Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 6V lead-acid battery should read 6.37V, not 6.0V? Many users assume their battery is healthy at 6V, but voltage tells a deeper story about charge state, sulfation risks, and lifespan. Whether you’re maintaining golf carts, solar systems, or vintage electronics, misreading voltage can lead to premature failure or dangerous overcharging.

In this guide, you’ll unlock a professional-grade understanding of 6V lead-acid battery voltage. We’ll decode resting vs. loaded voltages, reveal why temperature changes matter, and provide a step-by-step voltage chart for charging and discharging.

Best 6V Lead-Acid Batteries for Reliable Power

Trojan T-605 6V Deep Cycle Battery

Ideal for solar setups and golf carts, the Trojan T-605 offers a robust 225Ah capacity and durable lead-calcium construction. Its thick plates resist sulfation, ensuring 1,200+ cycles at 50% depth of discharge. Perfect for users needing long-term reliability in off-grid applications.

Universal Power Group UBGC2 6V AGM Battery

This maintenance-free AGM battery (model UBGC2) delivers 200Ah with spill-proof safety, making it great for RVs and medical equipment. Its high discharge rate and vibration resistance outperform flooded batteries, and it recharges 30% faster than standard lead-acid models.

- UPG # D5736 UB6120 6V 12Ah

- Dimensions: 5.94 inches x 1.94 inches x 3.94 inches. Weight: 4.18 Lbs

- SLA/AGM maintenance free, spill proof battery

VMAXTANKS VMAX SLR125 6V AGM Deep Cycle

With a military-grade design, the SLR125 handles extreme temperatures and deep discharges (up to 400 cycles at 80% DoD). Its 125Ah capacity and low self-discharge (3% monthly) suit marine and backup power systems where durability is non-negotiable.

- 12 Volt 125Ah group 31 AGM deep cycle heavy duty battery

- 8mm hex screw in terminals (included,for use with ring terminals) ….

- Float service life span of 8 to 10 years

6V Lead-Acid Battery Voltage States

A 6V lead-acid battery’s voltage isn’t static—it fluctuates based on charge level, temperature, and load conditions. Unlike what many assume, “6V” is just the nominal rating; actual voltage ranges from 4.5V (fully discharged) to 7.2V (absorption charging). Knowing these variations helps prevent undercharging or overcharging, both of which degrade battery life.

6V Lead-Acid Battery Voltage vs. State of Charge

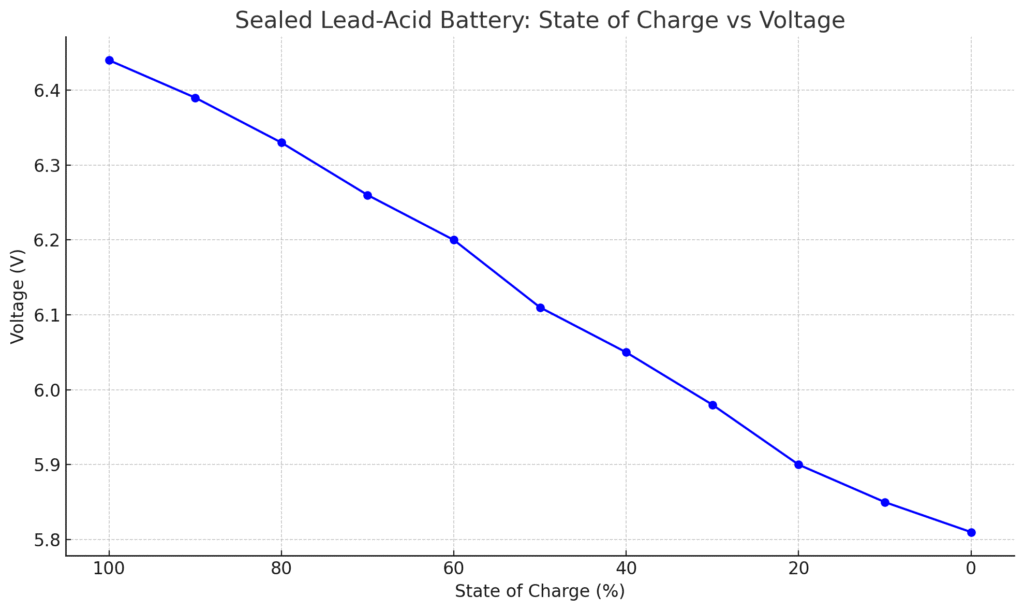

Sealed Lead-Acid (SLA/VRLA, AGM & Gel)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 6.44 |

| 90% | 6.39 |

| 80% | 6.33 |

| 70% | 6.26 |

| 60% | 6.20 |

| 50% | 6.11 |

| 40% | 6.05 |

| 30% | 5.98 |

| 20% | 5.90 |

| 10% | 5.85 |

| 0% (empty) | 5.81 or lower |

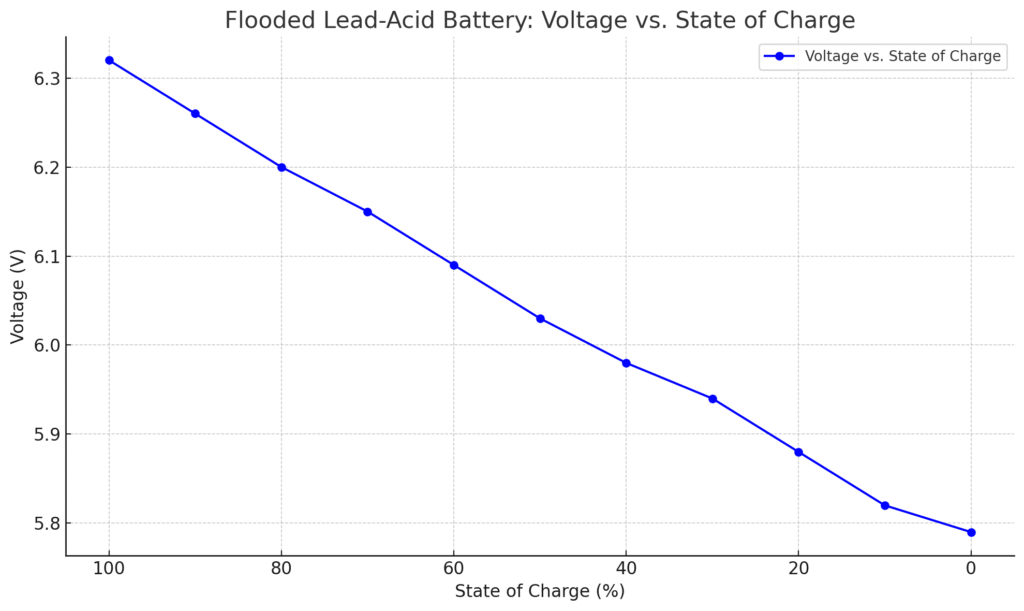

Flooded Lead-Acid

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 6.32 |

| 90% | 6.26 |

| 80% | 6.20 |

| 70% | 6.15 |

| 60% | 6.09 |

| 50% | 6.03 |

| 40% | 5.98 |

| 30% | 5.94 |

| 20% | 5.88 |

| 10% | 5.82 |

| 0% (empty) | 5.79 or lower |

Resting Voltage vs. Loaded Voltage

Resting voltage (measured after 2+ hours without charge/discharge) reveals true state of charge:

- 6.37V = 100% charged (specific gravity ~1.265)

- 6.25V = 75% charged

- 6.12V = 50% charged—the minimum safe threshold for deep-cycle batteries

Loaded voltage drops during use—a 6V battery powering a 100W motor might show 5.8V. This temporary dip is normal, but if voltage doesn’t recover to at least 6.1V after load removal, the battery is likely sulfated.

Temperature’s Critical Role

Voltage readings must compensate for temperature:

- Below 20°C (68°F): Add 0.0036V per degree to readings

- Above 20°C: Subtract 0.0036V per degree

For example, a battery showing 6.30V at 5°C is actually at ~6.19V when corrected to 20°C—a difference that could misdiagnose a healthy battery as undercharged.

Charging Stage Voltage Benchmarks

During charging, expect these voltage ranges:

- Bulk stage: 7.1–7.4V (constant current)

- Absorption stage: 7.2–7.5V (constant voltage)

- Float stage: 6.6–6.8V (maintenance mode)

Exceeding 7.5V risks boiling electrolyte, while stopping at 6.8V leaves the battery only 80% charged. Golf cart chargers often use tapered currents to avoid this.

Pro Tip: For flooded batteries, check voltage and specific gravity with a hydrometer. AGM batteries may show higher voltages (6.4V at rest) due to lower internal resistance.

How to Properly Charge and Maintain 6V Lead-Acid Batteries

Proper charging techniques can double the lifespan of your 6V lead-acid battery, while improper methods can destroy it in months. Unlike lithium-ion batteries, lead-acid chemistry requires specific voltage thresholds at each charging stage to prevent damage.

Step-by-Step Charging Process

Follow this professional charging protocol for optimal results:

- Pre-Charge Check: Verify battery voltage is above 5V (below indicates severe sulfation). Clean terminals with baking soda solution to prevent voltage drop.

- Bulk Stage: Charge at 10-30% of battery capacity (e.g., 20A for 200Ah battery) until voltage reaches 7.1V (25°C). This typically recovers 70-80% capacity.

- Absorption Stage: Maintain 7.3V while current tapers down. For flooded batteries, this takes 3-8 hours; AGM batteries require 1-3 hours.

- Float Stage: Reduce to 6.7V indefinitely for standby applications. Critical for solar systems to prevent daytime overcharging.

Maintenance Best Practices

Extend battery life with these proven techniques:

- Watering: For flooded batteries, maintain electrolyte 1/4″ above plates. Use distilled water only – tap water minerals cause sulfation.

- Equalization: Monthly, charge at 7.5V for 2-4 hours to desulfate plates. Only for flooded batteries – AGMs will be damaged.

- Storage: Store at 6.35V in cool (10°C) location. Disconnected batteries lose 3-5% charge monthly – recharge every 60 days.

Troubleshooting Common Issues

When facing problems:

- Rapid Discharge: If voltage drops below 5.8V under minimal load, test for parasitic draws or internal shorts using a clamp meter.

- Will Not Hold Charge: Check for sulfation (white crystals on plates) or low electrolyte. A desulfator may recover mildly sulfated batteries.

- Overheating During Charge: Immediately reduce current by 50%. This indicates failing cells or incorrect charger settings.

Pro Tip: For series-connected 6V batteries (common in 12V systems), always use identical batteries from the same production batch. Mixing ages/capacities creates imbalance that reduces overall lifespan by up to 40%.

Advanced Voltage Analysis and Performance Optimization

Mastering voltage interpretation unlocks maximum performance from 6V lead-acid batteries. Beyond basic charging, sophisticated voltage analysis reveals hidden battery conditions and opportunities for efficiency gains.

Voltage Drop Analysis Under Load

When analyzing performance:

- Healthy Battery: Should maintain ≥5.8V under 50% max load (e.g., 300W for 100Ah battery)

- Warning Signs: Drops below 5.5V indicate either:

- High internal resistance (sulfation)

- Insufficient conductor sizing (voltage loss in cables)

| Load Duration | Acceptable Voltage Drop | Recovery Time |

|---|---|---|

| 5 minutes | 0.3V | ≤15 minutes |

| 30 minutes | 0.5V | ≤1 hour |

| Continuous | 0.2V max | N/A |

State-of-Charge (SoC) Precision Measurement

For accurate SoC determination:

- Disconnect all loads/chargers for ≥4 hours (24h ideal)

- Measure voltage at terminals using calibrated multimeter

- Apply temperature correction: ±0.0036V/°C from 25°C

- Cross-reference with specific gravity for flooded batteries

Note: AGM batteries show 0.1-0.15V higher than flooded at same SoC due to compressed separators.

Advanced Charging Techniques

Professional maintenance strategies include:

- Pulse Charging: 7.5V pulses at 100-150Hz help break down sulfate crystals

- Temperature-Compensated Charging: Adjusts voltage by -3mV/°C/cell above 25°C

- Capacity Testing: Discharge at C/20 rate (5A for 100Ah battery) to 5.25V to verify true capacity

Common Optimization Mistakes

Avoid these critical errors:

- Overlooking Intercell Connections: Loose connections between cells can cause 0.2-0.4V artificial drop

- Ignoring Charge Acceptance: Batteries below 10°C need 0.3V higher charging voltage

- Mixing Battery Types: Combining AGM and flooded in same system creates chronic under/overcharging

Expert Insight: For solar applications, implement 3-stage charging with voltage thresholds adjusted seasonally – higher in winter (7.4V absorption) and lower in summer (7.2V absorption) to account for temperature effects on charge acceptance.

Safety Protocols and Industry Standards for 6V Lead-Acid Batteries

Working with 6V lead-acid batteries requires strict adherence to safety standards to prevent accidents and ensure optimal performance. These heavy-duty power sources contain hazardous materials and store substantial energy that demands professional handling.

Essential Safety Equipment and Procedures

Always use proper protective gear:

- Chemical Protection: Acid-resistant gloves (neoprene or nitrile) and polycarbonate face shields when handling flooded batteries

- Ventilation Requirements: Charge in areas with ≥5 air changes/hour – hydrogen gas accumulation above 4% becomes explosive

- Tool Safety: Use insulated tools with VRLA-rated (Vent Regulated Lead Acid) designs to prevent sparking near battery vents

Industry Standard Voltage Tolerances

Recognized voltage parameters per IEEE 1187-2013:

| Condition | Minimum Voltage | Maximum Voltage |

|---|---|---|

| Standby Float | 6.6V | 6.9V |

| Cyclic Service | 5.25V (discharge) | 7.5V (equalization) |

| Storage (6 months) | 6.2V | 6.4V |

Exceeding these ranges voids most manufacturer warranties and risks thermal runaway.

Proper Disposal and Recycling

Follow EPA 40 CFR Part 273 guidelines:

- Neutralize terminal acid with baking soda solution (1 cup per gallon)

- Secure terminals with non-conductive tape to prevent accidental discharge

- Deliver to authorized recyclers – 98% of lead and plastic is recoverable

- Never dispose in municipal waste – $10,000+ fines may apply for violations

Advanced Installation Best Practices

For mission-critical applications:

- Rack Systems: Maintain 1″ minimum spacing between batteries for airflow and thermal management

- Bus Bars: Use tin-plated copper with 125% of expected current capacity (e.g., 250A busbar for 200A system)

- Seismic Protection: In earthquake zones, use steel retention systems that allow ≤1/4″ movement

Professional Tip: Implement continuous voltage monitoring systems with automatic load shedding when voltage drops below 5.8V under load. This prevents damaging deep discharges in telecom and medical applications where uptime is critical.

Long-Term Performance Optimization and Future Trends

Maximizing the lifespan of 6V lead-acid batteries requires understanding their complex aging processes and implementing proactive maintenance strategies. These deep-cycle batteries typically offer 500-1,200 cycles when properly maintained, but most users achieve only 30-60% of this potential.

Advanced Life Extension Techniques

Professional battery banks use these methods to extend service life:

- Pulsed Equalization: Applying 7.6V pulses (2-4 hours monthly) dissolves sulfate crystals without electrolyte loss

- Temperature-Controlled Environments: Maintaining 20-25°C ambient temperature reduces aging by 50% compared to 35°C operation

- Current Profiling: Smart chargers that adapt absorption time based on recent usage patterns (longer after deep discharges)

| Maintenance Factor | Impact on Lifespan | Cost/Benefit Ratio |

|---|---|---|

| Monthly Equalization | +40% cycles | 1:8 (Low cost, high return) |

| Climate Control | +60% cycles | 1:3 (Higher initial cost) |

| Advanced Chargers | +25% cycles | 1:5 (Mid-range investment) |

Emerging Technologies and Alternatives

While traditional lead-acid remains dominant, new developments are changing the landscape:

- Carbon-Enhanced Plates: Batteries like Firefly’s Oasis series use carbon foam to triple cycle life (3,000+ cycles)

- Hybrid Systems: Pairing 6V lead-acid with small lithium buffers reduces peak loads by 30%, extending lead battery life

- Smart Battery Sensors: IoT-enabled monitors track internal resistance trends to predict failures 2-3 months in advance

Environmental Impact Mitigation

Modern lead-acid batteries achieve 99% recyclability, but proper handling remains crucial:

- Choose AGM over flooded when possible – reduces acid mist emissions by 90%

- Implement closed-loop water systems for flooded battery maintenance

- Participate in manufacturer take-back programs (most offer core charge refunds)

Future Outlook: The 6V lead-acid market is shifting toward specialized applications like off-grid renewable systems, where their cost-effectiveness and reliability outweigh weight disadvantages. New UL 1974 standards are driving improvements in recombination efficiency, potentially pushing cycle life beyond 1,500 cycles by 2025.

System Integration and Specialized Applications for 6V Lead-Acid Batteries

6V lead-acid batteries serve as critical components in complex systems where proper integration determines overall performance and reliability. Their unique voltage characteristics require careful consideration when designing power systems.

Series and Parallel Configurations

When connecting multiple 6V batteries:

- Series Connections: For higher voltage (e.g., 12V/24V systems)

- Always use identical batteries (same model, age, and cycle count)

- Balance charge each battery individually monthly

- Maximum recommended string length: 4 batteries (24V system)

- Parallel Connections: For increased capacity

- Use cables of equal length to prevent current imbalance

- Install fuses within 7″ of each positive terminal

- Limit to 3 parallel strings to avoid charging inconsistencies

Renewable Energy System Integration

For solar/wind applications:

- Size battery bank to handle 3-5 days autonomy (deeper discharges require larger capacity)

- Program charge controllers for 3-stage charging with temperature compensation

- Install DC disconnects within 1 foot of battery bank (NEC Article 690 requirement)

- Use battery-to-inverter cables sized for ≤3% voltage drop at peak load

Specialized Industrial Applications

Unique considerations for different sectors:

| Application | Voltage Parameters | Special Requirements |

|---|---|---|

| Telecom Backup | Float: 6.65V ±0.05V | VRLA batteries with 10-year design life |

| Electric Forklifts | Discharge cutoff: 5.4V | Heavy-duty plates for vibration resistance |

| Marine Trolling | Cyclic: 6.0-7.3V | Spill-proof AGM with corrosion-resistant terminals |

Advanced Monitoring Systems

Modern battery management solutions:

- Shunt-Based Monitors: Track amp-hours consumed with ±1% accuracy

- Impedance Spectroscopy: Detects cell degradation before capacity loss occurs

- Cloud-Based Analytics: Predicts maintenance needs using historical performance data

Critical Integration Tip: When connecting to inverters, always verify the unit’s low-voltage disconnect matches your battery’s minimum voltage (typically 5.25V/cell for deep-cycle). Mismatched settings can cause premature battery failure.

Comprehensive Performance Validation and Risk Management

Ensuring optimal 6V lead-acid battery performance requires systematic validation protocols and proactive risk mitigation strategies. These procedures are particularly critical for mission-critical applications where failure is not an option.

Advanced Performance Testing Protocols

Professional battery validation includes:

- Capacity Verification: Conduct full discharge test at C/20 rate annually (5A for 100Ah battery) to 5.25V cutoff

- Internal Resistance Mapping: Measure each cell with AC impedance tester (should be ≤5mΩ difference between cells)

- Charge Acceptance Test: Measure current at 7.1V after 50% discharge (healthy batteries accept ≥80% of rated charge current)

| Test Parameter | Acceptance Criteria | Measurement Frequency |

|---|---|---|

| Resting Voltage | 6.35V ±0.05V | Monthly |

| Specific Gravity | 1.265 ±0.005 (flooded) | Quarterly |

| Terminal Resistance | ≤0.2mΩ | Biannually |

Risk Assessment and Mitigation

Critical failure modes and prevention:

- Thermal Runaway: Install temperature sensors on center cells with automatic charge reduction at 40°C

- Stratification: For flooded batteries, implement controlled overcharge (7.5V for 2 hours) quarterly to mix electrolyte

- Grid Corrosion: Maintain float voltage below 6.9V and temperature below 30°C

Quality Assurance Procedures

Industrial best practices include:

- Incoming Inspection: Verify OCV (Open Circuit Voltage) ≥6.35V and impedance ≤ manufacturer specs

- Installation Qualification: Document torque values (typically 5-7 Nm for terminal connections) and polarity checks

- Performance Qualification: Conduct 3 full charge/discharge cycles before putting into service

Predictive Maintenance Framework

Advanced monitoring approaches:

- Track capacity fade rate (should be ≤2% per month for healthy batteries)

- Monitor charge efficiency (should be ≥85% for batteries under 2 years old)

- Analyze voltage recovery time after load (should return to 6.2V within 1 hour after 20% discharge)

Expert Recommendation: Implement a Battery Management System (BMS) that logs historical data and automatically adjusts charging parameters based on usage patterns. This can extend battery life by 30-40% compared to static charging profiles.

Conclusion

Mastering 6V lead-acid battery voltage management requires understanding the nuanced relationship between voltage states, temperature effects, and charging protocols.

As we’ve explored, proper maintenance extends beyond simple voltage checks to include advanced techniques like pulsed equalization, capacity testing, and system integration best practices. Whether you’re maintaining golf carts, solar arrays, or industrial equipment, implementing these professional-grade strategies can double your battery’s lifespan and prevent costly failures.

Now equipped with comprehensive voltage charts, charging methodologies, and troubleshooting insights, you’re prepared to optimize your 6V battery systems with confidence.

For maximum results, begin by conducting a full system assessment using the diagnostic techniques outlined, then establish a regular maintenance schedule. Remember – in lead-acid battery care, proactive measures always yield better returns than reactive repairs.

Frequently Asked Questions About 6V Lead-Acid Batteries

What exactly does the voltage reading tell me about my 6V battery’s condition?

Voltage readings reveal your battery’s state of charge and health. A fully charged 6V lead-acid battery should read 6.37V at rest (20°C), while 6.12V indicates 50% charge – the minimum safe level for deep-cycle use.

Consistently low voltage readings (<6.0V) suggest sulfation or cell damage. For accurate assessment, measure voltage after the battery rests for 4+ hours without charging or discharging.

How often should I perform equalization charging on my 6V flooded battery?

Flooded batteries benefit from monthly equalization at 7.5V for 2-4 hours, or whenever specific gravity varies more than 0.030 between cells. This controlled overcharge mixes stratified electrolyte and removes sulfate crystals.

Never equalize AGM or gel batteries – their sealed construction makes them vulnerable to damage from overvoltage. Always monitor temperature during equalization, stopping if it exceeds 45°C.

Why does my new 6V battery show 6.4V instead of 6.37V when fully charged?

Modern AGM and gel batteries often display slightly higher voltages (6.4-6.45V) due to lower internal resistance and compressed separators. This is normal and actually indicates better charge acceptance.

However, if a flooded battery shows these readings, it may suggest overcharging or insufficient electrolyte. Always check manufacturer specs – some premium batteries like Odyssey PC625 are designed to operate at higher voltages.

Can I mix old and new 6V batteries in the same system?

Absolutely not. Mixing batteries with different ages, capacities, or chemistries creates imbalance that reduces overall performance by 30-50%. Even batteries of the same model but purchased 6 months apart can have different internal resistances.

Always replace entire banks together, and for series connections, use batteries from the same production batch (check date codes).

What’s the proper way to store 6V lead-acid batteries long-term?

For storage exceeding 30 days, charge to 6.35V, clean terminals, and disconnect all loads. Store in a cool (10-15°C), dry place. Flooded batteries need monthly recharge, while AGM can last 3-6 months between charges. Never store below 6.0V – irreversible sulfation begins at this voltage. For winter storage, use a maintainer that provides 6.7V float charge.

How can I accurately test my 6V battery’s remaining capacity?

Perform a controlled discharge test:

- Fully charge to 6.37V

- Discharge at C/20 rate (5A for 100Ah battery)

- Measure time until voltage reaches 5.25V

Compare results to manufacturer specs – a 100Ah battery should provide 5A for 20 hours. For quick checks, professional conductance testers like Midtronics MDX-650 provide reliable capacity estimates in seconds.

Why does my 6V battery voltage drop significantly when I connect a load?

Voltage drop under load indicates either high internal resistance (aging/sulfation) or insufficient capacity for the load. A healthy battery shouldn’t drop below 5.8V with moderate loads (≤C/3). If voltage plunges to <5.5V immediately, test individual cells for shorts. For example, a golf cart battery showing 5.2V under acceleration likely has failed cells.

Is it worth repairing a 6V battery that won’t hold charge?

Repair feasibility depends on the failure mode. Flooded batteries with mild sulfation may recover with desulfation charging, while physical damage requires replacement. AGM batteries are rarely repairable. Consider repair if:

- Battery is <2 years old

- Capacity is >60% of original

- No physical damage exists

Otherwise, replacement is more cost-effective, especially with today’s advanced carbon-enhanced models offering longer lifespans.