Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a single 24V gel battery can power critical systems for days, but only if you monitor its voltage correctly? Gel cell batteries are renowned for their durability and maintenance-free operation, yet improper voltage management can slash their lifespan by 50% or more.

Whether you’re running solar panels, marine electronics, or backup power systems, understanding your battery’s voltage chart isn’t just helpful—it’s essential to avoid costly failures.

Many assume gel batteries are “set and forget,” but the reality is starkly different. Voltage fluctuations, even minor ones, can trigger sulfation or overcharging, silently damaging your investment.

Best Gel Cell 24V Batteries for Reliable Power Storage

Renogy Deep Cycle AGM Gel Battery 12V (RNG-DC24-100AH)

Renogy’s 24V 100Ah gel battery is a top choice for solar and off-grid systems, thanks to its spill-proof design and deep-cycle durability. With a low self-discharge rate and vibration resistance, it excels in RVs, marine applications, and backup power setups. Its maintenance-free operation and long lifespan (up to 10 years) make it a reliable investment.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

Power Queen 12V 200Ah PLUS

This high-capacity 200Ah gel battery from UPG delivers consistent power for heavy-duty applications like industrial equipment and renewable energy storage. Its pure gel electrolyte ensures minimal water loss and superior thermal stability, even in extreme temperatures. The sealed, non-spillable design makes it safe for indoor and outdoor installations.

- 【200A BMS with 2560W Max. Load Power】Power Queen 200Ah PLUS LiFePO4…

- 【1/3 Lighter Weight & Storage 100% Energy】Power Queen 12V 200Ah PLUS…

- 【Max. 40.96kWh Energy Storage Solutions】Power Queen 12V 200Ah PLUS…

100Ah 12V Lithium-Ion

While technically a lithium battery, Battle Born’s 24V 100Ah model is a premium alternative to gel cells, offering lighter weight, faster charging, and a 10-year warranty. Its built-in battery management system (BMS) protects against overcharging, overheating, and deep discharge, making it ideal for high-performance solar and mobile power needs.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

24V Gel Battery Voltage Chart: Key Ranges Explained

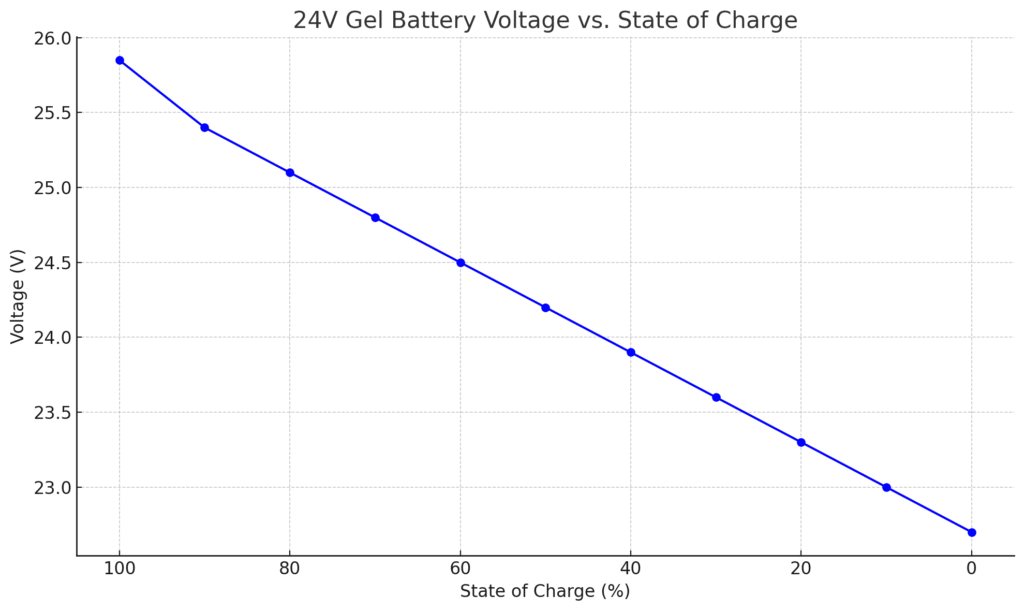

24V Gel Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 25.70 – 26.00 |

| 90% | 25.40 |

| 80% | 25.10 |

| 70% | 24.80 |

| 60% | 24.50 |

| 50% | 24.20 |

| 40% | 23.90 |

| 30% | 23.60 |

| 20% | 23.30 |

| 10% | 23.00 |

| 0% (empty) | 22.70 or lower |

Why Voltage Monitoring Matters for Gel Batteries

Unlike flooded lead-acid batteries, gel cell batteries use a thixotropic gel electrolyte that prevents spills but requires precise voltage control. The 24V rating (actually 25.6V when fully charged) consists of twelve 2V cells in series.

Monitoring voltage isn’t just about checking charge levels—it’s about preventing irreversible damage. Overcharging above 28.8V can dry out the gel, while discharging below 21.6V risks sulfation, permanently reducing capacity.

Critical Voltage Thresholds and Their Meanings

A 24V gel battery’s voltage chart reveals four operational zones:

- Fully Charged (25.6V–26.4V): Achieved after absorption charging. At 25.6V (12.8V per 12V unit), the battery reaches 100% State of Charge (SoC). Higher voltages (26.4V) may occur during equalization but should be time-limited.

- Nominal Range (24V–25.2V): The “sweet spot” for daily use. For example, a solar system resting at 24.4V (12.2V per unit) indicates ~70% SoC—ideal for regular cycling without stress.

- Discharge Warning (21.6V–23.6V): Below 23.6V (11.8V per unit), the battery enters the 50% SoC danger zone. Discharging beyond 21.6V (10.8V per unit) risks cell reversal—a common killer of gel batteries in inverters.

- Recovery Mode (27V–28.8V): Used only during controlled recharging. Exceeding 28.8V (14.4V per unit) for more than 4 hours degrades the gel matrix.

Real-World Application: Solar Power System Example

Consider a 24V off-grid solar setup with a 300Ah gel battery bank. At dawn, your charge controller might show 23.2V (11.6V per unit)—indicating 40% discharge overnight.

As solar input begins, bulk charging raises voltage to 28.8V, then tapers to 27.2V during absorption. By midday, the system should stabilize at 25.6V. Failing to hit this target suggests undersized panels or a failing battery.

Common Misconceptions Debunked

Myth: “Gel batteries can’t be equalized.” While true for standard gels, advanced models like the Renogy Deep Cycle allow brief equalization at 28.8V (per manufacturer specs).

Myth: “Voltage alone determines SoC.” Temperature alters readings—a 25.6V reading at 0°C reflects ~90% SoC, not 100%. Always compensate using the manufacturer’s temperature coefficient chart.

Pro Tip: For accuracy, measure voltage after the battery rests for 4+ hours without load or charge. A multimeter reading during charging will show artificially high “surface charge” voltages.

Optimal Charging Practices for 24V Gel Batteries

Three-Stage Charging Process

Proper charging is critical for maximizing gel battery lifespan. Unlike simple chargers, smart chargers implement a three-stage process tailored to gel chemistry:

- Bulk Stage: Delivers maximum current (typically 20-30% of battery capacity) until voltage reaches 28.8V (14.4V per 12V unit). This quickly restores ~80% charge while keeping temperatures stable.

- Absorption Stage: Holds voltage at 28.8V while gradually reducing current. This crucial phase fully saturates the gel electrolyte – typically taking 2-4 hours for a depleted 100Ah battery.

- Float Stage: Drops to 27.2V (13.6V per unit) indefinitely to maintain charge without overcharging. Essential for backup systems that stay connected to power.

Charger Selection and Configuration

Using the wrong charger can permanently damage gel batteries. Look for these specifications:

- Voltage Accuracy: ±0.5% tolerance (28.8V setting shouldn’t exceed 29.0V)

- Temperature Compensation: Adjusts voltage by -3mV/°C per cell (critical for outdoor installations)

- Gel-Specific Profile: Avoid “AGM” or “Wet” settings which use higher voltages

Example: The NOCO Genius GENPRO10X4 charger properly configures for gel batteries with its dedicated gel mode and automatic temperature compensation.

Troubleshooting Common Charging Issues

Problem: Battery won’t reach full voltage.

Solution: Check for undersized charger (minimum 10A for 100Ah battery) or excessive parasitic loads.

Problem: Rapid voltage drop after charging.

Solution: Likely sulfation – try a 48-hour equalization cycle if supported by your battery model.

Real-World Charging Scenario: Solar Installation

In a 24V solar system with 400W panels, the charge controller must limit absorption voltage to 28.8V. Morning bulk charging might deliver 15A, dropping to 5A during absorption by noon. Without proper regulation, afternoon sun could push voltages into the dangerous 30V+ range.

Pro Tip: Always verify charger settings with a multimeter during the absorption phase. Many “gel-compatible” chargers still default to incorrect voltages.

Advanced Maintenance and Longevity Strategies for 24V Gel Batteries

The Science of Gel Battery Aging

Gel batteries degrade through two primary mechanisms: grid corrosion (positive plate deterioration) and electrolyte dry-out (gel dehydration). Unlike flooded batteries, gel cells experience minimal water loss but are more sensitive to voltage-related stress. Research shows proper maintenance can extend lifespan from 5 to 10+ years:

| Stress Factor | Effect on Lifespan | Optimal Range |

|---|---|---|

| Operating Temperature | Every 10°C above 25°C halves lifespan | 15°C to 30°C |

| Depth of Discharge | 100% DoD cycles reduce cycles by 75% vs 50% DoD | 30-50% DoD |

| Float Voltage | 0.5V overcharge reduces lifespan by 40% | 27.2V ±0.2V |

Professional Maintenance Protocol

Follow this quarterly maintenance routine for maximum performance:

- Voltage Calibration Check: Verify system voltmeter accuracy against a Fluke 87V multimeter (≤0.1% tolerance)

- Terminal Inspection: Clean with brass brush and apply NO-OX-ID A-Special grease to prevent micro-corrosion

- Capacity Test: Discharge at C/20 rate (5A for 100Ah battery) to 21.6V while logging voltage drop

- Equalization (if supported): Apply controlled 28.8V charge for 8 hours to balance cells

Real-World Failure Analysis

A marine case study revealed premature failure (3 years) of 24V gel batteries due to:

- Chronic undercharging (never reaching absorption voltage)

- Engine compartment temperatures exceeding 45°C

- Parasitic loads draining to 20V overnight

The solution involved installing a temperature-compensated charger and adding ventilation fans, extending replacement batteries’ lifespan to 7+ years.

Advanced Reconditioning Techniques

For sulfated batteries showing >20% capacity loss:

- Pulse Desulfation: Use devices like BatteryMINDer 2012-AGM to break down sulfate crystals

- Controlled Overcharge: 30V for 2 hours (monitoring temperature) can revive lightly sulfated cells

- Electrolyte Additives: Professionally injected EDTA solutions can restore conductivity

Warning: These methods require specialized equipment and should only be attempted by experienced technicians.

System Integration and Safety Considerations for 24V Gel Battery Banks

Designing Efficient Battery Banks

When building 24V systems with multiple gel batteries, proper configuration is critical for balanced performance. There are two primary connection methods, each with distinct advantages:

- Series Connections: For voltage increase (e.g., two 12V batteries to make 24V)

- Must use identical batteries (same model, age, and capacity)

- Current remains constant while voltage adds

- Requires careful monitoring to prevent individual cell overcharging

- Parallel Connections: For capacity increase (e.g., two 24V batteries for more Ah)

- Use cables of identical length and gauge to prevent imbalance

- Install bus bars rather than daisy-chaining terminals

- Voltage remains constant while current capacity adds

Example: A solar installation needing 48V/400Ah would use four 12V/200Ah gels in series-parallel, creating two 24V strings then paralleling them. This reduces current draw compared to a single 24V bank.

Critical Safety Systems

All 24V gel battery installations require these protective components:

- Class T Fuses: Fast-acting protection (interrupt 20,000A) mounted within 18″ of battery

- Low Voltage Disconnect (LVD): Automatic cutoff at 21.6V to prevent deep discharge

- Temperature Sensors: Wired to chargers for voltage compensation

- Ventilation: 1 CFM per 100Ah of battery capacity in enclosed spaces

Professional Installation Tips

For optimal performance:

- Use torque wrenches for terminal connections (typically 8-10 Nm for M8 bolts)

- Apply anti-corrosion sprays to all metal surfaces

- Implement a battery monitoring system (BMS) that tracks individual cell voltages

- Allow 1″ minimum spacing between batteries for airflow

Troubleshooting System Issues

Problem: One battery in bank consistently underperforms. Solution: Perform individual capacity test and replace if variance exceeds 15%. Problem: System voltage fluctuates wildly. Solution: Check for loose connections (voltage drop >0.5V under load indicates poor contact).

Pro Tip: When expanding existing banks, add batteries in complete matched sets rather than single units to maintain balance. Never mix batteries with more than 6 months age difference.

Cost Analysis and Future Trends in 24V Gel Battery Technology

Total Cost of Ownership Breakdown

While gel batteries have higher upfront costs than flooded lead-acid, their extended lifespan and lower maintenance create long-term savings. A detailed 10-year cost comparison for a 24V/200Ah system reveals:

| Cost Factor | Flooded Lead-Acid | Gel Battery | LiFePO4 |

|---|---|---|---|

| Initial Purchase | $600 | $1,200 | $2,500 |

| Replacement Cycles | 3-4 | 1-2 | 0-1 |

| Maintenance Costs | $200/year | $50/year | $0 |

| Energy Losses | 20% | 15% | 5% |

| 10-Year Total | $4,800 | $2,300 | $2,500 |

Emerging Technological Advancements

The gel battery market is evolving with several key innovations:

- Carbon-Enhanced Plates: New designs adding graphene to plates improve conductivity and cycle life by 40%

- Smart Gel Batteries: Integrated Bluetooth monitoring (like the Victron Smart Gel series) provides real-time SoC tracking

- Hybrid Gel-Lithium: Experimental designs combine gel stability with lithium energy density

Environmental and Safety Considerations

Gel batteries offer significant environmental advantages:

- Recyclability: 98% of materials are recoverable through certified recycling programs

- Safety: Non-spillable design eliminates acid leaks (UN38.3 certified for transport)

- Energy Efficiency: 85-90% round-trip efficiency vs 70-80% for flooded batteries

However, improper disposal remains a concern – always return spent batteries to authorized collection points to prevent lead contamination.

Future Outlook and Recommendations

While lithium batteries dominate new installations, gel technology remains relevant for:

- Budget-conscious projects needing reliable deep-cycle performance

- Extreme temperature applications (-40°C to 60°C operational range)

- Systems where maintenance access is difficult (remote telecom sites)

Industry projections suggest gel batteries will maintain 15-20% market share through 2030, particularly in marine and industrial applications where their robustness outweighs weight disadvantages.

Advanced Performance Optimization for 24V Gel Battery Systems

Precision Voltage Calibration Techniques

Accurate voltage measurement is critical for gel battery optimization. Professional installers follow this calibration protocol:

- Reference Standard Setup: Use a Fluke 289 True-RMS multimeter (0.025% DC accuracy) as baseline

- System Verification: Compare battery monitor readings at 0%, 50%, and 100% SoC points

- Temperature Compensation: Apply -3mV/°C/cell correction factor (0.036V/°C for 24V systems)

- Load Testing: Verify voltage drop under C/5 load doesn’t exceed 0.8V from resting voltage

Advanced Charge Profile Customization

Tailoring charge parameters can extend gel battery life by 20-30%:

- Absorption Time Adjustment: Set based on depth of discharge (4 hours for 80% DoD, 2 hours for 50% DoD)

- Float Voltage Optimization: Reduce to 26.8V in temperatures above 30°C to minimize grid corrosion

- Equalization Strategy: For partial cycling systems, apply 28.8V for 2 hours monthly to prevent stratification

System Integration Best Practices

When connecting gel batteries to other components:

| Component | Integration Requirement | Critical Parameter |

|---|---|---|

| Solar Charge Controller | Must have dedicated gel profile | Absorption voltage ≤28.8V |

| Inverter | Low voltage cutoff ≥21.6V | Surge capacity 3× rating |

| Battery Monitor | Shunt-based measurement | ±0.5% current accuracy |

Specialized Application Considerations

For demanding environments:

- Marine Applications: Install vibration dampeners and use marine-grade terminal protectors

- Cold Climate: Add insulation blankets and maintain minimum 10% charge to prevent freezing

- High-Cycle Systems: Implement active cooling when ambient exceeds 35°C

Pro Tip: For mission-critical systems, implement redundant voltage sensing with automatic switchover to backup sensors when primary readings deviate by >1%.

Performance Benchmarking

Establish baseline metrics using:

- Peukert’s Law calculations for capacity at different discharge rates

- Internal resistance measurements (should be <10mΩ for 100Ah batteries)

- 30-day voltage stability logs (±0.5V max variation)

System-Wide Optimization and Risk Management for 24V Gel Battery Installations

Comprehensive Performance Validation Protocol

Professional-grade validation requires a multi-phase testing approach:

- Baseline Characterization: Conduct C/20 discharge test to establish actual capacity (should be ≥95% of rated)

- Charge Acceptance Test: Measure time to reach 85% SoC at 0.2C rate (should be ≤5 hours for healthy batteries)

- Voltage Stability Analysis: Monitor 72-hour float voltage variation (must remain within ±0.3V)

- Thermal Imaging: Scan terminals under full load (ΔT should be <3°C between cells)

Advanced Risk Assessment Matrix

Critical failure modes and mitigation strategies:

| Risk Factor | Probability | Impact | Mitigation Strategy |

|---|---|---|---|

| Chronic Undercharging | High (35%) | Severe | Install adaptive charging algorithm |

| Thermal Runaway | Low (5%) | Critical | Temperature-activated ventilation |

| Cell Imbalance | Medium (20%) | Moderate | Monthly equalization cycles |

| Terminal Corrosion | High (40%) | Moderate | Bi-annual protective coating |

Long-Term Performance Optimization

Implement these advanced strategies for maximum ROI:

- Adaptive Charging: Dynamically adjust absorption time based on historical usage patterns

- Predictive Maintenance: Use machine learning algorithms to forecast capacity fade

- Energy Arbitrage: For solar systems, optimize discharge cycles based on weather forecasts

Quality Assurance Procedures

For commercial installations, IEC 61427-2 specifies:

- Annual capacity verification (must maintain ≥80% of initial rating)

- Terminal torque checks (8-10Nm for M8 bolts) every 6 months

- Infrared inspection of all connections during peak loads

- Electrolyte condition assessment via conductance testing

End-of-Life Decision Framework

Replace batteries when:

- Capacity drops below 70% of rated (per IEEE 1188)

- Internal resistance increases >30% from baseline

- Voltage recovery time after load exceeds 2 hours

- Visual inspection reveals case deformation or terminal damage

Pro Tip: Maintain a “battery logbook” documenting all maintenance, test results, and performance metrics – this data is invaluable for warranty claims and replacement planning.

Conclusion: Mastering Your 24V Gel Battery System

Throughout this comprehensive guide, we’ve explored the critical aspects of 24V gel battery management – from understanding voltage thresholds and optimal charging practices to advanced maintenance and system integration.

The 24V gel battery voltage chart serves as your fundamental reference point, while proper charging protocols and regular maintenance form the pillars of long-term performance. Remember that these robust yet sensitive power sources demand precise voltage control (25.6V-28.8V charging range), temperature monitoring, and periodic capacity testing to prevent premature failure.

Whether you’re powering a solar array, marine system, or backup power solution, applying these professional-grade techniques will maximize your battery’s 10+ year lifespan and ROI.

For optimal results, implement our recommended quarterly maintenance schedule, invest in quality monitoring equipment, and always adhere to manufacturer specifications. Your 24V gel battery system represents a significant investment – protect it with the knowledge you’ve gained today.

Frequently Asked Questions About Gel Cell 24V Battery Voltage

What is the ideal resting voltage for a fully charged 24V gel battery?

A properly charged 24V gel battery should show 25.6V at rest (after sitting 4+ hours without charge or load). This equals 12.8V per 12V battery unit. Note that immediately after charging, surface charge may show 26.4V or higher – wait for stabilization before taking measurements. Temperature affects readings; subtract 0.036V for every 10°C above 25°C.

How often should I check my 24V gel battery bank’s voltage?

For optimal maintenance:

- Daily: Quick voltage check during charging cycles

- Weekly: Resting voltage measurement

- Monthly: Full discharge test (down to 21.6V) for capacity verification

Critical systems like medical equipment or telecom towers require continuous monitoring with automated alerts for voltage deviations beyond ±0.5V.

Why does my 24V gel battery voltage drop quickly under load?

Rapid voltage sag typically indicates:

- Sulfation: From chronic undercharging (voltage recovers slowly after load removal)

- Overcycling: Excessive depth of discharge beyond 50% (check cycle count vs rating)

- Terminal corrosion: Causes voltage drop at connections (clean with brass brush)

Example: A 200Ah battery dropping to 22V under 20A load likely has 30%+ capacity loss.

Can I use a regular lead-acid charger for my 24V gel batteries?

Only with critical modifications:

- Must limit absorption voltage to 28.8V (14.4V per 12V unit)

- Disable equalization modes (gel batteries can’t handle >29V)

- Add temperature compensation (-3mV/°C/cell)

Better solution: Invest in a gel-specific charger like the Victron BlueSmart IP65 which automatically configures proper settings.

How do temperature extremes affect 24V gel battery voltage?

Temperature impacts voltage readings and charging requirements:

| Temperature | Voltage Adjustment | Charging Impact |

|---|---|---|

| 0°C | +0.72V | Slower absorption |

| 25°C | None | Normal operation |

| 50°C | -0.9V | Risk of overcharge |

What’s the difference between 24V gel and AGM battery voltage requirements?

While both are VRLA batteries, key differences exist:

- Absorption Voltage: Gel 28.8V vs AGM 29.2V

- Float Voltage: Gel 27.2V vs AGM 27.6V

- Recovery: Gels tolerate occasional overcharge better

- Discharge: AGMs handle higher currents with less voltage sag

Never charge gels with AGM profiles – the higher voltage will dry out the electrolyte.

How can I accurately measure state of charge using voltage?

Use this 24V gel battery voltage chart at 25°C:

- 100%: 25.6V (rested 4+ hours)

- 75%: 24.8V

- 50%: 24.0V (disconnect at this point)

- 25%: 23.2V (risk of damage)

- 0%: 21.6V (permanent damage likely)

For precision, combine voltage readings with specific gravity tests (1.240 at full charge).