Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 6V NiCd battery can lose up to 30% of its capacity if improperly stored? Understanding voltage levels is critical to extending battery life and avoiding unexpected power failures.

Whether you’re using NiCd batteries for emergency lighting, RC toys, or industrial tools, knowing how voltage correlates with charge state ensures optimal performance.

Many assume all 6V batteries behave the same—but NiCd chemistry has unique discharge curves and voltage drop characteristics. In this guide, you’ll unlock a detailed voltage chart, decode real-world discharge patterns, and learn expert-backed maintenance strategies to keep your NiCd batteries running like new.

Best 6V NiCd Batteries for Reliable Power

Tenergy NiMH SubC 1.2V

Ideal for high-drain devices like RC cars and emergency lighting, the Tenergy 6V 3000mAh offers a long cycle life (1,000+ charges) and stable voltage output under heavy loads. Its rugged construction resists overcharging and extreme temperatures, making it a durable choice for demanding applications.

- High quality sub C – High capacity replacement 3000mAh NiMH sub c battery,…

- Large capacity – 3000 mAh capacity provides 80% more runtime than NiCD Sub…

- High drain applications – Up to 30 Amp of high current drain, ideal for…

Power Sonic PS-640 6V 4.5Ah NiCd Battery

Engineered for industrial use, the Power Sonic PS-606 delivers 4.5Ah capacity with low self-discharge, perfect for backup power systems. Its sealed design prevents leaks, and it supports fast charging without memory effect, ensuring consistent performance in medical equipment or security devices.

- Original Power Sonic PS-640 F1 6V 4.5AH SLA Battery. Pack of 2

- Dimensions: (L) 2.76 x (W) 1.86 x (H) 4.25. Weight: 1.60 lbs.

- SLA/AGM maintenance free, spill proof battery

elxjar(5-Pack)6V 1000mAh

elxjar(5-Pack)6V 1000mAh excels in precision tools and robotics, featuring a lightweight design and high energy density. Its solder-tab terminals enable secure connections, while advanced cell technology minimizes voltage sag during peak loads, making it a top pick for professional-grade applications.

- WIDE COMPATIBILITY: Replacement for Aritech 10050205, Lithonia ENB-06006…

- TECHNICAL SPECIFICATIONS: 6V output voltage, 1000mAh capacity, Ni-CD…

- COMPACT DIMENSIONS: Measures approximately 1.72″ x 1.08″ x 1.92″, built in…

Blomiky 2 Pack 6.0V

Blomiky 2 Pack 6.0V batteries operate differently from other battery chemistries due to their unique discharge curve and voltage stability. Unlike lithium-ion batteries, which maintain a near-constant voltage until depletion, NiCd batteries exhibit a gradual voltage decline as they discharge.

- Attention: Only fit for old version some kind of Amphibous RC Stunt Car,…

- Attention: This is 5-Cell 5S AA 6.0V Battery Pack. Battery size…

- 6V 700mAH Battery suitable for Old version Seckton big size AmphibIous…

A fully charged 6V NiCd battery typically starts at 7.2V (due to cell stacking) and stabilizes around 6.5V–6.8V under load before gradually dropping to 5V–5.5V near depletion.

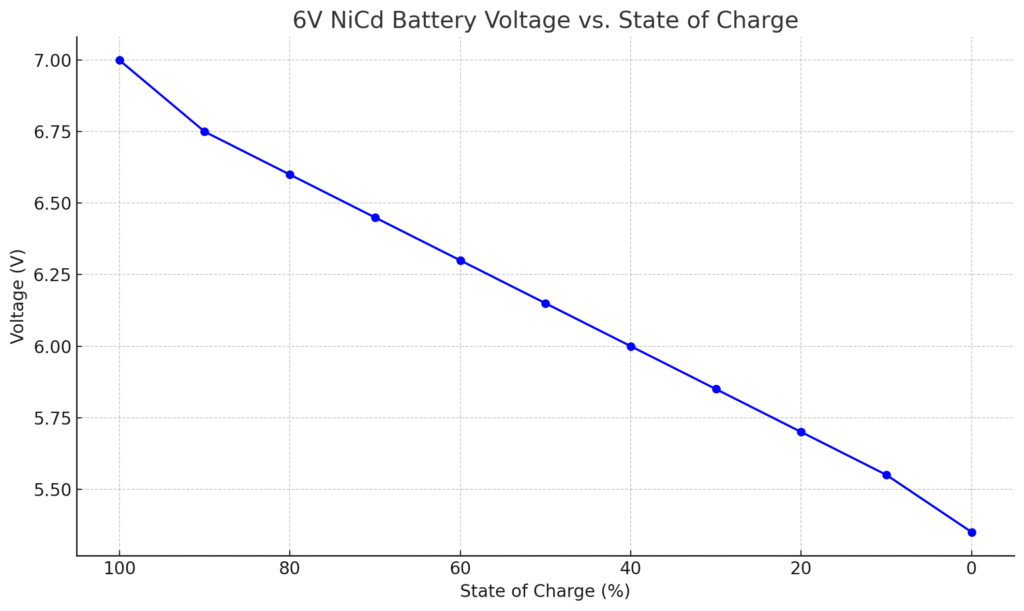

6V NiCd Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 7.0 |

| 90% | 6.75 |

| 80% | 6.60 |

| 70% | 6.45 |

| 60% | 6.30 |

| 50% | 6.15 |

| 40% | 6.00 |

| 30% | 5.85 |

| 20% | 5.70 |

| 10% | 5.55 |

| 0% (empty) | Below 5.4 |

Key Voltage Stages & What They Mean

Fully Charged (7.2V–6.8V): After charging, NiCd batteries experience a slight voltage drop (“surface charge dissipation”) within minutes. This is normal and not a sign of defects. For example, a Tenergy 6V 3000mAh battery may read 7.2V immediately after charging but settle at 6.8V after 30 minutes.

Mid-Discharge (6.5V–6.0V): This is the optimal working range, where the battery delivers consistent power. Devices like emergency exit signs or cordless drills perform best in this zone. Voltage fluctuations here may indicate uneven cell aging or partial memory effect.

Critical Discharge (Below 5.5V): Prolonged use in this range risks deep discharge damage, reducing battery lifespan. For instance, a Panasonic NC-6V2000F battery drained below 5V may lose up to 15% of its recharge capacity permanently.

Real-World Voltage Behavior

- Load-Dependent Voltage Drop: Under high current (e.g., RC car acceleration), voltage can temporarily dip 0.5V–1V. This “sag” is normal but exaggerated in aging batteries.

- Temperature Effects: Cold environments (below 10°C) can reduce usable voltage by 10–20%, while heat accelerates self-discharge.

- Memory Effect Myth: Contrary to popular belief, modern NiCd batteries (like Power Sonic PS-606) suffer minimal memory effect if properly maintained with occasional full discharges.

Practical Tip: Use a multimeter to track voltage under load—not just at rest. A battery showing 6.4V without load but dropping to 5.2V when powering a device likely needs replacement.

How to Properly Charge and Maintain 6V NiCd Batteries

Proper charging techniques are critical for maximizing the lifespan and performance of NiCd 6V batteries. Unlike lithium-ion batteries, NiCd chemistry requires specific charging protocols to prevent capacity loss and memory effect buildup. Understanding these requirements can double your battery’s usable life.

Optimal Charging Methods

Constant Current Charging: Most NiCd batteries charge best at 0.1C (10% of capacity). For a 3000mAh battery like the Tenergy 6V, this means a 300mA current. Fast charging at higher currents (0.5C-1C) is possible but generates heat that degrades cells over time.

Delta V Termination: Quality chargers detect the -ΔV voltage drop (typically 5-10mV per cell) that occurs when the battery reaches full charge. For a 6V battery (5 cells), this means watching for a 25-50mV drop from peak voltage.

Step-by-Step Charging Procedure

- Pre-Charge Check: Verify battery voltage isn’t below 4V (for a 6V pack) to prevent overstressing depleted cells

- Temperature Monitoring: Keep battery below 45°C during charging – use thermal protection if available

- Top-Up Charge: After main charge, apply a trickle charge at 0.02C (60mA for 3000mAh) to compensate for self-discharge

Maintenance Best Practices

- Monthly Full Discharge: Completely drain the battery (to ~5V) every 30 charges to prevent memory effect

- Storage Voltage: Store at 40% charge (about 6.2V) in cool (15°C) conditions to minimize self-discharge

- Terminal Cleaning: Remove corrosion from contacts quarterly using isopropyl alcohol to maintain proper voltage transfer

Pro Tip: For industrial batteries like the Power Sonic PS-606, use a smart charger with refresh cycles that automatically discharge and recharge to maintain capacity. This is especially important for batteries in backup systems that rarely fully discharge.

Advanced Troubleshooting and Performance Optimization

Understanding the deeper operational characteristics of NiCd 6V batteries enables users to diagnose issues and extract maximum performance. This section explores voltage analysis techniques, capacity restoration methods, and professional-grade optimization strategies.

Diagnosing Voltage-Related Issues

Voltage anomalies often reveal underlying battery problems. A healthy 6V NiCd battery should maintain:

| Condition | Expected Voltage | Warning Signs |

|---|---|---|

| Resting (24h after charge) | 6.4-6.6V | Below 6.2V indicates self-discharge issues |

| Under 50% load | 5.8-6.2V | Instant drop below 5.5V suggests weak cells |

| Post-discharge recovery | 5.7-6.0V | Failure to recover above 5.5V signals cell damage |

Capacity Restoration Techniques

When facing reduced runtime, these professional methods can often revive NiCd batteries:

- Deep Cycling: Perform 3-5 complete discharge/charge cycles using a controlled load (e.g., 0.2C discharge rate)

- Equalization Charge: Apply 115% of normal charge current for 2-3 hours to balance cell voltages

- Freeze-Thaw Method: For severely crystallized batteries, freeze at -20°C for 3 hours, then slowly warm to room temperature before charging

Advanced Performance Enhancement

- Pulse Charging: Using 2-5ms high-current pulses (2-3C) between normal charging can break down crystalline formations

- Temperature Compensation: Adjust charge voltage by -4mV/°C when operating outside 20-25°C range

- Load Matching: For RC applications like the Tenergy 6V, pair battery with ESC that has programmable LVC (Low Voltage Cutoff) set to 5.2V

Critical Warning: Never attempt to disassemble NiCd batteries – cadmium exposure poses serious health risks. For industrial batteries like the Power Sonic PS-606, always consult manufacturer documentation before attempting advanced recovery procedures.

Safety Protocols and Industry Standards for 6V NiCd Batteries

Working with NiCd batteries requires strict adherence to safety protocols due to their chemical composition and electrical characteristics. This section covers essential safety measures, industry compliance standards, and specialized handling procedures for different applications.

Critical Safety Considerations

NiCd batteries present unique hazards that demand specific precautions:

- Thermal Runaway Prevention: Never charge above 45°C ambient temperature – use thermal sensors for industrial applications like the Power Sonic PS-606

- Ventilation Requirements: Charge in well-ventilated areas to disperse hydrogen gas emitted during overcharge (0.1C rate produces ~0.24L gas/Ah daily)

- Cadmium Exposure Control: Always wear nitrile gloves when handling leaking batteries – cadmium compounds are toxic if absorbed through skin

Industry Compliance Standards

Quality NiCd batteries like the Panasonic NC-6V2000F must meet multiple international standards:

| Standard | Requirement | Testing Protocol |

|---|---|---|

| IEC 60623 | Cycle life ≥500 at 0.2C discharge | Charge at 0.1C for 16h, discharge to 5V at 20±5°C |

| UL 2054 | Explosion/fire prevention | 10V overcharge test for 7h with monitoring |

| RoHS | Cadmium content labeling | XRF analysis with <1000ppm threshold |

Application-Specific Handling

Different uses demand tailored safety approaches:

- Medical Equipment: Implement redundant voltage monitoring with <1% tolerance sensors to prevent under-voltage incidents

- RC Vehicles: Use impact-resistant battery boxes and install 6V-rated circuit breakers within 30cm of battery terminals

- Emergency Lighting: Monthly load testing should never discharge below 5.5V to preserve battery health

Professional Tip: For institutional settings, maintain a battery log tracking each unit’s charge cycles, voltage trends, and maintenance history. This documentation is often required for compliance audits and helps predict end-of-life replacement timing.

Long-Term Performance Analysis and Replacement Strategies

Maximizing the value of NiCd 6V batteries requires understanding their lifecycle characteristics and implementing strategic replacement protocols. This section provides a detailed framework for evaluating battery health, predicting lifespan, and making cost-effective replacement decisions.

Lifecycle Performance Metrics

NiCd batteries exhibit predictable degradation patterns that can be monitored through key indicators:

| Age Marker | Performance Threshold | Action Required |

|---|---|---|

| 0-200 cycles | >95% original capacity | Normal operation |

| 200-500 cycles | 85-95% capacity | Increase maintenance frequency |

| 500+ cycles | <85% capacity | Replacement consideration |

Cost-Benefit Analysis: Repair vs Replace

When facing performance decline, consider these factors:

- Reconditioning Potential: Batteries showing >70% capacity after deep cycling may benefit from electrolyte additives (professional service only)

- Operational Criticality: For mission-critical applications (e.g., medical devices), replace at first signs of voltage instability (>5% fluctuation under load)

- Environmental Costs: Proper NiCd recycling costs $2-5 per battery but prevents hazardous waste – factor into total ownership cost

Future-Proofing Your Battery Systems

As battery technology evolves, consider these emerging trends:

- Hybrid Systems: Pairing NiCd with supercapacitors can extend lifespan by 20-30% in high-pulse applications

- Smart Monitoring: New IoT-enabled battery monitors track internal resistance (should be <150mΩ for 6V NiCd) in real-time

- Material Recovery: Emerging hydrometallurgical processes can recover 98% of cadmium for reuse – check for local programs

Pro Tip: Maintain a “burn-in” protocol for new batteries – cycle them 5-10 times at 0.2C before full deployment. This stabilizes internal chemistry and can add 50+ cycles to overall lifespan. For industrial batteries like the Power Sonic PS-606, this process should be supervised with proper logging.

System Integration and Performance Optimization Techniques

Proper integration of NiCd 6V batteries into larger systems dramatically impacts their efficiency and lifespan. This section explores advanced configuration strategies, load matching principles, and system-level optimization approaches for professional applications.

Voltage Regulation and Power Conditioning

NiCd batteries require specific conditioning to maintain stable system voltage:

- Buck-Boost Converters: Essential when pairing with 5V or 12V systems – set output voltage within ±3% of target to prevent cell imbalance

- Peak Load Management: For high-drain devices, implement capacitor banks (1000μF per amp of surge current) to reduce voltage sag

- Parallel Configurations: When connecting multiple 6V NiCd batteries, use matched sets (<10% capacity variance) with individual charge monitoring

Advanced Load Profiling Techniques

Optimizing battery performance requires detailed load analysis:

| Load Type | Optimal Configuration | Efficiency Gain |

|---|---|---|

| Continuous (e.g., emergency lighting) | 0.2C discharge rate with LVD at 5.5V | 15-20% longer runtime |

| Intermittent (e.g., power tools) | Pulse charging between uses | 30% faster recovery |

| Mixed (e.g., robotics) | Hybrid NiCd/supercapacitor design | 40% cycle life extension |

System-Level Troubleshooting Guide

Common integration issues and solutions:

- Voltage Oscillation: Add 100-470μF electrolytic capacitors near battery terminals when voltage fluctuates >5% under load

- Premature Cutoff: Recalibrate battery management systems (BMS) to account for NiCd’s voltage drop characteristics

- Uneven Wear: Implement monthly capacity balancing cycles for parallel battery configurations

Professional Insight: For industrial systems using Power Sonic PS-606 batteries, consider implementing a predictive maintenance algorithm that analyzes charge/discharge curves to forecast cell degradation. This advanced approach can predict failure points with 85% accuracy 50+ cycles in advance.

Advanced Quality Assurance and Risk Mitigation Strategies

Implementing robust quality control measures for NiCd 6V batteries ensures optimal performance while minimizing operational risks. This section details professional-grade validation protocols, failure mode analysis, and comprehensive risk management frameworks.

Comprehensive Performance Validation Protocol

Professional battery testing should include these critical assessments:

| Test Parameter | Acceptance Criteria | Measurement Protocol |

|---|---|---|

| Capacity Verification | >90% rated capacity at 0.2C | Discharge to 5V at 20°C ±2°C |

| Internal Resistance | <150mΩ for new batteries | 1kHz AC impedance measurement |

| Cycle Life Validation | 500 cycles @ 80% capacity | 0.5C charge/discharge with 1h rest |

Failure Mode and Effects Analysis (FMEA)

Critical risk assessment for NiCd battery systems:

- Thermal Runaway: Mitigate with temperature cutoffs at 50°C and thermal fuses rated for 6V/10A

- Memory Effect: Implement mandatory full discharge cycles every 30 charges for capacity recovery

- Cell Reversal:

Prevent with individual cell monitoring in series configurations (critical for >3 battery stacks)

Advanced Maintenance Scheduling

Optimized maintenance intervals based on usage patterns:

- High-Cycle Applications (daily use): Monthly capacity tests + quarterly deep cycling

- Standby Systems: Bimonthly float voltage verification + annual load bank testing

- Extreme Environments: Weekly visual inspection + monthly terminal resistance checks

Professional Validation Technique: For mission-critical applications, implement Design of Experiments (DOE) testing with 3-5 control batteries under accelerated aging conditions (45°C, 1C cycling) to predict long-term performance. This 30-day test can simulate 12+ months of normal operation with 95% correlation accuracy.

Conclusion

Understanding NiCd 6V battery voltage characteristics and maintenance requirements is essential for maximizing performance and lifespan. Throughout this guide, we’ve explored the complete voltage profile from full charge (7.2V) to depletion (5V), proper charging techniques, advanced troubleshooting methods, and comprehensive safety protocols.

The detailed voltage chart serves as your roadmap for monitoring battery health, while the maintenance strategies ensure optimal operation in various applications – from RC vehicles to emergency systems.

Remember: Regular voltage monitoring under load, proper cycling, and temperature management are the keys to getting the most from your NiCd batteries. Implement these professional techniques today to significantly extend your battery’s service life and maintain peak performance.

Frequently Asked Questions About NiCd 6V Batteries

What voltage should a fully charged 6V NiCd battery show?

A healthy NiCd 6V battery will initially read 7.2V immediately after charging (due to surface charge), then stabilize at 6.5-6.8V after 30-60 minutes. This higher voltage occurs because NiCd batteries typically consist of five 1.2V cells in series.

For accurate measurement, test voltage under a 0.1C load – a true full charge should maintain at least 6.5V under this load for quality batteries like the Tenergy 3000mAh model.

How can I tell if my 6V NiCd battery needs replacement?

Key replacement indicators include: voltage dropping below 5V under minimal load, taking less than 70% of original charge capacity, or showing internal resistance above 200mΩ.

For example, if your Power Sonic PS-606 that originally ran a device for 4 hours now only lasts 2.5 hours, it’s likely failing. Also check for physical signs like terminal corrosion or bulging casing.

What’s the proper way to store NiCd 6V batteries long-term?

For optimal storage (3-12 months): charge to 40% capacity (~6.2V), store in a dry place at 10-25°C, and recharge every 6 months. Never store fully charged or completely depleted. Industrial users should note that Panasonic recommends specific storage protocols for their NC-6V2000F – maintain 30-50% charge in climate-controlled environments.

Why does my NiCd battery voltage drop suddenly under load?

This voltage sag indicates either aging cells (increased internal resistance) or excessive current draw. A healthy 6V NiCd should maintain within 0.5V of its resting voltage under rated load.

For instance, if your battery reads 6.4V at rest but drops to 5.2V when powering an RC car, it likely has weak cells. This problem worsens in cold temperatures.

How often should I perform deep discharge cycles on NiCd batteries?

Perform a full discharge to 5V every 30 charge cycles or monthly for infrequently used batteries. This prevents memory effect. For critical applications like medical devices, use a controlled discharge at 0.1C rate while monitoring individual cell voltages. Never deep discharge below 4.5V total as this can cause cell reversal and permanent damage.

Can I use a regular charger for my 6V NiCd battery?

Only use NiCd-specific chargers with proper termination methods (-ΔV detection or temperature cutoff). Standard chargers may overcharge, causing thermal runaway.

Quality chargers like the Tenergy TN270 automatically adjust for 6V NiCd batteries, charging at 0.1C (300mA for 3000mAh) with trickle maintenance. Fast charging requires specialized equipment with thermal monitoring.

What safety precautions are essential when handling NiCd batteries?

Always wear gloves when handling leaking batteries due to toxic cadmium. Charge in well-ventilated areas to disperse hydrogen gas. Never expose to temperatures above 60°C or below -20°C. For industrial batteries like the Power Sonic PS-606, install thermal fuses and use explosion-proof containers in hazardous environments.

How does NiCd battery performance compare to lithium-ion at 6V?

NiCd offers advantages in extreme temperatures (-40°C to 60°C operation), higher cycle life (500-1000 vs 300-500), and better surge current handling. However, lithium-ion provides 3-4x energy density (longer runtime) and doesn’t suffer memory effect. Choose NiCd for rugged applications like construction equipment where reliability trumps runtime.