Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a single voltage misstep can shorten your AGM 48V battery’s lifespan by up to 50%? Whether you’re powering a solar system, electric vehicle, or backup energy solution, understanding your battery’s voltage is non-negotiable.

Many assume all 48V batteries behave the same, but AGM (Absorbent Glass Mat) technology demands precise voltage management to avoid irreversible damage.

In this guide, you’ll unlock a comprehensive voltage chart, decode state-of-charge percentages, and learn actionable maintenance strategies—equipping you to prolong battery health, prevent failures, and save thousands in replacements. Let’s dive into the science behind AGM 48V performance.

Best AGM 48V Batteries for Reliable Power Storage

Renogy Deep Cycle AGM Battery 12V 100Ah

Renogy’s 12V 100Ah AGM battery is a top choice for solar and off-grid applications, thanks to its spill-proof design, deep-cycle durability, and low self-discharge rate. With a robust lifespan of 8+ years and vibration resistance, it’s ideal for RVs, marine use, and renewable energy systems.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

100Ah Lithium-Ion

While technically a lithium battery, is often paired with AGM systems due to its seamless compatibility and superior efficiency. It offers 10,000+ cycles, built-in battery management, and lightweight construction—perfect for high-demand setups like electric vehicles and industrial backup power.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

Universal Power Group UB121000-45978 48V AGM Battery

This maintenance-free AGM battery delivers reliable performance for telecom, medical, and UPS applications. Its high discharge rate and leak-proof design ensure safety, while the sealed construction minimizes upkeep. A cost-effective option for users needing dependable 48V power without frequent replacements.

- UB121000 SLA is a 12V 100AH Group 30H Sealed Lead Acid (SLA)…

- USA-based company | UL recognized | Reliable power for critical…

- Absorbent Glass Mat (AGM) technology, designed for versatile mounting,…

AGM 48V Battery Voltage: Key Concepts and Importance

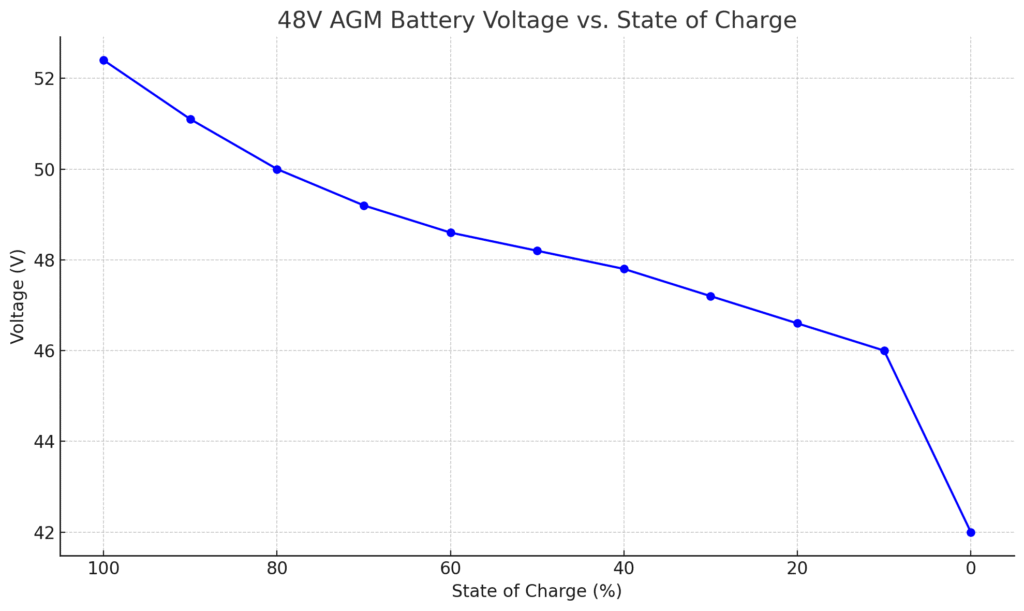

48V AGM Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 52.0 – 52.8 (charging) |

| 90% | 51.1 |

| 80% | 50.0 |

| 70% | 49.2 |

| 60% | 48.6 |

| 50% | 48.2 |

| 40% | 47.8 |

| 30% | 47.2 |

| 20% | 46.6 |

| 10% | 46.0 |

| 0% | 42.0 or lower |

What Voltage Ranges Mean for AGM 48V Batteries

AGM (Absorbent Glass Mat) batteries operate within specific voltage ranges that indicate their state of charge (SoC) and health. A fully charged 48V AGM battery typically measures between 50.4V and 52.8V (at rest), while a completely discharged battery falls to around 42V.

Unlike flooded lead-acid batteries, AGM variants maintain more stable voltage under load due to their fiberglass mat electrolyte absorption, but they’re also more sensitive to overcharging or deep discharges.

Why Voltage Monitoring Is Critical

Ignoring voltage thresholds can lead to irreversible damage. For example:

- Overcharging (>54V) causes excessive gassing, drying out the electrolyte and warping internal plates.

- Deep Discharge (<42V) triggers sulfation, where sulfate crystals harden on plates, reducing capacity.

Solar system owners often face this issue when inverters lack low-voltage cutoffs, draining batteries overnight.

Real-World Voltage Scenarios

Consider a golf cart using a 48V AGM battery bank:

- Under Load: Voltage drops to ~46V during acceleration but should rebound to 48V+ when idle.

- After Charging: A healthy battery settles to ~51.2V within 2 hours post-charge (surface charge dissipation).

Industrial UPS systems, however, prioritize float voltage (typically 54V) to maintain readiness without overcharging.

Temperature’s Impact on Voltage

AGM batteries lose ~0.22V per 12V block (or ~0.88V for 48V) for every 10°F below 77°F. In freezing climates, a “fully charged” 48V battery may read 49.1V—a false low that tempts users to overcharge. Advanced chargers with temperature compensation adjust voltage automatically to prevent this.

Pro Tip: Always measure voltage after the battery rests for 4+ hours without load or charge for accurate SoC readings. A multimeter’s momentary reading under load reflects resistance, not true capacity.

How to Properly Charge and Maintain AGM 48V Batteries

Optimal Charging Parameters for Maximum Lifespan

Charging an AGM 48V battery requires precision to balance performance and longevity. The ideal charging profile follows a three-stage process:

- Bulk Stage: Delivers maximum current until voltage reaches ~56.4V (14.1V per 12V unit). This typically recovers 70-80% capacity.

- Absorption Stage: Holds voltage at 56.4V while current tapers down, filling the remaining 20-30%.

- Float Stage: Maintains 54V (13.5V per unit) indefinitely to prevent self-discharge without overcharging.

Industrial battery analyzers show improper absorption timing reduces cycle life by 40%—many users unknowingly skip this stage with automotive chargers.

Common Charging Mistakes and Solutions

Three frequent errors compromise AGM 48V systems:

- Using Flooded Battery Chargers: Their higher voltage settings (up to 15V per 12V unit) boil AGM electrolytes. Solution: Use chargers with explicit AGM modes like the NOCO Genius GEN5.

- Partial State-of-Charge (PSoC) Cycling: Repeatedly charging to only 80% causes acid stratification. Monthly equalization charges at 58V (14.5V per unit) for 2-4 hours prevents this.

- Temperature Neglect: Charging at 95°F+ without voltage compensation accelerates corrosion. Quality chargers like Victron Blue Smart adjust automatically.

Maintenance Practices for Peak Performance

While AGM batteries are “maintenance-free,” proactive care extends service life:

- Terminal Care: Clean terminals quarterly with baking soda solution—corrosion increases resistance, causing voltage discrepancies.

- Capacity Testing: Annually discharge to 42V at 20-hour rate (5A for 100Ah battery). If capacity drops below 80% of rating, replacement is due.

- Storage Protocol: For seasonal use, charge to 100%, then disconnect and store below 77°F. Self-discharge is just 1-3% monthly versus 5-8% for flooded batteries.

Case Example: A marine electronics installer doubled battery lifespans by switching from constant 54V float to pulsed maintenance charging (intermittent 56V spikes). This prevents electrolyte stratification while minimizing grid corrosion.

Interpreting and Using the AGM 48V Battery Voltage Chart

Decoding Voltage-to-State-of-Charge Relationships

The voltage chart for AGM 48V batteries reveals precise correlations between voltage readings and actual capacity. Unlike linear discharge curves in flooded batteries, AGM batteries exhibit a non-linear voltage drop due to their unique electrolyte absorption:

| State of Charge | Resting Voltage (48V System) | Under Load Voltage |

|---|---|---|

| 100% | 51.2V – 52.8V | 48.5V – 50.4V |

| 75% | 50.0V – 50.8V | 46.8V – 48.2V |

| 50% | 48.8V – 49.6V | 44.5V – 46.0V |

| 25% | 46.4V – 47.2V | 42.0V – 43.5V |

| 0% | 42.0V (Do Not Discharge Below) | N/A |

Advanced Voltage Analysis Techniques

Professional battery technicians use three measurement methods for accurate assessment:

- Open Circuit Voltage (OCV): Measure after 4+ hours rest period – most accurate for SoC determination

- Dynamic Voltage Analysis: Compare voltage sag under known loads (e.g., 0.1C discharge rate) to detect weak cells

- Charge Acceptance Voltage: Monitor how quickly voltage rises during charging to identify sulfation

Example: A telecom backup system showing 49.2V OCV (indicating ~55% charge) but dropping to 42.5V under 20A load suggests severe cell degradation needing replacement.

Voltage Compensation for Temperature Variations

AGM battery voltage fluctuates approximately 0.004V per cell per °F from the standard 77°F reference. For a 48V system (24 cells):

- At 32°F: Add 0.096V per 12V block (2.3V total correction for 48V)

- At 104°F: Subtract 0.13V per 12V block (3.1V total correction)

Smart battery monitors like the Victron BMV-712 automatically apply these corrections, preventing false low-voltage alarms in cold weather or dangerous overcharging in heat.

Advanced Troubleshooting for AGM 48V Battery Systems

Diagnosing Common Voltage-Related Issues

When AGM 48V batteries underperform, voltage analysis reveals root causes. Three frequent problems with diagnostic methods:

- Voltage Depression: If voltage drops abnormally fast under load (e.g., from 50V to 42V at 20A), perform a load bank test at 0.1C rate. More than 15% voltage deviation between cells indicates sulfation.

- Surface Charge Deception: Immediately after charging, voltage may read 53V but drops to 50V within hours. Use a capacitive discharge tester to eliminate surface charge effects.

- Thermal Runaway Signs: Voltage fluctuations exceeding ±0.5V without load changes suggest overheating. Measure case temperature – anything above 120°F requires immediate shutdown.

Balancing Multi-Battery 48V Systems

For battery banks with series/parallel configurations (common in solar installations):

- Individual Voltage Checks: Measure each 12V unit in a 4-battery series string. Variations >0.3V indicate imbalance.

- Equalization Procedure: Apply 15V per 12V battery (60V total) for 2-4 hours max, monitoring temperatures. Only for AGMs specifically rated for equalization.

- Reconditioning Protocol: For chronically unbalanced banks, discharge to 42V, then recharge at C/20 rate (5A for 100Ah bank) with periodic 2-hour rests.

Safety Protocols for High-Voltage Testing

Working with 48V systems requires specific precautions:

| Risk | Prevention | Emergency Response |

|---|---|---|

| Arc Flash | Use insulated tools, wear face shield when testing >30A circuits | Cut power with insulated disconnect, never use water on electrical fires |

| Thermal Events | Install thermal fuses on each battery, maintain 1″ spacing between units | Apply Class D fire extinguisher for lithium fires, sand for lead-acid |

Professional Tip: When troubleshooting intermittent issues, log voltage every 15 minutes for 48 hours using a data logger like the Fluke 289. This captures voltage drops that manual testing might miss.

Long-Term Performance Optimization for AGM 48V Battery Systems

Cost-Benefit Analysis: AGM vs. Alternative Technologies

While AGM 48V batteries have higher upfront costs than flooded lead-acid, their total lifecycle value becomes apparent when analyzing 10-year operational data:

| Parameter | AGM 48V | Flooded 48V | LiFePO4 48V |

|---|---|---|---|

| Cycle Life (80% DoD) | 500-800 cycles | 300-500 cycles | 3,000-5,000 cycles |

| Maintenance Hours/Year | 2-4 | 20-30 | 1-2 |

| 10-Year TCO (100Ah system) | $1,200-$1,800 | $1,500-$2,200 | $2,000-$3,000 |

AGM systems shine in applications requiring maintenance-free operation with moderate cycling (e.g., backup power systems). For daily deep cycling, lithium becomes cost-effective after year 4.

Environmental and Safety Considerations

AGM 48V batteries present unique environmental advantages and handling requirements:

- Recyclability: 98% of AGM battery materials are recyclable, with lead recovery rates exceeding 80% at proper facilities

- Thermal Management: Unlike lithium, AGM batteries don’t require active cooling but must stay below 113°F to prevent electrolyte vaporization

- Disposal Protocols: Spent AGM batteries are classified as hazardous waste (UN2800) and require certified recyclers due to lead content

Future-Proofing Your AGM 48V System

Emerging technologies are enhancing AGM performance:

- Carbon-Enhanced AGM: New models with carbon additives (e.g., Firefly Oasis) achieve 1,200+ cycles at 50% DoD

- Smart Charging Integration: IoT-enabled chargers using adaptive algorithms can extend lifespan by 20-30%

- Hybrid Configurations: Pairing AGM with small lithium buffers handles peak loads while preserving AGM cycle life

Pro Tip: For systems expecting future expansion, select AGM batteries with inter-cell connectors that allow easy capacity upgrades without complete system replacement.

System Integration and Optimization for AGM 48V Battery Banks

Advanced Configuration Strategies for Large Installations

When designing multi-battery 48V systems, proper configuration impacts both performance and longevity. For parallel strings (common in solar arrays and telecom applications):

- Impedance Matching: Ensure all parallel strings have identical cable lengths (within 3%) and connection types to prevent circulating currents that can vary by up to 15% between strings

- Modular Design: Limit parallel strings to 4 maximum – beyond this, use DC-DC converters to maintain charge balance and prevent the “weakest link” effect

- Voltage Monitoring: Install individual string monitors (like the Victron SmartShunt) to detect failing batteries before they drag down entire banks

Integration with Renewable Energy Systems

AGM 48V batteries require specific considerations when paired with solar/wind systems:

- Charge Controller Programming: Set absorption voltage to 56.4-57.6V (temperature-compensated) with a minimum absorption time of 3 hours, regardless of solar input

- Load Management: Program inverters to limit discharge to 42V (10.5V per 12V battery) with a 2-stage warning system at 46V (20% remaining)

- Generator Integration: Configure auto-start generators to trigger at 48V (50% DoD) rather than lower thresholds to prevent deep cycling

Advanced Voltage Profiling Techniques

Sophisticated users can implement dynamic voltage adjustment strategies:

| Application | Optimal Voltage Range | Special Considerations |

|---|---|---|

| Forklift/Power Equipment | 46.8-52.8V (80-20% SoC) | Higher float (54.6V) compensates for rapid cycling |

| Medical Backup Systems | 50.4-52.8V (90-100%) | Monthly equalization at 58V for 1 hour maintains readiness |

| Marine Hybrid Systems | 48.0-51.2V (60-90%) | Salt spray corrosion requires bimonthly terminal voltage checks |

Expert Insight: In grid-tied systems, adding a small (10-20%) lithium buffer bank dramatically reduces cycling on AGM batteries while maintaining the AGM’s superior surge capacity for motor starts.

Advanced Performance Validation and Risk Management for AGM 48V Systems

Comprehensive Battery Health Assessment Protocol

Professional maintenance programs should incorporate these diagnostic procedures quarterly:

- Dynamic Impedance Testing: Measure internal resistance at 1000Hz using a microohmmeter – values above 20% of manufacturer specs indicate degradation

- Capacity Verification: Conduct a 20-hour discharge test at 0.05C rate (5A for 100Ah battery) with voltage logging every 15 minutes

- Thermal Imaging: Scan terminals and case surfaces during charging – temperature variations >5°F between cells suggest imbalance

Risk Mitigation Framework for Critical Systems

For mission-critical applications (hospitals, data centers), implement this risk management matrix:

| Risk Factor | Probability | Impact | Mitigation Strategy |

|---|---|---|---|

| Cell Dryout | Medium (15%) | High | Install voltage-regulated hydration sensors on valve caps |

| Grid Corrosion | High (25%) | Medium | Apply antioxidant gel quarterly and use tin-plated copper lugs |

| Thermal Runaway | Low (5%) | Critical | Implement dual-temperature cutoffs (105°F and 115°F) |

Advanced Performance Optimization Techniques

For maximum ROI on AGM 48V investments:

- Pulsed Equalization: Monthly 4-hour cycles alternating between 56.4V (absorption) and 54.0V (float) at 2Hz frequency reduces stratification

- Load Profiling: Match discharge patterns to battery characteristics – AGMs perform best with <50% depth-of-discharge daily cycles

- Environmental Control: Maintain ambient temperature at 75±5°F – every 15°F above 80°F halves battery life

Quality Assurance Tip: Maintain a “battery logbook” tracking:

- Monthly specific gravity readings (using refractometers for sealed AGMs)

- Cumulative amp-hours processed

- Charging efficiency trends (calculated as [Ah out]/[Ah in])

This data reveals degradation patterns before failures occur.

Conclusion: Mastering AGM 48V Battery Voltage Management

Throughout this comprehensive guide, we’ve explored the critical relationship between voltage and AGM 48V battery performance – from interpreting voltage charts and proper charging techniques to advanced troubleshooting and system integration.

Key takeaways include the importance of maintaining voltage between 50.4V-52.8V for optimal charge, avoiding discharges below 42V, and implementing temperature-compensated charging. Remember that proper voltage management can double your battery’s lifespan while preventing costly failures.

For maximum results, implement these best practices today: regularly monitor your system’s voltage, invest in quality charging equipment, and establish a preventive maintenance schedule.

By mastering these voltage management principles, you’ll ensure reliable power and significant long-term savings from your AGM 48V battery investment.

Frequently Asked Questions About AGM 48V Battery Voltage

What is the ideal resting voltage for a fully charged AGM 48V battery?

A healthy AGM 48V battery should measure between 51.2V to 52.8V after resting for 4+ hours post-charging. This range accounts for temperature variations – at 77°F (25°C), expect 51.8V±0.3V.

Note that immediately after charging, surface charge may show 53-54V, which dissipates within 2-3 hours. For accurate readings, use a calibrated digital multimeter with 0.1V resolution.

How often should I check my AGM 48V battery voltage?

For critical systems (medical, telecom), check voltage weekly under consistent conditions. For general use, monthly checks suffice. Always measure:

- After full charge cycle (absorption stage completes)

- During peak discharge periods

- After extreme temperature changes (>20°F variation)

Log readings to identify trends – consistent voltage drops >0.5V indicate degradation.

Why does my AGM 48V battery voltage drop quickly under load?

Rapid voltage sag (e.g., 52V to 46V at 20A) typically indicates:

- Sulfation from chronic undercharging (reversible with equalization)

- High internal resistance from aging (replace if >25% above spec)

- Insufficient conductor sizing (upgrade cables if voltage drop exceeds 3%)

Test by applying 0.1C load (10A for 100Ah battery) – healthy batteries should maintain >48V for 30+ minutes.

Can I use a regular lead-acid charger for my AGM 48V battery?

While possible, it’s not recommended. Flooded battery chargers often exceed AGM voltage limits (56.4V max vs. 58V+ for flooded). Use an AGM-specific charger with:

- Temperature compensation (±3mV/°C/cell)

- 3-stage charging (bulk/absorption/float)

- Current limiting (≤0.2C for most AGMs)

The Victron Blue Smart IP65 is an excellent choice for 48V systems.

How does temperature affect AGM 48V battery voltage readings?

Voltage varies ≈0.88V per 10°F change for 48V systems. At freezing (32°F), a “full” battery may read 50.3V instead of 51.8V. Conversely, at 104°F, it may show 53.1V. Always:

- Compensate readings using NEMA battery temperature charts

- Install temperature sensors on middle cells

- Adjust charger settings seasonally

What voltage should trigger a low-battery alarm for my 48V system?

Set alarms at two thresholds:

- Warning at 48.0V (≈40% remaining) for non-critical systems

- Critical at 45.6V (≈20% remaining) to prevent damage

For deep-cycle applications (solar, EVs), never discharge below 42V (0% SoC). The Midnite Solar Classic 150 includes programmable voltage alarms.

Why do my 48V AGM batteries charge to different voltages in the same bank?

Voltage imbalances >0.5V between batteries indicate:

- Unequal cable lengths (limit to <3% variation)

- Cell defects (test individual 12V units)

- Temperature differentials (>5°F between batteries)

Solution: Perform controlled equalization at 57.6V for 2 hours max, monitoring temperatures. Rebalance monthly if variations persist.

How can I extend the lifespan of my AGM 48V battery bank?

Follow these proven strategies:

- Maintain charge between 50.4V-52.8V (20-100% SoC)

- Perform monthly equalization charges

- Keep ambient temperature 60-80°F

- Clean terminals quarterly with baking soda solution

- Limit discharge depth to 50% for daily cycling

Properly maintained AGM 48V batteries last 5-7 years in typical applications.