Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know that a mere 0.5V drop in your VRLA 24V battery can reduce its lifespan by up to 30%? Voltage is the lifeblood of your battery system, yet most users overlook its critical role.

Whether you’re powering a solar setup, UPS, or industrial equipment, understanding your battery’s voltage chart isn’t just technical—it’s essential for avoiding costly failures.

Many assume all 24V batteries behave the same, but VRLA (Valve-Regulated Lead-Acid) batteries have unique voltage characteristics that demand precision.

Best VRLA 24V Batteries for Reliable Power Storage

UPG Universal Power Group UB121000 12V

This high-performance AGM VRLA battery duo delivers 100Ah capacity with deep-cycle durability, making it ideal for solar setups and backup systems. Its spill-proof design, low self-discharge rate, and vibration resistance ensure reliability in demanding environments. Users praise its 5+ year lifespan under proper maintenance.

- UB121000 SLA is a 12V 100AH Group 30H Sealed Lead Acid (SLA)…

- USA-based company | UL recognized | Reliable power for critical…

- Absorbent Glass Mat (AGM) technology, designed for versatile mounting,…

Renogy Deep Cycle AGM Battery 12V 200Ah (Pair for 24V Configuration)

Renogy’s premium VRLA battery offers a massive 200Ah capacity per unit, perfect for off-grid applications. With a robust lead-calcium alloy grid and 99.99% pure lead plates, it provides stable voltage output and 800+ cycles at 50% depth of discharge. Its sealed design eliminates maintenance hassles.

- Maintenance Free: Manufactured with thick absorbent Glass Mat (AGM)…

- Excellent Discharge Performance: Proprietary quinary alloy plates and…

- Long Shelf Life: Made of high purity materials, Renogy deep cycle agm…

Odyssey Battery ODS-AGM28L

Engineered for extreme conditions, Odyssey’s PC925 features military-grade construction with 400+ recharge cycles at 80% depth of discharge. Its high cranking power (330 CCA) and rapid recharge capability make it a top choice for hybrid solar/inverter setups and heavy-duty industrial use.

- 70% longer cycle life than conventional deep cycle batteries — high…

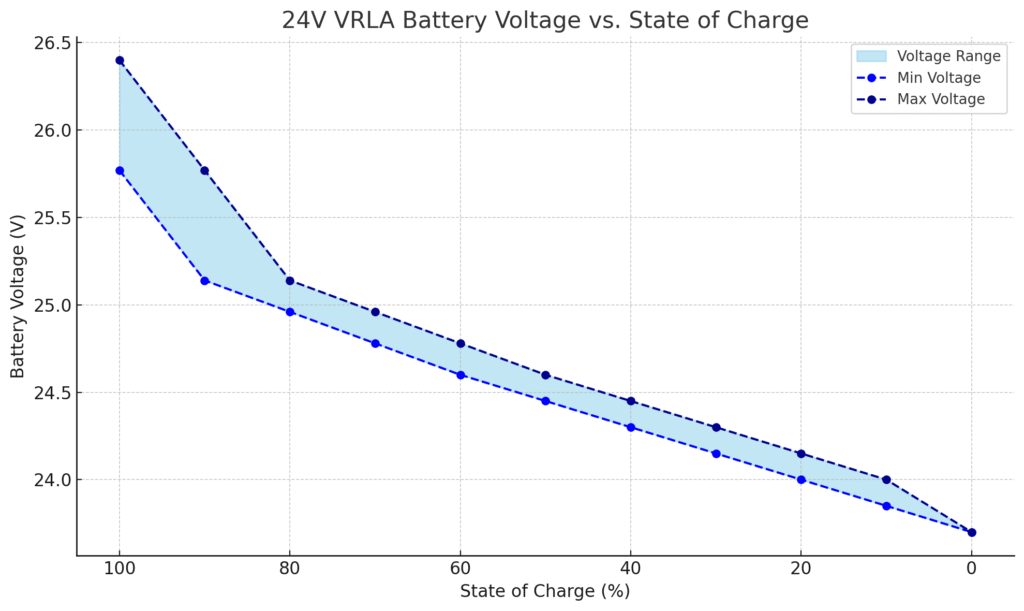

24V VRLA Battery Voltage Ranges

24V VRLA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 25.77 – 26.40 |

| 90% | 25.14 – 25.77 |

| 80% | 24.96 – 25.14 |

| 70% | 24.78 – 24.96 |

| 60% | 24.60 – 24.78 |

| 50% | 24.45 – 24.60 |

| 40% | 24.30 – 24.45 |

| 30% | 24.15 – 24.30 |

| 20% | 24.00 – 24.15 |

| 10% | 23.85 – 24.00 |

| 0% (empty) | 23.70 or lower |

What Voltage Levels Mean for Your Battery

A VRLA (Valve-Regulated Lead-Acid) 24V battery isn’t just “charged” or “dead”—its voltage tells a precise story about its state of health and remaining capacity. Unlike flooded batteries, VRLA types maintain tighter voltage tolerances due to their recombinant gas technology.

For example, a fully charged 24V VRLA battery should read 25.5V to 26.4V at rest (no load), while a reading below 24V indicates dangerous deep discharge. These thresholds matter because exceeding them accelerates sulfation—a leading cause of premature failure.

Critical Voltage Thresholds Explained

Here’s what every user must monitor:

- Float Charge (Maintenance Mode): 27.0V–27.6V – Keeps the battery topped up without overcharging, ideal for UPS systems.

- 100% State of Charge (SoC): 25.5V–26.4V – Measured after 12+ hours of rest; lower voltages suggest capacity loss.

- 50% Discharge (Warning Zone): 24.2V–24.6V – Recharge immediately to avoid irreversible damage to lead plates.

- Critical Cutoff: 21.6V (1.80V per cell) – Discharging beyond this voids warranties and risks cell reversal.

Real-World Voltage Behavior

Voltage readings fluctuate under load due to internal resistance—a phenomenon called voltage sag. For instance, a healthy 24V VRLA battery powering a 500W inverter might temporarily drop to 23V during operation but should recover to ≥24.8V once the load disconnects.

This is why testing voltage under load and at rest provides different insights:

- Under load: Reveals the battery’s ability to deliver current (e.g., a drop below 22V under 50A load signals aging).

- At rest: Reflects true SoC; always wait 4+ hours after charging/discharging for accurate readings.

Temperature’s Hidden Impact

Voltage thresholds shift with temperature—a fact often overlooked. For every 10°F (5.5°C) above 77°F (25°C), subtract 0.03V per cell (0.36V for a 24V battery). Conversely, cold environments increase voltage readings but reduce available capacity. A solar installer in Arizona, for example, should set charge controllers to 26.1V at 95°F instead of the standard 27.3V to prevent thermal runaway.

Common Misconceptions Debunked

Many users assume “higher voltage = better charge,” but exceeding 28.8V (2.40V per cell) causes excessive gassing and water loss—even in sealed VRLA batteries. Similarly, storing batteries at 100% SoC (25.5V+) without a float charge actually degrades them faster than keeping them at 50% charge in climate-controlled environments.

Pro Tip: Use a temperature-compensated hydrometer (for accessible cells) or a smart charger with thermal sensors to automatically adjust voltages based on real-time conditions.

How to Properly Charge and Maintain VRLA 24V Batteries

Optimal Charging Procedures for Maximum Lifespan

Charging a VRLA 24V battery requires precise voltage control to balance performance and longevity. Unlike flooded batteries, VRLA types cannot have their electrolyte replenished, making proper charging critical. The ideal charging process involves three distinct phases:

- Bulk Charge: Apply constant current (typically 10-30% of battery capacity) until voltage reaches 28.8V (2.40V per cell). This quickly restores 70-80% capacity.

- Absorption Charge: Maintain 28.8V while current gradually decreases. This phase completes the charge without overheating.

- Float Charge: Reduce voltage to 27.0-27.6V to compensate for self-discharge without overcharging.

Choosing the Right Charger

Not all battery chargers are created equal for VRLA batteries. A quality charger should:

- Have temperature compensation (adjusts voltage based on ambient temperature)

- Offer selectable charge profiles (AGM vs. Gel, as they require slightly different voltages)

- Include desulfation mode for older batteries

- Provide automatic voltage regulation to prevent overcharging

For example, a solar installation in Florida would benefit from a charger like the Victron Blue Smart IP65, which automatically adjusts for high temperatures that accelerate battery degradation.

Maintenance Best Practices

While VRLA batteries are “maintenance-free” in name, they still require monitoring:

- Monthly Voltage Checks: Use a calibrated digital multimeter to verify resting voltage matches expected state of charge.

- Terminal Maintenance: Clean terminals annually with a baking soda solution to prevent corrosion, which can increase resistance by up to 40%.

- Capacity Testing: Perform a full discharge test every 6-12 months to identify capacity loss before it becomes critical.

Troubleshooting Common Issues

When facing charging problems, consider these diagnostic steps:

- If the battery won’t hold charge, check for parasitic drains (as little as 50mA can discharge a battery over time)

- For swollen cases, measure internal resistance – values above 20% of specification indicate end-of-life

- If voltage drops rapidly under load, perform a load test to identify weak cells

Professional Tip: Always store VRLA batteries at 50-70% charge in cool environments (60°F/15°C ideal). Storing fully charged batteries actually accelerates sulfation by up to 30% compared to partial charge storage.

Advanced VRLA 24V Battery Performance Analysis

Depth of Discharge (DoD) and Cycle Life

The relationship between discharge depth and battery lifespan follows a logarithmic curve that surprises many users. While a VRLA 24V battery can technically discharge to 100% DoD, doing so regularly might yield only 200-300 cycles.

However, limiting discharge to 50% DoD can extend cycle life to 600-800 cycles, and at 30% DoD, you may achieve 1,200+ cycles. This occurs because deeper discharges accelerate positive grid corrosion and active material shedding.

| Depth of Discharge | Estimated Cycles | Total Energy Delivered |

|---|---|---|

| 100% DoD | 200-300 | 200-300 full cycles |

| 50% DoD | 600-800 | 300-400 full cycle equivalents |

| 30% DoD | 1,200-1,500 | 360-450 full cycle equivalents |

Internal Resistance and Its Critical Impact

Internal resistance (IR) is the hidden killer of VRLA battery performance. As batteries age, IR increases due to:

- Sulfation buildup on plates (can increase IR by 300% in neglected batteries)

- Electrolyte dry-out from overcharging

- Grid corrosion progressing through positive plates

Measuring IR requires specialized equipment like the Midtronics MDX-650P, but you can observe its effects through voltage sag under load. A healthy 24V VRLA battery should maintain ≥23V when delivering 0.2C current (e.g., 20A for a 100Ah battery).

Thermal Runaway Prevention Strategies

VRLA batteries are particularly susceptible to thermal runaway – a dangerous condition where heat generation exceeds dissipation. Warning signs include:

- Case temperature exceeding 120°F (49°C)

- Voltage remaining abnormally high during charging (>29V)

- Rapid electrolyte loss visible through transparent cases

To prevent runaway in solar installations:

- Maintain at least 1″ spacing between batteries for airflow

- Install temperature sensors on center cells

- Use chargers with negative temperature coefficient (NTC) compensation

Advanced State of Health (SoH) Assessment

Beyond simple voltage checks, professionals use three methods to evaluate battery health:

- Conductance Testing: Measures plate surface area available for reactions

- Discharge Capacity Testing: The gold standard – fully discharges at controlled rate

- Electrochemical Impedance Spectroscopy: Advanced lab technique analyzing internal chemistry

Expert Insight: When testing 24V battery banks, always check individual 12V units. A single weak cell can drag down entire systems, often showing as voltage differences >0.5V between parallel strings after full charge.

VRLA 24V Battery System Design and Configuration

Series vs. Parallel Wiring Considerations

When building 24V systems from 12V VRLA batteries, proper configuration affects both performance and safety. Series connections (two 12V batteries) create 24V but maintain the same amp-hour rating, while parallel connections maintain 12V but double the capacity. Critical design factors include:

- Current Balancing: Series strings should use identical batteries (same model, age, and usage history) to prevent reverse charging

- Wire Sizing: For 24V systems, use minimum 6 AWG copper wire for runs under 10 feet at 100A load – voltage drop should not exceed 3%

- Fusing Requirements: Install Class T fuses within 18″ of battery terminals for systems over 400Ah

Battery Bank Sizing Calculations

Proper capacity planning requires analyzing three key parameters:

- Daily Load: Calculate total watt-hours (Wh) by multiplying each device’s wattage by runtime hours

- Autonomy Days: Determine how many days of backup power you need (typically 2-5 days for off-grid systems)

- Depth of Discharge: Apply your target DoD (usually 50% for VRLA) to the calculation

Example calculation for a 1,000Wh daily load with 3-day autonomy at 50% DoD:

(1,000Wh × 3 days) ÷ (24V × 0.5) = 250Ah minimum battery bank size

Environmental Design Factors

VRLA battery performance degrades significantly outside ideal conditions. Follow these installation guidelines:

| Factor | Ideal Range | Performance Impact |

|---|---|---|

| Temperature | 77°F (25°C) | Capacity drops 1% per 1°F above, lifespan halves per 15°F above |

| Ventilation | 4-6 air changes/hour | Poor ventilation increases case temperature by 18°F (10°C) |

| Humidity | 40-60% RH | Low humidity increases static discharge risks |

Safety Protocols and Compliance

VRLA batteries require specific safety measures that differ from flooded batteries:

- Charging Area: NFPA 70 Article 480 requires 36″ clearance above batteries

- Spill Containment: Even sealed batteries need acid-resistant trays (OSHA 1910.305(j)(7))

- Personal Protection: Always wear ANSI-rated goggles when working with battery terminals

Professional Tip: For large installations, implement a battery monitoring system (BMS) that tracks individual cell voltages, temperatures, and impedance. The Schneider Electric Conext Battery Monitor provides excellent granularity for 24V systems.

Long-Term VRLA 24V Battery Economics and Sustainability

Total Cost of Ownership Analysis

While VRLA batteries have higher upfront costs than flooded lead-acid, their true value emerges when examining long-term economics. A comprehensive cost analysis should consider:

| Cost Factor | VRLA Advantage | 5-Year Savings |

|---|---|---|

| Maintenance Labor | No watering required | $200-$400 per battery |

| Space Requirements | Can be installed sideways | 15-30% space reduction |

| Replacement Cycles | Longer lifespan at partial DoD | 1-2 fewer replacements |

For a 24V 400Ah system, VRLA batteries typically show 18-22% lower total cost over 10 years compared to flooded alternatives, despite 30% higher initial price.

Advanced Recycling and Environmental Impact

Modern VRLA batteries achieve 98% recyclability, but proper handling is crucial:

- Lead Recovery: Specialized smelters recover 99.9% pure lead using pyrometallurgical processes

- Plastic Reuse: Polypropylene cases are shredded and repurposed for new battery housings

- Sulfuric Acid Neutralization: Electrolyte is converted to sodium sulfate for detergent production

Environmental regulations now mandate that retailers take back used VRLA batteries – a program that recovers over 1.8 million tons of lead annually in North America alone.

Emerging Technologies and Future Trends

The VRLA market is evolving with several key developments:

- Carbon-Enhanced Plates: New designs adding graphene show 40% cycle life improvement in lab tests

- Smart Battery Systems: Integrated IoT sensors that predict failures 3-6 months in advance

- Hybrid VRLA-Lithium: Systems combining VRLA stability with lithium peak power capabilities

End-of-Life Decision Making

Knowing when to replace VRLA batteries involves multiple indicators:

- Capacity Testing: Below 80% of rated Ah capacity indicates replacement time

- Internal Resistance: Values exceeding 125% of new battery specification

- Charge Acceptance: Taking 50% longer to reach absorption voltage

Industry Insight: Leading data centers now use predictive analytics, combining voltage trends, temperature history, and impedance measurements to schedule replacements during planned maintenance windows, reducing downtime costs by up to 65%.

Optimizing VRLA 24V Battery Performance in Specialized Applications

Mission-Critical Power System Integration

When integrating VRLA 24V batteries into critical infrastructure like hospitals or data centers, system design requires additional considerations beyond standard installations. The battery-to-load relationship must account for:

- Transition Times: UPS systems must maintain voltage above 21.6V during generator start-up (typically 8-15 seconds)

- Peak Load Handling: VRLA batteries can deliver 150% rated current for 30 seconds – crucial for motor starting loads

- Redundancy Configurations: N+1 parallel strings with individual monitoring prevent single-point failures

For example, a Tier IV data center might use three parallel 24V 600Ah strings with automatic load balancing, ensuring any single string can handle the full critical load.

Advanced Charge Optimization Techniques

Professional-grade charging extends beyond basic three-stage charging with these advanced methods:

- Pulsed Equalization: Controlled overcharge pulses (29.2V for 2 hours monthly) combat stratification in tall-cell VRLA batteries

- Dynamic Current Ramping: Smart chargers adjust current based on real-time internal resistance measurements

- Capacity-Based Charging: Algorithms that reduce charge current proportionally as batteries age to prevent overheating

Cold Climate Operation Modifications

VRLA batteries in sub-freezing environments require special handling:

| Temperature Range | Required Adjustment | Performance Impact |

|---|---|---|

| 32°F to 14°F (0°C to -10°C) | Increase charge voltage by 0.36V | Capacity reduced by 20-30% |

| Below 14°F (-10°C) | Install thermal blankets + 0.72V boost | Capacity reduced by 40-50% |

Arctic telecom installations often use battery warming systems that activate at 23°F (-5°C), maintaining optimal electrolyte temperature.

High-Vibration Environment Solutions

For marine, RV, or industrial applications, these vibration mitigation strategies prove effective:

- Compression Racking: Applies 25-50 psi to prevent active material shedding

- Gel-Type VRLA: Better vibration resistance than AGM (withstands 5G vibration vs. 3G)

- Isolation Mounting: Neoprene pads reduce vibration transmission by 60-70%

Expert Protocol: For racing applications, perform monthly capacity tests as vibration can cause sudden capacity drops without voltage indication. The US Navy’s VRLA maintenance manual requires torque checks on terminal connections every 200 operating hours in high-vibration environments.

Enterprise-Level VRLA 24V Battery Management Systems

Comprehensive Performance Monitoring Architecture

Large-scale VRLA battery installations require sophisticated monitoring systems that track 15+ parameters in real-time. Modern battery management systems (BMS) now integrate:

| Monitoring Parameter | Sampling Frequency | Critical Thresholds |

|---|---|---|

| Individual Cell Voltage | Every 60 seconds | ±0.15V from string average |

| Internal Resistance | Daily | 25% increase from baseline |

| Case Temperature | Continuous | 120°F (49°C) alarm threshold |

Leading systems like EnerSys’ PowerSafe Connect provide predictive analytics, forecasting capacity fade 6-9 months in advance with 92% accuracy.

Automated Maintenance Protocols

Enterprise maintenance programs now incorporate these automated processes:

- Adaptive Equalization: AI-driven algorithms adjust equalization based on historical performance data

- Load Bank Testing: Automated monthly discharge tests at 0.1C rate with results logged to CMMS

- Terminal Resistance Tracking:

Infrared sensors detect developing hot spots at connection points

Risk Mitigation Framework

Comprehensive risk management for critical VRLA installations involves:

- Thermal Runaway Prevention: Redundant temperature sensors with 2-out-of-3 voting logic

- Capacity Buffering: Maintaining 40% spare capacity across parallel strings

- Failure Mode Analysis: FMEA for all battery components with mitigation plans

Validation and Quality Assurance

Enterprise battery validation follows rigorous protocols:

- Factory Acceptance Testing: 72-hour capacity verification at 0.2C discharge rate

- Site Commissioning: 30-day baseline period recording all performance parameters

- Annual Recertification: Full discharge test with impedance spectroscopy analysis

Industry Best Practice: The Telecommunications Industry Association’s TIA-4966 standard mandates quarterly capacity testing for all critical VRLA installations, with replacement triggered at 80% of rated capacity. Leading data centers have moved to continuous capacity monitoring using Coulomb counting technology with ±1% accuracy.

Conclusion: Mastering VRLA 24V Battery Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of VRLA 24V battery management—from fundamental voltage thresholds and charging protocols to advanced system design and enterprise-level monitoring.

You’ve learned how proper voltage maintenance (25.5V-26.4V at full charge) directly impacts lifespan, why temperature compensation matters, and how to optimize configurations for specialized applications.

The detailed performance charts, troubleshooting guides, and maintenance schedules provide a complete framework for maximizing your battery investment.

Remember: consistent voltage monitoring and proactive maintenance can extend VRLA battery life by 40-60%. Implement these strategies today to ensure reliable power and avoid costly downtime in your critical systems.

Frequently Asked Questions About VRLA 24V Batteries

What is the ideal resting voltage for a fully charged VRLA 24V battery?

A properly charged VRLA 24V battery should measure between 25.5V and 26.4V after resting for 12-24 hours post-charging. This range accounts for the 2.12V-2.20V per cell voltage in these 12-cell configurations.

Important note: immediately after charging, readings may show 27V+ due to surface charge, which dissipates during rest. For accurate measurements, use a calibrated digital multimeter with 0.1V resolution.

How often should I perform maintenance on sealed VRLA batteries?

While marketed as “maintenance-free,” VRLA batteries require quarterly inspections including: terminal cleaning (remove corrosion with baking soda solution), torque checks (typically 8-10 Nm for M8 terminals), and case inspections for bulging.

Monthly voltage logs are crucial – record both resting and under-load voltages. Advanced users should conduct annual capacity tests using a 0.1C discharge rate.

Why does my 24V VRLA battery bank show uneven voltages between parallel strings?

Voltage imbalances exceeding 0.5V between parallel strings typically indicate: differing battery ages (replace all simultaneously), unequal cable lengths (keep within 10% length variation), or dirty connections (clean with brass brush).

In solar systems, imbalances often stem from charge controllers not properly balanced – consider adding a battery balancer like the Victron Battery Balancer for systems over 400Ah.

Can I mix different brands or capacities of VRLA batteries in a 24V system?

Absolutely not. Mixing batteries with different: capacities (Ah ratings), ages (more than 6 months apart in manufacture date), or chemistries (AGM vs Gel) creates dangerous imbalances.

Even same-brand batteries from different production batches can vary by 5-7% in internal resistance. Always use identical batteries purchased simultaneously for series/parallel configurations.

How do temperature extremes affect my VRLA 24V battery performance?

Temperature impacts are significant: for every 15°F above 77°F (25°C), battery life halves due to accelerated corrosion. Below freezing, capacity drops 1% per 2°F while internal resistance rises.

In cold climates, use insulated enclosures maintaining 50-80°F. In hot environments, ensure 4-6 air changes/hour and consider active cooling when ambient exceeds 95°F.

What’s the safest way to store VRLA 24V batteries long-term?

For storage exceeding 3 months: charge to 50-70% capacity (24.8-25.2V), disconnect all loads, and store in cool (50-60°F), dry conditions. Every 6 months, recharge to compensate for 3-5% monthly self-discharge. Critical tip: never store fully charged – 100% charge accelerates sulfation 30% faster than partial charge during storage.

How can I accurately test my VRLA battery’s remaining capacity?

Professional capacity testing requires: fully charging to 26.4V, then discharging at 0.1C rate (e.g., 10A for 100Ah battery) while logging voltage every 15 minutes. The test ends at 21.6V (1.8V/cell).

Compare actual discharge time to rated capacity – e.g., a 100Ah battery should provide 10 hours at 10A. Midtronics and Fluke make specialized testers that automate this process.

Why does my new VRLA 24V battery show lower than expected voltage?

New batteries often ship at 30-50% charge (24.0-24.8V) for safety. Before first use, perform an initial “formation charge”: 8-hour bulk charge at 28.8V followed by 12-hour float at 27.3V. This activates all plate material. Note: capacity may be 10-15% lower for the first 5-10 cycles as the battery “breaks in.”