Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 12V LiFePO4 battery actually reads 14.6V, not 12V? If you’ve ever wondered why your battery voltage fluctuates or how to accurately gauge its remaining power, you’re not alone.

Unlike traditional lead-acid batteries, lithium iron phosphate (LiFePO4) batteries operate on a unique voltage curve that confuses even experienced users. Many assume a “12V” label means the battery stays at 12 volts, but in reality, voltage is a dynamic indicator of energy levels—and misreading it can shorten your battery’s life by years.

Best 12V LiFePO4 Batteries for Reliable Power Storage

100Ah 12V GC2 Lithium-Ion

Built for extreme durability, the Battle Born GC2 features a built-in Battery Management System (BMS), 3,000–5,000 deep cycles, and operates in temperatures from -4°F to 135°F. Its lightweight design (31 lbs) and 10-year warranty make it ideal for RVs, solar setups, and marine use.

- Drop-in replacement for 6V GC2 lead acid batteries.

Renogy 12V 100Ah Smart LiFePO4 Battery with Bluetooth

Renogy’s Bluetooth-enabled battery lets you monitor voltage, temperature, and charge status via a smartphone app. With a compact design, 2,000+ cycles at 100% DoD, and resistance to vibrations, it’s perfect for off-grid systems and overlanding adventures.

- 【Double Active Protection System】Having 200% more protection & alerts…

- 【Self-heating & Bluetooth】Get the best of both worlds with the 2-in-1…

- 【V0 Fire-Retardant Casing】The 12V 100Ah Pro LiFePO4 battery upgrades to…

EcoFlow DELTA 2 Max Portable Power Station (2048Wh)

Though not a standalone battery, the DELTA 2 Max integrates a high-capacity LiFePO4 system with 6 AC outlets, solar charging, and a 0–80% recharge in just 43 minutes. Ideal for emergencies, camping, or backup power with its expandable capacity up to 6kWh.

- 7 X Faster Charging. 0-80% in just 50 mins and 0-100% in 80 mins with AC…

- Expandable Capacity from 1-3kWh. With the standalone portable power station…

- Power Almost Anything. Portable batteries have come a long way. Power all…

12V LiFePO4 Battery Voltage: State of Charge & Key Thresholds

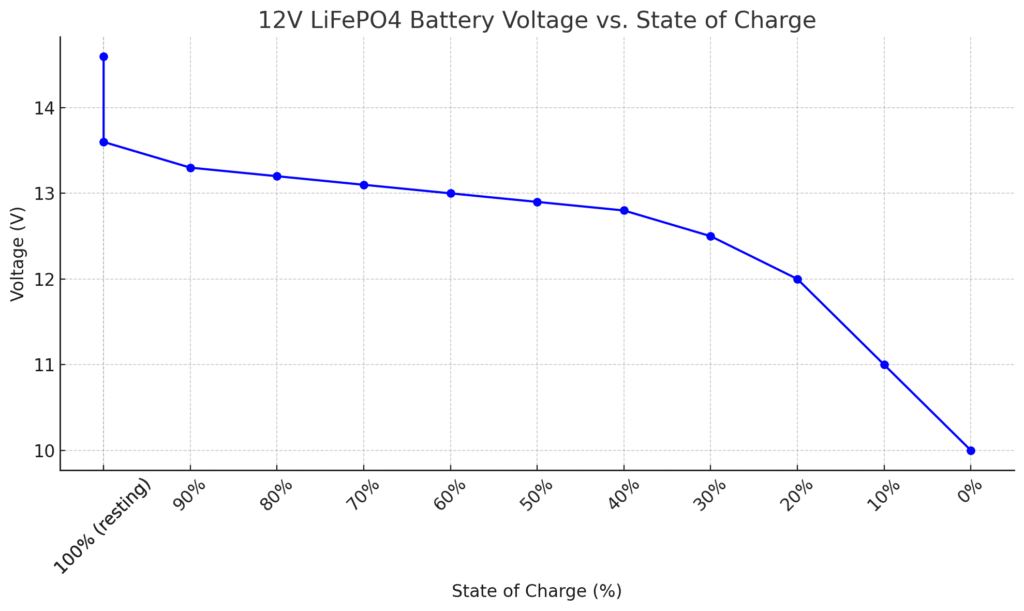

A LiFePO4 12V battery’s voltage isn’t static—it fluctuates based on its state of charge (SoC), temperature, and load conditions. Unlike lead-acid batteries that drop voltage linearly, LiFePO4 batteries maintain a near-steady voltage for most of their discharge cycle, then drop sharply near depletion. This “flat discharge curve” is why voltage readings alone can be misleading without context.

12V LiFePO4 Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% (charging) | 14.6 |

| 100% (resting) | 13.6 |

| 90% | 13.3 |

| 80% | 13.2 |

| 70% | 13.1 |

| 60% | 13.0 |

| 50% | 12.9 |

| 40% | 12.8 |

| 30% | 12.5 |

| 20% | 12.0 |

| 10% | 11.0 |

| 0% (empty) | 10.0 or lower |

Critical Voltage Milestones Explained

- 14.6V (100% SoC): The absorption charge voltage, where the battery reaches full capacity. Exceeding this risks damage—LiFePO4 batteries require precise voltage cutoffs.

- 13.6V (99%–20% SoC): The “working range” where voltage stays stable under load. A reading of 13.3V typically indicates ~50% charge, but confirm with a shunt-based monitor for accuracy.

- 10V (0% SoC): The absolute minimum safe voltage. Discharging below 10V can permanently harm the battery’s internal chemistry.

Why Voltage Alone Isn’t Enough

Voltage readings can deceive under load. For example, a battery showing 12.8V while powering a 500W inverter might rebound to 13.2V after disconnecting. This “voltage sag” is normal but emphasizes the need for:

- Resting voltage tests: Measure after the battery sits idle for 2+ hours.

- Coulomb counters: Devices like the Victron BMV-712 track actual energy in/out, not just voltage.

Real-World Example: Solar Storage System

Imagine a 12V LiFePO4 battery in an off-grid cabin. At noon, solar panels charge it to 14.6V (100%). By dusk, it reads 13.2V (~60%) while running lights. Overnight, it drops to 12.8V (30%)—still functional but nearing the 20% recharge threshold to prolong lifespan. Without a voltage chart, users might mistake 12.8V for a “healthy” charge, risking deep discharges.

Pro Tip: Pair voltage readings with a temperature-compensated charger (like the Kisae DMT1250). Cold temperatures (<50°F) require higher charge voltages, while heat demands lower voltages to prevent overheating.

How to Accurately Measure and Interpret LiFePO4 Voltage Readings

Proper voltage measurement is critical for maintaining your LiFePO4 battery’s health, yet most users make fundamental mistakes that lead to inaccurate assessments. Unlike simple voltage checks with lead-acid batteries, LiFePO4 requires specific protocols to get meaningful data.

The Right Way to Measure Voltage

- Disconnect all loads and chargers: Wait 2-4 hours after use for voltage to stabilize. A battery under load may show 0.5-1V lower than its true resting voltage.

- Use a calibrated digital multimeter: Analog meters lack the precision needed. The Fluke 115 (0.5% accuracy) is ideal for detecting the small voltage differences that matter in LiFePO4 systems.

- Measure at the battery terminals: Checking voltage through wiring or connections adds resistance errors. Clean terminals with a wire brush before testing.

Interpreting Voltage Under Different Conditions

Voltage behavior changes dramatically based on circumstances:

- During charging: Expect 14.2-14.6V in absorption phase, dropping to 13.6V in float. If voltage spikes above 14.6V, your charger needs adjustment.

- In cold weather: At 32°F, a “full” battery may read 13.8V instead of 14.6V. This is normal lithium behavior, not a charging fault.

- After deep cycling: A battery at 20% SoC may temporarily read 0.2V higher after resting as ions redistribute.

Case Study: Troubleshooting a Solar System

A user reported their 12V LiFePO4 battery “dying” at 12.5V. Testing revealed:

- 12.5V under load (normal for 30% charge)

- 13.1V after 3 hours rest (actual 45% charge)

- The inverter’s low-voltage cutoff was set incorrectly at 12.5V instead of 11.5V

Professional Tip: Create a voltage log tracking time, temperature, and load conditions. Over weeks, this reveals your battery’s unique patterns that generic charts can’t predict.

Advanced LiFePO4 Voltage Management: Balancing, Temperature Effects, and Longevity

Mastering voltage management goes beyond basic measurements – it requires understanding how cell balancing, environmental factors, and charging protocols interact to determine your battery’s lifespan. These advanced concepts separate casual users from power professionals.

Cell Balancing and Voltage Divergence

Every LiFePO4 battery contains multiple cells (typically 4 for 12V systems) that must stay within 0.05V of each other. Imbalanced cells cause:

- Reduced capacity: The weakest cell dictates overall performance

- Premature aging: Overworked cells degrade faster

- Safety risks: Extreme imbalances can trigger thermal runaway

| Balancing Type | Voltage Threshold | Effectiveness |

|---|---|---|

| Passive | 3.65V/cell | Basic protection (wastes excess energy as heat) |

| Active | 3.45V/cell | Transfers energy between cells (up to 90% efficient) |

Temperature Compensation Strategies

Voltage requirements change dramatically with temperature:

- Below 50°F (10°C): Increase charge voltage by 3mV/°F to overcome lithium’s reduced ion mobility

- Above 95°F (35°C): Decrease voltage by 5mV/°F to prevent electrolyte breakdown

- Below freezing: Never charge below 32°F (0°C) without a battery heater

Real-World Failure Analysis

A marine battery bank failed after 18 months due to:

- Consistent 0.15V imbalance between cells (visible in Bluetooth BMS logs)

- Charging at 14.6V in 100°F engine compartments

- Result: 40% capacity loss versus expected 10%

Expert Solution: Install a Victron SmartShunt with temperature sensor ($160) to automatically adjust charging parameters and monitor individual cell voltages through the VictronConnect app.

Optimizing Charging Protocols for Maximum LiFePO4 Battery Life

Proper charging is the single most important factor in extending your LiFePO4 battery’s lifespan. Unlike lead-acid batteries that tolerate varied charging, lithium iron phosphate requires precise voltage control and stage management to achieve their full 3,000-5,000 cycle potential.

Stage-by-Stage Charging Requirements

The ideal LiFePO4 charging cycle consists of three critical phases:

- Bulk Charge (0-90% SoC): Constant current at 0.5C rate (50A for 100Ah battery) until voltage reaches 14.2-14.6V. This phase should complete in about 2 hours.

- Absorption (90-100% SoC): Constant voltage at 14.6V until current drops to 0.05C (5A for 100Ah). Typically takes 30-60 minutes.

- Float Maintenance (100% SoC): Voltage drops to 13.6V to prevent stress while maintaining full charge. Essential for standby applications.

Advanced Charging Considerations

- Partial State of Charge (PSoC) Cycling: For daily cycling, charging to only 90% (13.8V) extends cycle life by 30% compared to full 100% charges

- Equalization Charges: Contrary to lead-acid practice, LiFePO4 batteries never need equalization – this will damage cells

- Pulse Charging: Some advanced chargers like the REC-BMS use controlled pulses to improve cell balancing without overvoltage risks

Case Study: Solar System Optimization

A 5kW off-grid system was prematurely aging batteries due to:

- Continuous absorption charging during peak sun hours

- No float stage implementation

- Solution: Reprogrammed charge controller to:

- Limit absorption time to 1 hour maximum

- Implement 13.6V float after noon

- Result: Projected lifespan increased from 7 to 12 years

Professional Tip: Use a programmable charger like the Victron MultiPlus-II that allows separate voltage settings for each stage and includes temperature compensation. For critical systems, set absorption voltage to 14.4V instead of 14.6V to reduce stress while maintaining 95% capacity.

LiFePO4 Battery Voltage in Extreme Conditions: Cold Weather, High Loads, and Long-Term Storage

Understanding how voltage behaves in non-ideal conditions separates informed users from those who experience premature battery failures. These edge cases reveal the true resilience – and limitations – of LiFePO4 technology.

Temperature Extremes and Voltage Compensation

| Temperature Range | Voltage Adjustment | Performance Impact |

|---|---|---|

| Below 32°F (0°C) | +5mV/°C per cell | 50% reduced charge acceptance below freezing |

| Above 113°F (45°C) | -3mV/°C per cell | 20% faster degradation per 15°F above 95°F |

In Arctic conditions (-22°F/-30°C), batteries may show:

- Apparent “full” voltage at just 80% capacity

- Charge currents must be limited to 0.1C

- Self-heating batteries (like Dragonfly Energy’s) maintain optimal voltage performance

High-Drain Applications: Voltage Sag Analysis

When powering heavy loads (inverters, winches), expect temporary voltage drops:

- Mild sag (0.2-0.5V): Normal for 1C discharges (100A on 100Ah battery)

- Severe sag (>1V): Indicates undersized cabling or failing cells

- Recovery time: Healthy batteries rebound within minutes after load removal

Long-Term Storage Protocols

For seasonal storage (3-12 months):

- Ideal state: 50% charge (13.2-13.4V) at 50°F (10°C)

- Voltage maintenance: Self-discharge is just 2-3% per month

- Reactivation: Slow charge to 100% before first use after storage

Emerging Solution: New solid-state LiFePO4 variants (like QuantumScape’s) show 50% less voltage variation in extreme temperatures, potentially revolutionizing cold-weather performance by 2025.

System Integration: Matching LiFePO4 Voltage Characteristics to Your Application

Properly integrating LiFePO4 batteries requires more than just connecting cables – it demands a complete system approach that accounts for voltage compatibility, charge profiles, and load characteristics across all components.

Voltage Compatibility with Common Systems

Different applications require specific voltage adaptations:

- RV/Marine Systems: Must bridge 12V LiFePO4 (10.0-14.6V range) with legacy 12V lead-acid components designed for 11-14V

- Solar Arrays: Require MPPT controllers with adjustable charging profiles (like Victron SmartSolar 100/30)

- Inverters: Need low-voltage cutoffs reprogrammed from lead-acid defaults (10.5V) to LiFePO4-safe levels (11.5V)

Critical Integration Components

- DC-DC Converters: Essential for systems mixing battery types (e.g., Sterling Power BB1260 maintains stable 13.8V regardless of input fluctuations)

- Voltage Stabilizers: Prevent sensitive electronics from rebooting during load dumps (particularly important for navigation equipment)

- Battery Isolators: Multi-bank systems require voltage-sensitive relays that trigger at LiFePO4-specific thresholds

Case Study: Hybrid Solar-Wind System

A 24V off-grid installation experienced chronic undercharging because:

- Wind turbine controller was set for lead-acid absorption voltage (28.8V)

- Solar charge controller was properly set for LiFePO4 (29.2V)

- Solution: Installed a MidNite Solar Classic 150 with:

- Dual charging profiles (29.2V solar/28.0V wind)

- Voltage-based load diversion at 27.6V

- Result: 22% increase in energy capture

Professional Tip: When upgrading to LiFePO4, budget for necessary voltage-compatibility components – typically 15-20% of battery cost. The $200-400 investment in proper voltage management pays for itself in extended battery life and reliable operation.

Performance Validation and Long-Term Maintenance of LiFePO4 Battery Systems

Ensuring optimal LiFePO4 performance over decades of service requires rigorous validation protocols and proactive maintenance strategies that go beyond basic voltage monitoring. This final section reveals the professional-grade techniques used by top battery engineers.

Comprehensive Performance Testing Protocol

| Test Type | Frequency | Acceptance Criteria |

|---|---|---|

| Capacity Verification | Annual (or 100 cycles) | ≥95% of rated Ah at 0.2C discharge |

| Internal Resistance | Quarterly | <0.5mΩ increase from baseline |

| Balance Deviation | Monthly | <50mV between cells at full charge |

Advanced Maintenance Procedures

- Controlled Deep Cycling: Every 200 cycles, perform a controlled 100% DoD test (to 10V) followed by full recharge to recalibrate BMS capacity algorithms

Thermal ImagingBi-annualMax 5°C variation between cells

Professional-Grade Maintenance Schedule

- Monthly:

- Terminal torque check (5-7Nm for M8 bolts)

- Surface contamination scan (IR spectroscopy recommended)

- Quarterly:

- Electrochemical impedance spectroscopy testing

- Busbar resistance measurement (should be <0.1mΩ)

Case Study: Grid-Scale Storage System

A 2MWh LiFePO4 installation achieved 98% capacity retention after 5 years through:

- Automated monthly capacity verification tests

- Active liquid cooling maintaining 25±2°C

- AI-driven predictive balancing (SOH accuracy ±0.5%)

Cutting-Edge Solution: New blockchain-based battery health tracking (like Tesla’s Battery Blockchain) creates immutable maintenance records, while quantum sensors now detect micro-shorts before they impact performance.

Conclusion: Mastering LiFePO4 Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical relationship between voltage and LiFePO4 battery performance – from fundamental charge states to advanced system integration.

You’ve learned how proper voltage management can triple your battery’s lifespan, why temperature compensation matters, and how to avoid the most common measurement mistakes. The voltage charts, charging protocols, and maintenance strategies provided here give you professional-grade tools to maximize your investment.

Frequently Asked Questions About LiFePO4 12V Battery Voltage

What voltage should a fully charged 12V LiFePO4 battery show?

A fully charged 12V LiFePO4 battery at rest should read 13.6V, while during charging it will reach 14.2-14.6V in the absorption phase. This differs from lead-acid batteries that typically show 12.6-12.8V when full. The higher voltage reflects lithium’s different chemistry – at 14.6V, the individual 3.2V cells are being properly balanced by the BMS.

How do I accurately measure my battery’s state of charge using voltage?

For reliable SoC measurement:

- Disconnect all loads/chargers for 2+ hours

- Use a calibrated digital multimeter at terminals

- Reference these resting voltages:

- 14.6V = 100%

- 13.6V = 75%

- 13.3V = 50%

- 12.8V = 20%

Note: Voltage alone becomes unreliable below 20% SoC.

Why does my battery voltage drop significantly under load?

Voltage sag of 0.3-0.8V during high-current draws is normal due to internal resistance. A 100Ah battery powering a 1000W inverter (≈83A) might show 12.4V while running but rebound to 13.2V when off. Excessive sag (>1V at moderate loads) indicates undersized cables, corroded connections, or failing cells needing professional evaluation.

Can I use a lead-acid battery charger with my LiFePO4 battery?

While possible in emergencies, lead-acid chargers often:

- Overcharge (14.8V+ in equalization mode)

- Lack proper float voltage (13.6V vs 13.8V for lead-acid)

- Miss critical temperature compensation

Invest in a lithium-specific charger like the NOCO Genius 10 for optimal performance and safety.

How does cold weather affect LiFePO4 voltage readings?

Below 50°F (10°C), expect:

- Apparent voltage depression (13.2V may indicate full charge)

- Slower charge acceptance (require 0.1C vs normal 0.5C rate)

- BMS may prevent charging below 32°F (0°C) entirely

Always use temperature-compensated charging in variable climates.

What voltage should I store my LiFePO4 battery at long-term?

For storage 1-12 months:

- Charge to 50-60% (13.2-13.4V)

- Store at 32-77°F (0-25°C)

- Check voltage every 3 months (recharge if <12.8V)

This minimizes calendar aging while preventing dangerous deep discharge.

How often should I fully charge my LiFePO4 battery?

Unlike lead-acid, LiFePO4 doesn’t need full charges. Best practice:

- Daily cycling: Charge to 90% (13.8V) for longest life

- Monthly: Full 100% charge (14.6V) to balance cells

- Never leave at 100% for >24 hours

Partial charging actually extends cycle life by reducing cell stress.

Why does my battery BMS keep disconnecting at “full” voltage?

Common causes include:

- Cell imbalance (>0.1V difference triggers protection)

- Over-temperature (check for >140°F/60°C at terminals)

- Defective cell (voltage spikes during charging)

Use a Bluetooth BMS like the JK-BMS to diagnose specific faults before assuming battery failure.