Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

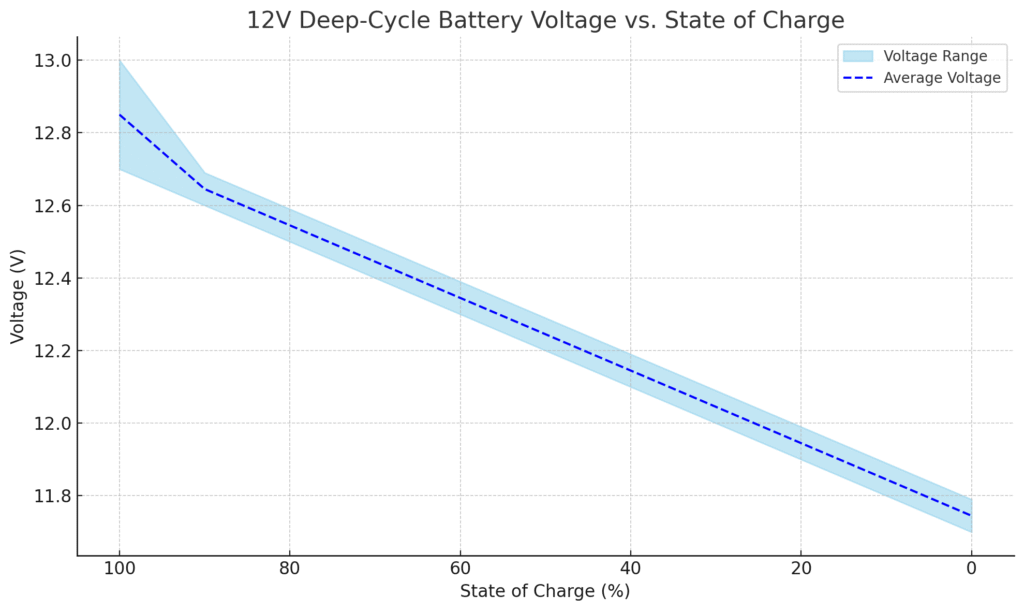

Did you know that a fully charged 12V deep-cycle battery should read 12.7V or higher, but most users mistakenly assume 12V means full capacity? Deep-cycle batteries power everything from RVs to solar setups, yet voltage misinterpretation is a leading cause of premature failure.

If you’ve ever wondered why your battery drains too fast or won’t hold a charge, the answer lies in understanding voltage states—not just a single number. Imagine setting off on a camping trip, only to find your RV battery dead by nightfall because it was actually at 50% capacity despite showing 12V.

Best 12V Deep-Cycle Batteries for Reliable Power Storage

Renogy Deep Cycle AGM Battery 12V 100Ah

Renogy’s AGM battery is a top choice for solar and off-grid setups due to its spill-proof design, deep discharge recovery, and 10-year lifespan. With a low self-discharge rate and vibration resistance, it’s ideal for RVs, marine use, and renewable energy systems.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

GOAL ZERO Yeti 1250 BATTERY

This heavy-duty battery boasts 1,250+ cycles at 50% depth of discharge, making it perfect for frequent deep cycling. Its high-purity lead plates and corrosion-resistant terminals ensure durability, while the sealed AGM design requires zero maintenance—ideal for backup power and trolling motors.

- 12 volt AGM deep cycle SLA group 31 battery

- Replaces and upgrades your goal zero yeti 1250 battery (the SLR125 fits…

- Military grade custom made plates

100Ah 12V Lithium-Ion

For cutting-edge performance, Battle Born’s lithium iron phosphate (LiFePO4) battery offers 3,000–5,000 cycles and lightweight construction. With built-in battery management and 100% usable capacity, it’s a premium pick for van lifers and solar enthusiasts needing long-term reliability.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

12V Deep-Cycle Battery Voltage States

A deep-cycle 12V battery’s voltage isn’t static—it fluctuates based on charge level, temperature, and load conditions. Unlike starter batteries that deliver short bursts of power, deep-cycle batteries are designed for prolonged energy discharge, making voltage interpretation critical for performance and longevity. Misreading voltage can lead to undercharging (reducing capacity) or overcharging (causing damage).

12V Deep-Cycle Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 12.70 – 13.00 |

| 90% | 12.60 – 12.69 |

| 80% | 12.50 – 12.59 |

| 70% | 12.40 – 12.49 |

| 60% | 12.30 – 12.39 |

| 50% | 12.20 – 12.29 |

| 40% | 12.10 – 12.19 |

| 30% | 12.00 – 12.09 |

| 20% | 11.90 – 11.99 |

| 10% | 11.80 – 11.89 |

| 0% (empty) | Below 11.80 |

Voltage Ranges and Their Meaning

Here’s how to decode voltage readings for a 12V deep-cycle battery at rest (no load for 24 hours):

- 12.7V–13.2V: Fully charged (100%). AGM and flooded lead-acid batteries typically settle at 12.8V, while lithium (LiFePO4) batteries read 13.2V+ due to higher nominal voltage.

- 12.4V–12.6V: Partial charge (75–50%). At 12.4V, lead-acid batteries have ~50% capacity left—discharging below this risks sulfation, permanently reducing lifespan.

- 12.0V–12.3V: Low charge (25–50%). Immediate recharge is needed; continued use strains the battery and accelerates degradation.

- Below 11.9V: Deeply discharged (0–25%). Lead-acid batteries risk irreversible damage, while lithium batteries shut off to protect cells.

Why Voltage Alone Isn’t Enough

Voltage is a snapshot, not a full diagnostic. For example, a battery showing 12.6V might seem healthy, but if it drops to 10V under load, it indicates internal resistance or aging cells. Always pair voltage checks with:

- Load testing: Apply a 50% amp draw (e.g., 50A for a 100Ah battery) for 15 seconds. Stable voltage confirms health.

- Specific gravity testing (for flooded batteries): Use a hydrometer to measure electrolyte density—1.265 indicates full charge.

Real-World Voltage Scenarios

Consider a solar-powered fridge drawing 5A continuously. A 100Ah battery starting at 12.8V will drop to ~12.4V after 10 hours (50% discharge). If voltage plummets to 11V within 2 hours, the battery likely has degraded capacity due to sulfation or plate corrosion.

Pro Tip: Temperature affects voltage—for every 10°F drop below 77°F, subtract 0.01V per cell (0.06V for 12V batteries). Cold weather can falsely indicate lower charge levels.

How to Accurately Measure and Monitor 12V Battery Voltage

Proper voltage measurement is the foundation of battery maintenance, yet most users make critical errors in technique that lead to false readings. Unlike simple voltage checks for car batteries, deep-cycle systems require precision methods to account for surface charge, load conditions, and battery chemistry differences.

Step-by-Step Measurement Process

- Prepare the battery: Disconnect all loads and chargers for 24 hours to eliminate surface charge (a temporary voltage spike that can show 13V+ on a depleted battery). For lithium batteries, 2 hours suffices.

- Select the right tools: Use a calibrated digital multimeter (0.5% accuracy or better) with 0.01V resolution. Analog meters lack precision for state-of-charge determination.

- Proper connection technique: Clean terminals with baking soda solution, then connect the red probe to positive and black to negative. Poor contact adds resistance, skewing readings by 0.1-0.3V.

Advanced Monitoring Solutions

For continuous tracking, install a battery monitor like the Victron BMV-712 that measures:

- Coulomb counting: Tracks actual amp-hours consumed rather than just voltage

- Temperature-compensated readings: Adjusts for thermal effects automatically

- Historical data: Identifies discharge patterns that indicate aging

Troubleshooting Common Measurement Issues

When voltage readings seem inconsistent:

Scenario: Your battery shows 12.9V after charging but drops to 11.8V when the inverter turns on.

Diagnosis: This “voltage sag” indicates high internal resistance from sulfation (lead-acid) or damaged cells (lithium). Load testing confirms this.

Professional Tip: Always measure voltage at the battery terminals, not through wiring. A 0.4V drop across 10 feet of 8AWG cable at 20A means your actual battery voltage is higher than what your device receives.

For flooded batteries, combine voltage checks with specific gravity tests using a refractometer – the only way to detect a failing cell that might still show normal overall voltage.

Optimizing Charging Practices for Maximum Battery Life

Proper charging is the single most important factor determining a deep-cycle battery’s lifespan, yet most users unknowingly follow practices that degrade performance. Different battery chemistries require specific charging profiles – a one-size-fits-all approach can reduce capacity by 30% within 50 cycles.

Chemistry-Specific Charging Parameters

| Battery Type | Bulk/Absorption Voltage | Float Voltage | Max Charge Current |

|---|---|---|---|

| Flooded Lead-Acid | 14.4-14.8V | 13.2-13.5V | 20% of Ah rating |

| AGM | 14.6-14.8V | 13.5-13.8V | 30% of Ah rating |

| LiFePO4 | 14.2-14.6V | 13.5V (optional) | 50-100% of Ah rating |

Advanced Charging Techniques

For lead-acid batteries, implement temperature-compensated charging – reduce voltage by 0.003V/°F above 77°F to prevent gassing. In cold climates, increase voltage by the same factor to ensure complete charging. Modern smart chargers like the NOCO Genius10 automatically adjust for temperature.

Equalization charging (for flooded batteries only) should be performed monthly at 15.5-16V for 2-4 hours to desulfate plates. Never equalize AGM or lithium batteries – this causes permanent damage.

Common Charging Mistakes

- Partial charging: Repeatedly charging to only 80% creates “stratification” in flooded batteries where acid concentrates at the bottom

- Overcharging lithium: Keeping LiFePO4 at 100% for extended periods accelerates calendar aging – store at 50-60% when not in use

- Wrong charger type: Using an automotive charger with deep-cycle batteries causes excessive gassing and plate corrosion

Pro Tip: For solar systems, set absorption time to 2-4 hours (not voltage-based) to ensure complete charging. Many systems switch to float too early when clouds pass, leading to chronic undercharging.

Battery Maintenance and Storage: Expert Strategies for Longevity

Proper maintenance can triple the lifespan of deep-cycle batteries, yet most users neglect critical care routines. Whether you’re storing batteries for winter or maintaining daily-use systems, these professional techniques ensure optimal performance through hundreds of cycles.

Seasonal Storage Protocols

For lead-acid batteries (flooded and AGM):

- Charge to 100% before storage – partial charge accelerates sulfation

- Disconnect all loads to prevent parasitic drain (even 0.5A can discharge a battery in weeks)

- Store in cool (40-60°F), dry locations – high temperatures increase self-discharge rates by 2x per 15°F

- Recharge every 3 months when stored – use a maintainer like BatteryMINDer 2012 to prevent sulfation

For lithium (LiFePO4) batteries:

- Store at 40-60% state of charge (13.0-13.2V) to minimize calendar aging

- No periodic charging needed – self-discharge is less than 3% per month

- Can withstand freezing temps but should not be charged below 32°F

Routine Maintenance Checklist

Monthly:

- Check and record voltage (after 24hr rest period)

- Inspect terminals for corrosion – clean with baking soda solution if needed

- For flooded batteries: check electrolyte levels and top up with distilled water

Quarterly:

- Perform equalization charge (flooded batteries only)

- Test specific gravity (flooded) or capacity via full discharge test

- Torque terminal connections to manufacturer specs (typically 5-7 Nm)

Troubleshooting Common Issues

Problem: Battery won’t hold charge after storage

Solution: For lead-acid, try a desulfation cycle with a pulse charger. For lithium, perform a full discharge/charge cycle to reset the BMS.

Problem: White powder on terminals

Solution: Remove corrosion with terminal cleaner, apply dielectric grease, and ensure proper ventilation to prevent acid condensation.

Professional Tip: Keep a battery log tracking voltage, charging cycles, and maintenance. This data helps predict end-of-life and validates warranty claims – most manufacturers require maintenance records for pro-rated replacements.

Cost Analysis and Environmental Impact: Choosing the Right Battery Solution

Selecting a deep-cycle battery involves more than upfront costs – total lifecycle value, environmental impact, and application requirements all play critical roles. This comprehensive analysis compares lead-acid and lithium technologies across multiple dimensions to inform your purchasing decision.

Total Cost of Ownership Breakdown

| Factor | Flooded Lead-Acid | AGM | LiFePO4 |

|---|---|---|---|

| Initial Cost (100Ah) | $100-$150 | $250-$350 | $600-$900 |

| Cycle Life (to 80% capacity) | 300-500 cycles | 500-800 cycles | 3,000-5,000 cycles |

| 10-Year Cost (including replacements) | $600-$900 | $750-$1,050 | $600-$900 |

| Energy Efficiency | 70-80% | 80-85% | 95-98% |

Environmental and Safety Considerations

Lead-Acid Batteries:

- 97% recyclable (most recycled consumer product in the US)

- Contains toxic lead and sulfuric acid requiring proper disposal

- Off-gassing requires ventilation in enclosed spaces

Lithium Batteries:

- Lower environmental impact during use (no emissions, higher efficiency)

- Recycling infrastructure still developing (currently ~5% recycling rate)

- Thermal runaway risk requires quality BMS and proper charging

Future Trends and Emerging Technologies

The industry is moving toward:

- Second-life applications: Repurposing EV batteries for solar storage (40-70% original capacity at 1/3 the cost)

- Sodium-ion batteries: Promising alternative without rare materials (projected $40/kWh by 2025)

- Smart battery systems: Cloud-connected batteries with AI-driven optimization (e.g., Tesla Powerwall diagnostics)

Professional Recommendation: For high-cycling applications (daily solar use), lithium provides better long-term value despite higher upfront cost. For backup power used occasionally, quality AGM offers the best balance of cost and maintenance-free operation.

System Integration and Performance Optimization Techniques

Properly integrating deep-cycle batteries into larger power systems requires careful planning to maximize efficiency and prevent performance bottlenecks. Whether designing solar arrays, marine systems, or off-grid power solutions, these professional techniques ensure optimal energy flow and system longevity.

Wiring and Configuration Best Practices

For multi-battery systems, follow these critical guidelines:

- Parallel vs. Series Wiring:

- Parallel connections (voltage stays same, capacity adds) require identical cable lengths to prevent imbalance

- Series connections (voltage adds, capacity stays same) demand matched batteries within 0.1V of each other

- Cable Sizing: Use the American Boat & Yacht Council (ABYC) formula:

- Cable Area (mm²) = (Current × Length × 0.017) ÷ (Voltage Drop × 1000)

- For 12V systems, never exceed 3% voltage drop between battery and load

Charge Controller Optimization

Match controllers to your battery type with these advanced settings:

- Absorption Time: Set 2-4 hours for lead-acid (prevents premature float transition)

- Tail Current: Configure to 2-3% of battery capacity (C/50 to C/30) for precise full-charge detection

- Temperature Compensation: Install remote sensors for accurate adjustments (-3mV/°C/cell for lead-acid)

Load Management Strategies

Implement these professional techniques to extend battery life:

| Load Type | Management Technique | Benefit |

|---|---|---|

| Inverter Loads | Programmable delay start (stagger high-draw devices) | Prevents voltage sag below 10.5V |

| DC Lighting | PWM dimming instead of voltage reduction | Avoids damaging low-voltage operation |

| Refrigeration | Temperature-compensated voltage cutoff | Maintains food safety without over-discharge |

Advanced Tip: For solar systems, implement DC coupling when possible – it’s 5-8% more efficient than AC coupling because it avoids double conversion losses. Use maximum power point tracking (MPPT) controllers with at least 98% peak efficiency ratings.

Advanced Diagnostics and Predictive Maintenance Strategies

Moving beyond basic voltage monitoring, professional battery management requires sophisticated diagnostic techniques that predict failures before they occur. These advanced methods can extend battery life by 20-40% while preventing unexpected system downtime.

Comprehensive Battery Health Assessment

Implement these diagnostic procedures quarterly:

| Test | Procedure | Healthy Threshold |

|---|---|---|

| Internal Resistance | Measure with AC impedance tester at 25°C | <5% increase from baseline |

| Capacity Verification | Controlled 20-hour discharge test at C/20 rate | >80% of rated capacity |

| Charge Acceptance | Measure current at 14.4V after 50% discharge | >25% of C rating for lead-acid |

Predictive Maintenance Framework

- Data Collection:

- Log cycle counts, depth of discharge, and charge efficiency

- Track temperature extremes and average operating voltage

- Trend Analysis:

- Plot capacity fade rate (normal is 0.5-1% per month for lead-acid)

- Monitor internal resistance growth (exponential increase signals failure)

- Intervention Triggers:

- Schedule replacement when capacity reaches 70% of original

- Initiate equalization when charge acceptance drops 15%

Risk Mitigation Strategies

Address these common failure modes with proactive measures:

- Sulfation Prevention: Maintain batteries above 12.4V, use pulse desulfators during storage

- Thermal Runaway Protection: Install temperature-activated circuit breakers on lithium banks

- Cell Balancing: For lithium systems, verify BMS balancing current (minimum 100mA per cell)

Professional Tip: Implement automated battery monitoring systems like the Victron GX series that track 27+ parameters and generate predictive maintenance alerts based on machine learning analysis of historical performance data.

For mission-critical applications, conduct infrared thermography scans annually to detect hot spots indicating loose connections or failing cells before they cause system failures.

Conclusion

Understanding deep-cycle 12V battery voltage is fundamental to maximizing performance and lifespan. As we’ve explored, proper voltage interpretation requires considering charge states, temperature effects, and battery chemistry.

From accurate measurement techniques to advanced charging protocols and predictive maintenance, each aspect plays a critical role in battery health. Remember that voltage alone tells an incomplete story – combining it with capacity testing and regular maintenance provides the full picture.

Whether you’re powering an RV, solar system, or marine application, applying these professional-grade practices will ensure reliable performance for years to come. Start implementing these strategies today – your batteries (and wallet) will thank you.

Frequently Asked Questions About Deep-Cycle 12V Battery Voltage

What exactly is a deep-cycle battery and how does it differ from regular car batteries?

Deep-cycle batteries are designed for prolonged energy discharge and frequent cycling, unlike starter batteries that deliver short bursts of high current. They feature thicker lead plates with denser active material and specialized separators to withstand 50-80% depth of discharge regularly.

While car batteries might provide 500 CCA (cold cranking amps), a deep-cycle 12V battery typically offers 100-200Ah capacity, prioritizing energy storage over peak power output.

How often should I check my deep-cycle battery’s voltage?

For active systems, check voltage weekly when in use and monthly during storage. Always measure after the battery rests (no charge/discharge for 24 hours for lead-acid, 2 hours for lithium).

Critical systems like medical equipment or marine navigation should use continuous monitors like the Victron BMV-712 that track voltage in real-time and log historical data.

Why does my battery show 13V right after charging but drops to 12.4V shortly after?

This indicates surface charge – a temporary voltage elevation that dissipates within hours. For accurate readings, either wait 24 hours or remove surface charge by applying a 10-15 minute load at C/20 rate (5A for 100Ah battery). Persistent voltage drops below 12.6V after 24 hours suggest insufficient charging or battery aging.

Can I use a car battery charger for my deep-cycle battery?

Only in emergencies – car chargers lack proper voltage regulation for deep-cycle applications. They typically charge at 14.4V+ without temperature compensation, causing excessive gassing and plate corrosion. Invest in a smart charger like NOCO Genius10 that offers selectable AGM/flooded/LiFePO4 profiles and proper absorption/float stages.

How does temperature affect battery voltage readings?

Voltage decreases about 0.01V per cell (0.06V for 12V) for every 10°F below 77°F. At freezing, a fully charged battery might read 12.6V instead of 12.7V. Always compensate charging voltage accordingly – increase by 0.03V/°F below 77°F for lead-acid. Lithium batteries automatically compensate via BMS.

What voltage indicates a completely dead 12V deep-cycle battery?

For lead-acid, below 10.5V under load (or 11.9V resting) is considered fully discharged. Lithium batteries typically shut off at 10V via BMS protection. However, repeatedly discharging below 12V (50% SOC) for lead-acid causes permanent sulfation damage. Always recharge immediately when voltage drops to 12.2V (25% SOC).

Why do different battery types (flooded, AGM, lithium) show different voltages at full charge?

This reflects their chemical composition: flooded lead-acid settles at 12.6-12.8V, AGM at 12.8-13.0V, and LiFePO4 at 13.3-13.6V due to higher nominal cell voltage (3.2V vs 2V for lead-acid). These differences require chemistry-specific charging profiles – using AGM settings on lithium can undercharge by 15-20%.

How accurate are battery voltage charts found online?

Most charts provide reasonable estimates but lack context. Accurate state-of-charge determination requires considering:

1) Resting time before measurement

2) Battery age

3) Temperature

4) Recent charge/discharge history.

For precision, combine voltage readings with specific gravity tests (flooded) or coulomb counting (lithium).