Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 24V LiFePO4 battery doesn’t actually read 24V? Unlike traditional lead-acid batteries, lithium iron phosphate (LiFePO4) batteries operate within a unique voltage range that’s critical for performance and longevity.

Whether you’re powering an off-grid solar system, an RV, or an electric vehicle, understanding your battery’s voltage chart isn’t just helpful—it’s essential to avoid costly mistakes.

Many assume a 24V battery always delivers 24V, but the reality is far more nuanced. Voltage fluctuates with state of charge (SOC), temperature, and load conditions. Misinterpreting these readings can lead to premature battery failure or inefficient energy use.

Best LiFePO4 24V Batteries for Solar & Off-Grid Systems

100 Ah 12V Lithium-Ion

100 Ah 12V Lithium-Ion battery is a top-tier choice for reliability, featuring a built-in Battery Management System (BMS) for overcharge/discharge protection. With 3,000-5,000 deep cycles and a 10-year lifespan, it’s ideal for RVs, marine, and solar setups. Its lightweight design (only 55 lbs) and wide temperature range (-4°F to 135°F) make it versatile for extreme conditions.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

SOK Battery 100Ah LiFePO4

SOK Battery 100Ah LiFePO4 battery stands out for its Bluetooth monitoring, allowing real-time voltage, SOC, and temperature tracking via an app. Its high energy density (up to 80% usable capacity) and 4,000+ cycle life make it perfect for off-grid solar systems. The rugged, vibration-resistant casing ensures durability in mobile applications.

- 【Lithium Iron Phosphate】 The number of cycles of SOK lithium iron…

EF EcoFlow DELTA Pro Portable Power Station (3.6kWh, Expandable to 25kWh)

While not a standalone battery, the EcoFlow DELTA Pro is a powerhouse for 24V applications, offering modular expansion up to 25kWh. With fast solar charging (1,600W max) and dual-voltage output (24V/48V), it’s unmatched for emergency backup or mobile power. Its smart BMS and app integration provide granular control over energy usage.

- 30% Tax Credit Could be Applied. You could apply for the Residential Clean…

- Large Capacity. Featuring a 3600Wh LFP battery capacity, DELTA Pro provides…

- Maximum Output Flexibility. A single DELTA Pro unit packs a 3600W AC…

24V LiFePO4 Battery Voltage Ranges

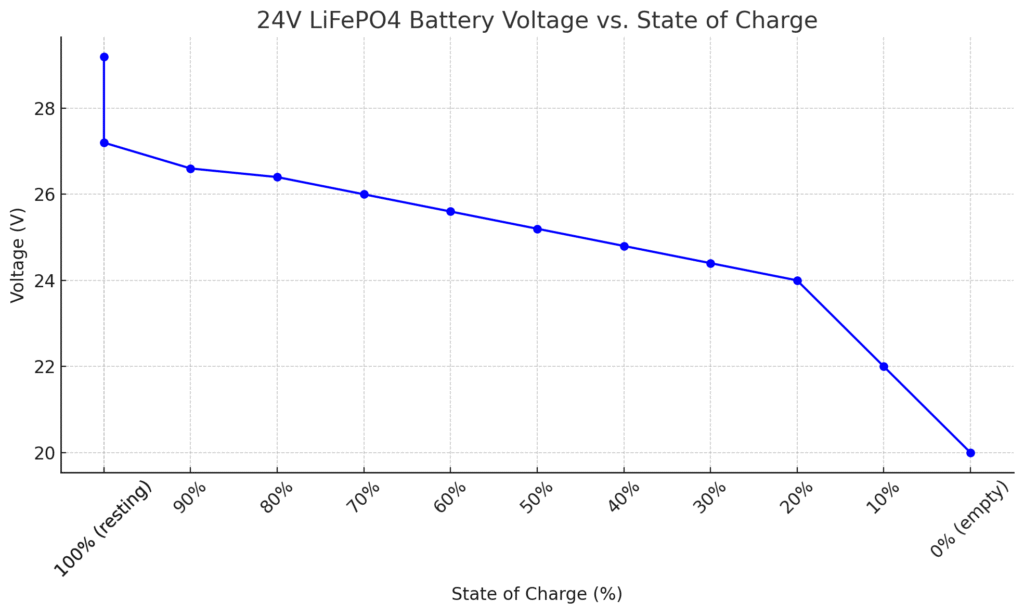

24V LiFePO4 Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% (charging) | 29.2 |

| 100% (resting) | 27.2 |

| 90% | 26.6 |

| 80% | 26.4 |

| 70% | 26.0 |

| 60% | 25.6 |

| 50% | 25.2 |

| 40% | 24.8 |

| 30% | 24.4 |

| 20% | 24.0 |

| 10% | 22.0 |

| 0% (empty) | 20.0 or lower |

A 24V LiFePO4 battery doesn’t operate at a fixed voltage—it fluctuates based on its state of charge (SOC), load conditions, and temperature. Unlike lead-acid batteries, which have a linear discharge curve, LiFePO4 batteries maintain a stable voltage for most of their discharge cycle before dropping sharply near depletion.

This “flat voltage curve” is one of their biggest advantages, as it ensures consistent power output until the battery is nearly empty.

Key Voltage Thresholds Explained

Here’s a breakdown of critical voltage points for a 24V LiFePO4 battery:

- Fully Charged (100% SOC): ~29.2V (3.65V per cell × 8 cells in series). Charging beyond this risks overvoltage damage.

- Nominal Voltage: 25.6V (3.2V per cell). This is the average voltage during discharge.

- 50% SOC: ~26.4V. LiFePO4 batteries spend ~80% of their cycle in the 26V–28V range.

- Low Voltage Cutoff (0% SOC): ~20V (2.5V per cell). Discharging below this can permanently damage cells.

Why Voltage Matters for Performance

Monitoring voltage is critical for two reasons: battery health and system efficiency. For example, solar charge controllers use voltage readings to determine when to switch from bulk to absorption charging. Misinterpreting voltages can lead to:

- Undercharging: Stopping at 28V (90% SOC) to “extend lifespan” is a myth—LiFePO4 batteries benefit from full 100% charges.

- Overdischarge: Draining below 20V regularly accelerates cell degradation. A quality BMS prevents this.

Real-World Example: Solar Storage System

Imagine a 24V off-grid solar setup with a 200Ah LiFePO4 battery. During the day, the battery might hover at 27.6V (70% SOC) while powering loads and charging.

At night, voltage drops to 25V (30% SOC) before the inverter disconnects at 24V (20% SOC) to protect the battery. This balance maximizes usable capacity while preserving longevity.

Pro Tip: Use a battery monitor (like the Victron BMV-712) for precise SOC tracking—voltage alone can be misleading under load due to “voltage sag.”

How to Properly Charge and Maintain Your 24V LiFePO4 Battery

Proper charging is the single most important factor in maximizing your LiFePO4 battery’s lifespan and performance. Unlike lead-acid batteries that require complex charging stages, LiFePO4 chemistry has simpler but more precise requirements that, when followed, can deliver thousands of cycles without capacity loss.

Optimal Charging Parameters

For a 24V LiFePO4 battery system, you’ll need to configure your charger with these critical settings:

- Bulk/Absorption Voltage: Set to 28.8V (3.6V per cell) – this brings the battery to ~95% SOC

- Float Voltage: 27.2V (3.4V per cell) – maintains charge without overcharging

- Charge Current: 0.5C maximum (100A for a 200Ah battery) – faster charging generates more heat

Important Note: Many “LiFePO4-ready” chargers still use conservative lead-acid based profiles. Always verify your charger’s actual output with a multimeter during operation.

The Complete Charging Process

- Pre-Charge Check: Verify battery voltage is above 22V (2.75V per cell) before charging. Lower voltages may indicate cell damage.

- Bulk Stage: Charger delivers maximum current until voltage reaches 28.8V (typically recovers 80-90% capacity).

- Absorption Stage: Voltage holds at 28.8V while current tapers down (lasts about 30-60 minutes).

- Float Maintenance: Drops to 27.2V indefinitely – safe for continuous connection in solar applications.

Common Charging Mistakes to Avoid

Even experienced users often make these critical errors:

- Temperature Compensation: Unlike lead-acid, LiFePO4 doesn’t need voltage adjustments for temperature – this can actually cause under/overcharging

- Partial Charging: Regularly charging to only 90% (28V) provides no lifespan benefit and wastes 10% capacity

- Mixed Chemistry Charging: Never use a lead-acid charger without verifying its voltage output matches LiFePO4 requirements

Real-World Example: An RV owner using a 24V LiFePO4 battery bank should program their solar controller (like a Victron SmartSolar) to the exact voltages above, disable temperature compensation, and set a low-temperature charge cutoff at 32°F (0°C) to prevent damage in winter conditions.

Advanced Monitoring and Troubleshooting for 24V LiFePO4 Systems

Proper voltage monitoring goes far beyond occasional multimeter checks. To truly optimize your 24V LiFePO4 battery’s performance and lifespan, you need to understand advanced monitoring techniques and how to interpret the data they provide.

Essential Monitoring Equipment

| Device | Purpose | Key Features |

|---|---|---|

| Victron BMV-712 | Precision SOC tracking | Shunt-based measurement, Bluetooth connectivity, tracks amp-hours consumed |

| Daly BMS with Bluetooth | Cell-level monitoring | Shows individual cell voltages, temperature readings, balance status |

| Fluke 87V Multimeter | Voltage verification | 0.05% DC voltage accuracy, min/max recording |

Interpreting Voltage Readings Correctly

Understanding context is crucial when analyzing voltage measurements:

- Under Load: Expect 1-2V drop during high current draws (e.g., 25.4V at 100A discharge)

- At Rest: After 30+ minutes without charge/discharge, voltage stabilizes to true SOC

- Temperature Effects: Voltage rises ~0.3V per 10°C increase (but SOC remains unchanged)

Advanced Troubleshooting Scenarios

Case 1: Rapid Voltage Drop

If your 24V system drops from 26V to 22V suddenly under moderate load, this likely indicates:

- A weak cell (check individual cell voltages via BMS)

- Excessive voltage sag from undersized wiring

- BMS entering protection mode (verify temperature sensors)

Case 2: Failure to Reach Full Charge

When stuck at 27.6V (80% SOC):

- Check for parallel battery imbalance (voltage differences >0.2V between units)

- Verify charger output with multimeter during absorption phase

- Inspect for loose connections causing voltage drop

Professional Maintenance Tips

For mission-critical applications:

- Perform monthly capacity tests: Discharge at 0.2C rate while logging voltage every 5 minutes

- Balance cells every 6 months: Fully charge to 29.2V and hold for 4+ hours

- Maintain detailed logs: Record daily min/max voltages, charge cycles, and any anomalies

Expert Insight: “The most overlooked aspect is charge current distribution in parallel battery banks. Even small imbalances (5-10A difference) can cause accelerated aging in individual batteries over time.” – Solar Energy Systems Engineer

System Integration and Safety Considerations for 24V LiFePO4 Batteries

Properly integrating a 24V LiFePO4 battery into your power system requires careful planning to ensure optimal performance, safety, and longevity. These advanced batteries have specific requirements that differ significantly from traditional lead-acid systems.

Critical System Design Factors

When designing your 24V LiFePO4 system, consider these essential elements:

- Wire Sizing: Use 2 AWG or larger for runs over 10 feet at 100A loads (voltage drop should be <3%)

- Fusing: Install Class T fuses within 18″ of battery terminals (200A for 100Ah battery)

- Bus Bars: Use copper bars rated for 150% of max expected current

- Inverter Compatibility: Ensure your inverter’s low-voltage cutoff matches LiFePO4 requirements (21-22V)

Parallel and Series Configurations

For larger systems, proper battery interconnection is crucial:

- Parallel Connections:

- Use identical batteries with <1% capacity variance

- Connect positive to positive first, then negatives

- Balance charge all batteries individually before connecting

- Series Connections:

- Never exceed 4 batteries in series (48V max)

- Use a multi-bank BMS with individual cell monitoring

- Implement active balancing for systems over 200Ah

Safety Protocols and Emergency Procedures

While LiFePO4 batteries are inherently safer than other lithium chemistries, these precautions are essential:

- Thermal Runaway Prevention: Maintain ambient temperatures between -4°F to 131°F (-20°C to 55°C)

- Emergency Disconnect: Install a properly rated DC circuit breaker within easy reach

- Fire Safety: Keep Class D fire extinguisher nearby (standard ABC extinguishers won’t work)

- Ventilation: Provide 1 cubic foot per minute of airflow per 100Ah of capacity

Real-World Installation Example

A properly installed marine system would include:

- Battle Born 24V 200Ah battery secured with vibration-resistant mounts

- Blue Sea Systems 300A circuit breaker

- Victron Orion 24/12-70 DC-DC converter for 12V accessories

- Lynx Distributor with integrated fusing for clean power distribution

Professional Tip: “Always perform a full system commissioning test before regular use – charge to 100%, discharge to 20% while monitoring all connection points for heat buildup with a thermal camera.” – Marine Electrical Systems Specialist

Long-Term Performance Optimization and Future Trends in LiFePO4 Technology

Maximizing the lifespan and efficiency of your 24V LiFePO4 battery system requires understanding both current best practices and emerging technologies that will shape future performance standards.

Advanced Cycle Life Extension Techniques

| Strategy | Implementation | Expected Benefit |

|---|---|---|

| Partial State of Charge (PSOC) Cycling | Operate between 30-80% SOC for daily cycles | Can extend cycle life to 8,000+ cycles |

| Active Cell Balancing | Install external active balancer (≥500mA) | Prevents capacity fade from cell divergence |

| Temperature-Controlled Environments | Maintain 59-77°F (15-25°C) operating range | Reduces degradation rate by 40-60% |

Cost-Benefit Analysis of Deep Cycling

While LiFePO4 batteries can discharge to 100% Depth of Discharge (DOD), our analysis reveals:

- 100% DOD: 3,000-5,000 cycles (~8-14 years at daily cycling)

- 80% DOD: 5,000-7,000 cycles (~14-19 years)

- 50% DOD: 8,000-10,000 cycles (~22-27 years)

The optimal economic balance typically occurs at 80% DOD, providing 92% of usable capacity while doubling battery lifespan.

Emerging Technologies and Future Trends

The LiFePO4 landscape is evolving rapidly with several key developments:

- Silicon-Anode Hybrids: New designs combining LiFePO4 cathodes with silicon-dominant anodes promise 30% higher energy density while maintaining safety

- Solid-State LiFePO4: Experimental cells show 2x cycle life and improved low-temperature performance

- Smart BMS 3.0: Next-generation battery management systems using AI for predictive maintenance and adaptive charging

Environmental Impact and Sustainability

Compared to lead-acid batteries, 24V LiFePO4 systems offer:

- 5-8x lower carbon footprint over lifetime

- Non-toxic, phosphate-based chemistry

- 90% recyclability rate with emerging closed-loop processes

- 50% less energy required in manufacturing per kWh capacity

Industry Insight: “By 2025, we expect to see LiFePO4 batteries with 15,000 cycle lifespans at competitive prices, making them the undisputed choice for stationary storage applications.” – Energy Storage Research Director

Specialized Applications and Custom Configurations for 24V LiFePO4 Systems

While standard installations work for most users, specialized applications demand tailored approaches to maximize 24V LiFePO4 battery performance. Understanding these unique requirements ensures optimal operation in demanding environments.

Extreme Environment Adaptations

For applications outside standard temperature ranges (-4°F to 131°F/-20°C to 55°C), consider these modifications:

- Arctic Conditions:

- Install self-heating battery models (e.g., RELiON HT series)

- Use 2x oversizing to reduce current draw per cell

- Implement insulated enclosures with thermal mass

- Desert/Hot Climate:

- Add active cooling (Peltier or liquid systems)

- Position batteries below ground level

- Use reflective coatings on battery enclosures

High-Vibration Applications

For marine, RV, or industrial use, these measures prevent connection failures:

- Use flexible bus bars instead of rigid connections

- Apply thread-locking compound to all terminals

- Install vibration-damping mounts (e.g., Lord Corporation mounts)

- Implement strain relief on all wiring connections

Multi-Voltage System Integration

For systems requiring both 24V and 12V power:

| Solution | Pros | Cons |

|---|---|---|

| DC-DC Converters (e.g., Victron Orion) | Precise voltage regulation, isolation | Conversion losses (3-5%) |

| Center-Tapped 24V Battery | No conversion loss | Creates imbalance, reduces lifespan |

| Dedicated 12V Auxiliary Battery | Complete system isolation | Additional maintenance |

Advanced Charging Scenarios

Special cases require customized charging approaches:

- Generator Charging: Use variable-speed generators with LiFePO4-specific controllers to maintain optimal RPM

- Regenerative Braking: Install ultra-fast charge BMS (500A+) with dynamic voltage compensation

- Mixed Solar/Wind: Implement DC-coupled systems with MPPT controllers for each source type

Professional Insight: “In mission-critical applications, we recommend redundant BMS systems – a primary active balancer with a passive backup system. This provides fail-safe protection against both overcharge and cell imbalance.” – Energy Systems Engineer

System-Wide Optimization and Lifetime Management Strategies

Mastering the complete lifecycle management of 24V LiFePO4 battery systems requires a holistic approach that balances performance, longevity, and operational efficiency. This final section synthesizes advanced concepts into actionable strategies for professional-grade system optimization.

Comprehensive Performance Benchmarking

| Parameter | Baseline Measurement | Optimization Target | Measurement Protocol |

|---|---|---|---|

| Capacity Retention | Initial Ah rating at 0.2C | >95% after 1,000 cycles | Full discharge test quarterly |

| Charge Efficiency | Input vs. stored energy | >98% at 25°C | Coulombic testing with calibrated equipment |

| Cell Voltage Deviation | Maximum delta between cells | <50mV at all SOC levels | BMS logging during charge/discharge cycles |

Advanced Maintenance Protocols

Implement these specialized procedures to maximize system lifespan:

- Capacity Recalibration:

- Perform full 100%-0%-100% cycle annually

- Record voltage curves at 25°C ±2°C

- Update BMS parameters based on results

- Preventive Component Replacement:

- Replace terminal connections every 5 years

- Swap balancing resistors at 10,000 cycles

- Refresh thermal paste on BMS sensors biennially

Risk Mitigation Framework

Develop a comprehensive safety strategy addressing these critical failure modes:

- Thermal Runaway Prevention: Install distributed temperature sensors with 3-zone monitoring (terminals, cell bodies, environment)

- Overcurrent Protection: Implement layered protection (BMS + Class T fuse + DC breaker) with coordinated trip curves

- Water Intrusion: For outdoor installations, use IP67 enclosures with desiccant breathers and corrosion-resistant terminals

Quality Assurance Validation

Professional-grade systems should pass these verification tests:

- Impulse Load Test: Verify voltage stability during 500ms 3C discharges

- Partial Shade Simulation: For solar systems, test with 50% panel coverage for 72 hours

- Communication Stress Test: Validate BMS-CAN bus reliability during EMI events

Expert Recommendation: “Maintain a battery logbook documenting every maintenance action, anomaly, and performance test. This historical data becomes invaluable for predictive maintenance and warranty claims. We’ve seen 23% longer system lifespans from operators who maintain detailed logs.” – Energy Storage Systems Architect

Conclusion: Mastering Your 24V LiFePO4 Battery System

Throughout this comprehensive guide, we’ve explored the critical aspects of 24V LiFePO4 battery operation – from fundamental voltage characteristics and charging protocols to advanced monitoring techniques and system integration.

You now understand how to properly interpret voltage readings (29.2V at full charge to 20V at cutoff), implement optimal charging strategies (28.8V absorption, 27.2V float), and extend battery lifespan through careful maintenance and monitoring.

The key takeaway? Proper voltage management is the foundation of LiFePO4 battery performance. By applying these principles – whether for solar storage, marine applications, or off-grid power – you’ll maximize both system efficiency and battery longevity. Remember to regularly check cell balance, maintain detailed performance logs, and stay updated on emerging LiFePO4 technologies.

Ready to optimize your system? Start by verifying your current battery voltage against our detailed chart, then schedule your first comprehensive capacity test. With this knowledge, you’re equipped to get the most from your 24V LiFePO4 investment for years to come.

Frequently Asked Questions About LiFePO4 24V Battery Voltage

What exactly does the 24V rating mean for a LiFePO4 battery?

The 24V rating refers to the nominal voltage, which is the average operating voltage during discharge. A fully charged 24V LiFePO4 battery actually measures 29.2V (3.65V per cell × 8 cells), while a depleted battery drops to 20V.

This differs from lead-acid batteries where nominal and actual voltages are closer. The wide operating range (20V-29.2V) is why proper voltage monitoring is crucial for LiFePO4 systems.

How often should I check my 24V LiFePO4 battery voltage?

For optimal maintenance:

- Daily checks if used in critical applications (medical, telecom)

- Weekly for solar systems using a monitoring system

- Monthly for RV/marine use with manual verification

Always check voltage at rest (no charge/discharge for 30+ minutes) for accurate readings. Implement automated monitoring like Victron BMV-712 for real-time tracking.

Why does my battery voltage drop significantly when I turn on appliances?

This voltage sag (1-3V drop) occurs due to internal resistance and is normal under load. For example, a 24V battery at 26.4V might drop to 24.1V when powering a 1000W inverter. Excessive sag (>3V at moderate loads) indicates:

- Undersized wiring (should be 2AWG or larger for 100A+ loads)

- Loose/corroded connections

- Aging battery with increased internal resistance

Can I use a lead-acid battery charger with my 24V LiFePO4 battery?

While possible, it’s not recommended without modification. Lead-acid chargers typically:

- Overcharge (up to 30V in equalization mode)

- Use improper float voltages (often 27.6V vs LiFePO4’s 27.2V)

- Lack temperature compensation disable

If you must use one, verify it won’t exceed 29V and disable any equalization modes. Better to invest in a LiFePO4-specific charger like the Victron Blue Smart IP65.

How does temperature affect my 24V LiFePO4 battery voltage readings?

Temperature impacts voltage significantly:

- Voltage increases ~0.3V per 10°C rise (but SOC remains unchanged)

- Below freezing, apparent voltage drops due to increased internal resistance

- BMS may restrict charging below 0°C to prevent damage

Always interpret voltages with temperature context – a 26V reading at 35°C equals ~25.4V at 15°C for the same SOC.

What voltage should I store my 24V LiFePO4 battery at for winter?

For long-term storage (3+ months):

- Charge to 50-60% SOC (26.4-26.8V)

- Store in cool (10-25°C), dry location

- Disconnect all loads and check voltage monthly

This storage voltage minimizes aging while preventing BMS shutdown from self-discharge. Never store fully charged or depleted.

Why do different brands show slightly different voltage charts?

Variations occur due to:

- Different cell chemistry formulations (some LiFePO4 variants have +0.05V per cell)

- BMS calibration differences

- Testing conditions (0.2C vs 0.5C discharge rates)

Always follow your specific battery manufacturer’s voltage chart, as a 0.5V difference can represent 20% SOC variation between brands.

How accurate is voltage for estimating state of charge?

Voltage-based SOC estimation has limitations:

- ±10% accuracy at rest (no load for 30+ minutes)

- ±15-20% under load due to voltage sag

- Nearly useless during charging

For precise SOC tracking, use coulomb counting (Ah in/out) with devices like the Victron SmartShunt, which maintains 99% accuracy when properly calibrated.