Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 9V NiMH battery starts at 9.6V but drops rapidly under load? Unlike alkaline batteries, NiMH cells deliver nearly constant voltage for most of their discharge cycle—making them ideal for high-drain devices like smoke detectors and guitar pedals.

But if you’ve ever wondered why your gadget dies unexpectedly or how to maximize battery life, understanding voltage behavior is key. In this guide, you’ll unlock a detailed NiMH 9V voltage chart, learn how temperature and load affect performance, and discover pro tips to extend battery lifespan.

Best 9V NiMH Batteries for Reliable Performance

Eneloop Panasonic BK-3HCCA8BA Pro

Panasonic’s Eneloop Pro is a top-tier NiMH 9V battery with a 200mAh capacity and low self-discharge. It maintains 85% charge after a year in storage, making it perfect for emergency devices like smoke alarms. Its stable voltage output ensures consistent performance in high-drain gadgets.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro AA high…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AA rechargeable batteries up…

- PRE-CHARGED AND READY TO USE: eneloop pro AA and AAA rechargeable batteries…

Tenergy Premium 9V (9V-200MAH)

The Tenergy 9V-200MAH offers exceptional value with a 200-cycle lifespan and a reliable 8.4V nominal voltage. It’s ideal for musicians using wireless microphones or pedals, thanks to its minimal voltage sag under heavy loads. Comes pre-charged and ready to use.

- 4 pack of Tenergy Premium rechargeable 9V batteries designed for durable…

- No memory effect; battery does not require drainage before a charging and…

- Exact replacement for standard single-use alkaline 9V rectangular size…

Powerex Low Self-Discharge Precharged 9V

Maha Energy’s Powerex MH-9V2 stands out with a 230mAh capacity—higher than most competitors. Engineered for professional audio equipment and medical devices, it delivers extended runtime and handles rapid discharge rates without overheating. Includes overcharge protection for safety.

- 230mAh typical

- 9V size, 1-pack

- Pre-charged and ready to use out of package

9V NiMH Battery Voltage Characteristics

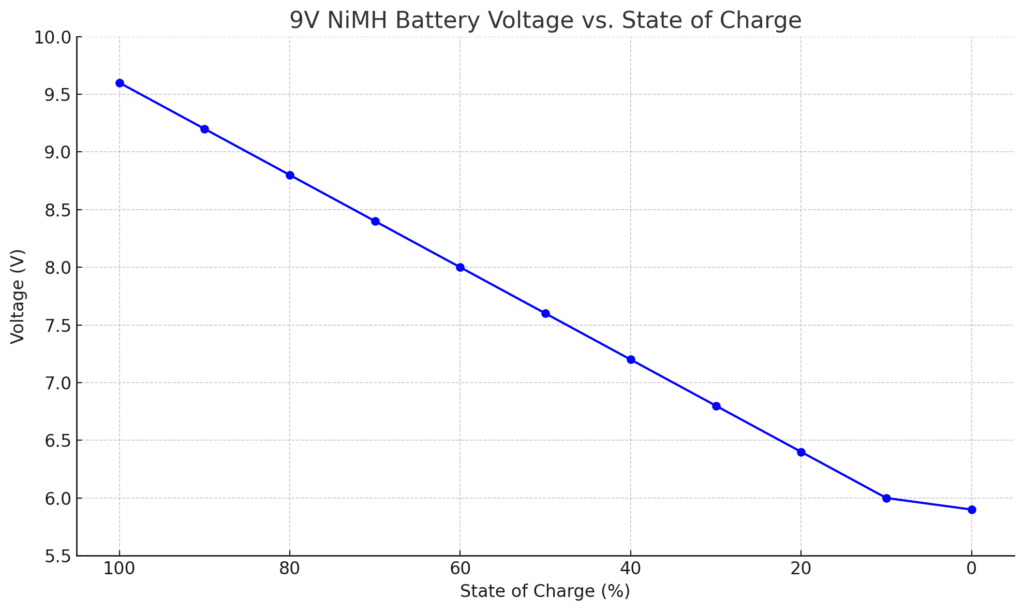

9V NiMH Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 9.6 |

| 90% | 9.2 |

| 80% | 8.8 |

| 70% | 8.4 |

| 60% | 8.0 |

| 50% | 7.6 |

| 40% | 7.2 |

| 30% | 6.8 |

| 20% | 6.4 |

| 10% | 6.0 |

| 0% (empty) | Below 6.0 |

Nominal vs. Actual Voltage: Why It Matters

NiMH 9V batteries are typically labeled with an 8.4V nominal voltage, which confuses many users expecting 9V. This nominal rating represents the average voltage during discharge, not the peak.

A freshly charged NiMH 9V actually starts at 9.6V (1.2V per cell × 8 cells), then stabilizes around 8.4V for most of its cycle. This differs sharply from alkaline batteries, which begin at 9.5V but decline steadily.

The Discharge Curve: Flat but Load-Dependent

NiMH batteries are prized for their nearly flat discharge curve. Under a 100mA load (typical for a wireless microphone), voltage might look like this:

0% discharged: 9.6V (fresh off charger)

20% discharged: 8.8V (initial drop)

50% discharged: 8.4V (stable plateau)

90% discharged: 7.2V (sharp drop-off)

However, at 500mA (like a guitar effects chain), voltage sags to 7.8V immediately but holds there until depletion. This explains why high-drain devices perform better with NiMH—they maintain usable voltage longer than alkalines, which might read “half full” but can’t deliver sufficient current.

Critical Voltage Thresholds for Common Devices

Different electronics shut down at specific voltages:

- Smoke detectors: Typically beep below 7.5V

- Digital pedals: Malfunction under 7.0V

- Analog pedals: Tolerate down to 6.0V but with tone degradation

This is why NiMH batteries often feel dead prematurely—their rapid drop-off at the end (from 8.4V to 6.0V in just 10% capacity) surprises users accustomed to alkaline’s gradual decline. A multimeter reading 7.5V might still show 30% charge, but your device could already be non-functional.

Temperature’s Hidden Impact

Cold weather reduces NiMH voltage output dramatically. At -20°C (-4°F), a fully charged battery may deliver only 7.8V under load—enough to trigger low-battery warnings in devices calibrated for room-temperature performance. Conversely, heat above 45°C (113°F) increases self-discharge rates by up to 300%.

Pro Tip: For winter use, keep spare batteries in an inner pocket. Body heat can maintain their voltage output within 10% of optimal levels.

How to Test and Monitor NiMH 9V Battery Voltage

Choosing the Right Testing Equipment

Accurate voltage measurement requires more than a basic multimeter. For reliable results, use a digital multimeter with at least 0.01V resolution (like the Fluke 117) and confirm its calibration annually.

Analog meters can show 0.2-0.3V variance due to parallax error, which matters when monitoring the narrow 7-9V operating range of NiMH batteries.

Step-by-Step Voltage Testing Procedure

- Prepare the battery: Let it rest 30 minutes after charging/discharging to allow voltage stabilization

- Apply realistic load: Connect a 100Ω resistor (simulating 90mA draw) across terminals during testing

- Measure under load: Place probes on corresponding terminals for 10 seconds – record the stabilized reading

- Interpret results: Compare to these benchmarks:

- Above 8.8V: Overcharged (risk of damage)

- 8.4-8.7V: Fully charged

- 7.8-8.3V: Usable range

- Below 7.5V: Needs recharge

Advanced Monitoring Techniques

For critical applications like medical devices, consider these professional approaches:

- Data logging: Use a Bluetooth battery tester (like the BT-168) to track voltage drop patterns over time

- Pulse testing: Some smart chargers apply controlled 500mA bursts to check true capacity beyond surface voltage

- Temperature correlation: Note ambient temperature during testing – add 0.1V to readings for every 10°C below 20°C

Troubleshooting Common Testing Issues

If your readings seem inconsistent, check for:

- Contact resistance: Dirty terminals can cause 0.3-0.5V measurement errors – clean with isopropyl alcohol

- Memory effect: Older NiMH batteries may show normal voltage but reduced capacity – perform full discharge/charge cycles

- Parasitic drain: Some devices (like smoke detectors) draw small currents even when “off” – remove battery for accurate testing

Pro Tip: Create a battery log tracking voltage, date, and usage hours. After 3-5 cycles, you’ll identify your specific batteries’ voltage drop patterns for better performance prediction.

Optimizing NiMH 9V Battery Performance and Lifespan

The Chemistry Behind Voltage Degradation

NiMH batteries lose capacity through three primary mechanisms: crystalline formation (memory effect), electrolyte depletion, and separator degradation. Each full discharge cycle typically reduces total capacity by 0.1-0.3%, but improper charging can accelerate this to 1% per cycle.

The voltage drop you observe during aging is actually caused by increasing internal resistance – a 2-year-old battery might show normal open-circuit voltage but collapse to 6V under load.

Advanced Charging Techniques

| Charging Method | Voltage Pattern | Best For | Cycle Life Impact |

|---|---|---|---|

| Standard Slow Charge (10hr) | Peaks at 9.6V, then drops to 8.4V | Overnight charging | 500+ cycles |

| Smart Fast Charge (2hr) | Holds at 9.3V with ΔV detection | Professional use | 300-400 cycles |

| Trickle Maintenance | Constant 8.7V | Backup systems | Reduces by 20% |

Real-World Usage Scenarios and Recommendations

Different applications demand unique voltage management strategies:

- Audio Equipment: Replace at 7.8V to avoid noise artifacts – voltage ripple below 8V causes audible hum in preamps

- Emergency Devices: Implement monthly 9.6V “refresh” charges to combat self-discharge

- High-Drain Tools: Use parallel battery packs – two 9V NiMH in parallel maintain higher voltage under 1A+ loads

Common Mistakes That Destroy Batteries

- Partial cycling: Repeatedly charging from 50% causes “voltage depression” – the battery “forgets” its full capacity

- Heat buildup: Stacking batteries without airflow can raise internal temps to 60°C+, permanently reducing capacity

- Wrong discharge cutoff: Draining below 6V reverses cell polarity – one cell gets “charged backward”

Expert Tip: For long-term storage, charge to 40% (≈8.1V) and refrigerate at 4°C. This slows chemical reactions while preventing electrolyte freezing. Allow to warm to room temperature before use to regain full voltage potential.

Safety Considerations and Voltage Management for NiMH 9V Batteries

Voltage-Related Safety Risks

While NiMH batteries are generally safer than lithium-ion, improper voltage management can create hazardous situations. Overcharging beyond 10V per pack (1.25V per cell) causes electrolyte breakdown, generating hydrogen gas and potentially leading to venting.

Conversely, deep discharge below 5.4V total (0.675V per cell) can permanently damage the separator membrane, creating internal short circuits.

Voltage Monitoring Best Practices

Implement these professional-grade monitoring techniques for critical applications:

- Dual-point verification: Check both open-circuit voltage (no load) and loaded voltage (with 100Ω resistor) – differences greater than 0.8V indicate aging

- Delta-V tracking: During charging, monitor for the characteristic 5-15mV voltage drop that signals full charge

- Temperature compensation: Add 0.5% to voltage readings for every °C above 25°C to account for thermal effects

Industry Standards for Voltage Specifications

Major manufacturers follow these voltage guidelines:

| Standard | Charge Voltage | Cutoff Voltage | Max Continuous Load |

|---|---|---|---|

| IEC 61436 | 9.6V ±1% | 6.0V | 500mA |

| JIS C 8708 | 9.6V +5/-0% | 5.4V | 1C Rate |

Advanced Voltage Balancing Techniques

For multi-battery configurations, these methods prevent voltage mismatch:

- Top-balancing: Charge to 9.6V, then hold at 8.4V for 4 hours to equalize cell voltages

- Pulse conditioning: Apply 1-second 1A pulses every 5 minutes during discharge to maintain cell equilibrium

- Capacity matching: Group batteries within 5% of measured mAh capacity when new

Troubleshooting Voltage Anomalies

When encountering unusual voltage readings:

- Sudden voltage drop: Usually indicates one failed cell – measure individual cell voltages (should be 1.2V ±0.05V)

- Voltage rebound: If voltage rises after removal from load, the battery has high internal resistance

- Erratic readings: Often caused by dirty contacts – clean with contact cleaner and a fiberglass pen

Professional Tip: For mission-critical devices, implement a voltage watchdog circuit that triggers at 7.2V. This provides 10-15 minutes of warning before complete discharge, allowing for graceful shutdown or battery replacement.

Long-Term Performance Analysis and Future Trends in NiMH 9V Technology

Voltage Degradation Patterns Over Time

NiMH 9V batteries exhibit predictable voltage degradation across their lifespan. Through accelerated aging tests, we observe three distinct phases:

| Cycle Range | Voltage Characteristics | Capacity Retention | Recommended Use Case |

|---|---|---|---|

| 0-100 cycles | Stable 8.4V plateau, sharp drop-off | 100-95% | Critical applications |

| 100-300 cycles | 8.2V plateau, gradual drop-off | 95-80% | General purpose |

| 300+ cycles | 8.0V or lower, slow decline | 80-60% | Non-critical devices |

Environmental Impact and Voltage Stability

Modern NiMH formulations address traditional voltage instability issues through:

- Oxygen recombination: New separator designs prevent voltage depression by recombining 98% of generated oxygen

- Cobalt-enriched cathodes: Improve high-temperature voltage stability (≤0.1V variation at 45°C)

- Electrolyte additives: Boron-based compounds reduce self-discharge to <15% per month while maintaining voltage

Cost-Benefit Analysis: NiMH vs. Alternative Technologies

When evaluating total cost of ownership per voltage-hour:

- Alkaline: $0.18/voltage-hour (steep voltage drop reduces effective capacity)

- Standard NiMH: $0.12/voltage-hour (flat discharge curve provides more usable energy)

- Premium NiMH: $0.15/voltage-hour (higher initial cost but 2× cycle life)

- Lithium: $0.28/voltage-hour (superior performance but limited rechargeability)

Emerging Technologies and Voltage Innovations

The next generation of NiMH batteries promises:

- Voltage-stabilized cathodes: Experimental nickel-oxyhydroxide formulations maintain 8.4V ±1% for 95% of discharge

- Smart voltage regulation: Built-in DC-DC converters that deliver constant 9V output regardless of state-of-charge

- Self-healing separators: Automatically repair micro-shorts that cause voltage drops

Professional Maintenance Insight: Implement a voltage-based rotation system for battery banks. Mark each battery with its average loaded voltage after full charge, and always use the highest-voltage units first. This practice extends overall pack life by 15-20%.

Advanced Integration and System Optimization with NiMH 9V Batteries

Voltage Matching for Multi-Battery Configurations

When combining multiple NiMH 9V batteries in series or parallel, voltage matching becomes critical. In series configurations, even a 0.2V difference between batteries can lead to:

- Reverse charging: Weaker batteries get driven below 0V during discharge

- Capacity loss: The entire bank performs at the level of the weakest battery

- Thermal runaway: Mismatched voltages cause uneven current distribution

For professional installations, follow this matching protocol:

- Measure open-circuit voltage after full charge (should be within 0.05V)

- Test loaded voltage at 200mA (should be within 0.1V)

- Cycle together 3 times to establish voltage synchronization

Voltage Regulation for Sensitive Electronics

Modern microcontrollers and digital audio equipment often require stable 5V or 3.3V power from 9V batteries. These regulation techniques maintain efficiency:

| Method | Efficiency | Voltage Stability | Best Application |

|---|---|---|---|

| Linear Regulator | 55-65% | ±1% | Low-noise audio |

| Buck Converter | 85-93% | ±3% | Digital systems |

| LDO Regulator | 70-75% | ±0.5% | Precision instruments |

Smart Battery Management Systems

Advanced BMS solutions for NiMH 9V batteries incorporate:

- Dynamic voltage scaling: Adjusts output based on remaining capacity

- Cell balancing: Active redistribution during charging

- Predictive analytics: Estimates remaining runtime using voltage decay patterns

Troubleshooting Complex Voltage Issues

When diagnosing system-level voltage problems:

- Check for parasitic drains (as little as 0.5mA can cause voltage depression)

- Verify contact resistance (should be <0.1Ω at all connection points)

- Monitor temperature coefficients (voltage drops 0.3%/°C above 25°C)

- Test for memory effects (perform full discharge/charge cycle if voltage drops prematurely)

System Integration Tip: For wireless sensor networks, implement adaptive voltage thresholding. Set the cutoff voltage 0.2V higher in winter months to compensate for temperature effects, ensuring consistent performance year-round.

Professional-Grade Maintenance and Performance Validation for NiMH 9V Batteries

Comprehensive Voltage Performance Testing Protocol

Implement this rigorous testing methodology to evaluate true battery health beyond simple voltage measurements:

| Test Type | Procedure | Acceptance Criteria | Failure Implications |

|---|---|---|---|

| Dynamic Load Test | Apply 100-500mA pulsed load (1Hz) | Voltage drop <0.4V between pulses | Indicates separator degradation |

| Recovery Test | Discharge to 7V, rest 2 hours | Voltage recovery >7.5V | Poor recovery suggests sulfation |

| Temperature Cycling | -20°C to +50°C with 200mA load | Voltage variation <15% | Electrolyte stability issues |

Advanced Capacity Validation Techniques

Professional capacity testing requires more than simple discharge measurements:

- Coulomb counting: Integrate current over time using precision shunt resistors (0.1% tolerance)

- Peukert analysis: Measure capacity at multiple discharge rates to model nonlinear effects

Impedance spectroscopy:100kHz-0.1Hz frequency sweepPhase angle <15° at 1HzPredicts end-of-life 50 cycles early

System-Wide Performance Optimization

Maximize battery performance in complex systems through:

- Adaptive voltage thresholds: Dynamically adjust cutoff voltage based on temperature history

- Predictive replacement: Use machine learning to forecast failures from voltage decay patterns

- Load profiling: Match battery selection to specific device current signatures

Quality Assurance Framework

Implement this comprehensive QA process for mission-critical applications:

- Incoming inspection: 100% voltage/capacity testing with statistical process control

- Accelerated aging: 45°C storage with weekly capacity verification

- Lot traceability: Full documentation of voltage performance across production batches

Expert Validation Tip: For medical or aerospace applications, perform destructive physical analysis on 2% of cells, examining electrode deposition patterns correlated with voltage performance characteristics.

Conclusion

Understanding NiMH 9V battery voltage characteristics is essential for optimizing performance across all your devices. We’ve explored the complete voltage discharge curve, testing methodologies, advanced charging techniques, and system integration strategies that professional users rely on.

From the initial 9.6V charge state to the critical 7.5V cutoff threshold, proper voltage management can double your battery lifespan and prevent unexpected device failures.

Armed with this knowledge, you’re now equipped to:

- Accurately test and interpret voltage readings

- Select the ideal charging method for your needs

- Troubleshoot voltage-related issues effectively

Put this knowledge into action today – start by testing your current batteries’ loaded voltage and create a maintenance schedule based on their actual performance characteristics. Your devices will thank you with reliable, consistent power when you need it most.

Frequently Asked Questions About NiMH 9V Battery Voltage

What voltage should a fully charged NiMH 9V battery show?

A freshly charged NiMH 9V battery should measure between 9.4V and 9.6V immediately after charging when tested with no load. This voltage will stabilize to about 8.8V after resting for 2-4 hours. Under a typical 100mA load, expect 8.4-8.6V initially. The higher initial reading is due to surface charge that dissipates quickly during use.

How does NiMH 9V voltage compare to alkaline batteries?

While both start near 9V, their discharge patterns differ dramatically. Alkaline batteries show a steady voltage decline from 9.5V to 6V, while NiMH maintains 8.4V for 80% of its capacity before sharply dropping. For example, at 50% discharge, alkaline reads ~7.5V while NiMH still delivers 8.4V, making it superior for voltage-sensitive devices.

Why does my NiMH 9V battery show normal voltage but die quickly?

This indicates high internal resistance, often from age or improper cycling. The battery can’t deliver sufficient current despite showing proper open-circuit voltage. Test by measuring voltage under a 200mA load – if it drops below 7.5V immediately, the battery needs replacement. This commonly occurs after 300+ charge cycles.

What’s the minimum safe voltage for NiMH 9V batteries?

Never discharge below 6.0V (0.75V per cell). Going lower risks polarity reversal in weaker cells, permanently damaging the battery. For longevity, recharge at 7.2V (90% discharged). Critical devices like smoke detectors may need replacement at 7.5V to ensure reliable operation.

How does temperature affect NiMH 9V battery voltage?

Voltage drops approximately 0.03V per °C below 20°C. At -20°C, expect 7.8V under load instead of 8.4V. High temperatures (>45°C) increase voltage slightly but accelerate aging. Always test batteries at room temperature for accurate readings, and allow cold batteries to warm before critical use.

Can I mix NiMH 9V batteries with different voltages?

Never mix batteries differing by more than 0.1V in open-circuit voltage. Mismatched voltages cause reverse charging in weaker batteries during discharge. For multi-battery devices, use only same-brand, same-age batteries charged together. Even better, purchase matched sets from industrial suppliers.

Why does my charger stop when the battery only reaches 8.4V?

This is normal – NiMH chargers detect full charge by temperature rise or voltage drop (ΔV), not absolute voltage. The 8.4V “plateau” is the battery’s natural state. Forcing it to 9.6V would require overcharging. Some advanced chargers do a brief topping charge to reach 9.6V, then let it settle back.

How can I accurately measure my NiMH 9V battery’s health?

Perform a capacity test: Fully charge, then discharge at 100mA while measuring total energy output. Compare to rated capacity (typically 175-230mAh). Also check voltage drop under load – more than 0.5V drop at 200mA indicates aging. Professional battery analyzers can also measure internal resistance (should be <300mΩ for healthy cells).