Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a 24V lead-acid battery at 50% charge can drop below 24V under load, risking permanent damage? Voltage is the lifeline of your battery system, yet many users misinterpret readings, leading to premature failures or inefficient energy use.

Whether you’re powering solar setups, industrial equipment, or backup systems, knowing exactly how voltage correlates with state of charge (SoC) is non-negotiable. You might assume a 24V battery always reads 24V, but reality is far more nuanced. Voltage fluctuates with temperature, load, and chemistry.

Best 24V Lead-Acid Battery for Reliable Power Storage

VMAXTANKS VMAX SLR125 24V Deep Cycle AGM Battery

Ideal for solar and off-grid systems, the VMAX SLR125 offers a robust 125Ah capacity with pure lead plates for extended cycle life. Its AGM design ensures spill-proof operation, and it handles deep discharges down to 50% without degradation. Perfect for RVs, marine, and backup power.

- 12 Volt 125Ah group 31 AGM deep cycle heavy duty battery

- 8mm hex screw in terminals (included,for use with ring terminals) ….

- Float service life span of 8 to 10 years

Renogy Deep Cycle AGM Battery 12V 100Ah

Renogy’s 24V 100Ah AGM battery combines affordability with high performance, featuring low self-discharge and vibration resistance. Its sealed construction requires zero maintenance, and the battery excels in renewable energy setups. Includes a 1-year warranty, making it a trusted choice for budget-conscious users.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

UPG 12V 100Ah AGM Sealed Lead Acid Battery

With a compact footprint and 100Ah capacity, the UPG 12V 100Ah AGM Sealed Lead Acid Battery is a versatile SLA battery for UPS and industrial applications. It delivers stable voltage output and boasts a 5-year shelf life when stored properly. A reliable option for critical backup systems and telecom equipment.

- UPG #45978 UB121000 12V 100Ah

- Dimensions: 12.17 inches x 6.61 inches x 9.16 inches. Weight: 63.93 Lbs

- SLA/AGM maintenance free, spill proof battery

24V Lead-Acid Battery Voltage States

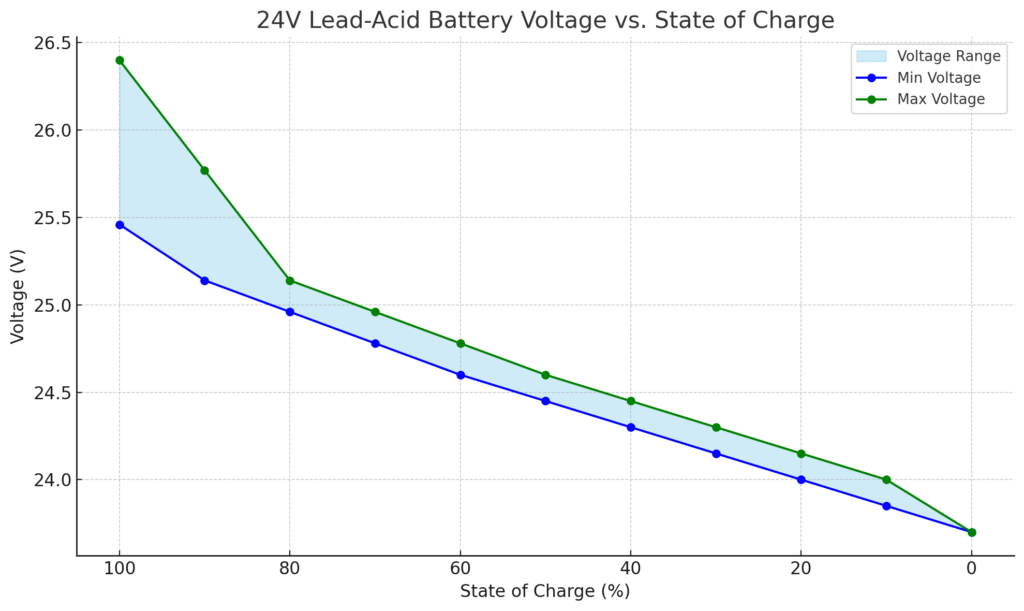

24V Lead-Acid Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 25.46 – 26.40 |

| 90% | 25.14 – 25.77 |

| 80% | 24.96 – 25.14 |

| 70% | 24.78 – 24.96 |

| 60% | 24.60 – 24.78 |

| 50% | 24.45 – 24.60 |

| 40% | 24.30 – 24.45 |

| 30% | 24.15 – 24.30 |

| 20% | 24.00 – 24.15 |

| 10% | 23.85 – 24.00 |

| 0% (empty) | 23.70 or lower |

What Voltage Readings Actually Mean

A 24V lead-acid battery isn’t always at exactly 24 volts—its voltage fluctuates based on charge state, load, and temperature. At full charge, a healthy 24V battery reads 25.2V–26.4V (2.1V–2.2V per cell), while a completely discharged battery drops to 21.6V (1.8V per cell). These thresholds are critical because over-discharging below 21.6V causes sulfation, permanently reducing capacity.

Key Voltage Benchmarks and Their Implications

Here’s how to interpret voltage readings under different conditions:

- Resting Voltage (No Load): Measured after 2+ hours without charging/discharging. A 24V battery at 50% charge rests at ~24.4V. This is the most accurate way to assess state of charge (SoC).

- Under Load Voltage: Drops temporarily when powering devices. A 10% voltage sag (e.g., to 22V) under moderate load is normal, but sustained drops below 21.6V indicate excessive drain.

- Charging Voltage: Rises to 28.8V during absorption charging (2.4V per cell) and tapers to 27V in float mode. Exceeding 29V risks overheating and water loss in flooded batteries.

Real-World Scenarios and Misconceptions

A common mistake is assuming a battery is “dead” at 24V—this actually reflects a ~70% charge. For example, a solar system battery bank reading 23V after sunset might seem low, but if it rebounds to 24.8V after resting, it’s still at ~50% capacity. Conversely, a battery showing 26V while charging isn’t necessarily full—it could be in the absorption phase.

Temperature’s Impact on Voltage

Voltage readings shift with temperature:

- Cold (0°C/32°F): Voltage reads higher than actual SoC. A “full” 26.4V battery at freezing temps may only deliver 80% capacity.

- Hot (40°C/104°F): Voltage reads lower, but capacity temporarily increases. Charging must be reduced by 0.03V per cell to avoid damage.

Always compensate charging voltage if temperatures exceed 25°C (77°F).

Practical Tip: When to Take Measurements

For accurate SoC assessment:

- Disconnect all loads and chargers for 2+ hours.

- Use a calibrated digital multimeter (e.g., Fluke 87V).

- Compare readings to a temperature-adjusted voltage chart (provided later in this guide).

This prevents false alarms from surface charge or load-induced voltage drops.

Optimal Charging Practices for 24V Lead-Acid Batteries

The Three-Stage Charging Process Explained

Proper charging extends battery life by 2-3 times compared to improper methods. A 24V lead-acid battery requires three distinct charging phases:

- Bulk Stage: Delivers 80% charge at maximum current (typically 10-30% of battery capacity). Voltage rises from ~21.6V to 28.8V while accepting full amperage.

- Absorption Stage: Holds voltage at 28.8V while current gradually decreases. This crucial phase completes the final 15-20% of charging and prevents stratification in flooded batteries.

- Float Stage: Maintains 27V indefinitely to counteract self-discharge without overcharging. Essential for standby power systems.

Charger Selection Criteria

Not all chargers are equal. For a 24V system:

- Voltage Precision: Must maintain ±0.5% voltage accuracy (28.8V±0.14V) to prevent under/overcharging

- Temperature Compensation: Look for sensors that adjust voltage by -3mV/°C per cell (-0.072V/°C for 24V systems)

- Current Rating: Should match battery capacity – 10A for 100Ah batteries, 25A for 200Ah systems

Common Charging Mistakes and Solutions

Many users encounter these preventable issues:

Problem: Battery never reaches full charge

Causes: Using automotive chargers (max 14.4V per 12V battery), insufficient absorption time

Fix: Use a true 3-stage charger and allow 4-8 hours absorption time for deep-cycle batteries

Problem: Rapid water loss in flooded batteries

Causes: Charging above 29V, missing float stage

Fix: Verify charger settings and add distilled water only after charging (never before)

Special Considerations for Different Battery Types

| Battery Type | Absorption Voltage | Float Voltage |

|---|---|---|

| Flooded | 28.8V | 27.0V |

| AGM | 28.4V | 27.2V |

| Gel | 28.2V | 27.4V |

Pro Tip: For solar systems, ensure your charge controller has equalization capability (30.5V for flooded batteries) to periodically balance cells and remove sulfation.

Advanced Maintenance and Troubleshooting for 24V Lead-Acid Systems

Comprehensive Battery Health Assessment

Proper maintenance begins with accurate diagnostics. Beyond voltage readings, these parameters reveal true battery condition:

- Specific Gravity (Flooded Batteries): Use a hydrometer to measure electrolyte density. Full charge should show 1.265±0.005 at 26.7°C (80°F). Variations >0.030 between cells indicate stratification or sulfation.

- Internal Resistance: Measured with an impedance tester. A 100Ah battery should read <4mΩ. Values doubling from new indicate end-of-life (EOL).

- Capacity Testing: Discharge at C/20 rate (5A for 100Ah battery) to 21.6V. Capacity <80% of rated Ah requires replacement.

Seasonal Maintenance Protocols

| Season | Action Items | Technical Parameters |

|---|---|---|

| Summer | Reduce float voltage by 0.3V Check water levels weekly | Max case temp: 50°C (122°F) Electrolyte temp: <40°C (104°F) |

| Winter | Increase charge voltage by 0.3V Insulate battery compartment | Min operating temp: -20°C (-4°F) Charge acceptance below 0°C drops 50% |

Advanced Troubleshooting Guide

Symptom: Rapid Self-Discharge (10%+ per week)

Possible Causes:

- Parasitic loads >3mA per 100Ah

- Internal short circuits (check for warm spots)

- Contaminated electrolyte (specific gravity <1.200 after full charge)

Diagnostic Steps:

- Perform 72-hour open-circuit voltage test

- Measure standing current with clamp meter

- Constitute capacity test with recording voltmeter

Professional Equalization Techniques

For flooded batteries only, controlled overcharging removes sulfation:

- Charge at 30.5V (2.55V/cell) until specific gravity stops rising

- Limit to 16 hours maximum

- Monitor cell temperatures – abort if any cell exceeds 52°C (125°F)

Critical Note: Never equalize AGM or gel batteries – this will cause irreversible damage to the glass mat or silica gel structure.

Battery Bank Balancing Methods

For multi-battery 24V systems (two 12V in series):

- Disconnect all parallel strings

- Charge each 12V battery individually to 14.4V

- Reconnect only when voltage differential <0.2V

- Install active balancers if persistent imbalance occurs

This prevents the “weak battery effect” where one battery drags down entire system performance.

System Integration and Safety Considerations for 24V Lead-Acid Installations

Proper Wiring and Connection Techniques

Correct cabling is critical for 24V systems to minimize voltage drop and ensure balanced operation. Follow these professional guidelines:

- Cable Sizing: Use AWG 4 for runs under 10 feet (100A load), AWG 2 for 10-20 feet. Voltage drop should never exceed 3% (0.72V at 24V).

- Parallel Connections: When connecting multiple batteries, use diagonal wiring (positive on one end, negative on opposite end) to equalize resistance across all units.

- Terminal Preparation: Clean with brass brush, apply anti-corrosion gel (NO-OX-ID A-Special), and torque to manufacturer specs (typically 8-12 Nm for most 24V batteries).

Protection Circuit Design

A comprehensive protection system should include:

| Component | Specification | Purpose |

|---|---|---|

| Class T Fuse | 125% of max current | Protects against dead shorts |

| DC Circuit Breaker | 80% of cable rating | Overcurrent protection |

| Low Voltage Disconnect | Set at 21.6V | Prevents deep discharge |

| Reverse Polarity Protection | MOSFET-based | Safeguards against wiring errors |

Ventilation and Thermal Management

Lead-acid batteries require specific environmental controls:

- Maintain 10-25°C (50-77°F) operating temperature for optimal performance

- Provide 1 cubic foot per minute (CFM) ventilation per 100Ah capacity

- Install thermal sensors that trigger fans at 30°C (86°F) and disconnect chargers at 50°C (122°F)

- Keep batteries elevated ≥1″ from concrete floors to prevent temperature differentials

Advanced Monitoring Systems

For mission-critical applications, implement these monitoring solutions:

- Smart Shunts: Victron BMV-712 provides 0.1% current measurement accuracy and tracks state-of-charge via Peukert’s equation

- Cell Monitors: Midnite Solar’s MNGP monitors individual 2V cells in 24V systems

- Remote Alerts: Set up SMS notifications for voltage excursions beyond 19V-32V range

Safety Protocols for Large Installations

When working with industrial-scale 24V banks (1000Ah+):

- Wear insulated tools and VRLA goggles when servicing

- Install clearly labeled emergency disconnect within 10 feet

- Maintain 36″ clearance on all sides for maintenance access

- Use fiberglass covers on busbars to prevent accidental contact

- Implement arc flash protection for systems capable of >10kA fault current

Lifecycle Management and Cost Optimization for 24V Lead-Acid Systems

Total Cost of Ownership Analysis

Understanding the complete financial picture requires evaluating these key factors over a 5-10 year period:

| Cost Factor | Flooded Lead-Acid | AGM | Gel |

|---|---|---|---|

| Initial Purchase | $150-$200 per 100Ah | $250-$350 per 100Ah | $300-$400 per 100Ah |

| Cycle Life (80% DOD) | 500-800 cycles | 600-1,200 cycles | 800-1,500 cycles |

| Maintenance Costs | $5-$10/month (water, equalization) | Negligible | Negligible |

| Replacement Interval | 3-5 years | 5-8 years | 7-10 years |

Key Insight: While AGM batteries cost 40% more upfront, their 2-3x longer lifespan often makes them more economical long-term for daily cycling applications.

Advanced Performance Degradation Models

Battery aging follows predictable patterns based on these acceleration factors:

- Temperature: Every 8°C (15°F) above 25°C (77°F) halves battery life (Arrhenius equation)

- Depth of Discharge: 50% DOD provides 2x more cycles than 80% DOD (Peukert effect)

- Charge Quality: Chronic undercharging by just 10% reduces capacity by 25% annually due to sulfation

Environmental Impact and Recycling

Modern lead-acid batteries achieve 99% recyclability, but proper handling is crucial:

- Return spent batteries to EPA-certified recyclers (find via Earth911 database)

- Never dispose in landfills – lead contamination persists for centuries

- New recycling methods can recover 95% of materials for new batteries

Emerging Technologies and Future Trends

The lead-acid industry is evolving with these innovations:

- Carbon-enhanced plates: Improve charge acceptance by 300% (Firefly’s Oasis battery)

- Bipolar designs: Reduce internal resistance for higher efficiency (Gridtential’s technology)

- Advanced alloys: Calcium-tin-silver grids extend life beyond 15 years in stationary applications

End-of-Life Decision Matrix

Replace batteries when any two conditions occur:

- Capacity <80% of rated Ah (verified by discharge test)

- Internal resistance >200% of new battery value

- Voltage recovery time >4 hours after charging

- Specific gravity variation >0.030 between cells

- Visible plate damage or excessive sediment

Advanced System Integration for 24V Lead-Acid Battery Banks

Multi-Bank Parallel Configuration Strategies

When connecting multiple 24V batteries in parallel, follow these critical guidelines to ensure balanced operation:

- Impedance Matching: All parallel strings should be within 5% internal resistance (use milliohm meter for verification)

- Cable Symmetry: Maintain identical cable lengths (±1%) and gauge between all parallel connections

- Bus Bar Design: Use copper bus bars with 200A/in² current density rating and thermal expansion joints for large installations

Example: For three 24V/200Ah strings, use 2/0 AWG cables exactly 18″ long for each positive and negative connection to the common bus.

Hybrid System Integration

24V lead-acid batteries often work with other technologies in modern systems:

| Integration Type | Key Considerations | Optimal Configuration |

|---|---|---|

| Solar + Generator | Set generator auto-start at 22.8V (40% DOD) | DC-coupled systems preferred for efficiency |

| Lithium Hybrid | Use voltage-based charge controllers | Lead-acid as backup, lithium for daily cycling |

| Grid-Tied Systems | UL1741 compliant inverters required | 72-hour autonomy design minimum |

Advanced Charge Controller Programming

Optimize these often-overlooked settings for 24V lead-acid systems:

- Absorption Timeout: Set to 4-6 hours for deep-cycle batteries (not auto-terminate based on current)

- Equalization Frequency: Program monthly for flooded batteries (disable for VRLA)

- Temperature Compensation: -3mV/°C/cell (-72mV/°C for 24V) with remote sensor placement

Load Management Techniques

Implement these strategies to extend battery life:

- Peak Shaving: Program inverters to limit discharge rate to C/3 (33A for 100Ah battery)

- Load Prioritization: Use programmable relays to shed non-critical loads at 23.2V (60% DOD)

- Cyclic vs. Standby: Designate separate battery banks for cyclic (daily) and standby (emergency) loads

Comprehensive System Commissioning

Follow this 10-point checklist when bringing a new 24V system online:

- Verify all connections with torque wrench (8-12 Nm for most terminals)

- Perform initial capacity test at C/20 rate

- Program all charge profiles per battery manufacturer specs

- Test all protection devices (fuses, breakers, LVD)

- Balance parallel strings within 2% voltage differential

- Calibrate all monitoring equipment

- Document baseline performance metrics

- Verify proper ventilation airflow

- Test emergency shutdown procedures

- Establish maintenance schedule

Performance Optimization and Risk Management for 24V Lead-Acid Systems

Advanced Performance Benchmarking

Establish these key performance indicators (KPIs) to quantify system health:

| Metric | Optimal Range | Measurement Protocol |

|---|---|---|

| Charge Acceptance | >85% at C/5 rate | Measure current drop during bulk phase |

| Voltage Recovery | <5 minutes to 24.8V after load | Apply 50% load for 30 minutes |

| Self-Discharge Rate | <3% per month | 72-hour open-circuit test |

| Energy Efficiency | >80% round-trip | Full charge/discharge cycle at C/20 |

Comprehensive Risk Assessment Matrix

Evaluate these critical failure modes and mitigation strategies:

- Thermal Runaway: Install redundant temperature sensors (action at 50°C/122°F)

- Stratification: Implement quarterly equalization for flooded batteries

- Positive Grid Corrosion: Monitor plate growth (>5% indicates EOL)

- Acid Leakage: Use secondary containment (1.5x battery volume)

Advanced Maintenance Protocols

Implement these specialized procedures for mission-critical systems:

- Electrochemical Impedance Spectroscopy (EIS): Quarterly testing to detect early sulfation

- Infrared Thermography: Annual scans to identify hot spots in connections

- Electrolyte Analysis: ICP-MS testing for trace metal contamination

- Torque Verification: Bi-annual checks with calibrated torque wrench

System-Wide Optimization Strategies

These advanced techniques can improve performance by 15-30%:

- Adaptive Charging: Dynamically adjust absorption voltage based on usage patterns

- Load Profiling: Match discharge rates to battery’s Peukert characteristics

- Predictive Maintenance: Machine learning analysis of historical performance data

Quality Assurance Validation

For industrial installations, conduct these verification tests:

- 72-Hour Load Bank Test: Verify system meets design specifications

- Failure Mode Testing: Simulate worst-case scenarios (simultaneous faults)

- EMC Compliance: Verify no electromagnetic interference with control systems

- Cyclic Endurance: Accelerated life testing (3x normal cycles)

Professional Insight: Maintain a “battery logbook” documenting all maintenance, test results, and performance observations – this historical data becomes invaluable for troubleshooting and warranty claims.

Conclusion

Mastering 24V lead-acid battery voltage management requires understanding the intricate relationship between voltage readings, state of charge, and environmental factors. Throughout this guide, we’ve explored:

- Precise voltage thresholds for different charge states

- Advanced charging methodologies and maintenance protocols

- System integration best practices and safety considerations

- Performance optimization techniques and lifecycle management

Proper voltage monitoring isn’t just about reading numbers—it’s about interpreting them in context of your specific application. Whether you’re maintaining a solar array, industrial equipment, or backup power system, these principles will help you maximize battery life and reliability.

Action Step: Begin implementing these strategies today by downloading our free 24V lead-acid voltage reference chart and conducting your first comprehensive battery health assessment. Your batteries—and your power system’s performance—will thank you.

Frequently Asked Questions About 24V Lead-Acid Batteries

What exactly does a 24V lead-acid battery voltage reading indicate?

A voltage reading reveals the battery’s state of charge (SoC) and health. At rest, 25.2-26.4V indicates full charge, while 21.6V signals complete discharge. However, voltage must be interpreted with context – a 24.0V reading could mean either 70% charge (resting) or imminent failure (under load). Always measure after 2+ hours without charging/discharging for accurate assessment, and consider temperature effects (-0.072V/°C from 25°C baseline).

How often should I perform equalization charging on my 24V flooded batteries?

For flooded lead-acid batteries, equalize monthly or after every 10 deep cycles. The process involves charging at 30.5V (2.55V/cell) until specific gravity stops increasing (maximum 16 hours).

Monitor cell temperatures closely – abort if any cell exceeds 52°C (125°F). Never equalize AGM or gel batteries as it causes irreversible damage to their internal structure.

Why does my 24V battery bank show voltage imbalance between strings?

Imbalances typically stem from three causes: unequal cable resistance (varying lengths/gauges), differing battery ages (older batteries have higher internal resistance), or charging inconsistencies. To correct, first measure each string’s resistance with a milliohmmeter. Then balance by: 1) Equalizing all batteries individually, 2) Replacing cables with identical lengths/gauges, and 3) Installing active balancers if differences persist beyond 0.2V.

Can I mix different capacity batteries in a 24V system?

Technically possible but strongly discouraged. Mixing capacities creates uneven current distribution – for example, pairing 100Ah and 200Ah batteries forces the smaller unit to work twice as hard, accelerating its failure.

If unavoidable, use separate charge controllers per string and implement current-limiting devices. However, for reliable operation, always use identical batteries from the same production batch.

What’s the safest way to store 24V lead-acid batteries long-term?

For storage exceeding 3 months:

1) Fully charge to 26.4V,

2) Clean terminals and apply protective grease,

3) Store in cool (10-15°C), dry location,

4) Disconnect all loads/chargers,

5) For flooded types, check electrolyte monthly and top up with distilled water.

Recharge every 6 months (AGM/gel) or 3 months (flooded). Storage below 0°C requires special precautions – maintain at least 70% charge to prevent freezing.

How can I accurately test my 24V battery’s remaining capacity?

Perform a controlled discharge test:

1) Fully charge to 26.4V,

2) Apply a known load (C/20 rate – 5A for 100Ah battery),

3) Record time until voltage drops to 21.6V,

4) Calculate capacity (hours × amps).

For example, a 100Ah battery should provide 20 hours at 5A. Professional setups use automated load testers that plot voltage curves, but this manual method provides reliable results for most users.

Why does my 24V system voltage drop significantly when starting motors?

This voltage sag (often 2-4V) occurs because lead-acid batteries have relatively high internal resistance. During high-current draws like motor starts, this resistance causes immediate voltage drop (V=IR). Solutions include:

1) Oversizing battery bank (minimum 3x surge current rating),

2) Using AGM batteries (lower internal resistance),

3) Adding supercapacitors for momentary loads, or

4) Implementing soft-start motor controllers to limit inrush current.

Is it worth upgrading from flooded to AGM 24V batteries?

The decision depends on your use case. AGM batteries offer advantages: maintenance-free operation, better vibration resistance, faster charging (up to 5x), and longer cycle life (1,200 vs 800 cycles at 50% DOD).

However, they cost 40-60% more and are more sensitive to overcharging. For stationary applications with regular maintenance, flooded may suffice. For mobile applications or where maintenance is difficult, AGM justifies its premium.