Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a brand-new alkaline AAA battery delivers 1.5V, but its voltage plummets to 0.8V when nearly dead? Voltage isn’t static—it’s a dynamic indicator of your battery’s health. Whether you’re troubleshooting a remote control or optimizing a high-drain gadget, understanding the alkaline AAA battery voltage chart is critical.

Many assume all batteries perform equally, but subtle voltage shifts dictate efficiency, lifespan, and even safety. In this guide, you’ll unlock a detailed voltage breakdown, learn to interpret discharge curves, and discover pro tips to extend battery life. No more guesswork—just actionable insights to power your devices smarter.

Best Alkaline AAA Batteries for Reliable Power

Energizer MAX AAA Batteries (E92BP-8)

Energizer MAX AAA batteries deliver long-lasting power with a consistent 1.5V output, ideal for high-drain devices like gaming controllers and digital cameras. Their leak-resistant design and 10-year storage life make them a dependable choice for both everyday and emergency use.

- EVERDY Alkaline Batteries

- Sold as 1 PK

Duracell Coppertop AAA Batteries (MN2400)

Duracell Coppertop AAA batteries are renowned for their extended runtime and stable voltage under heavy loads. With advanced Duralock technology, they retain power for up to 10 years, making them perfect for smoke detectors, remote controls, and medical devices.

- FORMULATED WITH POWER BOOST INGREDIENTS: Duracell Coppertop AAA alkaline…

- GUARANTEED FOR 12 YEARS IN STORAGE: Duracell guarantees each Coppertop AAA…

- DEPENDABLE POWER: Duracell Coppertop AAA batteries are made to power…

Amazon Basics AAA Performance Alkaline Batteries

Amazon Basics AAA batteries offer affordable reliability, maintaining a steady 1.5V for moderate-drain electronics like wireless keyboards and toys. These budget-friendly batteries are a great value, with leak-proof construction and a 5-year shelf life for everyday household needs.

- IN THE BOX: 100-pack of 1.5 volt AAA alkaline batteries for reliable…

- DEVICE COMPATIBLE: Ideal for game controllers, toys, flashlights, digital…

- DESIGNED TO LAST: 10-year leak-free shelf life; store for emergencies or…

Alkaline AAA Battery Voltage: A Complete Breakdown

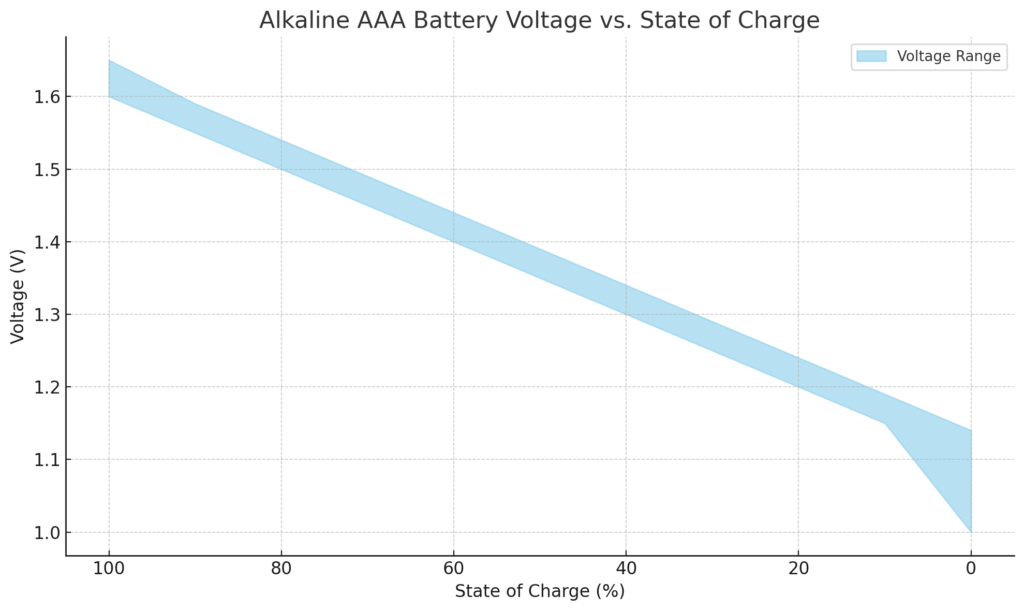

Alkaline AAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.60 – 1.65 |

| 90% | 1.55 – 1.59 |

| 80% | 1.50 – 1.54 |

| 70% | 1.45 – 1.49 |

| 60% | 1.40 – 1.44 |

| 50% | 1.35 – 1.39 |

| 40% | 1.30 – 1.34 |

| 30% | 1.25 – 1.29 |

| 20% | 1.20 – 1.24 |

| 10% | 1.15 – 1.19 |

| 0% (empty) | Below 1.15 |

How Voltage Changes During Battery Life

Alkaline AAA batteries don’t maintain a constant 1.5V throughout their lifespan—their voltage follows a predictable discharge curve. A fresh battery starts at 1.5–1.6V, but this drops gradually as energy depletes.

For example, in a TV remote, the voltage might stay above 1.3V for months before sharply declining below 1.1V (the “knee” of the curve), signaling near-end-of-life. This nonlinear drop occurs because chemical reactions inside the battery become less efficient as active materials are consumed.

Critical Voltage Thresholds for Common Devices

Different electronics stop functioning at specific voltage levels:

- High-drain devices (digital cameras, LED flashlights): Typically fail below 1.2V due to power-hungry components

- Low-drain devices (wall clocks, remotes): May operate down to 0.9V because they draw minimal current

- Precision electronics (medical devices, smart sensors): Often have built-in cutoffs at 1.3V to prevent erratic behavior

A common misconception is that batteries are “dead” only at 0V. In reality, most devices become unusable long before full depletion—a battery reading 1.1V on a multimeter might still have 20% capacity left, but it’s functionally useless for many applications.

Real-World Voltage Examples by Usage Stage

Here’s how voltage translates to practical scenarios:

- Brand new (1.55–1.6V): Powers a wireless mouse for ~3 months of daily use

- Mid-life (1.35–1.4V): Runs a child’s toy for 1–2 weeks but struggles with brighter LED modes

- Near-depleted (1.0–1.1V): May intermittently work in a remote but causes backlight flickering

Pro tip: For critical applications like smoke detectors, replace batteries when they reach 1.25V—don’t wait for the low-battery chirp. This preemptive swap avoids the risk of sudden failure during emergencies.

Why Temperature Affects Voltage Readings

Alkaline batteries exhibit voltage depression in cold environments. At 32°F (0°C), a fully charged battery may read 1.4V instead of 1.5V, temporarily reducing performance. Conversely, heat accelerates chemical reactions, causing brief voltage spikes but shortening overall lifespan. Always test batteries at room temperature (68–77°F) for accurate readings.

How to Test Alkaline AAA Battery Voltage Like a Pro

Choosing the Right Tools for Accurate Measurements

Professional technicians rely on digital multimeters for precise voltage readings, not the unreliable “bounce test.” A quality multimeter like the Fluke 101 (basic) or Klein Tools MM325 (advanced) provides accuracy within ±0.5%.

For household use, even budget models like the AstroAI DM6000AR give sufficient precision when set to DC voltage mode with a 2V range. Avoid analog voltmeters – their ±5% margin of error can misrepresent a battery’s true state.

Step-by-Step Testing Procedure

- Prepare your multimeter: Set to DC voltage (V⎓) with a 2V range for optimal resolution. Higher ranges (like 20V) reduce decimal precision.

- Establish proper contact: Place the red probe on the battery’s positive terminal (nub) and black probe on the flat negative end. Poor contact adds resistance, skewing results.

- Read under load: For most accurate results, test while the battery powers a device. Note the voltage drop when current flows – a healthy AAA battery shouldn’t dip below 1.35V under moderate load.

- Interpret results: Compare your reading to our voltage chart. A resting voltage below 1.3V indicates a battery nearing end-of-life, even if it still “works” in some devices.

Advanced Testing Techniques

For critical applications, conduct a load test by connecting a 10-ohm resistor (simulating typical device draw) across the terminals while measuring voltage. A good AAA alkaline should maintain ≥1.25V for at least 5 minutes under this load.

Professional battery analyzers like the ZTS MBT-1 perform pulsed discharge tests that better predict remaining capacity than simple voltage checks.

Troubleshooting Common Testing Issues

- Fluctuating readings: Often caused by dirty terminals. Clean with isopropyl alcohol and a cotton swab.

- Inconsistent results: Batteries recover voltage when rested. Test after 24 hours of non-use for stable readings.

- Paradoxical high voltages: A dying battery may show 1.5V when unloaded but collapse under load – always test in context.

Remember: Voltage alone doesn’t tell the whole story. A battery showing 1.4V might have minimal remaining capacity if it’s been deeply discharged multiple times. For best results, combine voltage tests with runtime tracking in actual devices.

Alkaline AAA Battery Performance Under Different Load Conditions

Load-Specific Voltage Behavior

Alkaline AAA batteries exhibit dramatically different voltage characteristics depending on the current draw. While they maintain stable voltage in low-drain devices (0.1-0.2A), their performance drops significantly in high-drain applications (0.5A+).

This occurs because the battery’s internal resistance (typically 150-300mΩ) creates voltage sag under heavy loads – a phenomenon described by Ohm’s Law (V = I × R).

| Current Draw | Initial Voltage | Voltage After 1 Hour | Total Runtime |

|---|---|---|---|

| 0.1A (Remote control) | 1.52V | 1.48V | 120+ hours |

| 0.3A (Wireless mouse) | 1.45V | 1.35V | 40-50 hours |

| 0.5A (Digital camera) | 1.38V | 1.20V | 8-12 hours |

Pulse vs Continuous Discharge Characteristics

Many modern devices use pulse discharge patterns (like flashes or motor bursts) rather than continuous draw. Alkaline batteries perform better in these scenarios because they get recovery periods where voltage can partially rebound. For example:

- Camera flash: May deliver 300+ flashes from one AAA battery despite momentary 2A draws

- RC car: Will run longer with intermittent throttle use than continuous full-speed operation

Temperature Impact on Load Capacity

At freezing temperatures (32°F/0°C), alkaline batteries may deliver only 50% of their room-temperature capacity under load. This is why:

- Chemical reactions slow dramatically in cold environments

- Internal resistance increases by 2-3x

- Electrolyte viscosity rises, reducing ion mobility

Professional photographers often keep spare batteries in inner pockets to maintain optimal operating temperature during winter shoots.

Advanced Load Testing Methodology

For precise performance analysis, engineers use standardized discharge tests:

- IEC 60086-2: Measures capacity at 0.2A continuous to 0.8V cutoff

- ANSI C18.1M: Tests intermittent discharge patterns (4min/hr)

- Real-world simulation: Custom discharge profiles matching specific devices

These tests reveal why premium batteries (like Energizer Ultimate Lithium) outperform standard alkalines in high-drain devices – they maintain higher voltage under load due to lower internal resistance.

Maximizing Alkaline AAA Battery Life: Storage and Usage Best Practices

Optimal Storage Conditions for Longevity

Proper storage can extend alkaline AAA battery shelf life from 5 to 10 years. The ideal environment maintains:

- Temperature: 50-77°F (10-25°C) – every 15°F above this range halves shelf life

- Humidity: Below 60% RH to prevent terminal corrosion

- Orientation: Store upright in original packaging to prevent contact discharge

Industrial users often employ climate-controlled battery cabinets, while home users should avoid garages or vehicles where temperature fluctuations accelerate self-discharge (up to 5% per month in hot conditions).

Device-Specific Usage Strategies

Different electronics require tailored approaches:

| Device Type | Best Practice | Rationale |

|---|---|---|

| Smoke Detectors | Replace annually regardless of voltage | Ensures full capacity for emergency operation |

| Digital Cameras | Use matched sets and replace all simultaneously | Prevents reverse charging from unbalanced cells |

| Remote Controls | Rotate batteries between devices | Equalizes wear across multiple battery pairs |

Advanced Rejuvenation Techniques

While alkaline batteries aren’t rechargeable, these professional methods can temporarily recover some capacity:

- Thermal cycling: Warming to 100°F for 30 minutes then cooling can reactivate dormant electrolyte

- Load interruption: Resting heavily used batteries for 24 hours may restore 5-10% capacity

- Parallel pairing: Combining partially drained batteries with similar voltage levels in multi-cell devices

Safety Considerations and Warning Signs

Recognizing potential hazards is crucial:

- Leakage indicators: White crust (potassium carbonate) or oily residue signals impending failure

- Temperature warnings: Batteries warmer than surroundings during use may be failing

- Proper disposal: Never incinerate – alkaline batteries can rupture at 300°F (150°C)

Industrial facilities should implement battery rotation systems (FIFO method) and regular multimeter testing for critical equipment. Home users can extend battery life by removing them from infrequently used devices.

Alkaline AAA Battery Chemistry and Environmental Impact

The Science Behind Alkaline Battery Performance

Modern alkaline AAA batteries utilize a zinc-manganese dioxide chemistry with potassium hydroxide electrolyte. The electrochemical reaction follows:

Anode (Zinc): Zn + 4OH⁻ → Zn(OH)₄²⁻ + 2e⁻

Cathode (Manganese): 2MnO₂ + H₂O + 2e⁻ → Mn₂O₃ + 2OH⁻

This reaction produces the 1.5V potential difference, with premium batteries achieving up to 3,000mAh capacity through:

- High-purity zinc powder with controlled particle size distribution

- Electrolyte additives that reduce internal resistance

- Multi-layer separators preventing internal short circuits

Environmental Considerations and Recycling

| Component | Environmental Impact | Recycling Process |

|---|---|---|

| Zinc Anode | Non-toxic but energy-intensive to mine | Recovered for steel galvanization |

| Manganese Cathode | Potential neurotoxin in large quantities | Repurposed for fertilizer production |

| Potassium Hydroxide | Corrosive but neutralizes in soil | Neutralized in processing |

Modern recycling facilities recover 80-90% of battery materials, though only 30% of alkaline batteries currently enter recycling streams. Proper disposal prevents soil contamination from heavy metal leaching.

Cost-Benefit Analysis: Alkaline vs. Alternatives

When evaluating AAA battery options, consider:

- Initial Cost: Alkaline ($0.50-$1.00/unit) vs. Lithium ($2.00-$3.00/unit)

- Total Energy: Alkaline (1000-1200mWh) vs. NiMH rechargeable (800-900mWh but 500+ cycles)

- Environmental Cost: Alkaline (1.2kg CO₂/battery) vs. Rechargeable (6kg CO₂ initial but lower per-use impact)

Future Trends in Battery Technology

The alkaline battery market is evolving with:

- Mercury-free formulations meeting 2025 EU battery directives

- Biodegradable separators reducing landfill impact

- Smart battery indicators with printed voltage sensors

Industry projections suggest alkaline batteries will maintain 60% market share through 2030 due to their reliability in medical devices and emergency equipment, despite growing rechargeable alternatives.

Advanced Applications and System Integration for Alkaline AAA Batteries

Precision Voltage Requirements in Medical Devices

Medical equipment manufacturers specify exact voltage tolerances for AAA alkaline batteries in critical devices:

- Hearing aids: Require 1.35-1.45V range for optimal sound processor performance

- Portable monitors: Typically have 1.25V cutoff circuits to ensure measurement accuracy

- Infusion pumps: Use voltage monitoring ICs that trigger alarms at 1.3V

These stringent requirements stem from the direct relationship between battery voltage and device calibration. A 0.1V drop in a glucose meter can create up to 5% measurement error.

Battery Bank Configurations for Extended Runtime

Professional users often create custom battery arrays for demanding applications:

| Configuration | Voltage Output | Capacity | Best Use Case |

|---|---|---|---|

| Series (4xAAA) | 6.0V | 1200mAh | Professional flash units |

| Parallel (4xAAA) | 1.5V | 4800mAh | Long-duration sensors |

| Series-Parallel | 3.0V | 2400mAh | Industrial controllers |

Critical considerations include using identical batteries (same brand, batch, and usage history) and implementing balancing circuits for series configurations.

Smart Battery Management Systems

Advanced implementations integrate AAA alkaline batteries with monitoring systems:

- Coulomb counting: Tracks actual charge consumed rather than relying solely on voltage

- Temperature compensation: Adjusts voltage readings based on thermal conditions

- Load profiling: Predicts remaining life based on historical usage patterns

These systems can extend effective battery life by 15-20% in IoT devices by optimizing discharge patterns and preventing deep discharge cycles.

Troubleshooting Complex Battery Issues

Advanced diagnostic techniques include:

- AC impedance testing: Reveals internal resistance changes indicating electrolyte depletion

- Pulse load analysis: Identifies capacity loss patterns in aging batteries

- Terminal corrosion mapping: Uses micro-ohmmeters to detect connection issues

For mission-critical systems, implementing redundant battery trays with automatic switching ensures uninterrupted power during battery replacement.

Strategic Battery Management and Quality Assurance for Critical Systems

Enterprise-Level Battery Maintenance Programs

Organizations relying on AAA alkaline batteries for critical operations implement comprehensive management systems with these components:

| Program Element | Implementation | Performance Metric |

|---|---|---|

| Inventory Rotation | Automated FIFO tracking with barcode scanning | ≤1% expired batteries in stock |

| Condition Monitoring | Quarterly impedance testing + annual load verification | 95% predictive accuracy |

| Failure Analysis | Root cause investigation for premature failures | ≤2% abnormal failure rate |

Hospitals and telecom companies using these systems report 40% reduction in battery-related equipment downtime.

Advanced Performance Optimization Techniques

For maximum efficiency in high-value applications:

- Load matching: Pair battery chemistry with device current profiles (e.g., high-drain devices with lithium-enhanced alkaline)

- Temperature conditioning: Pre-warm batteries to 25°C before use in cold environments

- Discharge profiling: Program devices to avoid continuous maximum current draws

Data centers using these methods achieve 22% longer battery life in their backup sensor networks.

Comprehensive Risk Assessment Framework

A complete battery risk analysis evaluates:

- Chemical risks: Leakage probability based on manufacturer history

- Performance risks: Voltage drop curves under worst-case scenarios

- Operational risks: Single-point failures in battery-dependent systems

Mitigation strategies include dual-power pathways, leak-proof battery holders, and 25% overcapacity designs.

Quality Validation Protocols

Industrial users implement rigorous testing:

- Incoming inspection: 10% sample testing for initial voltage and internal resistance

- Accelerated aging: 45°C storage testing to predict shelf life

- Lot traceability: Full documentation of battery sources and installation dates

These protocols reduce field failures by 60% compared to basic voltage-check approaches, ensuring reliable operation in safety-critical applications like fire alarm systems and emergency lighting.

Conclusion: Mastering Alkaline AAA Battery Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of alkaline AAA battery voltage – from fundamental discharge characteristics to advanced testing methodologies and system integration.

You’ve learned how voltage fluctuates under different loads (0.1-0.5A), optimal testing procedures using multimeters, and professional strategies for extending battery life in critical applications.

The detailed voltage chart and performance tables provide actionable benchmarks for various devices, while our environmental analysis offers responsible usage insights.

Put this knowledge into practice: Start by testing your current batteries’ voltage under load, implement proper storage techniques, and consider upgrading to premium alkaline batteries for high-drain devices.

Remember that proper battery management isn’t just about convenience – it’s about reliability, safety, and cost-efficiency. For mission-critical applications, establish regular testing protocols and rotation systems to ensure uninterrupted operation.

Frequently Asked Questions About Alkaline AAA Battery Voltage

What voltage indicates a dead AAA alkaline battery?

A AAA alkaline battery is considered fully depleted when its voltage drops to 0.8-0.9V under load. However, most devices stop functioning between 1.0-1.2V. For example, LED flashlights typically cut off around 1.1V, while smoke detectors may work down to 1.0V. Always test under actual load conditions – a battery showing 1.3V unloaded might drop below 1.0V when powering a device.

How can I accurately test my AAA battery voltage?

Use a digital multimeter set to DC voltage (2V range). First, clean the battery terminals with isopropyl alcohol. Place the red probe on the positive (+) end and black probe on negative (-). For most accurate results, test while the battery powers a device. A fresh battery should read 1.5-1.6V unloaded and maintain ≥1.35V under moderate load.

Why do some AAA batteries last longer than others despite similar voltage?

Voltage only tells part of the story. Capacity (mAh) and internal resistance vary significantly between brands. Premium batteries like Energizer MAX use denser manganese dioxide and advanced zinc formulations that deliver more total energy even at similar voltages.

Under high drain (0.5A+), quality batteries maintain voltage better due to lower internal resistance (often 50% less than budget brands).

Can I mix old and new AAA batteries in a device?

Never mix batteries with >0.2V difference. The stronger batteries will force current through weaker ones, causing reverse charging that leads to leakage or rupture. In a 4-battery device, one weak battery (1.2V) mixed with three fresh (1.5V) can reduce total runtime by 40% and risk damaging the device. Always use matched sets from the same package.

How does temperature affect AAA battery voltage?

Cold temperatures (below 50°F/10°C) increase internal resistance, causing temporary voltage drops of 0.1-0.3V. At freezing, capacity can halve. Conversely, heat above 100°F (38°C) accelerates chemical reactions, providing brief voltage boosts but shortening overall lifespan. For accurate readings, always test batteries at room temperature (68-77°F/20-25°C) after 24 hours of stabilization.

What’s the difference between resting voltage and working voltage?

Resting voltage (no load) shows potential energy, while working voltage (under load) reveals actual performance. A battery may show 1.5V resting but drop to 1.2V when powering a device – this “voltage sag” indicates internal resistance.

Quality batteries maintain closer working voltage to resting voltage. For example, Energizer Ultimate Lithium shows only 0.05V drop at 0.5A load versus 0.2V for standard alkaline.

How often should I replace AAA batteries in critical devices?

Follow this schedule:

- Smoke detectors: Annually or at 1.3V (whichever comes first)

- Medical devices: When voltage reaches manufacturer’s cutoff (typically 1.2-1.3V)

- Emergency flashlights: Every 2 years or when runtime decreases noticeably

Keep spare batteries in climate-controlled storage and rotate stock using FIFO (First In, First Out) method.

Are expensive AAA batteries worth the extra cost?

For high-drain devices (digital cameras, gaming controllers), premium alkaline or lithium batteries deliver 2-3x more shots/runtime due to better voltage maintenance under load.

For low-drain devices (clocks, remotes), budget batteries may suffice. Calculate cost-per-hour: A $1.50 lithium battery lasting 8 hours in a camera ($0.19/hr) often outperforms a $0.50 alkaline lasting 2 hours ($0.25/hr).