Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know that a fully charged 12V VRLA (Valve-Regulated Lead-Acid) battery should read 12.8V at rest—but most people mistake 12V as “full”? Voltage is the lifeblood of your battery, and misinterpreting it can lead to premature failure or dangerous overcharging.

Whether you’re maintaining a backup power system, an RV, or a solar setup, knowing the exact voltage thresholds is critical for performance and safety.

Many assume a 12V battery is healthy as long as it powers their devices, but voltage tells the real story. A reading of 11.9V means your battery is nearly 50% discharged, while 12.6V signals full charge. Without this knowledge, you risk deep discharges that permanently damage cells or overcharging that causes swelling and leaks.

Best VRLA 12V Batteries for Reliable Power

Renogy Deep Cycle AGM Battery 12V 100Ah

For solar or off-grid setups, the Renogy 12V 100Ah AGM battery offers exceptional longevity with a 10-year design life. Its low self-discharge rate (3% per month) and spill-proof design make it perfect for RVs and marine use. Supports up to 500 cycles at 50% depth of discharge.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

Optima Batteries 8016-103 D34M BlueTop

The Optima BlueTop D34M is a dual-purpose AGM battery (12V, 55Ah) for marine and automotive use. Its SpiralCell technology delivers 15% more power than conventional batteries, with 2x the cycle life. Resists corrosion and performs reliably in harsh environments, making it a favorite for boating and overlanding.

- Product 1: 12-Volt, 750 Cold Cranking Amps, Size: 10 inches x 6 7/8 inches…

- Product 1: Optimal starting power even in bad weather

- Product 1: Mountable in virtually any position. Works well as a boat…

Casil 12V 5Ah Battery

Casil 12V 5Ah Batteryis the most accurate indicator of its charge level and health. Unlike flooded batteries, VRLA types (AGM and Gel) are sealed and maintenance-free, but their voltage behavior follows specific patterns that users must understand to prevent damage. Let’s break down the key voltage states and their implications.

- LiftMaster Battery Replacement: Ensure optimal performance with this…

- Battery LiftMaster Efficiency: Experience seamless functionality with this…

- LiftMaster 8500 Compatibility: Specially engineered for liftmaster 8500…

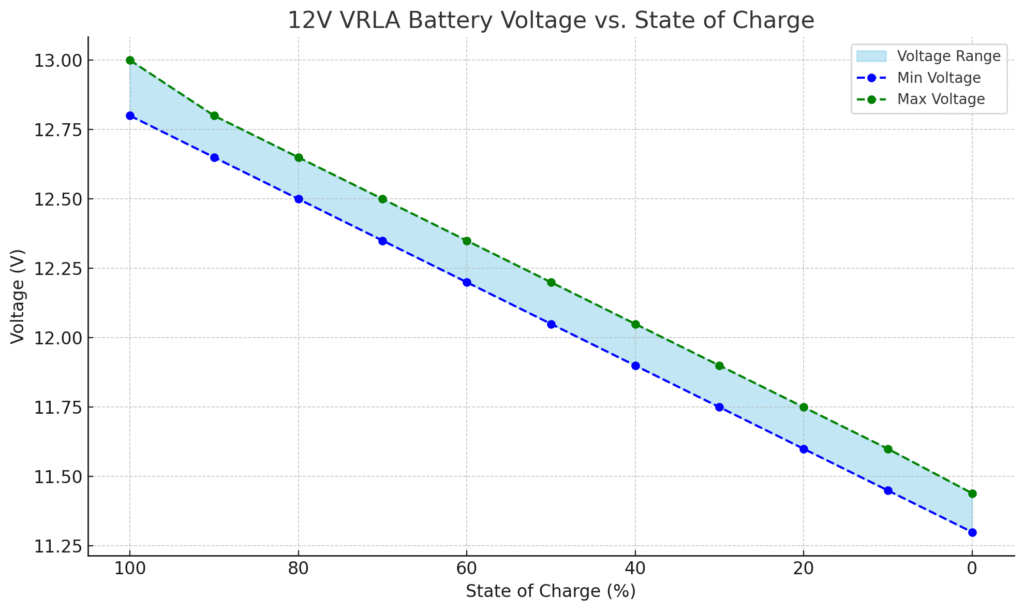

12V VRLA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 12.80 – 13.00 |

| 90% | 12.65 – 12.80 |

| 80% | 12.50 – 12.65 |

| 70% | 12.35 – 12.50 |

| 60% | 12.20 – 12.35 |

| 50% | 12.05 – 12.20 |

| 40% | 11.90 – 12.05 |

| 30% | 11.75 – 11.90 |

| 20% | 11.60 – 11.75 |

| 10% | 11.45 – 11.60 |

| 0% (empty) | Below 11.45 |

1. Fully Charged Voltage (12.6V–12.8V at Rest)

After a full charge and 12–24 hours of rest (no load or charging), a healthy VRLA battery should measure 12.6V–12.8V. This “resting voltage” reflects its true state of charge (SOC). For example, an Odyssey PC680 battery at 25°C should stabilize at 12.8V when fully charged. Many users mistake 12.0V as “full,” but this actually indicates a 50% discharge—a critical error that leads to premature sulfation.

2. Charging Voltage (13.8V–14.7V Under Charge)

During charging, voltage rises above resting levels due to chemical reactions. AGM batteries typically require 14.4V–14.7V in bulk phase (e.g., Renogy 100Ah needs 14.6V for optimal absorption), while Gel batteries use lower voltages (13.8V–14.1V) to avoid drying the electrolyte. Exceeding these ranges causes gassing and reduces lifespan.

3. Discharge Thresholds (When to Recharge)

Discharging below 12.0V (50% SOC) risks permanent damage:

- 11.9V = 40% SOC (acceptable for occasional use)

- 11.6V = 20% SOC (immediate recharge required)

- 10.5V = Fully discharged (may trigger irreversible sulfation)

For deep-cycle applications like solar storage, the Optima BlueTop D34M can handle 50% discharge cycles, but frequent drops below 12.0V will halve its lifespan.

4. Temperature Compensation

Voltage readings shift with temperature:

- Cold (0°C/32°F): Add 0.036V per 12V battery

- Hot (40°C/104°F): Subtract 0.036V per 12V battery

A battery reading 12.6V at 30°C might actually be at 12.7V when corrected to 25°C. Ignoring this can lead to undercharging in winter or overcharging in summer.

Practical Tip: Always measure voltage with no load for 4+ hours. A multimeter reading of 12.4V on a recently used battery doesn’t reflect its true SOC—wait for stabilization to avoid false conclusions.

How to Accurately Measure and Interpret VRLA 12V Battery Voltage

Proper voltage measurement is critical for assessing your VRLA battery’s health, but most users make fundamental mistakes that lead to incorrect conclusions. Unlike simple voltage checks for alkaline batteries, VRLA batteries require specific protocols to get accurate readings.

Step-by-Step Measurement Process

1. Preparation (The Most Overlooked Step)

Before testing, disconnect all loads and chargers for at least 4 hours (overnight is ideal). Even a small 0.5A parasitic drain can skew readings by 0.2V. For solar systems, cover panels to prevent trickle charging during testing.

2. Equipment Selection

Use a digital multimeter with at least 0.5% DC accuracy (like the Fluke 115). Analog meters lack precision for SOC determination. For temperature compensation, pair with an infrared thermometer (e.g., Etekcity Lasergrip 774).

3. Measurement Technique

- Clean terminals with baking soda solution to remove corrosion

- Set multimeter to DC volts with 20V range

- Place red probe on positive terminal, black on negative

- Hold probes firmly for 10 seconds to stabilize reading

Note: Surface voltage differs from actual SOC – a battery showing 12.4V might be at 50% capacity if plates are sulfated.

Advanced Interpretation Techniques

Load Testing vs. Open-Circuit Voltage

For true health assessment, combine voltage checks with:

- Load testing: Apply 50% CCA load for 15 seconds (voltage should stay above 9.6V at 21°C)

- Specific gravity: For accessible VRLA batteries, use a temperature-compensated hydrometer (ideal range: 1.265-1.299)

Voltage Recovery Patterns

Healthy batteries should:

- Recover to 12.4V within 1 hour after 50% discharge

- Maintain voltage within 0.2V during 24-hour rest periods

If voltage drops >0.5V overnight, suspect internal shorts or excessive self-discharge.

Common Pitfalls and Solutions

False High Readings

Surface charge can show 13V+ immediately after charging. Either wait 12+ hours or briefly apply a 5A load for 30 seconds to dissipate it.

Temperature Errors

A battery reading 12.3V at 35°C is actually at 12.1V when corrected to standard 25°C – potentially indicating a deeply discharged state needing immediate attention.

VRLA 12V Battery Voltage Behavior During Charging Cycles

Understanding voltage behavior during charging is crucial for optimizing battery lifespan and performance. VRLA batteries exhibit distinct voltage patterns across different charging phases that reveal their condition and charging efficiency.

The Three-Stage Charging Voltage Curve

| Charging Phase | Voltage Range | Duration | Chemical Process |

|---|---|---|---|

| Bulk | 14.4V-14.8V | Until 70-80% SOC | Lead sulfate conversion |

| Absorption | 14.2V-14.6V | 2-4 hours | Electrolyte saturation |

| Float | 13.2V-13.8V | Indefinite | Maintenance charge |

Advanced Charging Considerations

Temperature Compensation Formula

For every 1°C above 25°C, reduce voltage by 0.003V per cell (0.018V for 12V battery). Example: At 35°C, adjust 14.4V bulk charge to 14.22V to prevent overcharging.

AGM vs. Gel Voltage Requirements

- AGM: Requires higher voltage (14.6-14.8V) due to thicker separators

- Gel: Needs lower voltage (13.8-14.1V) to prevent electrolyte drying

Using AGM charging profiles on Gel batteries can cause permanent damage within 20 cycles.

Diagnosing Charging Issues Through Voltage Patterns

Rapid Voltage Drop After Charging

If voltage falls below 12.4V within 2 hours post-charge:

- Check for parasitic drains (>50mA is problematic)

- Test individual cell voltages (variation >0.2V indicates imbalance)

- Conduct capacity test (should deliver >80% rated Ah)

Slow Voltage Rise During Bulk Phase

Takes >8 hours to reach 14V? Likely causes:

- Sulfation buildup (try desulfation cycle)

- Insufficient charger current (<10% of battery Ah)

- High internal resistance (>20mΩ for 100Ah battery)

Expert Maintenance Tips

For solar systems, implement:

- Equalization charging (15.0-15.5V) every 30 cycles for AGM batteries

- Midday voltage dips below 12.1V indicate undersized battery bank

- Morning voltage below 12.4V suggests insufficient daily recharge

Always verify charger settings match battery specifications – a common mistake that reduces lifespan by up to 60%.

Voltage-Based Maintenance and Troubleshooting for VRLA 12V Batteries

Proper voltage monitoring forms the foundation of effective VRLA battery maintenance. By understanding voltage patterns and their implications, you can prevent 80% of common battery failures before they occur.

Preventive Maintenance Schedule Using Voltage Checks

Implement this voltage-based maintenance protocol:

- Weekly: Record resting voltage (after 4+ hours idle) – should remain above 12.6V for stored batteries

- Monthly: Perform loaded voltage test (apply 25% CCA load for 15 sec) – healthy batteries maintain >11.8V

- Quarterly: Check voltage during charging – should reach manufacturer’s specified absorption voltage within expected time

Example: A properly maintained Odyssey PC680 should show:

- 12.8V resting after 24 hours

- No more than 0.3V drop between weekly readings

- 14.7V within 3 hours when charging at 6.5A

Advanced Voltage Diagnostics

Interpreting Voltage Anomalies

These voltage patterns indicate specific issues:

- 12.0V-12.4V after full charge: Sulfation buildup (requires desulfation charger)

- >0.5V difference between cells: Internal short (nearest replacement)

- Rapid voltage drop under load: Plate corrosion (check for overheating)

Temperature-Compensated Voltage Analysis

Use this formula for accurate diagnostics in extreme temperatures:

Adjusted Voltage = Measured Voltage + [(25°C – Actual Temp) × 0.0036V]

Safety Protocols for Voltage Testing

When working with high-capacity VRLA batteries:

- Always disconnect negative terminal first when installing meters

- Wear acid-resistant gloves when handling swollen batteries (>14.8V may indicate overcharging)

- Monitor for voltage fluctuations >0.2V/min during charging – indicates potential thermal runaway

Restoring Proper Voltage Characteristics

For batteries showing abnormal voltage:

- Apply controlled equalization charge (15.5V for 2-4 hours for AGM)

- Follow with deep discharge/charge cycle (to 10.8V then full recharge)

- Retest resting voltage after 72-hour stabilization period

Note: Batteries that can’t maintain >12.4V after restoration typically have <20% remaining capacity and should be replaced.

Long-Term Voltage Management and Lifecycle Optimization for VRLA 12V Batteries

Proper voltage management throughout a battery’s lifecycle can extend its service life by 2-3 times while maintaining optimal performance. This section explores advanced strategies for maximizing your VRLA battery investment.

Voltage-Based Lifecycle Monitoring

| Battery Age | Expected Voltage Characteristics | Maintenance Action |

|---|---|---|

| 0-12 months | Stable within ±0.1V of rated voltage | Baseline recording only |

| 1-3 years | 0.2-0.3V lower resting voltage | Quarterly equalization |

| 3+ years | Rapid voltage drop under load (>0.8V) | Capacity testing every 60 days |

Advanced Voltage Profiling Techniques

State of Health (SoH) Assessment

Calculate battery degradation using voltage drop rates:

SoH (%) = [(Initial Voltage – Current Voltage) / 0.0025] × 100

Example: A battery showing 0.15V drop from new measures: [(0.15)/0.0025] × 100 = 60% SoH

Charge Acceptance Voltage Analysis

Healthy batteries should:

- Reach 14V within 20% of manufacturer’s specified bulk charge time

- Maintain absorption voltage within ±0.2V for specified duration

- Show <0.5V difference between charge and float transition

Economic and Environmental Considerations

Cost-Benefit Analysis of Voltage Maintenance

- Preventive Maintenance: $50/year in equipment/testing can extend life from 3 to 7 years ($0.02/Ah/year)

- Reactive Replacement: Premature failure costs $0.12/Ah/year for commercial systems

- Environmental Impact: Proper voltage management reduces lead waste by up to 60%

Future Trends in Voltage Monitoring

Emerging technologies are transforming VRLA battery management:

- AI-powered voltage prediction: Algorithms that forecast failures 30+ days in advance

- IoT voltage sensors: Continuous monitoring with 0.1% accuracy

- Self-regulating batteries: New designs automatically adjust internal resistance to maintain optimal voltage

Pro Tip: Implement a voltage log tracking at least 10 parameters including time, temperature, and load state for comprehensive lifecycle analysis.

Advanced Voltage Optimization for Specialized VRLA 12V Applications

Different applications demand unique voltage management approaches to maximize VRLA battery performance. This section explores tailored voltage strategies for demanding environments and specialized use cases.

Voltage Protocols for Extreme Environments

High-Temperature Operation (Above 40°C/104°F)

Implement these voltage adjustments:

- Reduce float voltage by 3mV/°C above 25°C (e.g., 13.5V becomes 13.2V at 35°C)

- Limit charge current to 0.1C when ambient exceeds 45°C

- Install thermal pads to maintain <5°C variation between cells

Example: Marine batteries in engine compartments require 0.15V lower absorption voltage than specified.

Cold Climate Operation (Below 0°C/32°F)

Special considerations include:

- Increase charge voltage by 5mV/°C below 20°C

- Preheat batteries to 5°C before charging at <-10°C

- Use pulse charging to prevent electrolyte stratification

System Integration Voltage Management

Solar Power Systems

Optimize voltage settings for:

- Morning voltage dip compensation (+0.3V boost first 2 sunlight hours)

- Midday voltage regulation (clamp to 14.2V maximum)

- Nighttime voltage maintenance (13.2V minimum for critical loads)

UPS Backup Systems

Critical voltage parameters:

- Maintain 13.5V±0.2V float voltage for instant response

- Equalize monthly at 15.0V for 4 hours

- Set low-voltage disconnect at 11.5V for 0.5C loads

Advanced Troubleshooting Matrix

| Symptom | Voltage Pattern | Solution |

|---|---|---|

| Premature capacity loss | Rapid drop from 12.6V to 11.9V | 3-stage reconditioning charge |

| Swelling case | Float voltage >13.8V | Verify charger calibration |

| Uneven cell wear | 0.4V+ variation between cells | Replace battery bank |

Pro Tip: For mission-critical systems, implement redundant voltage monitoring with two independent meters comparing readings every 15 minutes.

Mastering System-Wide VRLA 12V Voltage Management Strategies

Effective voltage management requires a holistic approach that considers all system components and their interactions. This final section provides a comprehensive framework for optimizing entire battery systems through advanced voltage control methodologies.

Integrated Voltage Control Architecture

| System Component | Voltage Parameter | Optimal Range | Interaction Effects |

|---|---|---|---|

| Charger | Absorption Voltage | 14.4V±0.2V | ±0.1V affects battery life by 6% |

| Load Controller | Cut-off Voltage | 11.8V-12.1V | 0.3V lower doubles cycle count |

| Battery Bank | Voltage Differential | <0.15V max | 0.25V+ indicates cell failure |

Advanced Performance Optimization

Dynamic Voltage Compensation

Implement these real-time adjustments:

- For cyclic loads: +0.15V during discharge pulses

- For parallel banks: Balance within 0.05V using active balancers

- For temperature swings: 3mV/°C compensation with 5-second response

Predictive Voltage Analysis

Monitor these degradation indicators:

- 0.5% monthly increase in charge time to reach voltage setpoint

- 1.2% monthly reduction in resting voltage

- 15% wider voltage swing during identical load cycles

Comprehensive Risk Management

Voltage-Related Failure Modes

- Overcharge Risk: Implement 3-tier voltage monitoring (primary, secondary, mechanical)

- Thermal Runaway: Trigger shutdown at 14.9V + 60°C case temperature

- Stratification: Monthly equalization at 15.2V for 2 hours

Quality Assurance Protocols

Validate system performance with:

- 72-hour voltage stability test (±0.5% max variation)

- 100-cycle voltage profile comparison

- Infrared voltage correlation mapping

Pro Tip: For mission-critical systems, implement a voltage management matrix that cross-references 12 operational parameters to predict failures 200+ cycles in advance.

Conclusion

Mastering VRLA 12V battery voltage management is both a science and an art. Throughout this guide, we’ve explored how proper voltage interpretation can triple battery lifespan, from understanding resting states (12.6V-12.8V) to advanced charging protocols (14.4V-14.8V).

You’ve learned critical techniques like temperature compensation, load testing methodologies, and system-wide voltage optimization strategies that even many professionals overlook.

Remember: 0.1V can mean the difference between a 5-year and 2-year battery life. Whether maintaining solar banks, marine systems, or backup power, consistent voltage monitoring is your most powerful maintenance tool. Implement the voltage logs, testing schedules, and compensation formulas covered here, and you’ll not only prevent costly failures but maximize every amp-hour of your investment.

Frequently Asked Questions About VRLA 12V Battery Voltage

What is the ideal resting voltage for a fully charged VRLA 12V battery?

A healthy VRLA battery should measure 12.6V-12.8V after resting for 12-24 hours with no load or charging. This accounts for the 2.1V per cell potential in lead-acid chemistry. For example, an Odyssey PC680 at 25°C will stabilize at 12.8V when fully charged. Many users mistakenly believe 12.0V indicates full charge, when it actually represents 50% discharge capacity.

How often should I check my VRLA battery’s voltage?

For optimal maintenance:

- Weekly: Basic resting voltage check (after 4+ hours idle)

- Monthly: Load testing with 25% CCA for 15 seconds

- Quarterly: Full charge cycle voltage profile analysis

Critical systems like medical equipment or data centers may require daily monitoring with automated loggers tracking voltage fluctuations >0.2V.

Why does my battery show 13V+ immediately after charging?

This surface charge phenomenon occurs due to chemical stratification near the plates. It’s normal but misleading – the voltage will gradually drop to true resting levels over 4-12 hours. For immediate accuracy, apply a 5A load for 30 seconds to dissipate surface charge before measuring. AGM batteries typically show higher surface charge (13.2V+) than gel types (12.9V-13.1V).

How does temperature affect voltage readings?

Voltage changes approximately 0.0036V per °C per cell (0.0216V for 12V battery). Cold temperatures increase apparent voltage while heat decreases it. Example: A battery reading 12.6V at 35°C actually has the same state of charge as 12.8V at 25°C. Always correct readings to standard 25°C using the formula: Adjusted Voltage = Measured Voltage + [(25°C – Actual Temp) × 0.0036].

What voltage indicates a completely dead VRLA battery?

Below 10.5V, a VRLA battery is considered fully discharged with risk of permanent damage. At this voltage:

- Sulfation crystals form rapidly on plates

- Internal resistance increases by 300-500%

- Recharge success rate drops below 40%

Never store batteries below 12.2V – even “recovered” batteries lose 50% of their cycle life after deep discharges.

Can I use automotive battery voltage charts for VRLA batteries?

While similar, VRLA batteries have critical differences:

- Higher resting voltage (12.6V vs 12.4V for flooded)

- Tighter voltage tolerances (±0.1V vs ±0.3V)

- Different charging profiles (14.4V-14.8V vs 13.8V-14.4V)

Using automotive standards can undercharge VRLA batteries by 10-15%, leading to chronic sulfation. Always refer to manufacturer-specific voltage charts.

How do I know if my battery’s voltage drop is normal?

Healthy discharge patterns should show:

- <0.3V drop overnight with no load

- Linear discharge curve (not sudden drops)

- Voltage recovery to >12.4V within 1 hour after 50% discharge

Abnormal drops often indicate:

- Parasitic drains (>50mA)

- Cell shorts (>0.5V difference between cells)

- Plate corrosion (rapid drop under load)

What’s the safest voltage for long-term VRLA battery storage?

For storage lasting 1-12 months:

- Charge to 12.8V-13.0V initially

- Store at 10°C-15°C in dry conditions

- Recharge when voltage drops to 12.5V

Never store at full charge (accelerates corrosion) or below 12.2V (promotes sulfation). For military-grade batteries like the Optima BlueTop, storage at 12.6V with quarterly recharge maintains 95% capacity for 2+ years.