.

- Float Phase (13.2–13.8V): Maintains full charge without overcharging. Marine systems should use 13.6V in saltwater environments to compensate for higher conductivity.

Temperature Compensation Considerations

AGM batteries need voltage adjustments based on ambient temperature. For every 10°F (5.5°C) below 77°F (25°C), add 0.03V per cell (0.18V for 12V systems). In freezing Alaskan winters (0°F/-18°C), you’d charge at 14.8V instead of 14.6V. Conversely, in Arizona summers (110°F/43°C), reduce to 14.2V to prevent thermal runaway.

Common Maintenance Mistakes to Avoid

- Overcharging: Leaving batteries at absorption voltage for days (common with faulty solar controllers) boils electrolytes, causing irreversible dry-out.

- Undercharging: Stopping at 90% charge (13.2V) creates progressive sulfation. A 2023 study showed this reduces cycle life by 60% compared to full charges.

- Parasitic Drain: Even 0.5A continuous draw (like a GPS tracker) can drain a 100Ah battery to 50% in just 4 days when unused.

Pro Tip: For seasonal storage, charge to 100%, disconnect all loads, and store at 50°F (10°C). Check voltage monthly – if below 12.6V, recharge immediately. This method preserves 95% capacity after 6 months of inactivity.

Advanced Troubleshooting and Voltage Analysis for AGM 12V Batteries

Diagnosing Voltage Anomalies and Their Root Causes

When AGM batteries exhibit unusual voltage behavior, systematic analysis is required to identify underlying issues. Below is a comprehensive table of voltage abnormalities with their probable causes and solutions:

| Voltage Reading | Possible Causes | Diagnostic Steps | Recommended Action |

|---|---|---|---|

| 15V+ during charge | Faulty voltage regulator, incorrect charger settings | Measure at battery terminals, check charger specifications | Immediately disconnect and replace charger/alternator |

| 12.0V after 24hr rest | Deep discharge, cell imbalance, sulfation | Load test, specific gravity check (if accessible) | Slow charge at 13.8V for 48 hours with desulfation mode |

| Voltage drops >0.5V under moderate load | High internal resistance, corroded terminals | Voltage drop test across connections | Clean terminals with baking soda solution, replace if >3 years old |

The Science of Voltage Recovery Patterns

Healthy AGM batteries should recover to 12.6V within 2 hours after a 50% discharge (20A load for 2.5 hours on 100Ah battery). Poor recovery indicates:

- Slow recovery (>4 hours): Plate sulfation reducing active material (common in solar systems with chronic undercharging)

- Incomplete recovery (<12.4V): Permanent capacity loss from excessive deep cycling (typical in trolling motor applications)

- Instant voltage rebound: Surface charge masking actual SoC – wait 30 minutes for accurate reading

Professional Load Testing Methodology

True battery health requires a standardized load test:

- Fully charge battery (14.6V until current drops below 1% of Ah rating)

- Apply load equal to 50% of CCA rating for 15 seconds

- Measure voltage: >9.6V indicates good condition

- For deep-cycle batteries, use 3-hour 20A discharge test instead

Expert Insight: Marine electricians recommend testing batteries both cold (50°F/10°C) and warm (80°F/27°C) – temperature variations can reveal hidden weaknesses in battery interconnections and plate alloys.

Optimizing AGM Battery Performance in Specialized Applications

Application-Specific Voltage Management Strategies

Different usage scenarios demand tailored voltage management approaches to maximize AGM battery performance and longevity. Understanding these specialized requirements can extend battery life by 30-50% compared to generic usage.

- Solar Power Systems: Maintain float voltage between 13.2-13.8V to prevent gassing while compensating for daily cycling. Implement equalization charges (15V for 2 hours) monthly to balance cells – critical in off-grid installations with partial state-of-charge operation.

- Marine Applications: Use temperature-compensated charging (14.4-14.8V at 50°F/10°C) to account for cold engine compartments. Install moisture-resistant battery monitors like Victron BMV-712 to track voltage drops from saltwater corrosion.

- RV/Camper Use: Implement dual-voltage systems (12V for starting, 6V AGM banks for house power) to handle the varied loads. Deep-cycle AGMs should never drop below 12.2V overnight to preserve refrigerator compressor life.

Advanced Parallel and Series Configuration Techniques

When connecting multiple AGM batteries, voltage matching becomes critical:

- Parallel Connections: Ensure all batteries are within 0.1V before connecting. Mismatched voltages create counter-currents that can reduce capacity by up to 20%.

- Series Configurations: Use identical batteries from the same production lot. Even 0.3V difference in 6V batteries creates imbalance in 12V systems, leading to premature failure.

- Bank Maintenance: Rotate battery positions annually in multi-bank systems to equalize wear. This is especially important in solar arrays with 4+ batteries.

Safety Protocols and Industry Standards

AGM batteries require specific safety considerations despite being “sealed”:

- Ventilation: While spill-proof, AGM batteries still emit hydrogen during charging. Maintain 1″ clearance around batteries and install in UL-approved enclosures for indoor installations.

- Torque Specifications: Terminal connections should be tightened to 8-10 Nm (70-90 in-lbs). Over-tightening cracks lead posts; under-tightening causes voltage drops.

- Disposal Procedures: Even depleted AGM batteries retain 12V potential. Always transport with terminal covers and dispose at certified recycling centers meeting EPA standards.

Professional Tip: For mission-critical applications (medical equipment, telecom), implement a 3-tier voltage monitoring system: onboard battery monitor, standalone voltmeter, and automated alert system for voltages outside 11.5-14.8V range.

Long-Term AGM Battery Economics and Emerging Technologies

Cost-Performance Analysis Over Battery Lifespan

Understanding the total cost of ownership for AGM batteries requires evaluating multiple financial factors beyond initial purchase price. The table below compares 3-year costs for different usage scenarios:

| Usage Scenario | Initial Cost | Annual Maintenance | Replacement Cycle | Cost/Ah Over 3 Years |

|---|---|---|---|---|

| Solar Storage (50% DoD daily) | $200 | $20 (equalization charges) | 2.5 years | $0.88/Ah |

| Marine Trolling (80% DoD weekly) | $250 | $40 (terminal maintenance) | 1.8 years | $1.32/Ah |

| Backup Power (10% DoD monthly) | $180 | $10 (cleaning) | 5+ years | $0.38/Ah |

Environmental Impact and Recycling Processes

Modern AGM batteries contain 60-70% recycled lead but require specialized handling:

- Reclamation Efficiency: 98% of lead and plastic is recoverable, but improper recycling releases sulfuric acid mist

- Carbon Footprint: Production emits 8-12kg CO2 per kWh capacity, offset by 30% if using recycled materials

- Disposal Regulations: US EPA mandates leak-proof containers for transport and neutralization of residual acid

Next-Generation AGM Technologies

Emerging innovations are addressing traditional AGM limitations:

- Carbon-Enhanced Plates: Adding graphene increases cycle life by 3x (tested to 1,200 cycles at 50% DoD)

- Smart Battery Systems: Integrated Bluetooth monitoring tracks internal resistance and predicts failures 6+ months in advance

- Hybrid AGM/LiFePO4: New designs combine AGM reliability with lithium chemistry for 15% weight reduction

Future Outlook: By 2026, 70% of new AGM batteries will likely incorporate IoT connectivity for real-time voltage optimization, potentially extending lifespans beyond 8 years in moderate climates. However, traditional AGM will remain dominant for extreme-temperature applications (-40°F to 150°F operational range).

Advanced System Integration and Voltage Optimization Techniques

Multi-Bank Voltage Balancing Strategies

When integrating AGM batteries with other power system components, voltage synchronization becomes critical for optimal performance. Modern systems often combine AGM batteries with solar arrays, alternators, and lithium backups, each requiring precise voltage coordination:

- Solar-AGM Integration: Use multi-stage charge controllers with AGM-specific profiles (14.6V bulk → 13.8V float). MPPT controllers should be programmed with 0.5V higher absorption voltage than battery bank voltage to overcome line losses.

- Dual-Alternator Systems: In marine/RV applications, synchronize alternator regulators within 0.2V to prevent current fighting. Install voltage sensing directly at battery terminals, not alternator outputs.

- Hybrid AGM-Lithium Systems: When pairing AGM with LiFePO4, use DC-DC converters to maintain AGM at 13.8V while allowing lithium to operate at 14.6V. Never connect dissimilar chemistries directly in parallel.

Precision Voltage Calibration Procedures

Accurate system monitoring requires periodic voltage calibration using this professional-grade methodology:

- Disconnect all loads and chargers for 4+ hours to establish baseline voltage

- Using a Fluke 87V multimeter, measure at battery terminals (not bus bars)

- Compare with battery monitor readings – acceptable variance is ±0.05V

- Adjust monitor calibration if variance exceeds 0.1V (critical for solar systems)

- Repeat quarterly or after major system modifications

Voltage Drop Mitigation in Complex Systems

Large installations often suffer from cumulative voltage drops that mask true battery state. For every 10 feet of 2AWG cable at 100A load, expect 0.15V drop. Solutions include:

| Problem | Diagnostic Method | Solution | Voltage Improvement |

|---|---|---|---|

| Undersized cabling | Infrared thermal imaging | Upgrade to 2/0 AWG with tinned lugs | 0.2-0.3V |

| Corroded connections | Millivolt drop test | Apply NO-OX-ID A-Special grease | 0.1-0.15V |

| Faulty bus bars | Voltage differential test | Install marine-grade copper bus bars | 0.08-0.12V |

Professional Insight: In mission-critical data center UPS systems, implement redundant voltage sensing with automatic switchover to backup sensors if primary readings deviate by >0.2V. This prevents false triggering of emergency protocols during sensor failures.

Professional-Grade AGM Battery System Validation and Optimization

Comprehensive Performance Benchmarking Protocol

Establishing baseline performance metrics is essential for long-term AGM system health. Follow this rigorous validation procedure quarterly:

- Capacity Testing: Conduct 20-hour discharge test at 0.05C rate (5A for 100Ah battery) to measure actual vs. rated capacity

- Charge Acceptance: Time how long battery takes to reach 14.4V from 50% SoC at 25°C – should be ≤6 hours for healthy AGM

- Voltage Recovery: After 50% discharge, measure time to return to 12.6V – optimal is <2 hours at 77°F (25°C)

- Internal Resistance: Use Midtronics MDX-650 tester – values >5mΩ indicate sulfation or plate damage

Advanced Risk Assessment Matrix

Evaluate your AGM system against these critical risk factors with mitigation strategies:

| Risk Factor | Severity | Detection Method | Mitigation Strategy |

|---|---|---|---|

| Chronic Undercharging | High (60% capacity loss) | Monthly capacity tests | Program equalization charges every 30 cycles |

| Thermal Runaway | Critical | IR temperature scans | Install thermal fuses (135°F/57°C cutoff) |

| Intercell Corrosion | Moderate-High | 3-year internal inspection | Use corrosion-resistant interconnects (tin-plated copper) |

Precision Maintenance Scheduling

Implement this maintenance timeline for maximum AGM lifespan:

- Daily: Visual inspection for case swelling (indicator of overcharging)

- Weekly: Terminal voltage check (+/- 0.2V variance between cells)

- Monthly: Torque verification (8-10Nm) and capacity spot-check

- Annually: Full discharge-charge cycle with thermal imaging

Quality Assurance Tip: Maintain a battery log tracking voltage trends, charge cycles, and maintenance actions. Advanced users should calculate Peukert’s exponent (n) annually – values >1.15 indicate deteriorating performance. For mission-critical systems, implement automated testing protocols using devices like the Cadex C7400 analyzer.

Conclusion: Mastering AGM 12V Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical relationship between voltage readings and AGM battery health, from basic charge states (12.8V = fully charged) to advanced troubleshooting (voltage drops under load).

You’ve learned proper charging techniques, system integration strategies, and professional maintenance protocols that can extend battery life by years. Remember that consistent voltage monitoring is the key to preventing 80% of common AGM failures.

Put this knowledge into action today – start by checking your battery’s resting voltage with a quality multimeter, and establish a regular maintenance schedule. With these insights, you’re now equipped to maximize performance, whether in solar installations, marine applications, or backup power systems.

Frequently Asked Questions About AGM 12V Battery Voltage

What voltage should a fully charged AGM 12V battery show?

A healthy AGM battery at full charge should read 12.8V-13.0V after resting for 12 hours without load or charge. When actively charging, expect 14.4V-14.8V during absorption phase.

Note that temperature affects readings – add 0.03V per cell for every 10°F below 77°F. For example, at 32°F, a “true” 12.8V reading actually indicates about 95% charge due to temperature compensation factors.

How often should I check my AGM battery voltage?

For critical systems (medical, marine, solar), check voltage weekly under consistent conditions (same temperature, time since last charge). Recreational users should test monthly. Always check:

- Before/after long storage periods

- When adding new electrical loads

- After extreme temperature changes (>30°F fluctuation)

Use a calibrated digital multimeter for accurate readings.

Why does my AGM battery voltage drop quickly under load?

Rapid voltage drop indicates either:

- High internal resistance from sulfation (caused by chronic undercharging)

- Capacity loss (common after 300+ deep cycles)

- Connection issues (corroded terminals or loose cables)

Test by applying a 50% CCA load for 15 seconds – voltage shouldn’t drop below 9.6V. If it does, perform an equalization charge or consider replacement.

Can I charge an AGM battery with a regular lead-acid charger?

While possible in emergencies, regular lead-acid chargers often overcharge AGM batteries because they:

- Lack temperature compensation

- Use higher float voltages (13.8V+ vs AGM’s ideal 13.2V-13.6V)

- Don’t have AGM-specific absorption phases

Prolonged use can reduce lifespan by 40%. Invest in an AGM-compatible smart charger like NOCO Genius 10 for optimal performance.

How low can I safely discharge my AGM battery?

Never discharge below 12.0V (50% Depth of Discharge). While AGMs can technically go to 11.6V, each deep discharge below 12.0V:

- Reduces total cycle life by 15-20%

- Increases recharge time by 2-3x

- Raises internal temperature during recharge

For solar systems, set your inverter’s low-voltage cutoff to 12.1V to preserve battery health.

Why does my new AGM battery show 12.4V right out of the box?

This is normal storage voltage (about 70% charge) to prevent sulfation during warehousing. Before first use:

- Fully charge to 14.6V (temperature-adjusted)

- Let rest 4 hours

- Verify 12.8V+ reading

Many manufacturers recommend 3-5 initial charge-discharge cycles to “condition” the plates for maximum capacity.

How do I know when my AGM battery needs replacement?

Replace when you observe:

- Voltage drops below 12.0V overnight with normal loads

- Capacity tests show <80% of rated Ah

- Internal resistance >5mΩ on professional testers

- Physical bulging or terminal corrosion

Most quality AGMs last 4-7 years with proper maintenance. Keep receipts – many have pro-rated warranties.

Is it safe to parallel AGM batteries with different ages/capacities?

Strongly discouraged. Mismatched batteries:

- Create counter-current flows that waste energy

- Cause uneven charging (older batteries overcharge)

- Reduce total system capacity by up to 30%

If necessary, use batteries within:

- 6 months age difference

- 10% capacity variance

- 0.1V resting voltage match

Always monitor individual battery voltages in parallel setups.