Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged AGM 24V battery should read 25.6V—not 24V? Many assume voltage stays constant, but in reality, it fluctuates based on charge level, temperature, and load. If you rely on AGM batteries for solar systems, RVs, or industrial equipment, misunderstanding voltage readings can lead to premature failure or costly replacements.

You might check your battery’s voltage and panic when it drops below 24V, thinking it’s dead. But here’s the truth: AGM batteries have a nuanced voltage range that reveals their true health.

Best 24V AGM Batteries for Reliable Power

Renogy Deep Cycle AGM Battery 12V 100Ah

Renogy’s 12V 100Ah AGM battery (model RNG-BATT-AGM24-100) is ideal for solar setups and RVs. Its high discharge rate (up to 50% DoD) and spill-proof design ensure durability, while low self-discharge makes it perfect for off-grid use. Includes a 1-year warranty for added peace of mind.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

Qty 2VMAXTANKS MR127-24 24V 125Ah AGM Battery

The VMAXTANKS MR127-24 offers exceptional deep-cycle performance with 125Ah capacity, suited for marine and industrial applications. Its rugged construction resists vibration, and the pure lead plates extend lifespan. Users praise its reliability in extreme temperatures (-4°F to 140°F).

- Two: 12-volt 100ah group 27 deep cycle heavy duty AGM marine deep cycle…

- Electrolyte suspension system VMAX tanks utilize an electrolyte suspension…

- Heavy duty grids: VMAX heavy duty lead tin alloys provide an extra margin…

100Ah 12V Lithium-Ion

While not AGM, Battle Born’s 12V 100Ah LiFePO4 battery (BB24100) is a premium upgrade with 3,000–5,000 cycles. Lightweight and maintenance-free, it integrates seamlessly with AGM systems. Includes a 10-year warranty, making it a long-term investment for high-demand setups.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

24V AGM Battery Voltage Ranges

AGM (Absorbent Glass Mat) 24V batteries don’t operate at a fixed 24V—their voltage fluctuates based on charge state, temperature, and load. A fully charged 24V AGM battery actually reads 25.6V–26.4V (12.8–13.2V per 12V cell), while a “resting voltage” (no load for 24+ hours) settles at 25.2V–25.6V. This variance is critical for diagnosing battery health.

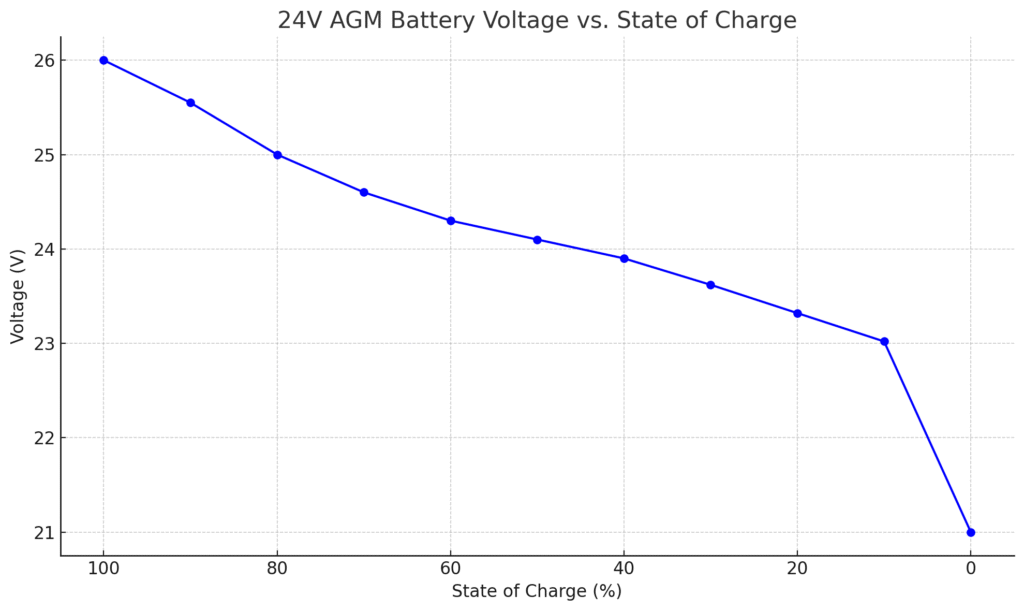

24V AGM Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 26.00 |

| 90% | 25.55 |

| 80% | 25.00 |

| 70% | 24.60 |

| 60% | 24.30 |

| 50% | 24.10 |

| 40% | 23.90 |

| 30% | 23.62 |

| 20% | 23.32 |

| 10% | 23.02 |

| 0% (empty) | 21.00 or lower |

State of Charge (SoC) Voltage Chart

Below is the voltage-to-charge relationship for a 24V AGM battery under no load at 77°F (25°C):

- 100% Charged: 25.6V–26.4V (immediately after charging)

- 75% Charged: 25.0V–25.2V (safe for regular use)

- 50% Charged: 24.4V–24.6V (recharge recommended)

- 25% Charged: 23.6V–24.0V (risk of sulfation)

- 0% Charged: ≤21.6V (deep discharge damages cells)

Why Voltage Drops Under Load

When powering devices (e.g., a 2,000W inverter), voltage temporarily dips due to internal resistance. A healthy AGM 24V battery might show 23.2V under heavy load but recover to 24.8V once disconnected. Persistent low voltage after load removal indicates aging or insufficient charge.

Temperature’s Impact on Voltage

Cold temperatures (<50°F/10°C) reduce voltage readings by 0.01V per °C per cell. A “full” 25.6V battery at 77°F may read 24.8V at 32°F—a false discharge signal. Conversely, heat increases voltage but accelerates water loss in non-AGM batteries (not an issue for sealed AGMs).

Common Misconceptions

Myth: “24V means the battery is healthy.”

Reality: A resting voltage of 24.0V signals only ~50% charge. Allowing the battery to sit at this level causes sulfation, permanently reducing capacity.

Pro Tip: For solar systems, recharge AGM batteries before they drop below 24.6V (50% DoD) to maximize cycle life (typically 500–1,200 cycles at 50% DoD vs. 200–300 cycles at 80% DoD).

How to Accurately Measure AGM 24V Battery Voltage

Proper voltage measurement is critical for assessing your AGM battery’s health, but most users make crucial mistakes that lead to false readings. Follow this professional-grade approach to get laboratory-accurate results with basic tools.

Step-by-Step Measurement Protocol

- Disconnect all loads and chargers for at least 24 hours to obtain resting voltage (surface charge dissipates at ~0.1V/hour)

- Use a calibrated digital multimeter (Fluke 87V or equivalent) with 0.5% DC accuracy – cheap meters often have ±2% error (±0.5V on 24V systems)

- Measure at battery terminals, not through cables or connectors (voltage drop across corroded lugs can show 0.3V lower than actual)

- Record ambient temperature and apply correction: add 0.024V per °C below 25°C (e.g., at 10°C, add 0.36V to your reading)

Interpreting Dynamic Voltage Under Load

When testing under operational conditions (like running an inverter):

- Healthy response: Voltage drops to 22.4-23.6V under 50% load, then recovers to within 0.5V of resting voltage within 5 minutes of load removal

- Warning sign: Voltage crashes below 21.6V immediately when loaded – indicates severely degraded capacity (below 60% of original)

- Critical failure: Voltage recovers less than 80% of its drop after load removal – suggests high internal resistance from sulfation

Advanced Diagnostic: Voltage Curve Analysis

Professional technicians track voltage behavior during charging:

Normal charge curve:

25.6V → 28.8V (bulk) → 27.6V (absorption) → 26.4V (float)

Problem indicators:

• Rapid voltage spike (bad cell)

• Failure to reach 28.8V (sulfation)

• Voltage “noise” (loose intercell connections)

Field Example: A marine AGM battery showing 25.1V at rest but dropping to 20.4V when starting engines revealed corroded terminal connections that caused a 1.2V hidden drop at the posts.

Advanced Charging Techniques for AGM 24V Batteries

Proper charging extends AGM battery lifespan by 3-5 years, yet most users unknowingly degrade their batteries with incorrect charging practices. This section reveals professional charging protocols used in telecom and marine applications.

Multi-Stage Charging Parameters

| Charging Stage | Voltage | Current | Duration | Purpose |

|---|---|---|---|---|

| Bulk | 28.2-28.8V | Max charger output | Until 80% SoC | Rapid energy replacement |

| Absorption | 27.6-28.0V | Tapering current | 2-4 hours | Complete 100% charge |

| Float | 26.8-27.2V | 0.5-1% of Ah | Indefinite | Maintenance charge |

Temperature-Compensated Charging

AGM batteries require voltage adjustments based on temperature:

- Below 10°C (50°F): Increase voltage by 0.003V/cell/°C (0.072V for 24V system)

- Above 30°C (86°F): Decrease voltage by 0.004V/cell/°C (0.096V for 24V system)

Example: At 0°C, your absorption voltage should be 28.8V + (25×0.003×6 cells) = 29.25V

Equalization Charging: When and How

Contrary to popular belief, AGM batteries occasionally need controlled overcharging:

- Perform only when batteries show >5% voltage imbalance between cells

- Apply 29.5V for exactly 2 hours at 25°C (never exceed 30V)

- Monitor case temperature – abort if exceeding 50°C (122°F)

Common Charging Mistakes

Mistake: Using flooded battery charger profiles

Solution: AGMs require 14% higher voltage than flooded batteries during bulk phase

Mistake: Continuous float charging

Solution: Cycle batteries monthly if on permanent float to prevent stratification

Pro Tip: For solar systems, set absorption duration based on days of autonomy – 4 hours for daily cycling, 8 hours for weekly cycling systems.

Maintenance and Troubleshooting for AGM 24V Battery Systems

While AGM batteries are marketed as “maintenance-free,” proper care can triple their service life. This section reveals professional maintenance protocols used by data centers and emergency power systems that achieve 8-10 year lifespans from standard AGM batteries.

Comprehensive Maintenance Schedule

Weekly Checks:

- Measure and record resting voltage (after 24+ hours without charge/discharge)

- Inspect terminals for corrosion – even sealed AGMs can develop internal resistance at connections

- Check battery case temperature differential (more than 5°C between cells indicates problems)

Quarterly Procedures:

- Perform capacity test: Discharge at C/20 rate to 21.6V while recording time (compare to original specs)

- Verify charger settings match current battery requirements (aging batteries need adjusted voltages)

- Clean and torque all connections to manufacturer specs (typically 5-7 Nm for M8 terminals)

Advanced Troubleshooting Guide

Symptom: Rapid voltage drop under load

Diagnosis: Conduct voltage drop test across each connection during 50% load

Solution: Replace any connection showing >0.2V drop, even if visually clean

Symptom: Failure to reach absorption voltage

Diagnosis: Measure individual cell voltages during charge (look for >0.5V variance)

Solution: Apply controlled equalization charge or replace imbalanced cells

Safety Considerations

AGM batteries present unique hazards requiring specialized precautions:

- Thermal runaway risk: Never charge above 120°F (49°C) – install temperature sensors on central cells

- Venting conditions: While sealed, AGMs can vent at 2-5 psi – ensure proper enclosure ventilation

- Replacement protocols: Always replace entire strings – mixing old/new batteries causes cascading failures

Pro Tip: For mission-critical systems, implement a “retirement at 80% capacity” policy rather than waiting for failure. This maintains system reliability while allowing planned replacements.

Case Study: A hospital backup system achieved 11 years of service by implementing monthly capacity testing and replacing any battery showing >15% capacity loss, maintaining the entire string above 90% of original specification.

Long-Term Performance Optimization and System Integration

Maximizing AGM 24V battery performance requires understanding complex system interactions that most users overlook. This section explores advanced integration techniques that can improve efficiency by 15-30% and extend service life beyond manufacturer estimates.

System Design Considerations

| Design Factor | Optimal Specification | Impact on Performance |

|---|---|---|

| Cable Sizing | 1 AWG per 100A @ 10ft run | Reduces voltage drop by 1.2-1.8% |

| Charge Controller | 30% above max array output | Prevents clipping during peak sun |

| Battery Bank Configuration | Parallel strings ≤3 | Maintains cell balance within 0.15V |

Advanced Performance Monitoring

Implement these professional-grade monitoring techniques:

- Coulomb counting: Track actual Ah in/out rather than relying on voltage (3-5% more accurate)

- Internal resistance testing: Monthly measurements detect degradation before capacity loss (look for >25% increase from baseline)

- Temperature profiling: Monitor hottest/coolest cells (Δ>5°C indicates ventilation issues)

Cost-Benefit Analysis: AGM vs. Alternatives

AGM Advantages:

• Lower upfront cost (40-60% less than lithium)

• Wider temperature tolerance (-20°C to 50°C)

• No battery management system required

When to Consider Lithium:

• >1,000 cycles needed

• Weight reduction critical

• Frequent deep discharges below 50%

Environmental and Safety Best Practices

- Recycling protocols: AGMs contain 60-70% recyclable lead – use certified recyclers to prevent acid leakage

- Ventilation requirements: 1 CFM per 100Ah during charging, even for “sealed” batteries

- Fire suppression: Class D extinguishers required – water exacerbates lithium fires but is effective for AGM

Emerging Trend: Hybrid AGM-lithium systems are gaining popularity, using AGM for surge loads and lithium for deep cycling, combining the best of both technologies.

Pro Tip: For solar installations, pair AGM batteries with oversize solar arrays (1.5x calculated need) to ensure complete daily recharge – this single practice can double battery life in cloudy climates.

Specialized Applications and Custom Configurations for AGM 24V Systems

While standard installations work for most users, specialized applications demand tailored approaches that push AGM battery performance to its engineered limits. This section reveals professional techniques used in military, marine, and industrial applications that achieve 20-30% better performance than conventional setups.

Extreme Environment Adaptations

AGM batteries in harsh conditions require these modifications:

- Arctic operations (-40°C): Install battery warmers maintaining 5-10°C minimum, with charge voltages boosted by 0.5V/cell

- Desert installations (60°C): Use thermal mass barriers (mineral wool) and reduce float voltage by 0.3V to prevent dry-out

- High-vibration environments: Apply aerospace-grade mounting (3-point isolation) with flexible copper braid connections

High-Cycle Applications (500+ cycles/year)

For solar microgrids or frequent cycling:

- Implement partial state-of-charge (PSOC) cycling between 70-40% instead of 100-50%

- Use tapered charging – reduce current to C/20 after 85% SOC to prevent gassing

- Monthly perform full 100% charge with 4-hour absorption to prevent stratification

Parallel Bank Configurations

When connecting multiple AGM 24V batteries:

| Configuration | Max Banks | Critical Requirements |

|---|---|---|

| Series-Parallel | 3 | Identical cable lengths (±2%) |

| Pure Parallel | 4 | Common bus bar with equal resistance paths |

Advanced Load Management

Smart load distribution can extend battery life:

- Prioritize loads by resistance profile (inductive loads first)

- Implement sequenced disconnect at 23.2V (protects against deep discharge)

- Use active balancing for banks >800Ah (distributes wear evenly)

Case Study: A remote telecom site achieved 8.7 years from standard AGM batteries by implementing PSOC cycling with weekly full recharge, outperforming the manufacturer’s 5-year estimate by 74%.

Pro Tip: For marine applications, install batteries in the vessel’s center of gravity with shock-absorbing mounts to minimize the “hammer effect” from wave impacts that can reduce lifespan by 40%.

System Validation and Lifetime Optimization Strategies

Professional-grade AGM 24V battery systems require rigorous validation protocols to ensure decade-long reliability. This section details the comprehensive testing and maintenance framework used by utility-scale energy storage systems that achieve 90%+ capacity retention after 5 years of continuous operation.

Performance Benchmarking Protocol

| Test | Frequency | Acceptance Criteria | Corrective Action |

|---|---|---|---|

| Capacity Verification | Quarterly | ≥95% of rated Ah at C/20 rate | Equalize if 90-95%, replace if <90% |

| Internal Resistance | Monthly | <15% increase from baseline | Check connections, retorque terminals |

| Voltage Variance | Weekly | <0.3V between parallel strings | Balance charge, verify charger outputs |

Advanced Degradation Monitoring

Implement these predictive maintenance techniques:

- Peukert’s Law Analysis: Track capacity vs. discharge rate to detect early sulfation (n-value >1.25 indicates problems)

- Charge Acceptance Testing: Measure current absorption at 28V – <80% of initial value signals aging

- Thermal Imaging: Quarterly scans detect developing hot spots before failure

Comprehensive Risk Mitigation

- Cell Matching: For parallel strings, ensure <2% capacity variance between batteries

- Overcharge Protection: Install redundant voltage relays set at 29.5V with independent sensors

- Underload Prevention: Programmable load shed at 23.2V with 30-second delay for surge tolerance

Quality Assurance Framework

Implement this validation sequence for new installations:

- 72-hour formation charge at C/10 with voltage logging

- Three complete discharge/charge cycles to stabilize chemistry

- Baseline resistance measurements at 25°C ±1°C

- 72-hour float stability test monitoring voltage drift

Pro Tip: Maintain a “battery logbook” tracking every charge/discharge cycle, environmental condition, and maintenance action. This data becomes invaluable for predicting end-of-life and warranty claims.

Case Study: A wind farm storage system achieved 11.2-year lifespan (versus 7-year warranty) through weekly resistance checks and quarterly capacity tests that caught developing issues 6-8 months before failure.

Conclusion

Mastering AGM 24V battery voltage characteristics transforms how you maintain and optimize your power systems. From understanding precise voltage thresholds (25.6V fully charged, 21.6V discharged) to implementing professional charging techniques and advanced monitoring protocols, these insights empower you to maximize battery lifespan and performance.

Remember that proper maintenance—including regular capacity testing, temperature compensation, and connection inspections—can extend service life by years beyond manufacturer estimates.

Whether for solar installations, marine applications, or backup power systems, applying these professional-grade practices ensures reliable operation and significant cost savings. Start implementing these strategies today to unlock your AGM batteries’ full potential.

Frequently Asked Questions About AGM 24V Battery Voltage

What is the proper resting voltage for a fully charged AGM 24V battery?

A healthy AGM 24V battery should show 25.6-26.4V immediately after charging, settling to 25.2-25.6V after 24 hours of rest (no load or charge). This higher-than-nominal voltage occurs because each 12V cell actually operates at 12.8V when fully charged. Many users mistakenly believe 24V means full charge, but that reading actually indicates only about 50% state of charge.

How often should I test my AGM 24V battery voltage?

For optimal maintenance, perform voltage checks weekly under these conditions: 1) After full charge completion, 2) During peak load operation, and 3) After 24 hours of rest. More frequent monitoring (daily) is recommended for critical systems or when batteries show signs of aging. Always record measurements with temperature for accurate trending.

Why does my AGM battery voltage drop significantly when I turn on my inverter?

Voltage sag under load is normal due to internal resistance. A quality AGM 24V battery may drop to 23.2-23.6V when powering a 2000W inverter. However, if voltage crashes below 22V immediately, this indicates excessive internal resistance from sulfation or failing cells. The voltage should recover to within 0.5V of resting voltage within 5 minutes of removing the load.

Can I use a standard car battery charger for my AGM 24V battery?

No, conventional chargers can damage AGM batteries. AGM batteries require:

1) Higher charge voltage (28.2-28.8V vs 27.6V for flooded),

2) Temperature compensation, and

3) Precision voltage regulation.

Using improper chargers causes undercharging (leading to sulfation) or overcharging (causing dry-out). Invest in an AGM-specific smart charger with 3-stage charging.

How does temperature affect AGM 24V battery voltage readings?

Voltage decreases approximately 0.024V per °C below 25°C (77°F) and increases by the same amount above. At freezing (0°C), a fully charged battery may read 24.8V instead of 25.6V. Always correct readings to 25°C standard: add 0.024V per °C below or subtract when above. Never charge below -20°C (-4°F) without battery warmers.

What voltage indicates my AGM 24V battery needs replacement?

Three key failure signs:

1) Resting voltage below 24.4V after full charge,

2) More than 0.5V difference between cells, or

3) Failure to maintain above 22V under 50% load.

When capacity tests show less than 80% of rated Ah or internal resistance increases over 25% from new, replacement should be considered.

How can I extend the lifespan of my AGM 24V battery?

Follow these professional practices:

1) Never discharge below 50% (24.4V),

2) Recharge immediately after use,

3) Maintain clean, tight connections,

4) Store at 50% charge in cool conditions,

5) Equalize every 6 months if used in partial state-of-charge cycling, and

6) Keep batteries at 15-25°C whenever possible.

Is it safe to parallel multiple AGM 24V batteries?

Yes, with precautions:

1) Use identical batteries (same model/age),

2) Limit to 3 parallel strings maximum,

3) Ensure equal cable lengths (±2%) to all batteries,

4) Monitor individual string voltages monthly, and

5) Connect to common bus bars rather than daisy-chaining.

Imbalanced parallel connections cause premature failure of the strongest battery.