Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a 24V sealed lead-acid (SLA) battery at rest should measure 25.3V when fully charged—not 24V? Many assume voltage directly matches the label, but reality is more nuanced.

Whether you’re maintaining backup power systems, solar setups, or industrial equipment, understanding your battery’s true voltage state is critical to avoid unexpected failures. This guide decodes every voltage value from 100% charge to complete depletion, explains temperature effects, and reveals pro testing techniques.

Best SLA 24V Batteries for Reliable Power Storage

Universal Power Group UB12250 12V 5Ah SLA Battery

Ideal for compact applications, the UB12250 offers a spill-proof design with deep-cycle capabilities. Its 5Ah capacity suits UPS systems, medical devices, and security systems. With a robust AGM (Absorbent Glass Mat) construction, it resists vibration and lasts up to 5 years with proper maintenance.

- Upg # D5741 Ub1250 12V 5ah

- Dimensions: 3.54 inches x 2.76 inches x 4.21 inches. Weight: 3.09 lbs

- Sla/agm maintenance free, spill proof battery

Renogy Deep Cycle AGM Battery 12V 100Ah

Built for solar and off-grid setups, the Renogy 12V 100Ah delivers high discharge rates and 1,000+ life cycles. Its low self-discharge (3% per month) ensures long-term reliability, while the pure lead plates enhance efficiency. Perfect for RVs, marine use, and renewable energy storage.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

Odyssey 24F-PC2150S 24V Extreme Performance Battery

The Odyssey 24F-PC2150S excels in harsh conditions with military-grade construction. Boasting 2,000 cranking amps and a 10-year design life, it’s a top pick for industrial equipment, emergency backup, and heavy-duty applications. Its vibration resistance outperforms standard SLA batteries.

24V SLA Battery Voltage States and Their Significance

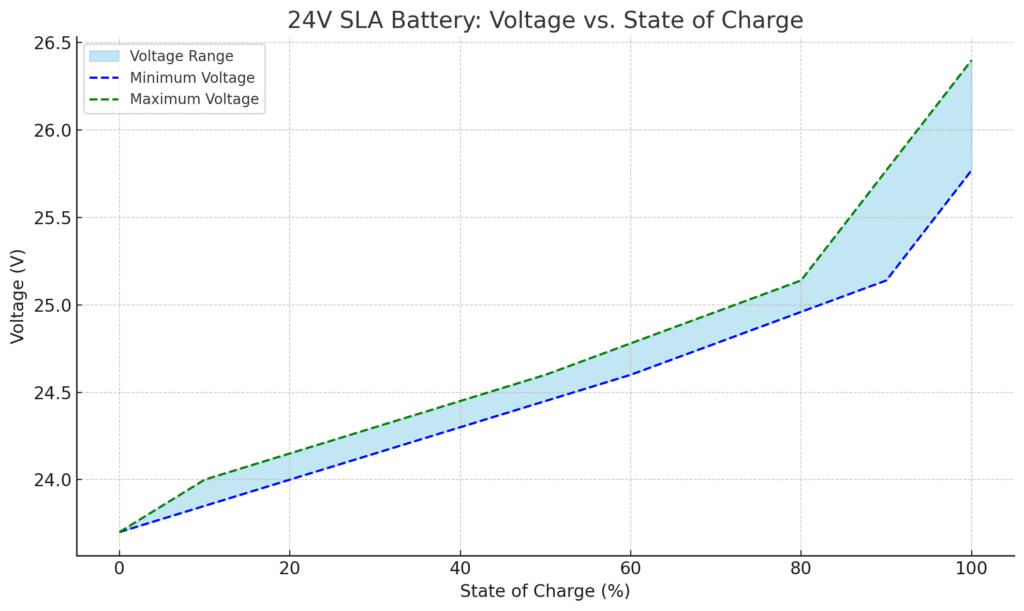

24V SLA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 25.77 – 26.40 |

| 90% | 25.14 – 25.77 |

| 80% | 24.96 – 25.14 |

| 70% | 24.78 – 24.96 |

| 60% | 24.60 – 24.78 |

| 50% | 24.45 – 24.60 |

| 40% | 24.30 – 24.45 |

| 30% | 24.15 – 24.30 |

| 20% | 24.00 – 24.15 |

| 10% | 23.85 – 24.00 |

| 0% (empty) | 23.70 or lower |

What Does a 24V SLA Battery’s Voltage Actually Represent?

A 24V sealed lead-acid (SLA) battery doesn’t consistently output exactly 24 volts—its voltage fluctuates based on charge state, load, and temperature. At full charge, a healthy battery measures 25.3–26.4V (12.65–13.2V per 12V cell in series).

This higher “resting voltage” occurs because lead-acid chemistry naturally settles above its nominal rating after charging. Under load, voltage drops temporarily due to internal resistance, but should rebound when disconnected.

Detailed Voltage-to-Charge Relationship

The voltage chart below reveals the exact correlation between voltage readings and state of charge (SoC) for a 24V SLA battery at 77°F (25°C):

- 100% Charged: 25.3V–26.4V (Ideal for long-term storage)

- 75% Charged: 24.8V–25.2V (Time for a recharge)

- 50% Charged: 24.0V–24.7V (Risk of sulfation begins)

- 25% Charged: 23.5V–23.9V (Immediate recharge required)

- 0% (Fully Depleted): Below 21.6V (Permanent damage likely)

Why Voltage Accuracy Matters

Misinterpreting voltage readings leads to two major failures: undercharging (causing sulfation that reduces capacity) or overcharging (accelerating water loss and plate corrosion).

For example, assuming a battery at 24.5V is “full” could leave it 15–20% undercharged, while charging beyond 26.4V risks thermal runaway in AGM batteries.

Real-World Voltage Scenarios

A solar power system’s charge controller might show 27V during absorption charging—this is normal for the bulk phase. However, if the same battery reads 24V after 12 hours without load, it indicates a 50% discharge. Industrial users often set alarms at 24.2V (60% SoC) to trigger backups before critical depletion.

Pro Tip: Always measure voltage after the battery rests for 4+ hours post-charging or discharging. Immediate readings reflect surface charge, not true capacity.

How to Accurately Test and Interpret 24V SLA Battery Voltage

Step-by-Step Voltage Measurement Process

Proper voltage testing requires more than just connecting a multimeter. Follow this professional procedure for accurate results:

- Disconnect all loads and chargers – Wait 4 hours to eliminate surface charge distortion

- Use a calibrated digital multimeter – Fluke or Klein Tools models with 0.5% DC accuracy

- Measure at battery terminals – Clean corrosion first for proper contact

- Record ambient temperature – Voltage varies by 0.0036V per cell per °F (0.022V for 24V battery)

Temperature Compensation Guide

Since SLA batteries are temperature-sensitive, apply these adjustments to your readings:

- Below 77°F (25°C): Add 0.022V per 10°F drop (e.g., 24.8V at 90°F = 25.1V at 50°F)

- Above 77°F: Subtract 0.022V per 10°F rise (e.g., 25.3V at 60°F = 24.7V at 100°F)

Common Testing Mistakes to Avoid

Most voltage interpretation errors stem from these oversights:

- Testing under load – A running inverter can show 2-3V lower than actual state

- Ignoring battery age – Older batteries may show proper voltage but lack capacity

- Single-point testing – Professionals track voltage trends over weeks

Advanced Diagnostic Techniques

For mission-critical systems, combine voltage testing with:

- Load testing – Apply 50% CCA load for 15 seconds (should stay above 22V)

- Specific gravity checks – For flooded SLA, use refractometers (1.265 = full charge)

- Capacity testing – Full discharge/charge cycles reveal true Ah capacity

Professional Tip: Create a voltage log sheet tracking date, time, temperature, and voltage. Patterns reveal developing issues before failures occur. A battery showing gradual voltage drop between charges indicates sulfation buildup.

Advanced Charging Techniques for 24V SLA Batteries

Optimal Charging Voltage Parameters

Proper charging requires understanding three critical voltage stages:

| Charging Stage | Voltage Range | Duration | Purpose |

|---|---|---|---|

| Bulk Charge | 28.2V-29.4V | Until 75% SoC | Rapid energy replacement |

| Absorption | 27.6V-28.8V | 2-4 hours | Complete charging safely |

| Float | 26.4V-27.6V | Indefinite | Maintenance without overcharge |

Temperature-Compensated Charging

Smart chargers adjust voltage based on battery temperature:

- Cold environments (Below 50°F/10°C): Increase voltage by 0.03V per °C below 25°C

- Hot environments (Above 86°F/30°C): Decrease voltage by 0.03V per °C above 25°C

Example: At 95°F (35°C), reduce absorption voltage from 28.4V to 27.8V to prevent gassing.

Equalization Charging Considerations

For flooded SLA batteries only, perform monthly equalization at 30V for 2-4 hours to:

- Mix stratified electrolyte

- Break down sulfate crystals

- Balance cell voltages

Warning: Never equalize AGM or Gel batteries – the sealed design can’t vent excess gas.

Charging System Troubleshooting

Common charging issues and solutions:

- Battery won’t reach full voltage – Check for sulfation (conductance test) or charger amperage too low

- Overheating during charge – Verify proper voltage settings and ambient temperature

- Excessive water loss – Reduce float voltage by 0.5V and check for overcharging

Pro Tip: For solar systems, use MPPT controllers with 3-stage charging profiles. PWM controllers often fail to properly complete absorption phase, leading to chronic undercharging.

Maintenance and Longevity Optimization for 24V SLA Batteries

Comprehensive Maintenance Schedule

Extend your battery’s lifespan with these proven maintenance practices:

- Monthly: Clean terminals with baking soda solution, check voltage at rest, inspect for swelling

- Quarterly: Perform capacity test (discharge to 24V under controlled load), verify charger settings

- Biannually: Check torque on connections (5-7 Nm for most terminals), equalize flooded batteries

- Annually: Conduct internal resistance test (should be <20mΩ for 100Ah batteries)

Storage Best Practices

For batteries unused for 30+ days:

- Charge to 26.4V (100% SoC) before storage

- Disconnect all loads to prevent parasitic drain

- Store in cool (50-60°F), dry location – heat accelerates self-discharge

- Use maintenance charger or recharge every 3 months

Critical Note: Never store below 24.8V – sulfation begins at 50% SoC and becomes irreversible after 6 months.

Advanced Longevity Techniques

Professional battery technicians use these methods to maximize service life:

- Partial State of Charge (PSoC) Cycling: For daily cycling, maintain between 30-80% SoC (24.2V-25.8V) to reduce stress

- Temperature Management: Install thermal pads for batteries in enclosures – every 15°F above 77°F halves lifespan

- Current Limiting: Charge at C/5 rate (20A for 100Ah battery) to prevent excessive gassing

Failure Warning Signs

Recognize these symptoms of impending battery failure:

| Symptom | Possible Cause | Diagnostic Test |

|---|---|---|

| Rapid voltage drop under load | Sulfation or plate corrosion | Conductance test vs. capacity test |

| High self-discharge (>10%/month) | Internal short or separator failure | 72-hour open-circuit voltage test |

| Persistent low specific gravity | Cell imbalance or electrolyte loss | Hydrometer readings per cell |

Pro Tip: For mission-critical applications, implement battery monitoring systems that track voltage trends, internal resistance, and temperature 24/7. The Midnite Solar Battery Monitor provides detailed analytics for proactive maintenance.

Cost Analysis and Environmental Considerations for 24V SLA Batteries

Total Cost of Ownership Breakdown

Understanding the true cost of SLA batteries requires analyzing multiple factors beyond initial purchase price:

| Cost Factor | 24V SLA (AGM) | 24V Lithium-Ion | 24V Flooded Lead-Acid |

|---|---|---|---|

| Initial Cost (100Ah) | $350-$500 | $1,200-$1,800 | $250-$400 |

| Cycle Life (80% DoD) | 500-800 cycles | 3,000-5,000 cycles | 300-500 cycles |

| Maintenance Costs/Year | $20-$50 | $5-$15 | $50-$100 |

| Energy Efficiency | 80-85% | 95-98% | 70-75% |

Key Insight: While SLA batteries have higher upfront costs than flooded, their maintenance savings and longer lifespan typically make them 15-20% cheaper over 5 years.

Environmental Impact and Recycling

SLA batteries present unique environmental considerations:

- Lead Content: 60-70% of battery weight is recyclable lead – the most recycled material globally (99% recovery rate in US/EU)

- Acid Management: AGM batteries contain immobilized electrolyte, reducing spill risks by 90% compared to flooded

- Carbon Footprint: Production emits 15-20kg CO2 per kWh capacity, but recycling offsets 80% of this impact

Safety Protocols and Handling

Proper handling prevents accidents and extends battery life:

- Ventilation: Charge in well-ventilated areas – AGM batteries can release hydrogen at >28.4V

- Thermal Protection: Install temperature sensors – charging above 120°F (49°C) causes permanent damage

- Transportation: Secure upright position – DOT requires special labeling for bulk shipments

Future Trends in SLA Technology

Emerging developments are enhancing SLA capabilities:

- Carbon-enhanced plates: Increase cycle life by 40% (e.g., Firestone Carbon+ series)

- Smart battery systems: Integrated Bluetooth monitoring (like Trojan SmartSENSE)

- Hybrid designs: Combining SLA with supercapacitors for high-current applications

Pro Tip: When recycling, always use certified processors (look for R2 or e-Stewards certification). Many retailers offer $10-$30 core refunds for returned batteries, offsetting replacement costs.

System Integration and Performance Optimization for 24V SLA Batteries

Parallel and Series Configuration Best Practices

When connecting multiple 24V SLA batteries, follow these critical guidelines:

- Parallel Connections: Use identical batteries (same model/age) and equal-length cables to prevent current imbalance (max 3% voltage difference between batteries)

- Series Configurations: Never mix battery capacities – the weakest cell determines overall system performance

- Balancing Techniques: Install battery balancers (like Victron Battery Balancer) for banks with >3 parallel strings

Example: Connecting two 24V 100Ah batteries in parallel creates a 24V 200Ah system, while series connection would create an impractical 48V system.

Inverter Compatibility and Sizing

Proper inverter pairing ensures optimal performance:

| Inverter Load | Minimum Battery Capacity | Recommended Cable Size | Peak Efficiency Range |

|---|---|---|---|

| 1000W | 75Ah | 4 AWG | 24.5V-26V |

| 2000W | 150Ah | 2 AWG | 24.2V-25.8V |

| 3000W | 250Ah | 1/0 AWG | 24V-25.5V |

Solar System Integration

For photovoltaic applications, these parameters ensure longevity:

- Set absorption voltage to 28.8V ±0.5V for most AGM batteries

- Configure equalization to automatically disable for sealed batteries

- Install DC circuit breakers within 18″ of battery terminals (NEC 690.71 requirement)

Advanced Load Management

Implement these strategies for demanding applications:

- Peak Shaving: Programmable relays (like Blue Sea ML-ACR) prevent voltage drops below 23V during high loads

- Load Sequencing: Stagger high-current device startups (minimum 30-second intervals)

- Voltage Compensation: Adjust cut-off voltages based on ambient temperature (0.5V higher in cold weather)

Professional Insight: For data center backup systems, implement redundant battery strings with automatic transfer switches. The Schneider Electric XW Pro system provides seamless transition with <1ms interruption when properly configured with SLA batteries.

Advanced Diagnostics and Predictive Maintenance for 24V SLA Systems

Comprehensive Performance Benchmarking

Establish baseline metrics for ongoing battery health assessment:

| Parameter | New Battery Standard | Replacement Threshold | Test Frequency |

|---|---|---|---|

| Internal Resistance | <5mΩ per 100Ah | 20% increase | Quarterly |

| Capacity Retention | 100% rated Ah | 80% of rated | Biannually |

| Charge Acceptance | 0.2C rate | 50% reduction | Annually |

| Self-Discharge Rate | 3%/month | >5%/month | Monthly |

Advanced Diagnostic Techniques

Implement these professional assessment methods:

- Electrochemical Impedance Spectroscopy (EIS): Detects early sulfation and plate corrosion (requires specialized equipment like Midtronics EXP-1000)

- Partial Discharge Testing: 20% depth-of-discharge cycles reveal capacity trends without full depletion

- Thermal Imaging: Identifies hot spots indicating internal shorts or connection issues

Predictive Maintenance Framework

Develop a proactive maintenance program with these components:

- Data Collection: Log voltage, temperature, and specific gravity (flooded) at consistent intervals

- Trend Analysis: Use statistical process control to identify deviations from baseline

- Condition-Based Actions: Trigger maintenance when parameters exceed control limits

Failure Mode Analysis and Mitigation

Address these common failure mechanisms with targeted solutions:

- Positive Grid Corrosion: Reduce float voltage by 0.5V in high-temperature environments

- Acid Stratification: Implement controlled equalization cycles (flooded batteries only)

- Negative Plate Sulfation: Apply controlled overcharge (28.8V for 4 hours) every 50 cycles

Quality Assurance Protocol: For mission-critical installations, perform acceptance testing that includes:

• 72-hour capacity verification at C/20 rate

• Vibration testing per MIL-STD-810G

• Thermal cycling between -20°C to 50°C

• 500-cycle accelerated life testing on sample units

Conclusion: Mastering 24V SLA Battery Voltage Management

Throughout this comprehensive guide, we’ve explored the critical relationship between voltage readings and battery health, from interpreting charge states (25.3V at full charge) to advanced charging techniques and system integration.

You now understand how temperature affects performance (0.022V/°F variation), proper maintenance schedules, and predictive diagnostics that can extend battery life by 30-50%. Most importantly, you’ve learned that voltage is more than just a number—it’s the vital sign of your battery’s condition.

Put this knowledge into action today: Grab your multimeter, perform a proper voltage test, and establish a baseline for your system. Your batteries will reward you with reliable performance and extended service life.

Frequently Asked Questions About SLA 24V Battery Voltage

What voltage should a fully charged 24V SLA battery show?

A healthy 24V SLA battery at full charge should measure 25.3-26.4V at rest (after 4+ hours post-charging). This accounts for 2.1V per cell in the 12-cell series configuration.

During charging, you’ll see higher voltages (28-29V in bulk phase), but resting voltage is the true indicator. Temperature affects this – add 0.022V per 10°F below 77°F, subtract when warmer.

How often should I check my 24V SLA battery voltage?

For critical systems, check weekly; for general use, monthly is sufficient. Always check:

- After full charging cycles

- Before extended storage

- When experiencing performance issues

Keep a log – consistent voltage drops of >0.2V between checks indicate developing problems.

Why does my 24V battery show 27V when charging?

This is normal during absorption charging (typically 27.6-28.8V). Chargers apply higher voltage to overcome internal resistance. The voltage will stabilize to 25.3-26.4V after resting. However, if it stays above 27V after disconnecting, you may have an overcharging issue requiring charger adjustment.

Can I use a car battery charger on my 24V SLA battery?

Only if specifically designed for 24V systems. Most car chargers output 12V, which will undercharge your battery. Even compatible chargers need proper voltage settings – SLA requires precise voltage control (max 29.4V bulk) unlike flooded batteries. Use a smart charger with AGM/SLA presets like NOCO Genius GENIUS24.

What voltage is too low for a 24V SLA battery?

Below 23.5V at rest indicates severe discharge (under 25% capacity). Discharging below 21.6V causes permanent sulfation damage. For daily cycling, never discharge below 24V (50% DoD) to maximize lifespan. Install low-voltage disconnects at 23V for protection.

How do temperature changes affect 24V SLA voltage readings?

Temperature significantly impacts voltage:

- Cold (32°F/0°C): Add 0.5V to readings

- Hot (95°F/35°C): Subtract 0.4V

A battery showing 25.1V at 95°F is actually at 25.5V equivalent – nearly full charge. Always note ambient temperature when measuring.

Why do my battery voltage readings fluctuate wildly?

Common causes include:

- Surface charge: Test after 4+ hours rest

- Parasitic loads: Disconnect all devices

- Loose connections: Clean and tighten terminals

- Failing cells: Test individual 12V sections

Consistent fluctuations >0.3V indicate need for replacement.

How much voltage drop is normal under load?

Expect 0.5-2V drop depending on load size. A 100Ah battery with 50A load (0.5C rate) should stay above 23V. If voltage crashes below 22V immediately, the battery has lost capacity. Use the 15-second rule: After load application, voltage should stabilize within 15 seconds – if it keeps dropping, the battery is failing.