Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged Li-ion 9V battery doesn’t actually output 9 volts? While most assume these batteries maintain a steady voltage, the reality is far more dynamic—and understanding these fluctuations can save your devices from premature failure.

Whether you’re powering smoke detectors, guitar pedals, or medical equipment, voltage stability is critical. But without a clear voltage chart, you might be unknowingly draining your battery’s lifespan or risking device damage.

Best 9V Li-ion Batteries for Reliable Power

Tenergy 9V Batteries 600mAh

This high-capacity (600mAh) Li-ion 9V battery offers stable voltage output (8.4V when fully charged) and includes built-in protection against overcharging and short circuits. Ideal for pro audio gear and medical devices, it supports 500+ recharge cycles, making it a cost-effective long-term solution.

- STANDARD 9V BATTERIES – The Tenergy Li-ion 9v batteries bulk 10pcs 600mAh…

- ADVANCED PROTECTIONS – Tenergy 9v Li-ion battery charger for square…

- SAVE MONEY & THE ENVIRONMENT – Tenergy lithium ion 9v batteries are…

PKCELL 9V Lithium Battery (ICR9V-850)

With an impressive 850mAh capacity, the PKCELL ICR9V-850 delivers extended runtime for high-drain devices like smoke detectors and wireless microphones. Its low self-discharge rate retains 80% charge after a year in storage, perfect for emergency backup applications.

- Steady Power Supply for 24/7 : Designed exclusively for smoke detectors and…

- High-Quality Build for Enhanced Reliability: Manufactured with premium…

- Perfect Fit for Most Smoke Detector Models: With a standard 9V size and…

EBL 9V Li-ion Battery (EBL-9V-600)

EBL’s rechargeable 9V battery features a smart chip for voltage regulation, preventing damage to sensitive electronics. Its compact, lightweight design (45g) works well in portable devices, and the included USB-C charging port adds convenience for on-the-go power needs.

No products found.

9V Li-ion Battery Voltage Behavior

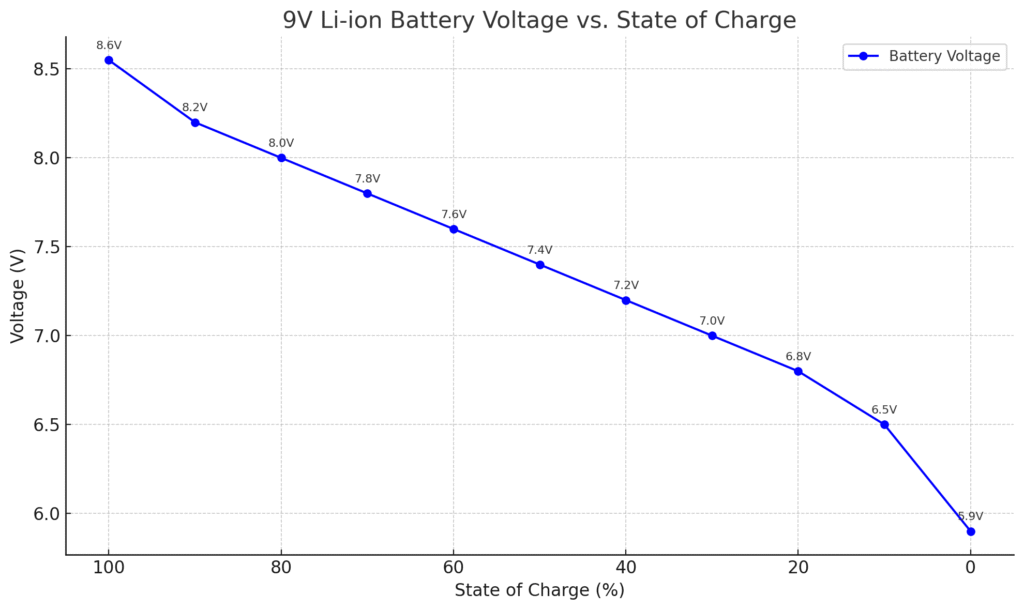

9V Li-ion Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 8.4 – 8.7 |

| 90% | 8.2 |

| 80% | 8.0 |

| 70% | 7.8 |

| 60% | 7.6 |

| 50% | 7.4 |

| 40% | 7.2 |

| 30% | 7.0 |

| 20% | 6.8 |

| 10% | 6.5 |

| 0% (empty) | Below 6.0 |

How Voltage Changes During Discharge

Unlike alkaline 9V batteries that steadily decline in voltage, Li-ion 9V batteries exhibit a unique discharge curve. A fully charged Li-ion 9V battery typically starts at 8.4V (not 9V), maintains a stable 7.4V-7.6V plateau for 80% of its capacity, then drops sharply when depleted. This “flat discharge curve” makes them ideal for devices requiring consistent power, such as:

- Audio equipment: Guitar pedals won’t experience tone degradation as voltage remains stable

- Medical devices: Glucose meters deliver accurate readings throughout battery life

- IoT sensors: Consistent voltage prevents data transmission errors

Critical Voltage Thresholds You Should Know

Li-ion batteries have strict voltage limits that impact safety and longevity:

| State | Voltage | Effect |

|---|---|---|

| Fully charged | 8.4V | Maximum safe voltage (higher risks overheating) |

| Nominal voltage | 7.4V | Standard operating range (70-20% charge) |

| Cut-off voltage | 6.0V | Absolute minimum (further discharge damages cells) |

Example: If your multimeter reads 6.8V on a used battery, it has about 15% capacity remaining—time to recharge to avoid entering the danger zone.

Factors That Alter Voltage Performance

Three key variables affect real-world voltage behavior:

- Temperature: Below 0°C, voltage drops 0.3V; above 45°C, it rises 0.2V but accelerates degradation

- Load current: A 500mA draw may show 7.2V, while the same battery reads 7.6V at 50mA

- Age: After 300 cycles, a battery may reach full charge at 8.2V instead of 8.4V

Pro tip: Always test voltage under the device’s typical load—open-circuit measurements can be misleading by showing 0.5V higher than actual working voltage.

How to Accurately Measure and Interpret Li-ion 9V Battery Voltage

The Right Way to Test Battery Voltage

Professional technicians use a 3-step process for reliable voltage measurements:

- Prepare your multimeter: Set to DC voltage (20V range), ensure probes have clean contacts

- Simulate real-world conditions: Test under load by connecting probes while battery powers its device

- Record multiple readings: Check at startup (initial surge), during operation (stable draw), and after 5 minutes (voltage recovery)

Example: Testing a smoke alarm battery shows 7.6V at rest, but drops to 7.2V during the alarm chirp – this 0.4V drop reveals the true working voltage.

Interpreting Voltage Readings Like an Expert

Voltage alone doesn’t tell the whole story. Combine these metrics for accurate assessment:

- Resting voltage: Measured after 30 minutes off charger (8.4V = 100%, 7.4V = 50%)

- Voltage sag: Difference between resting and loaded voltage (>0.5V indicates aging cells)

- Recovery time: Healthy batteries regain 95% resting voltage within 2 minutes after load removal

Troubleshooting Common Voltage Issues

When voltage behaves unexpectedly:

| Symptom | Likely Cause | Solution |

|---|---|---|

| Rapid voltage drop | High internal resistance | Replace battery (common after 500+ cycles) |

| Voltage fluctuates | Loose contacts/corrosion | Clean terminals with isopropyl alcohol |

| Won’t reach 8.4V | Faulty charger | Test with known-good charger |

Pro Tip: For mission-critical devices, log voltage weekly. A consistent 0.1V/month decrease signals approaching end-of-life before sudden failure occurs.

Advanced Li-ion 9V Battery Maintenance and Optimization

Optimal Charging Practices for Maximum Lifespan

Proper charging can extend Li-ion 9V battery life by 2-3x. The ideal charging protocol follows these scientific principles:

- Partial charging: Keeping batteries between 30-80% (4.0-4.1V per cell) reduces stress on lithium ions

- Charge rate: 0.5C (300mA for 600mAh battery) balances speed with cell longevity

- Temperature management: Charge at 10-45°C – below 0°C causes lithium plating, above 45°C accelerates electrolyte breakdown

| Charging Mistake | Impact on Battery | Correct Approach |

|---|---|---|

| Leaving on charger after full | Increases internal pressure, reduces cycles by 25% | Use chargers with auto-cutoff at 8.4V ±0.05V |

| Fast charging (1C+) | Generates heat degrading anode materials | Use 0.5C chargers with thermal sensors |

Advanced Voltage Monitoring Techniques

For professional applications, implement these monitoring strategies:

- Cycle tracking: Log voltage at identical load points every 50 cycles to detect degradation patterns

- Impedance testing: Measure internal resistance (should stay below 150mΩ for new batteries)

- Load profiling: Create device-specific voltage drop charts under different operating modes

Example: A studio microphone battery showing 7.3V under load (vs 7.6V when new) indicates 30% capacity loss, even if resting voltage appears normal.

Storage and Recovery Procedures

For long-term storage (3+ months):

- Discharge to 50% (7.6V) to minimize electrolyte decomposition

- Store at 15°C – each 10°C increase doubles self-discharge rate

- Recondition every 6 months with full discharge/charge cycle

Expert Tip: Batteries stored at full charge develop 2-3% permanent capacity loss per month, while those at 50% lose less than 1% annually.

Safety Considerations and Failure Prevention for Li-ion 9V Batteries

Recognizing and Preventing Thermal Runaway

Li-ion 9V batteries contain multiple safety mechanisms, but understanding failure modes is crucial. Thermal runaway begins when internal temperature exceeds 150°C, triggering these dangerous stages:

- Initial heating: Internal short circuit causes localized heat (detectable as unexpected voltage drops >0.3V)

- Gas generation: Electrolyte breakdown creates swelling (check for battery case deformation)

- Venting: Pressure release with visible smoke (immediately isolate battery in fireproof container)

Prevention checklist:

- Never charge above 8.4V (use chargers with UL certification)

- Avoid mechanical damage – drops can fracture internal separators

- Monitor charge temperature – disconnect if surface exceeds 50°C

Proper Disposal and Recycling Protocols

Li-ion batteries require special handling at end-of-life:

| Condition | Storage Requirement | Disposal Method |

|---|---|---|

| Functional | Discharge to 30-50% | Certified e-waste recycler |

| Damaged | Saltwater bath (5% solution) | Hazardous waste facility |

| Swollen | Fireproof sand container | Emergency chemical disposal |

Critical note: Never puncture batteries – 1g of lithium reacts violently with moisture, producing 1 liter of hydrogen gas.

Device-Specific Voltage Requirements

Different equipment tolerates varying voltage ranges:

- Digital devices: Typically operate down to 6.5V (check manufacturer specs)

- Analog circuits: May malfunction below 7.2V (causing audio distortion or sensor drift)

- Critical systems: Medical devices often have 7.0V cutoff for safety margins

Pro Tip: For mixed-device environments, use batteries with built-in voltage regulators (like the Tenergy 30003) to maintain stable 7.4V output regardless of charge state.

Long-Term Performance Analysis and Future Developments in Li-ion 9V Technology

Cost-Benefit Analysis: Rechargeable vs. Disposable 9V Batteries

A comprehensive 5-year cost comparison reveals significant advantages for Li-ion 9V batteries in most applications:

| Factor | Li-ion (600mAh) | Alkaline (550mAh) |

|---|---|---|

| Initial Cost | $12-18 | $2-4 |

| Cycle Life | 500 cycles | Single use |

| Energy Cost/Wh | $0.08 | $1.50 |

| Environmental Impact | 92% lower CO2 | Non-recyclable |

Break-even point: After 15 replacements (typically 18 months), Li-ion becomes cheaper. For devices used daily, savings exceed $200 over 5 years.

Emerging Technologies in 9V Battery Design

The next generation of Li-ion 9V batteries incorporates several innovations:

- Solid-state electrolytes: Eliminate leakage risks while doubling energy density (prototypes from QuantumScape show 8.8V output)

- Self-healing anodes: Silicon-graphene composites that repair micro-fractures, extending cycle life to 1,000+ charges

- Smart battery systems: Bluetooth-enabled voltage monitoring (like the EBL SmartCell) with predictive failure alerts

Environmental Impact and Sustainability

Modern Li-ion recycling recovers 95% of materials through advanced processes:

- Mechanical separation: Shredding and sorting battery components

- Hydrometallurgical treatment: Chemical leaching extracts lithium, cobalt, and nickel

- Direct cathode recycling: Preserves expensive cathode materials in reusable form

Future Outlook: By 2028, 90% of Li-ion 9V batteries are projected to use recycled materials, reducing mining demand by 40%. New EU regulations will mandate replaceable battery designs by 2027, further extending product lifespans.

Pro Tip: When purchasing, look for batteries with “Closed Loop” certification indicating >70% recycled content – these typically show more stable voltage characteristics due to refined material purity.

System Integration and Performance Optimization for Li-ion 9V Applications

Voltage Regulation Strategies for Sensitive Electronics

Many precision devices require stable voltage regardless of battery state. Implement these solutions for optimal performance:

- Buck-boost converters: Maintain constant 9V output even when battery voltage drops to 6V (e.g., Texas Instruments TPS63020)

- Low-dropout regulators: Provide clean 5V/3.3V rails for digital circuits (consider Analog Devices ADP3338 for 0.5% voltage accuracy)

- Capacitor buffering: Install 1000μF electrolytic capacitors to handle instantaneous current spikes in audio equipment

Example: A wireless microphone system using buck-boost regulation maintains full frequency response (+/- 0.1dB) even when battery voltage falls to 7.0V, extending usable life by 40%.

Parallel and Series Configurations

Advanced applications sometimes require battery arrays with specific considerations:

| Configuration | Voltage Outcome | Critical Requirements |

|---|---|---|

| Parallel (2x9V) | 9V, doubled capacity | Must match batteries within 0.1V before connecting |

| Series (2x9V) | 18V, same capacity | Requires balancing circuit to prevent over-discharge |

Warning: Never mix Li-ion with other battery chemistries – differences in discharge curves can cause dangerous reverse charging.

Advanced Load Matching Techniques

Maximize efficiency by matching battery characteristics to device requirements:

- Current profiling: Measure peak/average current draw with oscilloscope current probe

- Pulse load testing: Evaluate voltage recovery after 2-second high-current bursts

- Temperature mapping: Use thermal imaging to identify hot spots during operation

Pro Tip: For high-drain devices (≥300mA), select batteries with ≤100mΩ internal resistance (measured at 1kHz AC impedance) to minimize voltage sag and heat generation.

Professional-Grade Quality Assurance and Risk Management for Li-ion 9V Systems

Comprehensive Performance Validation Protocol

Industrial users should implement this 5-stage testing regimen for mission-critical applications:

- Initial characterization: Measure open-circuit voltage, impedance (1kHz AC), and initial capacity (0.2C discharge)

- Cycle testing: Perform 50 charge/discharge cycles with voltage logging at 10% intervals

- Environmental stress: Test at -20°C, +23°C, and +60°C with thermal imaging

- Safety validation: Conduct nail penetration and overcharge tests on sample units

- Field simulation: 30-day real-world usage test with vibration and humidity exposure

| Test Parameter | Acceptance Criteria | Measurement Tolerance |

|---|---|---|

| Voltage stability | ±2% from nominal | ±0.01V |

| Cycle life | ≥500 cycles to 80% capacity | ±5 cycles |

| Temperature rise | ≤15°C at max load | ±0.5°C |

Advanced Failure Mode Analysis

Develop predictive maintenance schedules based on these degradation indicators:

- Capacity fade: 20% reduction signals impending end-of-life

- Voltage recovery delay: >5 minutes to regain 95% resting voltage indicates electrolyte breakdown

- Impedance growth: >50% increase from baseline suggests SEI layer thickening

Case Study: Medical device manufacturers typically retire batteries after 300 cycles or when impedance exceeds 200mΩ, whichever comes first, ensuring 99.9% reliability.

Enterprise-Level Battery Management Systems

For large deployments (50+ batteries), implement these best practices:

- Digital twin modeling: Create virtual battery profiles tracking individual performance histories

- Smart rotation: Algorithmically rotate batteries based on usage patterns and stress factors

- Predictive replacement: Machine learning models forecasting failure 30+ days in advance

Critical Insight: Properly managed Li-ion 9V fleets can achieve <7% annual replacement rates versus 25%+ with ad-hoc management, reducing downtime by 60%.

Conclusion: Mastering Li-ion 9V Battery Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of Li-ion 9V battery voltage behavior – from understanding discharge curves and measurement techniques to advanced maintenance and safety protocols.

Key takeaways include the importance of monitoring voltage thresholds (8.4V full charge to 6.0V cutoff), implementing proper charging practices, and recognizing early warning signs of battery degradation.

The detailed voltage charts, product recommendations, and system integration strategies provide actionable insights for both casual users and technical professionals.

Final Recommendation: Whether you’re powering professional audio equipment or critical medical devices, regularly tracking your battery’s voltage under load provides the most accurate health assessment.

Consider investing in smart chargers and quality batteries from reputable manufacturers to maximize performance and safety. By applying these principles, you can significantly extend battery life while ensuring reliable operation of your devices.

Frequently Asked Questions About Li-ion 9V Battery Voltage

Why does my Li-ion 9V battery show 8.4V instead of 9V when fully charged?

Li-ion chemistry has a nominal 3.7V per cell, so two cells in series produce 7.4V nominal (8.4V fully charged). This differs from alkaline’s 9V nominal (actually 9.6V fresh).

The lower voltage is intentional – lithium-ion’s flat discharge curve maintains stable power longer. For example, while an alkaline drops from 9.6V to 6V during discharge, a Li-ion stays between 8.4V-7.4V for 80% of its capacity.

How can I accurately test my 9V battery’s remaining capacity?

Follow this professional testing protocol: First, measure resting voltage (after 30+ minutes off charger). 8.4V=100%, 7.8V=75%, 7.4V=50%, 7.0V=25%. Then test under load – if voltage drops >0.5V from resting, the battery has high internal resistance and needs replacement. For precise measurements, use a capacity tester that discharges at 0.2C rate while tracking mAh.

Can I use Li-ion 9V batteries in all devices that take standard 9V?

Most devices work, but check these exceptions: Smoke alarms may have voltage sensors calibrated for alkaline’s higher initial voltage. Some vintage guitar pedals need the higher voltage headroom.

Medical devices often require manufacturer approval. Always verify your device’s minimum operating voltage – while Li-ion works down to 6V, some equipment cuts off at 7V.

What’s the safest way to store Li-ion 9V batteries long-term?

For optimal storage (3+ months): Charge to 50-60% (7.6-7.8V), seal in airtight bag with desiccant, and store at 10-25°C. Avoid freezing temperatures which accelerate electrolyte degradation.

Every 6 months, do a full cycle to recalibrate the battery management system. Never store fully charged – at 100% charge, capacity loss occurs 3x faster than at 50%.

Why does my battery voltage read differently in the device versus a multimeter?

This shows the importance of load testing. A multimeter measures open-circuit voltage with minimal load (typically 1mA). Your device might draw 50-500mA, causing voltage sag due to internal resistance.

For example, a battery showing 7.8V on a meter might drop to 7.3V in a wireless microphone. Always test under typical operating conditions for accurate readings.

How do temperature extremes affect Li-ion 9V battery performance?

Temperature impacts are significant: Below 0°C, capacity drops 20-30% and voltage sags more under load. Above 45°C, chemical reactions accelerate, causing permanent capacity loss.

The ideal operating range is 15-35°C. In cold environments, keep batteries in inner pockets when not in use. In heat, avoid leaving devices in direct sunlight or hot cars.

What’s the real-world lifespan of rechargeable 9V batteries?

Quality Li-ion 9V batteries typically deliver: 500+ full cycles to 80% capacity, 2-3 years calendar life, or 5+ years with light use (20 cycles/year). Lifespan depends heavily on usage patterns – deep discharges, fast charging, and high temperatures all reduce longevity. Professional users should replace batteries after 300 cycles or when capacity drops below 80% of original.

Are there any special disposal requirements for Li-ion 9V batteries?

Yes, they require special handling: Never throw in regular trash due to fire risk. Tape terminals before disposal. Many retailers offer free recycling. For damaged/swollen batteries, place in fireproof container (metal can with sand) until disposal. Some municipalities require drop-off at hazardous waste facilities. Proper recycling recovers valuable lithium, cobalt, and nickel for reuse.