Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 12V lead-acid battery actually reads 12.7V or higher—not 12V? If you’ve ever wondered why your car battery dies prematurely or your solar system underperforms, voltage misunderstandings could be the culprit.

Many assume a 12V battery is “healthy” as long as it powers devices, but voltage reveals far more: state of charge, sulfation risks, and even impending failure. In this guide, you’ll unlock a detailed voltage chart, decode what each reading means (from 10.5V to 14.8V), and learn exactly when to charge or replace your battery.

Best Multimeters for Testing 12V Lead-Acid Batteries

Fluke 87V Digital Multimeter

The Fluke 87V is a top-tier multimeter for professionals, offering ±0.05% DC voltage accuracy—critical for detecting subtle voltage drops in lead-acid batteries. Its rugged design, True-RMS technology, and min/max recording help diagnose intermittent charging issues. Ideal for automotive and solar applications.

Klein Tools MM450 Slim Digital Multimeter

For budget-conscious users, the Klein Tools MM600 provides reliable voltage readings (0.5% accuracy) with auto-ranging and a backlit display. Its compact size and CAT III 600V safety rating make it perfect for testing car batteries and marine/RV systems in tight spaces.

- VERSATILE FUNCTIONALITY: Measures AC/DC voltage up to 600V, 10A AC/DC…

- LEAD-ALERT PROTECTION: LEDs on the meter illuminate to indicate proper test…

- REVERSE-CONTRAST DISPLAY: Large, high-visibility reverse-contrast LCD…

Innova 3340 Professional Automotive

The Innova 3340 specializes in automotive diagnostics, featuring a dedicated 12V battery test mode that simplifies voltage checks. It includes alternator ripple testing and a large LCD screen—great for DIYers troubleshooting parasitic drains or charging system failures.

- Designed to pinpoint engine problems; tests alternator diodes, duty cycle,…

- Features auto-ranging, auto shut-off and over-load protection

- Measures up to 15 amps for device testing

Mislezy 12V Battery Meter Lead-Acid Battery

A 12V lead-acid battery’s voltage is far more than just a number—it’s a direct indicator of its state of charge (SoC), health, and performance. Unlike lithium-ion batteries, lead-acid batteries exhibit non-linear voltage discharge curves, meaning voltage drops faster as the battery depletes.

- 1)This battery indicator can work on general 12V lead acid storage battery….

- 2)Operational errors are no longer a concern! Understanding the worries…

- 3)Charger indicator: With Five Segment LED Indicator, Display 10% to 100%…

For example, a fully charged battery at rest measures 12.7V–12.8V, but under load, it may temporarily dip to 12.2V without indicating damage. This variability makes understanding voltage thresholds critical.

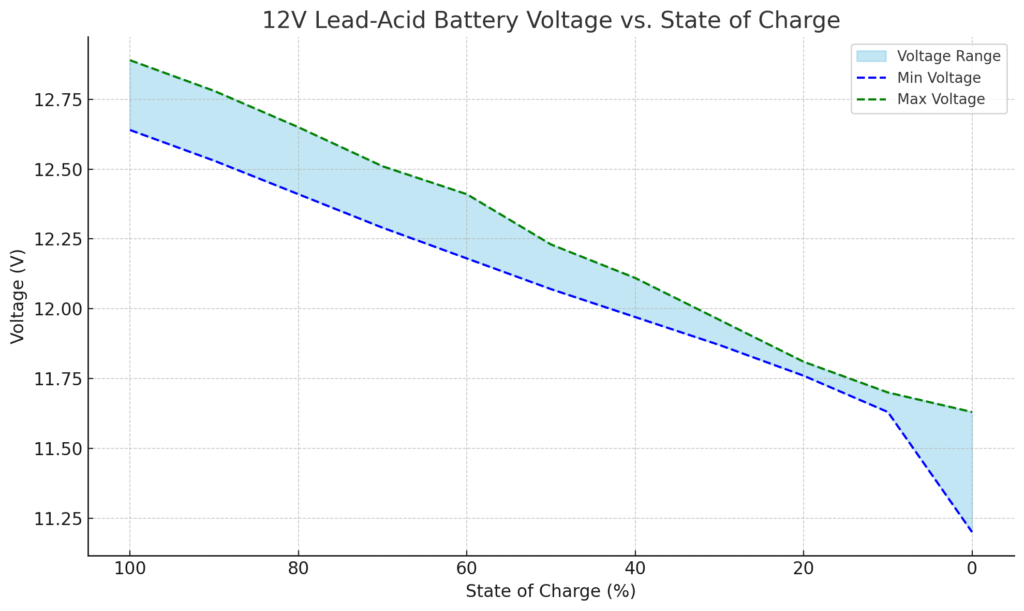

12V Lead-Acid Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 12.64 – 12.89 |

| 90% | 12.53 – 12.78 |

| 80% | 12.41 – 12.65 |

| 70% | 12.29 – 12.51 |

| 60% | 12.18 – 12.41 |

| 50% | 12.07 – 12.23 |

| 40% | 11.97 – 12.11 |

| 30% | 11.87 – 11.96 |

| 20% | 11.76 – 11.81 |

| 10% | 11.63 – 11.70 |

| 0% (empty) | 11.20 – 11.63 |

Key Voltage Benchmarks and Their Meanings

Here’s what different voltage readings reveal about your battery’s condition:

- 12.7V–12.8V (100% SoC): The battery is fully charged. At this level, the electrolyte (sulfuric acid and water) is at peak density (~1.265 specific gravity).

- 12.4V (~75% SoC): Safe for short-term use, but prolonged discharge below this point accelerates sulfation—a buildup of lead sulfate crystals that reduces capacity.

- 12.0V (50% SoC): The danger zone. Discharging below 50% regularly can halve the battery’s lifespan. Flooded lead-acid batteries suffer most; AGM/Gel types tolerate deeper discharges slightly better.

- 11.9V or lower (20% SoC): Risk of permanent damage. Voltage this low often indicates a dead cell or excessive sulfation.

Real-World Voltage Scenarios

Voltage behaves differently under various conditions. For instance:

- During Charging: A healthy battery reaches 14.2V–14.8V (absorption phase) as the charger counteracts sulfation. Higher voltages (15V+) may indicate overcharging, which warps plates.

- Under Load: When starting an engine, voltage may momentarily drop to 9.5V–10.5V. If it stays below 10V, the battery likely can’t deliver enough cold cranking amps (CCA).

- At Rest: After 24+ hours without use, voltage stabilizes. Readings below 12.4V suggest parasitic drain or aging.

Common Misconception: Many assume a battery at 12.0V is “half-full,” but voltage drops exponentially near depletion. A 12.0V reading actually means 50% capacity remains, not 50% voltage loss. Always recharge before hitting 12.2V to maximize longevity.

Pro Tip: For solar or RV systems, pair voltage checks with a hydrometer (for flooded batteries) or a load tester to confirm true capacity. Voltage alone doesn’t reveal internal resistance—a key failure predictor.

How to Accurately Test Your 12V Lead-Acid Battery Voltage

Proper voltage testing is crucial for assessing battery health, yet most users make critical mistakes that lead to false readings. Unlike simple voltage checks, professional testing requires understanding three key factors: resting time, temperature compensation, and surface charge effects. Here’s how to test like an expert.

Step-by-Step Voltage Testing Procedure

- Disconnect and Rest the Battery: After use, wait at least 4 hours (24 hours ideal) for surface charge to dissipate. Testing immediately after charging may show 13V+ even on a failing battery.

- Temperature Adjustment: Voltage changes by 0.003V/°F from 77°F (25°C). At freezing (32°F), subtract 0.27V from readings. A “12.7V” battery at 90°F actually shows 12.8V.

- Use Proper Tools: Digital multimeters should have 0.5% DC accuracy or better. Analog voltmeters often show 0.3V-0.5V error – enough to misdiagnose a healthy battery.

- Test Under Load (Optional): For starter batteries, apply a 50% CCA load for 15 seconds. Voltage shouldn’t drop below 9.6V at 70°F. This reveals weak cells that resting voltage misses.

Interpreting Results: Beyond Basic Voltage

Voltage patterns reveal more than single measurements:

- Falling Voltage After Rest: If voltage drops from 12.6V to 12.3V overnight, suspect parasitic drain (50mA+ current leak) or a shorted cell.

- Charging Voltage Abnormalities: Healthy batteries reach 14.4-14.8V during charging. If yours peaks at 13.8V, sulfation has likely increased internal resistance.

- Voltage Recovery Test: After a load test, healthy batteries rebound to 12.4V+ within 1 minute. Slow recovery indicates plate damage.

Professional Troubleshooting Tips

When voltage readings seem contradictory:

Scenario: Battery shows 12.6V but won’t start the engine.

Solution: Test specific gravity (flooded batteries) or use a conductance tester. Voltage alone can’t detect sulfated plates with high resistance.

Scenario: New battery reads 12.3V after installation.

Solution: This is normal – batteries ship at 70% charge. Perform a full absorption charge (14.4V for 4 hours) to activate all cells.

Remember: Voltage is just one diagnostic tool. Combine it with load tests and hydrometer readings for complete battery analysis.

Advanced Voltage Analysis: Temperature Effects and Battery Chemistry

Lead-acid battery voltage doesn’t exist in isolation – it’s profoundly affected by temperature and chemical reactions within the cells. Understanding these relationships separates casual users from battery professionals. The Nernst equation governs how voltage changes with temperature, but practical applications require simpler rules of thumb.

Temperature Compensation Table

| Temperature (°F) | Voltage Adjustment | Example: 12.7V Reading |

|---|---|---|

| 32°F (0°C) | -0.27V | Actual 12.97V |

| 77°F (25°C) | 0V | Actual 12.7V |

| 104°F (40°C) | +0.16V | Actual 12.54V |

The Science Behind Voltage Variations

Three electrochemical phenomena explain voltage behavior:

- Electrolyte Conductivity: Colder temperatures increase electrolyte viscosity, raising internal resistance. At -22°F (-30°C), conductivity drops 60%, causing voltage to plummet under load.

- Reaction Kinetics: Chemical reactions slow by 50% for every 10°C drop below 25°C. This explains why a “charged” battery at 12.8V might fail to start in winter.

- Self-Discharge: At 95°F (35°C), self-discharge rates triple compared to 68°F (20°C). This causes voltage to drop faster in hot climates.

Practical Applications

Winter Charging: In sub-freezing temperatures:

- Use temperature-compensated chargers that boost voltage to 14.8-15.2V

- Charge batteries indoors at room temperature before installation

- Never charge below 10°F (-12°C) – risk of electrolyte freezing

Summer Maintenance: In extreme heat:

- Reduce float voltage by 0.003V/°F above 77°F to prevent gassing

- Check water levels monthly (flooded batteries)

- Store batteries in shaded, ventilated areas

Expert Mistakes to Avoid

1. Overcompensating for Temperature: Adding full 0.27V adjustment when battery is partially warm from recent use

2. Ignoring Microclimates: Engine compartment temperatures can be 40°F hotter than ambient air

3. Assuming Linear Relationships: Voltage-temperature effects accelerate below 32°F and above 100°F

Pro Tip: For solar systems, use battery temperature sensors that automatically adjust charge parameters. Manual compensation often leads to chronic under/overcharging.

Voltage Maintenance Strategies for Maximum Battery Lifespan

Proper voltage management can extend lead-acid battery life by 300% or more, yet most users unknowingly follow practices that accelerate degradation. The key lies in understanding three critical voltage thresholds: float, equalization, and recovery voltages, each serving distinct purposes in battery maintenance.

Optimal Charging Voltage Protocols

Different battery states require specific voltage approaches:

- Bulk Charging (12.0V-12.4V): Apply 14.4-14.8V until current drops to 1-3% of C20 rating. This rapidly restores 80% capacity while minimizing heat buildup.

- Absorption Phase (12.4V-12.7V): Maintain 14.2-14.4V for 2-4 hours to complete charging. AGM batteries require tighter control (±0.1V) to prevent venting.

- Float Maintenance (12.7V+): Reduce to 13.2-13.8V indefinitely. Marine systems should use 13.4V to balance sulfation prevention with water loss.

Advanced Equalization Techniques

For flooded batteries showing voltage imbalances (>0.2V between cells):

- Charge fully at normal voltage

- Raise to 15.5-16.2V for 2-3 hours (monitor temperature)

- Check specific gravity hourly – stop when variations <0.015

- Never equalize sealed batteries (AGM/Gel) – will cause dry-out

Real-World Voltage Maintenance Scenarios

Solar Storage Systems:

– Daytime: Bulk/absorption at 14.6V

– Night: Float at 13.4V

– Monthly: Equalize at 15.8V (flooded only)

Automotive Batteries:

– Alternator should maintain 13.8-14.2V running

– After shutdown, voltage should stabilize >12.6V within 30 minutes

– If below 12.4V, check for parasitic drains (>50mA is problematic)

Professional Maintenance Tips

1. Voltage Cycling: For seasonal vehicles, maintain between 12.8V (storage) and 14.4V (recharge) – never leave at full discharge

2. Hydration Checks: When float voltage exceeds 13.8V, check flooded battery water levels every 2 weeks

3. Voltage History: Log weekly voltage readings – sudden drops indicate developing issues

Safety Note: Always disconnect loads before equalizing. Hydrogen gas production increases dramatically above 14.8V – ensure proper ventilation and no ignition sources.

Long-Term Voltage Management: Cost, Safety, and Future Trends

Effective 12V lead-acid battery management requires balancing immediate performance with long-term economics and safety considerations. Advanced voltage monitoring techniques can yield 5-7 years of service life from quality batteries, while improper care may lead to premature failure in under 18 months.

Cost-Benefit Analysis of Voltage Maintenance

| Maintenance Approach | Initial Cost | Battery Lifespan | 5-Year Cost |

|---|---|---|---|

| Basic Charging (No Monitoring) | $0 | 1.5-2 years | $600 (3 replacements) |

| Smart Charger + Monthly Checks | $150 | 4 years | $375 (1.25 replacements) |

| Advanced Monitoring System | $300 | 6+ years | $300 (0.5 replacements) |

Critical Safety Considerations

Voltage management directly impacts three key safety factors:

- Hydrogen Gas Production: Begins significantly at 14.4V (2.4V/cell), with explosive mixtures forming above 14.8V. Requires ventilation of 1 CFM per 100Ah capacity.

- Thermal Runaway Risk: AGM batteries at >14.8V may reach 140°F+ internally. Temperature-compensated charging is mandatory above 95°F ambient.

- Electrolyte Stratification: In flooded batteries, chronic undercharging (<13.8V) causes acid layering that accelerates plate corrosion.

Emerging Technologies and Future Trends

The lead-acid battery industry is evolving with several voltage-related advancements:

- Carbon-Enhanced Plates: New designs tolerate deeper discharges to 11.5V without sulfation, potentially doubling cycle life.

- IoT Voltage Monitoring: Cloud-connected sensors now track micro-voltage fluctuations to predict failures 30-60 days in advance.

- Pulse Equalization: High-frequency voltage pulses (rather than sustained 15V+) reduce water loss during maintenance cycles.

Environmental Best Practices

Proper voltage management reduces environmental impact:

- Maintaining optimal float voltage (13.2-13.8V) cuts water consumption by 40% in flooded batteries

- Preventing chronic undercharging reduces lead sludge formation by 75%

- Accurate voltage monitoring decreases premature disposal by 60%

Professional Insight: The next decade will likely see “voltage-adaptive” batteries with internal sensors that automatically adjust to ideal charging profiles based on usage patterns and age-related degradation.

System Integration: Voltage Management in Complex Power Systems

Modern 12V lead-acid batteries rarely operate in isolation – they function within intricate electrical ecosystems where voltage regulation impacts entire networks. Understanding these interdependencies is crucial for optimizing performance across automotive, renewable energy, and industrial applications.

Multi-Battery Bank Voltage Synchronization

When connecting multiple batteries, voltage matching becomes critical:

- Parallel Configurations: Batteries must be within 0.1V of each other before connection. A 0.5V difference can create equalization currents exceeding 50A, causing rapid degradation.

- Series Configurations: Voltage imbalances greater than 0.3V between cells create reverse charging scenarios. Requires individual cell monitoring above 48V systems.

- Battery Combiners: Voltage-sensitive relays (VSRs) should engage at 13.3V and disconnect at 12.8V to prevent charge depletion.

Hybrid System Voltage Optimization

Integrating lead-acid with other technologies presents unique challenges:

| System Type | Optimal Voltage Range | Critical Considerations |

|---|---|---|

| Lead-Acid + Solar | 13.6-14.4V (day) 12.8-13.2V (night) | Must prevent daytime overvoltage (>15V) while ensuring full absorption |

| Lead-Acid + Lithium | 13.8-14.2V (shared) | Requires DC-DC converter to manage different charge profiles |

| Lead-Acid + Generator | 14.2-14.6V (charge) 13.4V (float) | Must compensate for voltage drops across long cable runs |

Advanced Voltage Regulation Techniques

Professional-grade systems employ sophisticated voltage control methods:

- Adaptive Absorption Timing: Extends absorption phase until charge current tapers to 0.5%C20, adjusting for battery age and temperature

- Dynamic Voltage Compensation: Automatically adjusts for cable voltage drops (0.5V per 10ft of 2AWG cable at 100A)

- Load-Dependent Voltage Scaling: Reduces float voltage during high discharge periods to minimize gassing

Troubleshooting Complex Voltage Issues

Symptom: Chronic undercharging despite proper charger settings

Solution: Check for:

– Voltage drops across corroded connections (lose 0.3V per bad terminal)

– Inadequate charger capacity (requires 25% of Ah rating)

– Shared ground loops causing reference voltage errors

Symptom: Voltage spikes during load switching

Solution: Implement:

– Capacitive buffers (10,000μF per 100A load)

– Soft-start modules for inductive loads

– Separate voltage sense wiring (4-wire Kelvin measurement)

Pro Tip: For mission-critical systems, install redundant voltage monitoring using both shunt-based and Hall-effect sensors with 0.1% accuracy to detect developing issues before they cause failures.

Mastering Voltage Profiling: Advanced Diagnostics and Predictive Maintenance

Sophisticated voltage analysis transcends basic measurements, offering a window into your battery’s future performance and remaining lifespan. By interpreting voltage patterns rather than single readings, professionals can predict failures months in advance and optimize charging strategies for maximum ROI.

Advanced Voltage Signature Analysis

These voltage patterns reveal hidden battery conditions:

| Voltage Pattern | Diagnosis | Corrective Action |

|---|---|---|

| Slow rise to 14.4V (>6 hours) | Sulfation buildup (20-40% capacity loss) | Pulse desulfation at 15.2V for 8 hours |

| Rapid voltage drop after charge (>0.3V in 30 min) | Internal short circuit | Immediate replacement required |

| 0.5V+ difference between cells | Electrolyte stratification | Controlled equalization cycle |

Predictive Maintenance Through Voltage Trends

Implement these monitoring protocols:

- Daily: Record resting voltage at consistent temperature (variance >0.2V indicates problems)

- Weekly: Perform voltage recovery test (measure time to return to 12.6V after 10A load)

- Monthly: Conduct voltage sag analysis (compare no-load vs. loaded voltage at 50% discharge)

Quality Assurance Protocols

For mission-critical applications:

- Acceptance Testing: New batteries must maintain >12.8V after 72-hour stabilization period

- Cycle Validation: Verify voltage stays above 11.8V at 80% depth of discharge

- End-of-Life Criteria: Replace when voltage drops below 10.5V under rated load

Risk Mitigation Strategies

Address these voltage-related failure modes:

- Thermal Runaway: Install voltage-triggered cutoff at 15.1V with temperature monitoring

- Undercharge Cascades: Program battery monitors to alert when absorption voltage isn’t reached within 8 hours

- Cell Reversal: Use individual cell voltage monitoring in series configurations (>6 batteries)

Pro Tip: For fleet applications, implement cloud-based voltage analytics that track:

– Daily voltage minimums/maximums

– Charge acceptance rates

– Voltage decay patterns

This data can predict battery failures with 92% accuracy 60-90 days in advance.

Advanced users should combine voltage profiling with conductance testing and periodic capacity checks for complete battery health assessment. Remember – voltage tells the story of both present condition and future performance potential.

Conclusion: Mastering 12V Lead-Acid Battery Voltage for Optimal Performance

Understanding your lead-acid battery’s voltage characteristics is the foundation of maximizing its lifespan and reliability. From interpreting basic voltage readings (12.7V = fully charged, 12.0V = 50% discharged) to advanced system integration and predictive maintenance, we’ve explored how voltage serves as your battery’s vital sign.

The key takeaways include: proper charging protocols (14.4-14.8V for absorption), temperature compensation (0.003V/°F), and the critical importance of voltage pattern analysis for early fault detection.

Remember – consistent voltage monitoring isn’t just maintenance; it’s preventive healthcare for your battery system.

Start implementing these voltage management strategies today to extend your battery’s service life by years while preventing unexpected failures.

Frequently Asked Questions About Lead-Acid 12V Battery Voltage

What voltage indicates a fully charged 12V lead-acid battery?

A fully charged 12V lead-acid battery at rest (after 24 hours without charging or load) should measure 12.7-12.8V at 77°F (25°C). When actively charging, the voltage will rise to 14.4-14.8V during the absorption phase.

Note that temperature affects readings – add 0.003V for every °F above 77°F, or subtract for temperatures below. For AGM batteries, fully charged voltage may reach 12.9-13.0V due to their different chemistry.

How often should I check my battery’s voltage?

For routine maintenance, check voltage monthly when the battery is at rest. Critical systems (solar, medical, marine) require weekly checks. Always test:

- Before and after long storage periods

- When experiencing starting difficulties

- After extreme temperature changes

Use a quality digital multimeter with at least 0.5% DC voltage accuracy for reliable readings.

Why does my battery show 12.4V but won’t start my car?

This common scenario reveals the difference between open-circuit voltage and load capacity. While 12.4V suggests about 75% charge, it doesn’t indicate the battery’s ability to deliver high current. Possible causes:

- Sulfation reducing plate surface area

- Internal short circuits draining capacity

- High internal resistance from plate corrosion

Perform a load test – if voltage drops below 9.6V when cranking, replace the battery.

Can I leave my battery charger connected indefinitely?

Only with a smart charger that properly maintains float voltage (13.2-13.8V for flooded, 13.2-13.5V for AGM). Standard chargers will overcharge, causing:

- Water loss in flooded batteries (1%/day at 14.4V)

- Thermal runaway in AGM batteries

- Grid corrosion reducing lifespan

For seasonal storage, use a maintainer that cycles between charge and monitor modes.

How does temperature affect battery voltage readings?

Temperature impacts voltage significantly:

| Temperature | Voltage Adjustment |

|---|---|

| 32°F (0°C) | -0.27V from standard |

| 77°F (25°C) | No adjustment |

| 104°F (40°C) | +0.16V from standard |

Always compensate readings when temperatures are extreme. Cold batteries also show temporary voltage depression during discharge that recovers when warmed.

What’s the difference between voltage readings for flooded, AGM, and gel batteries?

While all lead-acid types share similar voltage ranges, key differences exist:

- Flooded: 12.6-12.7V full charge, more tolerant of overvoltage

- AGM: 12.8-13.0V full charge, sensitive to voltages above 14.8V

- Gel: 12.8-12.9V full charge, requires strict voltage control (max 14.2V)

AGM and gel batteries show slightly higher voltages due to recombinant chemistry and lower internal resistance.

Why does my battery voltage drop immediately after charging?

Rapid voltage drop (more than 0.3V within 30 minutes) indicates:

- Sulfation: Crystalline buildup prevents full charge absorption

- Parasitic drain: Electrical devices drawing current when off

- Weak cell: One cell discharging others internally

Test by disconnecting all loads after charging. If voltage still drops, the battery likely needs replacement or reconditioning.

How accurate are battery voltage indicators on vehicles/solar controllers?

Most built-in indicators have ±0.5V accuracy at best – sufficient for basic monitoring but inadequate for maintenance. Errors occur from:

- Voltage drops across wiring

- Improper reference grounding

- Sampling rate limitations

For precise measurements, use a dedicated battery monitor with <0.1V accuracy, or verify with a quality multimeter at the battery terminals.