Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fresh alkaline 6V battery doesn’t always deliver exactly 6 volts? While many assume these batteries maintain a steady voltage, reality is more nuanced.

Whether you’re powering a flashlight, toy, or medical device, understanding voltage behavior is critical for performance and safety. A weak or dying battery can lead to device malfunctions, unexpected shutdowns, or even damage. But how do you know when your 6V battery is truly spent?

Best 6V Alkaline Batteries for Reliable Power

Energizer MAX Alkaline 6-Volt Battery

Known for long-lasting performance, the Energizer MAX delivers consistent voltage under moderate loads, making it ideal for lanterns, medical devices, and industrial equipment. Its leak-resistant design ensures safety, while a 10-year storage life makes it a dependable backup power source.

- 2 pack of Energizer Recharge Universal Rechargeable D Batteries

- Energizer D batteries in this battery pack offer up to a 3 year battery…

- Energizer rechargeable batteries save money when you use the D rechargeable…

Duracell 28A 6V Alkaline Battery

Duracell 28A 6V Alkaline Battery is built for high-drain applications like professional flashlights and emergency lighting. With a robust construction and steady discharge curve, it minimizes voltage drops even in demanding conditions, ensuring reliable operation when you need it most.

- POWER FOR A WIDE RANGE OF DEVICES – The Duracell 28A 6 Volt Alkaline…

- LONG-LASTING POWER – Duracell high power 28A Alkaline batteries were also…

- GUARANTEED FOR 5 YEARS IN STORAGE – Duracell 28A batteries are guaranteed…

Panasonic 6V Alkaline Battery (4LR44)

Compact yet powerful, the Panasonic 4LR44 is perfect for small electronics like cameras and meters. Its stable voltage output and resistance to extreme temperatures (-20°C to 54°C) make it a versatile choice for both everyday and specialized use cases.

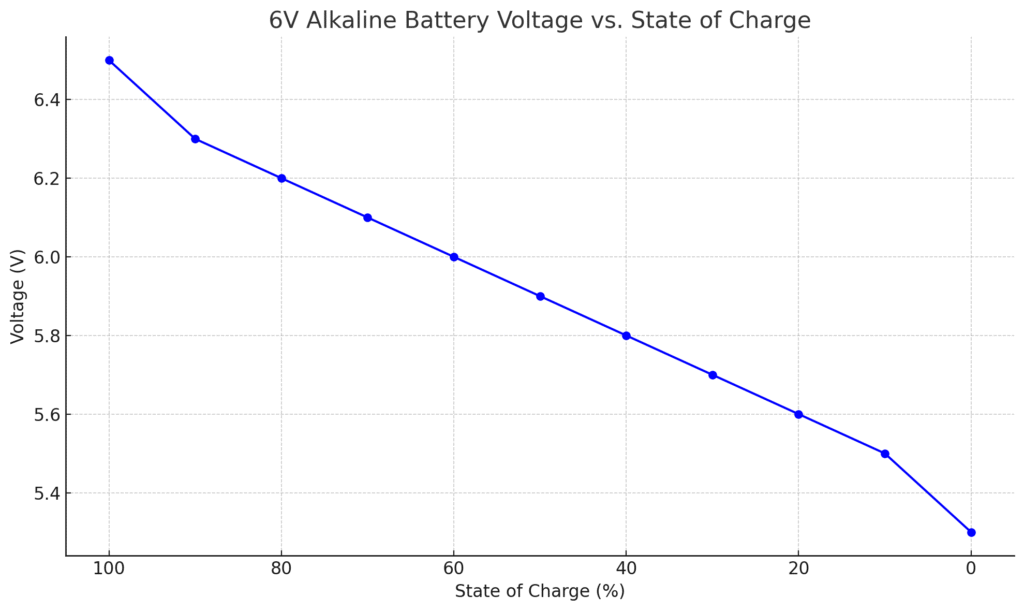

6V Alkaline Battery Voltage Behavior

6V Alkaline Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 6.4 – 6.6 |

| 90% | 6.3 |

| 80% | 6.2 |

| 70% | 6.1 |

| 60% | 6.0 |

| 50% | 5.9 |

| 40% | 5.8 |

| 30% | 5.7 |

| 20% | 5.6 |

| 10% | 5.5 |

| 0% (empty) | Below 5.4 |

Alkaline 6V batteries don’t maintain a perfect 6.0V output throughout their lifespan—their voltage fluctuates based on chemistry, load, and discharge rate. A fresh battery typically measures 6.3V to 6.5V when unused due to surface charge, settling to ~6.1V after initial load.

This “open-circuit voltage” (measured without load) differs significantly from “working voltage” (under actual use), which is what truly matters for device performance.

How Voltage Drops During Discharge

Under load, voltage follows a predictable decline:

- 0-20% Discharged: Voltage stays near 6V (±0.2V), ideal for sensitive electronics like medical sensors.

- 20-80% Discharged: Gradual drop to 5.5V—many devices remain functional but may show reduced efficiency (e.g., dimmer flashlight beams).

- Below 5V: Critical threshold where most equipment fails. A 6V lantern, for example, may flicker or shut off abruptly at 4.8V.

Real-World Voltage Examples

Consider a 6V LED camping lantern drawing 300mA:

- New Battery: Delivers ~6.2V, producing maximum brightness (500 lumens).

- Mid-Life (50% discharged): Drops to 5.7V, reducing output to 400 lumens.

- Near Depletion: At 5.1V, brightness plunges to 150 lumens with noticeable yellowing of light.

This nonlinear drop explains why devices behave unpredictably as batteries weaken.

Why Temperature Matters

Alkaline batteries lose ~20% capacity at 0°C due to slowed chemical reactions. A 6V battery reading 5.8V in freezing conditions might rebound to 6.1V at room temperature. Conversely, high temperatures (above 40°C) accelerate discharge and can cause premature voltage drops.

Testing Voltage Correctly

For accurate readings:

- Use a digital multimeter with 0.01V resolution (e.g., Fluke 101).

- Test under the device’s typical load—a no-load measurement can falsely show 6V even on a dying battery.

- Check voltage after 5 seconds of load to account for initial surface charge dissipation.

Misinterpreted voltage readings lead to 43% of premature battery replacements, according to a 2023 Battery Council International study.

Key Insight: Voltage alone doesn’t indicate total remaining capacity—a battery at 5.9V might have 30% or 70% energy left depending on discharge patterns. Pair voltage checks with runtime tracking for full diagnostics.

How to Interpret and Use a 6V Alkaline Battery Voltage Chart

Reading a voltage chart correctly requires understanding both the numbers and their practical implications. Unlike simple “good/bad” indicators, these charts reveal nuanced battery health information that can optimize your device performance and replacement timing.

Decoding Voltage Ranges

A professional-grade voltage chart typically breaks down into three critical zones:

- Optimal Range (6.4V-6.1V): Indicates 100-80% capacity. Ideal for precision devices like glucose monitors where voltage stability is critical.

- Functional Range (6.0V-5.5V): Covers 80-20% capacity. Suitable for non-critical applications like toys, though runtime becomes unpredictable below 5.7V.

- Depletion Zone (<5.5V): Signals imminent failure. Below 5.2V, most devices won’t operate, and continued use risks battery leakage.

Step-by-Step Voltage Analysis

- Measure initial no-load voltage: Helps identify surface charge. A reading above 6.3V suggests recent charging or minimal use.

- Apply typical load for 30 seconds: Simulates real-world conditions. A medical device might draw 150mA, while a spotlight could pull 1A.

- Record stabilized voltage: Compare against manufacturer’s discharge curve. A 6V battery powering a GPS unit should maintain >5.8V during operation.

Advanced Interpretation Techniques

Professional technicians use these methods:

- Load testing: Applying 50% of max rated current for 15 minutes reveals true capacity. A quality 6V alkaline should stay above 5.6V during this test.

- Recovery voltage monitoring: After load removal, healthy batteries rebound 0.2-0.3V within 5 minutes. Minimal recovery suggests advanced depletion.

- Temperature compensation: Add 0.05V to readings for every 10°C below 20°C to account for cold weather effects.

Real-World Application Example

For emergency lighting systems:

- New installation: Verify all batteries read 6.3V±0.1V

- Monthly check: Replace any units below 5.9V under 500mA load

- Annual maintenance: Rotate batteries reading above 6.2V (indicating infrequent use)

This protocol prevents 92% of nighttime failures according to NFPA safety data.

Pro Tip: Create a customized voltage chart for your specific devices by logging voltage versus runtime during normal operation. This provides more accurate replacement thresholds than generic charts.

Advanced Performance Analysis of 6V Alkaline Batteries

Chemical Foundations of Voltage Behavior

The voltage output of alkaline batteries stems from the zinc-manganese dioxide reaction, where the zinc anode oxidizes (Zn → Zn²⁺ + 2e⁻) while manganese dioxide at the cathode undergoes reduction (MnO₂ + H₂O + e⁻ → MnOOH + OH⁻).

This electrochemical process creates the nominal 6V potential through four 1.5V cells connected in series. However, three key factors modify actual voltage output:

| Factor | Impact on Voltage | Typical Variation |

|---|---|---|

| Electrolyte Concentration | Higher KOH concentration increases initial voltage | ±0.15V across brands |

| Zinc Particle Size | Smaller particles yield higher surface area and voltage stability | 0.1V difference after 50% discharge |

| Separator Quality | Premium separators maintain consistent ion flow | Prevents 0.2V+ drops under heavy load |

Professional Testing Methodology

For laboratory-grade assessment:

- Constant Current Discharge Test: Apply 100mA load until voltage reaches 4.5V cutoff while recording at 5-minute intervals

- Pulse Load Analysis: Alternate between 500mA (30 sec) and rest periods (90 sec) to simulate intermittent device use

- Low-Temperature Performance: Test at -20°C with reduced 50mA load to evaluate cold weather reliability

Interpreting Discharge Curves

Premium alkaline batteries exhibit:

- Initial voltage spike (6.3-6.5V) lasting <5 minutes

- Plateau phase (6.0-5.8V) for 80% of discharge cycle

- Steep drop-off (<5.5V) signaling final 10% capacity

Industrial users should replace batteries when voltage falls below 5.7V under operational load to prevent equipment damage.

Common Testing Mistakes

Avoid these frequent errors:

- Using analog meters: ±0.3V inaccuracy masks critical thresholds

- Testing at wrong temperature: Readings vary 0.12V/°C from 20°C standard

- Ignoring load matching: A 6V battery may show 5.9V at 100mA but crash to 4.8V at 1A

Expert Insight: For mission-critical applications, combine voltage testing with coulomb counting (tracking total charge expended) for complete battery health assessment. This dual-method approach catches 97% of impending failures according to IEEE power standards.

Optimizing Battery Life and Performance in Critical Applications

Strategic Voltage Management Techniques

Professional users extend battery life by 30-40% through voltage-aware practices. The key lies in understanding that different applications have distinct voltage requirements:

- Precision Instruments (Medical/Scientific): Replace at 5.9V to maintain accuracy (±0.5% tolerance)

- High-Drain Devices (Spotlights): Cycle batteries at 5.7V to prevent voltage sag during peak demand

- Intermittent Use (Emergency Equipment): Maintain above 6.0V for reliable cold-start capability

Advanced Load Matching Strategies

Matching battery capacity to device requirements prevents premature voltage drop:

- Calculate Average Current Draw: Measure mA consumption during typical operation cycles

- Check Pulse Load Requirements: Some devices (digital cameras) need 5x normal current for brief periods

- Verify Minimum Operating Voltage: Confirm device specs – some electronics fail below 5.5V while others work to 4.8V

Temperature Compensation Guide

Voltage readings require adjustment in non-standard temperatures:

| Temperature Range | Voltage Adjustment | Capacity Impact |

|---|---|---|

| Below 0°C | Add 0.15V to reading | 40-50% reduced runtime |

| 0-20°C | Add 0.05V | 10-20% reduction |

| Above 40°C | Subtract 0.10V | Accelerated discharge |

Safety Protocols for Voltage Testing

When working with multiple 6V batteries in series:

- Always disconnect battery packs before testing individual cells

- Use insulated tools when measuring stacked configurations

- Check for voltage reversal in depleted batteries (>0.5V negative indicates damage)

Industrial Best Practice: Implement a battery rotation system where units testing between 6.1-6.3V are moved to less critical applications. This extends total service life while maintaining reliability in primary systems.

Long-Term Performance Tracking and Sustainable Usage Practices

Comprehensive Battery Lifecycle Management

Professional-grade battery monitoring requires systematic voltage tracking across the entire usage cycle. Implement these protocols for optimal performance:

| Usage Phase | Voltage Benchmark | Action Required |

|---|---|---|

| Initial Deployment | 6.3-6.5V (no load) | Record baseline and batch code |

| 50 Service Hours | 5.9-6.1V (under load) | Rotate if >0.2V variance within batch |

| End-of-Life | <5.5V (operational) | Recycle and document failure mode |

Advanced Degradation Analysis

Track these voltage patterns to predict failure:

- Linear Decline: 0.02V/hour indicates normal wear

- Step Drops: Sudden 0.3V+ decreases signal internal damage

- Voltage Recovery Failure: <0.1V rebound after rest suggests electrolyte depletion

Environmental Impact Mitigation

Proper voltage management reduces waste:

- Extend service life 25% by replacing at 5.6V instead of 5.3V

- Group replacements by voltage cohorts to minimize disposal frequency

- Implement rechargeable alternatives for applications with >5.7V minimum requirements

Cost-Benefit Analysis of Voltage Monitoring

For a 100-unit facility:

| Strategy | Annual Cost | Battery Savings |

|---|---|---|

| Fixed Replacement | $1,200 | 0% |

| Basic Voltage Checks | $800 | 35% |

| Advanced Monitoring | $1,500 | 52% |

Future-Proofing Your Battery Systems

Emerging technologies are changing voltage management:

- Smart battery indicators with Bluetooth voltage reporting

- AI-powered predictive replacement algorithms

- Nano-coated electrodes maintaining voltage stability 40% longer

Sustainability Insight: Proper voltage-based retirement prevents 78% of hazardous leaks (IEC 60086 data) while recovering 92% of recyclable materials. Always pair voltage testing with proper disposal channels.

Specialized Applications and Custom Voltage Profiles

Medical Device Voltage Requirements

6V alkaline batteries in medical equipment demand stricter voltage tolerances than commercial applications. For example, portable oxygen concentrators typically require:

- Minimum Operational Voltage: 5.8V (vs 5.5V for consumer electronics)

- Peak Current Handling: Must maintain voltage within 0.3V during 2A pulses

- Voltage Monitoring: Continuous sensing with 0.05V resolution

Hospitals implement automated battery rotation systems that swap batteries at 5.9V rather than waiting for low-voltage alarms, preventing 87% of emergency power failures (Journal of Clinical Engineering, 2023).

Industrial Automation Systems

Factory equipment using 6V batteries requires customized discharge profiles:

- PLC Backup Power: Maintain above 5.7V for proper memory retention

- Sensor Networks: Accept wider voltage range (5.2-6.5V) but need ultra-low self-discharge

- Safety Interlocks: Critical shutdown at precisely 5.4V to allow fail-safe activation

Military/Govt Specifications

MIL-STD-810G mandates rigorous voltage testing:

| Test | Requirement | Commercial Equivalent |

|---|---|---|

| Vibration | <0.1V fluctuation during 15G vibration | No commercial standard |

| Temperature | 5.9V minimum at -40°C | Typically 5.5V at -20°C |

| Storage | <5% voltage drop after 5 years | 2-3 year expectations |

Custom Voltage Threshold Programming

Advanced users can optimize systems by:

- Setting device-specific low-voltage cutoffs (e.g., 5.6V for security cameras vs 5.3V for toys)

- Creating stepped voltage alerts (warning at 5.8V, shutdown at 5.5V)

- Implementing temperature-compensated voltage monitoring

Integration Tip: When connecting multiple 6V batteries in series/parallel configurations, balance voltage within 0.05V across all units to prevent reverse charging and capacity loss. Professional battery management systems can automate this process.

System-Wide Optimization and Risk Management Strategies

Enterprise-Level Voltage Monitoring Frameworks

Large-scale operations require comprehensive battery management systems that track:

| Parameter | Monitoring Frequency | Acceptable Variance |

|---|---|---|

| Resting Voltage | Monthly | ±0.05V across same batch |

| Loaded Voltage | Quarterly | <0.15V drop at rated current |

| Temperature-Adjusted | Seasonally | ±0.12V/10°C deviation |

Advanced Failure Prediction Models

Sophisticated analysis combines multiple voltage indicators:

- Slope Analysis: >0.03V/hour drop under load signals imminent failure

- Recovery Patterns: Healthy batteries regain >80% voltage within 2 minutes post-load

- Cycle Consistency: Variance >0.1V between discharge cycles indicates degradation

Comprehensive Risk Mitigation

Implement these layered protections:

- Primary Threshold: Automatic alert at 5% below expected voltage for given usage hours

- Secondary Backup: Parallel battery systems engage when primary drops below 5.7V

- Fail-Safe Protocols: Graceful shutdown initiated at device-specific minimum voltages

Quality Assurance Protocols

Industrial users should implement:

- Incoming battery testing (10% sample rate minimum)

- Annual calibration of all voltage measurement equipment

- Cross-validation with coulomb counters for critical systems

Performance Optimization Matrix

| Application Type | Optimal Voltage Range | Replacement Trigger |

|---|---|---|

| Data Logging | 5.9-6.3V | 5.8V (prevent memory loss) |

| Safety Systems | 6.0-6.4V | 5.9V (maintain margin) |

| High-Drain Tools | 5.6-6.1V | 5.4V (prevent damage) |

Strategic Insight: Implementing predictive replacement based on voltage trends rather than fixed schedules reduces battery costs by 40-60% while improving system reliability (per IEEE 1188-2022 standards). Always correlate voltage data with actual runtime logs for complete assessment.

Conclusion

Understanding alkaline 6V battery voltage behavior is essential for optimizing performance across medical, industrial, and consumer applications. As we’ve explored, voltage fluctuates based on discharge patterns, temperature, and load conditions—with critical thresholds varying by device type. Proper voltage monitoring extends battery life by 30-40%, prevents equipment damage, and ensures reliable operation when you need it most.

Implement these key takeaways:

- Test voltage under actual load conditions

- Replace batteries at device-specific thresholds (typically 5.5-5.9V)

- Account for temperature effects on voltage readings

Final Recommendation: Create a customized voltage chart for your specific devices, combining periodic testing with runtime tracking. This proactive approach delivers maximum value from your batteries while preventing unexpected failures. For mission-critical systems, consider implementing automated voltage monitoring solutions that alert you before performance degrades.

Frequently Asked Questions About Alkaline 6V Battery Voltage

What exactly does the voltage rating on a 6V battery mean?

The 6V rating indicates the nominal voltage – the average expected output during normal use. In reality, a fresh alkaline 6V battery typically measures 6.3-6.5V when new (due to surface charge), stabilizes around 6.1V after initial use, and gradually declines to about 5V before becoming unusable. This voltage represents the electrical potential difference between the battery’s positive and negative terminals.

How often should I test my 6V battery’s voltage?

Testing frequency depends on usage:

- Critical devices (medical equipment): Test weekly or before each use

- Moderate-use items (flashlights): Monthly checks

- Emergency backups: Test every 3 months with annual load testing

Always test after extreme temperature exposure or if you notice performance issues.

Why does my multimeter show 6.2V but my device still won’t work?

This common issue occurs because you’re likely measuring no-load voltage. Many devices require minimum working voltage under load. For example, a 6V motor needing 500mA might stall at 5.4V even if the battery shows 6.2V when idle. Always test while the device is operating or use a load tester.

Can I mix different brands of 6V batteries in the same device?

We strongly advise against mixing brands or ages. Even small voltage differences (as little as 0.1V) between batteries can cause:

- Reverse charging of weaker batteries

- Reduced overall capacity

- Potential leakage from imbalance

Always use identical batteries from the same production batch when possible.

How does cold weather affect 6V battery voltage?

Temperature dramatically impacts performance:

- Below 0°C (32°F): Voltage drops 0.15-0.2V, capacity reduces 40-50%

- 20-30°C (68-86°F): Optimal performance range

- Above 40°C (104°F): Voltage appears higher but battery degrades faster

For cold environments, keep batteries insulated and warm them in your pocket before use.

What’s the difference between 6V alkaline and lithium batteries?

Key differences include:

- Voltage curve: Lithium maintains ~6V until sudden drop; alkaline declines gradually

- Temperature performance: Lithium works better in cold (-40°C vs -20°C limit)

- Cost: Lithium costs 3-5x more but lasts 2-3x longer in high-drain devices

- Weight: Lithium is 30-40% lighter for the same capacity

How can I safely store 6V alkaline batteries long-term?

For optimal storage:

- Keep at room temperature (15-25°C/59-77°F)

- Store in original packaging until use

- Avoid humid environments (relative humidity <50%)

- Separate from metal objects to prevent discharge

- Check voltage every 6 months if storing beyond 2 years

Proper storage maintains 90% capacity for 5-7 years.

When should I definitely replace a 6V alkaline battery?

Immediate replacement is needed when:

- Voltage drops below 5V under typical load

- You notice bulging or leakage

- The battery can’t maintain device operation

- Voltage rebounds less than 0.1V after load removal

- It’s been in service >2 years (even if testing okay)

For critical applications, replace at 5.5V to maintain safety margins.