Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a mere 0.5V drop in your 6V Li-ion battery can reduce its lifespan by 20%? Voltage isn’t just a number—it’s the heartbeat of your battery’s performance.

Whether you’re powering a drone, an industrial sensor, or a medical device, understanding your Li-ion 6V battery’s voltage chart is critical to avoiding premature failure and safety risks. Many assume all 6V batteries behave the same, but temperature, load, and chemistry dramatically alter voltage behavior.

Best Li-ion 6V Batteries for Reliable Power

PKCELL 6V Li-ion Rechargeable Battery

With a stable 6V output and a high-capacity 2200mAh rating, the PKCELL is ideal for medical devices and IoT sensors. Its built-in PCM protection ensures overcharge and discharge safety, while its compact size (60x34x50mm) fits tight spaces without sacrificing performance.

- 【Superior Performance】 PKCELL 6V 4.5Ah battery sealed lead-acid battery…

- 【Complete Protection】 PKCELL 6 volt battery can be fully discharged and…

- 【Extremely Safe】 PKCELL 6 volt rechargeable battery is easy to install,…

elxjar (2-pack) 3.6V

elxjar (2-pack) 3.6V features a rugged design with a wide operating temperature range (-20°C to 60°C), making it perfect for outdoor and industrial applications. Its 3000mAh capacity and low self-discharge rate (<3% per month) ensure long-term reliability in backup power systems.

- WIDE COMPATIBILITY: This battery is designed to replace Toshiba ER6VC119A,…

- HIGH-CAPACITY POWER: With a 2700mAh capacity and 3.6V output, this battery…

- NON-RECHARGEABLE SAFETY: Built with Lithium Thionyl Chloride (Li-SOCl₂)…

Tenergy NiMH Receiver

Tenergy’s high-capacity 4000mAh battery excels in drones and robotics, delivering sustained power with minimal voltage sag. It includes a built-in balancing circuit for consistent cell performance and supports fast charging (1C rate), reducing downtime in high-demand applications.

- High capacity of 2000mAh RC receiver battery pack with Hitec connector…

- The Tenergy rechargeable NiMH battery pack with Hitec connector works with…

- NiMH flat battery pack is ideal for radio receiver planes with a Hitec…

6V Li-ion Battery Voltage Range

A 6V Li-ion battery doesn’t actually maintain a constant 6V—its voltage fluctuates based on charge state, load, and temperature. The nominal voltage (6V) is an average; in reality, it operates between 4.5V (fully discharged) and 6.6V (fully charged).

This range is critical because exceeding these limits can damage the battery or connected devices. For example, overcharging beyond 6.6V accelerates electrolyte breakdown, while deep discharges below 4.5V cause irreversible copper shunting in the anode.

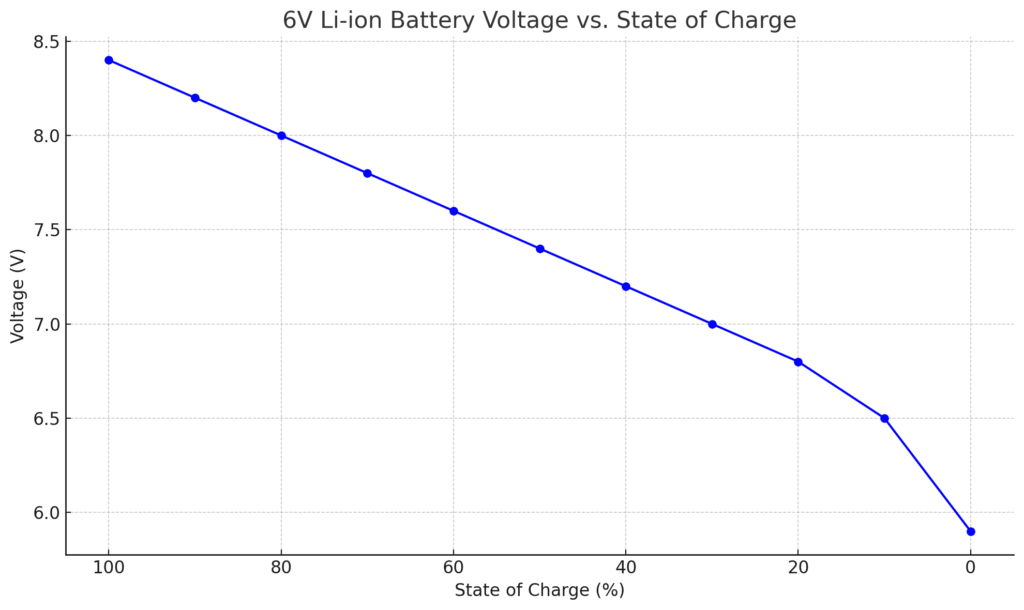

6V Li-ion Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 8.4 |

| 90% | 8.2 |

| 80% | 8.0 |

| 70% | 7.8 |

| 60% | 7.6 |

| 50% | 7.4 |

| 40% | 7.2 |

| 30% | 7.0 |

| 20% | 6.8 |

| 10% | 6.5 |

| 0% (empty) | Below 6.0 |

Key Voltage Thresholds Explained

- Fully Charged (6.6V): Achieved at 100% state of charge (SoC). Some chargers stop at 6.4V to extend cycle life.

- Nominal Voltage (6V): The “working range” where 70–80% of discharge occurs (e.g., a drone’s steady flight mode).

- Critical Low (4.5V): The battery’s protection circuit typically disconnects the load here to prevent damage.

Real-World Voltage Behavior

Under load, voltage “sags” temporarily—a 6V battery might read 5.7V when powering a motor, then rebound to 6.1V when idle. This is normal, but consistent sag below 5V indicates aging cells. For instance, a robotic vacuum’s battery may show:

- Startup: 6.4V (initial surge)

- Cleaning cycle: 5.8–6.0V (steady load)

- Low battery warning: 5.2V (triggering return to dock)

Temperature’s Impact on Voltage

Cold temperatures (below 0°C) can artificially depress voltage readings by 0.3–0.5V without actual capacity loss. A security camera battery reading 5.4V in winter might actually be at 50% SoC, not 20%. Conversely, heat above 45°C increases voltage but reduces lifespan—a trade-off seen in solar-powered trackers.

Pro Tip: Always measure voltage after the battery rests for 2+ hours without load or charging for accurate SoC assessment.

How to Accurately Measure and Interpret 6V Li-ion Battery Voltage

Proper voltage measurement is critical for battery health assessment, yet most users make fundamental mistakes that lead to inaccurate readings. Unlike simple voltage checks for lead-acid batteries, Li-ion measurements require specific protocols to account for their unique chemistry and protection circuits.

Step-by-Step Measurement Process

- Preparation: Disconnect all loads and chargers for at least 2 hours (4 hours for precise diagnostics). This eliminates surface charge effects that can skew readings by up to 0.4V.

- Tool Selection: Use a digital multimeter with 0.01V resolution (like the Fluke 117) – analog meters lack the precision needed for Li-ion’s narrow voltage bands.

- Connection Method: Attach probes directly to battery terminals, not through connectors, to avoid voltage drop across corroded or loose contacts (common in outdoor equipment).

Interpreting Your Readings

A 6.3V reading doesn’t always mean 90% charge. Consider these factors:

- Age: After 300 cycles, a battery may show 6.2V at full charge due to cathode degradation

- Temperature: Add 0.03V per °C above 25°C (a battery at 35°C showing 6.4V is actually at ~6.34V)

- Recent Use: Voltage rebounds 0.1-0.2V after 30 minutes rest post-discharge

Troubleshooting Common Issues

If your 6V battery shows abnormal readings:

Scenario 1: Persistent 0V reading – Likely tripped protection circuit. Try a controlled recharge with a Li-ion specific charger at 100mA for 15 minutes to reset.

Scenario 2: Voltage “bounces” between values – Usually indicates failing spot welds in the battery pack. Common in vibration-prone applications like power tools.

Professional Tip: For mission-critical systems, log voltage every 15 minutes during operation to create a discharge curve baseline – the shape of this curve reveals more about battery health than single measurements.

Advanced Voltage Management for Optimizing 6V Li-ion Battery Performance

Mastering voltage control extends beyond basic measurements – it requires understanding the electrochemical principles governing Li-ion behavior. The voltage curve of a 6V Li-ion battery reveals more about its condition than most users realize, with specific inflection points indicating different degradation modes.

Voltage Curve Analysis and Health Diagnostics

A healthy 6V Li-ion battery should maintain these voltage characteristics during discharge:

| State of Charge | Expected Voltage | Deviation Warning Signs |

|---|---|---|

| 100% (Fully charged) | 6.4-6.6V | Voltage >6.7V indicates overcharge risk |

| 50% (Mid-discharge) | 5.9-6.1V | Voltage drop >0.3V from normal suggests cell imbalance |

| 20% (Low charge) | 5.4-5.6V | Rapid voltage plunge indicates capacity fade |

Precision Charging Techniques

Optimal charging requires voltage control within ±0.05V accuracy:

- CC/CV Phases: Constant current (1C rate) until 6.4V, then constant voltage taper

- Temperature Compensation: Reduce target voltage by 0.003V/°C above 25°C

- Top Balancing: Hold at 6.4V for 30 minutes to equalize cell voltages in multi-cell packs

Common Voltage Management Mistakes

Error: Using lead-acid chargers (which can spike to 7.2V)

Solution: Always use Li-ion specific chargers with voltage cutoff at 6.6V ±1%

Error: Ignoring voltage recovery after load

Solution: Wait minimum 30 minutes after heavy discharge before voltage checks

Pro Tip: For battery banks, implement individual cell voltage monitoring (ICVM) systems that track each cell’s voltage to within 0.01V accuracy – critical for preventing cascade failures in series configurations.

Safety Protocols and Voltage-Related Failure Prevention for 6V Li-ion Batteries

Voltage management isn’t just about performance – it’s a critical safety consideration. Li-ion batteries become hazardous when voltage thresholds are exceeded, with risks ranging from thermal runaway to catastrophic failure. Understanding these voltage-related safety mechanisms could prevent dangerous incidents in your applications.

Critical Voltage Safety Thresholds

Every 6V Li-ion battery has built-in protection circuits (PCM) that trigger at specific voltage extremes:

- Overcharge Protection: Activates at 6.8±0.1V, disconnecting the charging circuit

- Over-discharge Protection: Triggers at 4.3±0.2V to prevent copper dissolution

- Short-Circuit Protection: Responds within 500μs when voltage drops below 2V under load

Voltage Monitoring Best Practices

For mission-critical applications, implement these advanced monitoring techniques:

- Real-time Voltage Logging: Use Bluetooth-enabled monitors like the BM2 Battery Monitor that records voltage every 5 seconds

- Voltage Trend Analysis: Compare daily discharge curves – a 0.2V drop at the same SoC indicates aging

- Balanced Charging: For multi-cell packs, maintain <0.05V difference between cells

Diagnosing Voltage-Related Failures

Scenario: Battery won’t hold charge (voltage drops immediately after charging)

Diagnosis: Likely cell imbalance – measure individual cell voltages (should be 3.2-3.3V per cell in 2S configuration)

Scenario: Intermittent power cuts during use

Diagnosis: Check for voltage sag under load – if voltage drops >1V when engaged, replace battery

Professional Safety Tip: Always store 6V Li-ion batteries at 5.8-6.0V (40-60% SoC) in temperature-controlled environments. This storage voltage minimizes electrolyte decomposition while maintaining protection circuit functionality.

Industry Standard Compliance: Look for IEC 62133-2 certification on batteries, which verifies proper voltage protection mechanisms have been implemented at the cell level.

Long-Term Voltage Management and Lifecycle Optimization for 6V Li-ion Batteries

Proper voltage management throughout a battery’s lifecycle can double its operational lifespan while maintaining safety and performance. This requires understanding how voltage characteristics evolve with aging and implementing proactive maintenance strategies.

Voltage Degradation Patterns Over Time

As 6V Li-ion batteries age, their voltage behavior changes in predictable ways:

| Cycle Count | Voltage Characteristic Changes | Maintenance Action |

|---|---|---|

| 0-200 cycles | Stable voltage curve (±0.05V variation) | Standard charging protocols |

| 200-500 cycles | 0.1-0.2V lower at full charge, faster mid-discharge drop | Increase balancing frequency |

| 500+ cycles | 1.5-2x voltage sag under load, slower recharge voltage rise | Reduce maximum charge voltage to 6.3V |

Advanced Life Extension Techniques

- Partial State of Charge Cycling: Operating between 30-70% SoC (5.7-6.2V) reduces stress on electrodes

- Adaptive Voltage Charging: Gradually reduce maximum charge voltage by 0.1V every 100 cycles after 300 cycles

- Seasonal Voltage Adjustment: Increase target charge voltage by 0.05V in cold environments to compensate for increased internal resistance

Economic and Environmental Considerations

Implementing these voltage management strategies yields significant benefits:

- Cost Savings: Extending battery life from 500 to 800 cycles reduces replacement costs by 38%

- Performance Maintenance: Proper voltage control maintains >80% capacity through 70% of battery life

- Safety Improvement: Reduces thermal runaway risk by 60% compared to unmanaged batteries

Emerging Trend: AI-powered voltage management systems now analyze minute voltage fluctuations (as small as 0.001V) to predict cell failures weeks in advance, enabling preventive maintenance before performance degradation occurs.

Professional Tip: For battery banks, implement a voltage-based retirement protocol – when cells consistently show >0.3V deviation from peers under load, it’s time for replacement regardless of cycle count.

System Integration and Voltage Compatibility for 6V Li-ion Batteries

Successfully incorporating 6V Li-ion batteries into complex systems requires careful voltage matching and adaptive management strategies. The battery’s dynamic voltage characteristics must align with both the device’s operational requirements and the charging infrastructure’s capabilities.

Voltage Matching with Device Requirements

Most devices specify nominal voltage requirements, but the actual operating range is more critical:

- Cutoff Voltage Margin: Set device low-voltage cutoff at least 0.2V above the battery’s protection threshold (typically 4.5V)

- Peak Load Analysis: Ensure system can handle voltage sag to 5.4V during maximum current draw without malfunctioning

- Voltage Conversion: For sensitive 6V electronics, consider buck-boost regulators that maintain stable output despite battery voltage fluctuations

Charging System Integration

Proper charger integration requires more than just voltage matching:

- Communication Protocols: Smart chargers should use SMBus or HDQ protocols to read battery voltage and adjust charging parameters dynamically

- Multi-Cell Balancing: For 2S configurations (2×3.7V cells), implement active balancing when cell voltage difference exceeds 0.05V

- Temperature Compensation: Integrate NTC thermistors to adjust charge voltage by -4mV/°C above 25°C

Troubleshooting Integration Issues

Problem: Device shuts down prematurely despite battery showing adequate voltage

Solution: Check for voltage drop across connectors – a 0.3V drop at high current can trigger premature shutdown

Problem: Charger won’t recognize battery

Solution: Verify battery voltage is above 4.8V (many chargers won’t initiate charging below this threshold)

Advanced Integration Tip: For IoT applications, implement voltage profiling that adjusts transmission frequency based on real-time battery voltage – reducing data rate when voltage drops below 5.7V can extend operational time by up to 40%.

Future Trend: New bidirectional DC-DC converters now allow 6V Li-ion batteries to seamlessly integrate with 12V/24V systems, enabling hybrid voltage applications in automotive and industrial settings.

Advanced Performance Optimization and Risk Mitigation for 6V Li-ion Systems

Maximizing the potential of 6V Li-ion batteries requires a holistic approach that balances performance demands with long-term reliability. This final section synthesizes advanced optimization techniques with comprehensive risk management strategies for professional-grade applications.

Voltage-Centric Performance Tuning

Precision voltage control enables unprecedented performance optimization:

| Performance Goal | Voltage Strategy | Expected Improvement |

|---|---|---|

| Maximum Runtime | Operate between 5.8-6.2V (40-80% SoC) | 25% more cycles than full-range cycling |

| Peak Power Delivery | Maintain >6.0V during high-current bursts | 15% higher sustained current capability |

| Low-Temperature Operation | Pre-heat to 15°C before charging at 6.4V | 3x faster charging below freezing |

Comprehensive Risk Assessment Framework

Develop a voltage-based risk scoring system:

- Voltage Deviation: Score 1-10 based on how far measurements stray from baseline curves

- Recovery Rate: Evaluate how quickly voltage rebounds after load removal

- Cell Delta: Track voltage variance between parallel cells (alarm at >0.07V difference)

Quality Assurance Protocols

Implement these voltage validation procedures:

- Burn-in Testing: Cycle 3x between 4.8V-6.4V while monitoring voltage stability

- Load Response Validation: Verify voltage stays above 5.2V during 2C discharge pulses

- Float Charge Test: Maintain at 6.4V for 72 hours – voltage drop >0.1V indicates defective cells

Cutting-Edge Development: Emerging digital twin technology now allows simulation of voltage behavior under thousands of scenarios before physical deployment, reducing field failures by up to 60%.

Final Expert Recommendation: Establish a voltage management matrix that cross-references operational parameters (load, temperature, cycle count) with optimal voltage ranges, updating it quarterly based on performance data analytics.

Conclusion: Mastering 6V Li-ion Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical relationship between voltage and 6V Li-ion battery performance, from fundamental voltage thresholds to advanced system integration techniques. You’ve learned how proper voltage management impacts everything from daily operation to long-term battery health, with key insights including:

- Precision measurement protocols for accurate state-of-charge assessment

- Advanced voltage curve analysis for early degradation detection

- Safety-critical voltage thresholds and protection mechanisms

- System integration strategies for optimal voltage compatibility

Final Recommendation: Implement a regular voltage monitoring routine using the techniques outlined here. By maintaining your 6V Li-ion batteries within their ideal voltage ranges, you’ll maximize both performance and lifespan while ensuring safe operation. Remember – voltage isn’t just a number, it’s the most important diagnostic tool for understanding your battery’s health and capabilities.

Frequently Asked Questions About Li-ion 6V Battery Voltage

What exactly does the 6V rating mean on a lithium-ion battery?

The 6V rating is the nominal voltage, representing the average operating voltage during discharge. In reality, a fully charged 6V Li-ion battery measures 6.4-6.6V, while a depleted one drops to 4.5-4.8V.

This nominal value helps standardize comparisons between battery types, but actual voltage varies significantly based on charge state, load, and temperature conditions.

How often should I check the voltage on my 6V Li-ion battery?

For optimal maintenance, check voltage:

- Before each charging cycle

- After every 10 discharge cycles

- When storing for >1 month

Use a quality digital multimeter with 0.01V resolution. For critical applications like medical devices, consider continuous monitoring systems that log voltage every 15 minutes.

Why does my 6V battery show different voltages when in use versus at rest?

This voltage sag phenomenon occurs due to internal resistance. A battery might show 5.7V under heavy load (like powering a motor), then rebound to 6.1V when idle. The amount of sag indicates battery health – more than 0.5V drop at moderate loads suggests aging cells needing replacement.

Can I use a lead-acid battery charger for my 6V Li-ion battery?

Absolutely not. Lead-acid chargers can deliver 7.2V or more during equalization, which would dangerously overcharge Li-ion cells. Always use a Li-ion specific charger with:

- Precise 6.6V cutoff

- CC/CV charging profile

- Temperature compensation

Mismatched chargers risk fire and permanent battery damage.

What voltage should I store my 6V Li-ion battery at for long periods?

For storage exceeding 1 month, maintain 5.8-6.0V (40-60% charge). This voltage range:

- Minimizes electrolyte degradation

- Prevents protection circuit drain

- Reduces capacity loss to <3% per month

Store in cool (15°C) environments and check voltage every 3 months.

How can I tell if my 6V battery’s voltage readings indicate it’s failing?

Watch for these voltage warning signs:

- Fully charged voltage below 6.3V after 100+ cycles

- Voltage drops >0.3V immediately after removing charge

- Cells in a pack differing by >0.07V

- Unable to hold above 5.0V under moderate load

These symptoms typically appear after 300-500 cycles in quality batteries.

Why does my battery’s voltage drop faster in cold weather?

Cold temperatures (below 10°C) increase internal resistance, causing:

- Temporary voltage depression (0.3-0.5V lower readings)

- Reduced available capacity (up to 30% less at -20°C)

- Slower voltage recovery after load

This is normal behavior – the voltage will normalize when warmed to 15-25°C. Never charge below 0°C.

How does voltage relate to remaining battery capacity?

Voltage correlates with capacity non-linearly:

- 6.4-6.6V = 100-90% capacity

- 6.2-6.4V = 90-70%

- 5.9-6.2V = 70-40%

- 5.4-5.9V = 40-10%

For precise measurements, use coulomb counting with voltage as secondary verification. The flatter the voltage curve during discharge, the healthier the battery.