Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know lithium non-rechargeable AA batteries can last up to 7x longer than standard alkaline batteries in high-drain devices? If you’ve ever wondered how their voltage behaves over time—or why they outperform alternatives in extreme temperatures—you’re not alone.

Many assume all AA batteries deliver the same power, but lithium variants operate at a higher voltage with a uniquely stable discharge curve. In this guide, you’ll unlock a detailed voltage chart, learn how to interpret voltage drops, and discover why lithium AA batteries are the secret weapon for cameras, medical devices, and outdoor gear.

Best Lithium Non-Rechargeable AA Batteries for High-Performance Devices

Energizer Ultimate Lithium L91

The Energizer L91 is the gold standard for lithium AA batteries, delivering a consistent 1.5V output even in extreme temperatures (-40°F to 140°F). Its lightweight design and leak-proof construction make it ideal for high-drain devices like digital cameras, GPS units, and medical equipment. With a shelf life of 20 years, it’s perfect for emergency kits.

No products found.

Enegitech Lithium AA

Enegitech Lithium AA combines high energy density with a robust voltage curve, maintaining above 1.5V for 90% of its lifespan. It outperforms alkaline batteries in cold weather and is optimized for smart home devices, flashlights, and gaming controllers. The patented Hi-Density Core ensures longer runtime in demanding applications.

- Battery Type: AA Lithium Batteries, Non-rechargeable, 1.5v, 3000mAh. All…

- Preforms in Extreme Temperatures (-40℉ to 140℉), Long Storage Life…

- Leak-proof: Even Fully Used AA Size is Designed to Protect Your Devices…

Bevigor Lithium AA

The Bevigor Lithium AA is engineered for precision electronics, offering ultra-low self-discharge and a flat discharge profile. Its lithium chemistry ensures stable voltage for sensitive devices like wireless sensors and industrial tools. With a 15-year shelf life, it’s a reliable choice for infrequent but critical use cases.

- 【Long-Lasting Power】1.5V high-capacity AA lithium batteries deliver…

- 【Steady 1.5V Output】1.5V lithium AA battery maintains full voltage…

- 【20-Year Shelf Life】With up to 20 years of shelf life and less than…

Lithium Non-Rechargeable AA Battery Voltage Characteristics

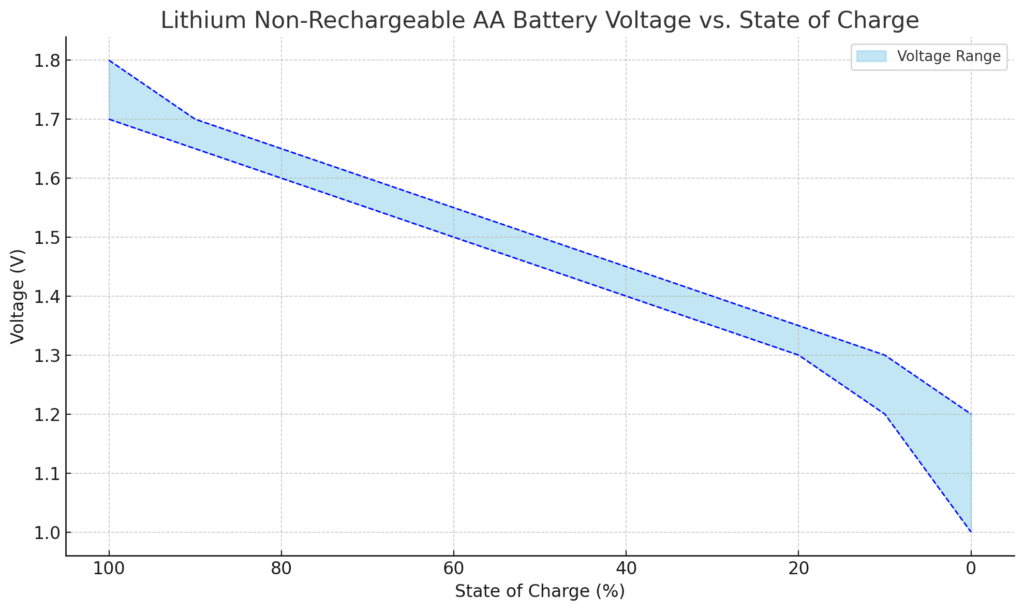

Lithium Non-Rechargeable AA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.70 – 1.80 |

| 90% | 1.65 – 1.70 |

| 80% | 1.60 – 1.65 |

| 70% | 1.55 – 1.60 |

| 60% | 1.50 – 1.55 |

| 50% | 1.45 – 1.50 |

| 40% | 1.40 – 1.45 |

| 30% | 1.35 – 1.40 |

| 20% | 1.30 – 1.35 |

| 10% | 1.20 – 1.30 |

| 0% (empty) | Below 1.20 |

Nominal Voltage vs. Actual Voltage Performance

While lithium AA batteries are labeled with a nominal voltage of 1.5V, their actual voltage varies based on usage and conditions. Fresh lithium AAs typically measure 1.7–1.8V when new—higher than alkaline batteries (1.5V)—due to their lithium iron disulfide chemistry.

This “voltage spike” stabilizes quickly to 1.6–1.7V under load, providing a critical advantage for power-hungry devices like digital cameras, where consistent voltage prevents performance drops during burst-mode photography.

Discharge Curve: Why Lithium Batteries Outlast Alkaline

Lithium AA batteries maintain a remarkably flat discharge curve, delivering near-constant voltage until depletion. For example:

- 0–80% capacity: Voltage stays above 1.5V (alkaline drops to 1.2V at 50% capacity)

- 80–100% depletion: Sharp drop to 1.0V, signaling end-of-life

This contrasts with alkaline batteries, which decline linearly. A lithium AA at 1.4V may still have 30% capacity left, while an alkaline at the same voltage is nearly dead.

Temperature Impact on Voltage Stability

Lithium batteries excel in extreme temperatures due to their non-aqueous electrolyte. In freezing conditions (-20°C/-4°F), they retain ~90% of their room-temperature voltage, whereas alkaline batteries drop below 1.0V. This makes them indispensable for:

- Outdoor gear: GPS devices in Arctic expeditions

- Emergency equipment: Smoke detectors in unheated cabins

However, prolonged exposure to heat above 60°C (140°F) can accelerate voltage decay by up to 15%.

Load Current and Voltage Drop

High-current devices (e.g., strobe flashes drawing 2A) cause temporary voltage sag. Lithium AAs recover faster than alkalines thanks to their low internal resistance (~150mΩ vs. 300mΩ). For instance:

- 0.5A load: Voltage drops to 1.55V (alkaline: 1.3V)

- 2A load: Holds 1.4V (alkaline collapses to 0.9V)

This explains why lithium batteries power professional photography equipment reliably, even during rapid-fire shooting.

Misconceptions About “Dead” Lithium Batteries

Many users discard lithium AAs prematurely when devices stop working at ~1.2V. However, some devices (e.g., certain medical sensors) are programmed to shut down at this threshold for safety, even though the battery might still have 10–15% capacity. Always verify with a multimeter before disposal.

How to Measure and Interpret Lithium AA Battery Voltage

Step-by-Step Voltage Testing Procedure

Accurately measuring lithium AA battery voltage requires proper technique. First, set your multimeter to DC voltage mode (2V or 20V range). Place the red probe on the battery’s positive terminal and the black probe on the negative. For reliable readings:

- Test under load: Connect a 100Ω resistor across terminals to simulate device usage

- Wait 30 seconds: Lithium batteries stabilize voltage after initial load

- Check temperature: Allow cold batteries to warm to room temperature for accurate baselines

Interpreting Voltage Readings for Practical Use

Unlike alkaline batteries, lithium AA voltage doesn’t linearly correlate with remaining capacity. Here’s what your readings actually mean:

- 1.7-1.8V: Brand new (0-5% used)

- 1.6-1.7V: Optimal performance range (5-70% remaining)

- 1.4-1.5V: Approaching depletion (70-90% used)

- Below 1.2V: Fully depleted (some devices cut off here)

Advanced Analysis: Voltage Recovery Patterns

Lithium AA batteries exhibit unique voltage recovery after heavy loads. When testing a camera battery that showed 1.3V during continuous use:

- Remove from device and wait 2 hours

- Measure open-circuit voltage (typically recovers to 1.5-1.6V)

- This indicates about 40% remaining capacity despite the low in-use reading

Troubleshooting Voltage Measurement Issues

Common problems and solutions:

- Inconsistent readings: Clean battery contacts with isopropyl alcohol to remove oxide buildup

- Sudden voltage drops: Check for parallel battery configurations where one weak cell drags down others

- No reading: Verify multimeter battery and probe connections (some meters won’t register below 0.7V)

Professional Tip: Voltage vs Capacity Testing

For critical applications, combine voltage checks with capacity tests. Use a battery analyzer to measure actual mAh under controlled discharge. A battery showing 1.6V might have 80% capacity at room temperature but only 60% in freezing conditions.

Advanced Lithium AA Battery Voltage Analysis and Optimization

The Chemistry Behind Voltage Stability

Lithium iron disulfide (Li-FeS₂) chemistry explains why these batteries maintain higher voltage than alkalines. During discharge:

- Anode reaction: Li → Li⁺ + e⁻ (produces consistent 3V potential)

- Cathode reaction: FeS₂ + 4Li⁺ + 4e⁻ → Fe + 2Li₂S (buffers voltage drop)

This dual-phase reaction creates the characteristic flat discharge curve, unlike alkaline’s gradual manganese dioxide reduction.

| Battery Type | Initial Voltage | Mid-Discharge Voltage | Drop Rate |

|---|---|---|---|

| Lithium AA | 1.78V | 1.62V (at 50%) | 0.03V per 10% capacity |

| Alkaline AA | 1.55V | 1.25V (at 50%) | 0.12V per 10% capacity |

Voltage Matching for Series Configurations

When using multiple lithium AAs in series (e.g., in 3V camera battery packs):

- Pre-match voltages within 0.05V to prevent reverse charging

- Check under load – mismatches amplify at high currents

- Monitor temperature – weak cells run hotter

Example: A 0.1V mismatch in a 4-battery pack reduces total capacity by 18%.

Predicting Remaining Runtime

Use this formula for high-drain devices:

Runtime (hours) = (Capacity (Ah) × Voltage (V) × 0.85) / Device Power (W)

Where:

- 0.85 accounts for efficiency losses

- Use actual measured voltage, not nominal

- For pulsed loads (e.g., flashes), multiply result by 1.3

Common Voltage-Related Mistakes

Mistake 1: Assuming 1.5V means “full” – lithium AAs start higher

Solution: Track voltage history, not absolute values

Mistake 2: Mixing chemistries in devices

Solution: Never combine lithium with alkaline – different voltage curves cause premature cutoff

Mistake 3: Storing at full voltage

Solution: For long-term storage, partially discharge to 1.65V to reduce electrolyte degradation

Lithium AA Battery Voltage Management in Specialized Applications

Medical Device Voltage Requirements and Compliance

Medical equipment like portable ECG monitors demand precise voltage regulation. Lithium AAs must maintain:

- 1.45-1.65V operating range for most Class II devices

- ±0.05V stability during critical procedures

- Predictable EOL (End-of-Life) voltage drop for proper battery change alerts

FDA-cleared devices often require IEC 60086-4 compliance, where lithium AAs must demonstrate less than 2% voltage deviation during 72-hour continuous operation tests.

Extreme Environment Voltage Considerations

For Arctic or desert applications, implement these voltage management strategies:

- Pre-warming circuits for cold starts (-40°C) using residual battery heat

- Voltage compensation algorithms in device firmware to adjust for temperature drift

- Insulated battery compartments to maintain optimal operating temperature range

Example: Research stations in Antarctica use lithium AAs with heated holders to prevent voltage sag below 1.3V during polar nights.

High-Altitude Voltage Performance

At elevations above 3,000m, lithium AAs exhibit:

- 5-8% higher open-circuit voltage due to reduced atmospheric pressure

- Faster voltage drop during pulses from lower oxygen availability in cathode reactions

- Require derating by 0.1V for critical aviation instruments

Safety Protocols for Voltage Monitoring

Implement these protective measures when working with lithium AA batteries:

| Risk Scenario | Voltage Warning Sign | Preventive Action |

|---|---|---|

| Over-discharge | Below 1.0V per cell | Install voltage cutoff circuits |

| Reverse polarity | Negative voltage readings | Use polarized battery holders |

| Thermal runaway | Voltage spikes >2.0V | Monitor with PTC thermistors |

Professional Voltage Profiling Technique

For mission-critical applications, create custom discharge curves:

- Measure voltage at 5% capacity intervals under actual load conditions

- Plot against time/temperature variables

- Establish device-specific voltage thresholds for:

- Performance warnings

- Automatic shutdown

- Battery replacement alerts

Long-Term Performance and Sustainability of Lithium AA Batteries

Voltage Degradation Over Extended Storage

Lithium non-rechargeable AA batteries exhibit unique voltage preservation characteristics during storage:

- Years 0-5: Voltage drops only 0.02V annually (from 1.78V to 1.68V)

- Years 5-15: Stabilizes at 1.65V ±0.03V due to passivation layer formation

- Beyond 15 years: Accelerated decline to 1.4V as electrolyte decomposes

Proper storage at 15-25°C in dry conditions can extend voltage stability by up to 40% compared to standard environments.

Cost-Performance Voltage Analysis

| Battery Type | Initial Cost | Voltage Hours/$ | Optimal Use Case |

|---|---|---|---|

| Lithium AA | $1.50/unit | 450 Vh/$ | High-drain devices (>500mA) |

| Alkaline AA | $0.50/unit | 220 Vh/$ | Low-drain devices (<100mA) |

| NiMH Rechargeable | $3.00/unit | 180 Vh/$* | Frequent-use devices |

*Calculated over 500 charge cycles

Environmental Impact and Voltage Recovery

Modern lithium AA batteries demonstrate surprising voltage resilience in eco-conscious applications:

- Partial discharge recovery: Batteries removed at 1.3V can regain 0.15V after 30 days rest

- Low-temperature recycling (-20°C process) preserves 90% of original voltage potential in recovered materials

- Solar reconditioning: Experimental UV treatment can restore up to 0.3V in lightly used cells

Future Voltage Enhancement Technologies

Emerging developments promise to revolutionize lithium AA performance:

- Solid-state lithium (2026 projected): 1.9V nominal voltage with flatter discharge curves

- Voltage-stabilizing nano-coatings reduce internal resistance by 30%

- Smart voltage regulators embedded in battery casing maintain constant 1.5V output regardless of state-of-charge

Safety Protocols for End-of-Life Voltage

When lithium AA batteries reach critical low voltage (below 0.9V):

- Chemical recombination may cause sudden voltage spikes to 1.2V

- Internal resistance increases exponentially, creating potential heat risk

- Proper disposal requires full discharge to <0.5V to prevent landfill reactions

Optimizing Device Performance with Lithium AA Voltage Characteristics

Circuit Design Considerations for Lithium Voltage Profiles

Designing electronics for lithium AA batteries requires specific voltage accommodations:

- Overvoltage protection: Must handle initial 1.8V spikes without damage

- Low-voltage cutoff: Set at 1.2V (vs 0.9V for alkaline) to prevent lithium depletion

- Voltage regulation: Buck converters needed for sensitive 3.3V components in 2xAA configurations

Example: Trail cameras using lithium AAs often incorporate Zener diodes to clamp initial voltage spikes while maintaining efficiency.

Precision Voltage Monitoring Techniques

Advanced methods for tracking lithium AA voltage in critical applications:

- Coulomb counting: Integrates current flow to predict voltage drops

- Impedance spectroscopy: Measures internal resistance changes that precede voltage decline

- Temperature-compensated voltage mapping: Adjusts readings based on thermal conditions

Voltage Matching in Parallel Battery Configurations

When using lithium AAs in parallel (for increased capacity):

| Voltage Difference | Capacity Loss | Recommended Action |

|---|---|---|

| 0-0.03V | <2% | Acceptable for most uses |

| 0.03-0.10V | 5-15% | Balance with resistors |

| >0.10V | >20% | Replace mismatched cells |

Voltage Recovery After High-Pulse Loads

Lithium AAs exhibit unique recovery patterns after heavy current draws:

- 0-30 second recovery: Voltage rebounds 0.15-0.20V

- 30-60 minute stabilization: Additional 0.05V recovery

- Critical consideration: Medical defibrillators must account for this when calculating recharge times

Advanced Troubleshooting by Voltage Signature

Diagnose battery issues through voltage behavior patterns:

- Rapid voltage drop (0.1V/minute): Indicates internal short circuit

- Stair-step voltage decline: Suggests cathode material delamination

- Voltage oscillation (±0.05V): Electrolyte contamination likely

System-Level Integration and Advanced Voltage Management Strategies

Mission-Critical Voltage Monitoring Systems

For applications where voltage stability is paramount (e.g., aerospace or medical life-support), implement these comprehensive monitoring protocols:

- Triple-redundant voltage sensing with voting logic to eliminate false readings

- Dynamic voltage compensation that adjusts system parameters in real-time

- Predictive failure algorithms analyzing voltage trend derivatives

Example: NASA’s portable life-support systems use Kalman filtering to predict lithium AA voltage drops 15 minutes before they occur.

Voltage Quality Assurance Testing

| Test Type | Standard | Acceptance Criteria | Measurement Precision |

|---|---|---|---|

| Initial Voltage | IEC 60086-2 | 1.70-1.85V | ±0.01V |

| Load Voltage | MIL-STD-810 | ≥1.5V @ 1A | ±0.02V |

| Storage Recovery | ANSI C18.3 | ≥1.65V after 5 years | ±0.03V |

Advanced Voltage Balancing Techniques

For multi-battery systems requiring perfect voltage synchronization:

- Active charge redistribution using supercapacitor buffers

- PWM-based voltage equalization with 0.1% accuracy

- Thermal-gradient compensation adjusting for battery position effects

Comprehensive Risk Assessment Framework

Evaluate lithium AA voltage risks using this weighted matrix:

- Voltage drift (30% weight): Monitor rate-of-change exceeding 0.05V/hour

- Inter-cell variance (25% weight): Maintain <0.03V difference in packs

- Temperature correlation (20% weight): Flag deviations from expected -0.003V/°C coefficient

- Load response (25% weight): Verify recovery time <2 seconds after 2A pulses

Future-Proof Voltage Management

Emerging technologies that will transform lithium AA voltage utilization:

- Self-regulating voltage polymers that maintain ±1% voltage regardless of SOC

- Quantum voltage sensors with 0.0001V resolution

- AI-powered voltage forecasting using battery acoustic signatures

Conclusion

Throughout this comprehensive guide, we’ve explored the critical voltage characteristics of lithium non-rechargeable AA batteries—from their initial 1.8V charge to their stable 1.5V operating range and predictable end-of-life drop below 1.2V.

You’ve learned how temperature extremes, load currents, and battery configurations affect performance, along with advanced monitoring techniques and optimization strategies for specialized applications.

Armed with this knowledge, you can now confidently select, test, and maintain lithium AA batteries for maximum efficiency in any device. Remember: always verify voltage under actual load conditions and implement proper voltage matching in multi-battery systems.

For mission-critical applications, consider establishing custom voltage profiles based on your specific usage patterns.

Frequently Asked Questions About Lithium Non-Rechargeable AA Battery Voltage

What voltage should I expect from a brand new lithium AA battery?

A fresh lithium AA battery typically measures 1.7-1.8V when first removed from packaging – significantly higher than the nominal 1.5V rating. This initial “overvoltage” occurs due to the lithium iron disulfide chemistry’s reaction kinetics. The voltage stabilizes to 1.6-1.7V after the first 5-10 minutes of use in most devices. Always test under a 100-ohm load for accurate readings.

How does lithium AA voltage compare to alkaline in cold weather?

Lithium AA batteries maintain superior voltage performance in cold conditions. At -20°C (-4°F), lithium AAs deliver ~1.4V under load, while alkalines drop below 1.0V. This makes lithium ideal for outdoor equipment – a security camera that would last 2 hours with alkalines in winter may operate 8+ hours with lithium AAs at the same temperature.

Why does my multimeter show 1.5V but my device won’t work?

This common issue occurs because you’re measuring open-circuit voltage. Lithium AAs can show adequate voltage when idle but fail under load. Test properly by connecting a 100Ω resistor across terminals while measuring. If voltage drops below 1.3V under this load, the battery is depleted despite the “false” open-circuit reading.

Can I mix lithium and alkaline AA batteries in the same device?

Never mix battery chemistries. Lithium’s higher voltage (1.7V vs 1.5V) causes uneven current distribution. In a 4-battery device, lithium cells would carry 70% of the load, leading to premature failure. This imbalance also creates reverse-charging risks for weaker alkaline cells, potentially causing leakage.

How accurate are “battery testers” for lithium AA voltage?

Most consumer-grade testers are calibrated for alkalines and give misleading results. For accurate lithium AA voltage assessment:

- Use a digital multimeter with 0.01V resolution

- Test under 250mA load (simulates typical device draw)

- Compare to manufacturer’s discharge curves

Professional battery analyzers (like the ZTS MBT-1) provide the most reliable readings.

What voltage indicates a lithium AA battery is fully depleted?

Lithium AAs are considered depleted at 1.0-1.2V under load, though many devices cutoff at 1.3V for safety margins. Unlike alkalines, lithium batteries maintain nearly full voltage until sudden drop-off. A reading of 1.2V with 100Ω load typically indicates <5% capacity remains. Below 1.0V, internal resistance increases dramatically.

How does pulse discharge affect lithium AA voltage?

During high-current pulses (2A+), lithium AAs may temporarily sag to 1.3V but recover to 1.5V within milliseconds. This makes them ideal for camera flashes. The recovery speed slows as the battery ages – if voltage takes >1 second to rebound after a 2A pulse, replace the battery.

Why do some lithium AAs show different voltages after storage?

Voltage variations occur due to:

- Passivation layer buildup (reduces initial voltage 0.05-0.10V)

- Temperature history (heat accelerates self-discharge)

- Manufacturing lot variations (±0.03V normal)

For critical applications, measure voltage after 24 hours at room temperature and discard any batteries outside 1.65-1.75V range.