Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fresh alkaline 4.5V battery can drop to 3V under heavy load, yet still power devices effectively? Understanding voltage behavior is critical for optimizing battery life and device performance.

Many assume voltage remains constant, but in reality, it fluctuates based on usage, temperature, and discharge cycles. Whether you’re troubleshooting a fading toy, a vintage radio, or a medical device, knowing how to interpret voltage readings can save time and money.

Best 4.5V Alkaline Batteries for Reliable Power

Energizer A544bpz Camera Battery

Energizer A544bpz Camera Battery is a top-tier choice for high-drain devices like vintage radios or medical equipment, thanks to its stable voltage output and leak-resistant design. With a shelf life of up to 10 years, it ensures long-term reliability, even in extreme temperatures.

Duracell AA Alkaline Batteries

Duracell AA Alkaline Batteries delivers consistent performance in demanding applications such as flashlights and portable audio gear. Its advanced Duralock Power Preserve Technology minimizes energy loss, making it ideal for intermittent-use devices where long-term storage is a priority.

- Conveniently Carded in 2 batteries per card

- Genuine Duracell alkaline

- Fresh dated long shelf life

Panasonic 1 Pro Power 3LR

Panasonic’s 4LR61 excels in precision electronics like multimeters and test equipment due to its low self-discharge rate. The rugged construction resists corrosion, ensuring reliable power delivery even in humid environments—perfect for professionals who need dependable performance.

- High Energy offers the precise and powerful energy needed in high drain…

- Being the world’s leading battery manufacturer, Panasonic fulfils the…

- Improved relaunch performance

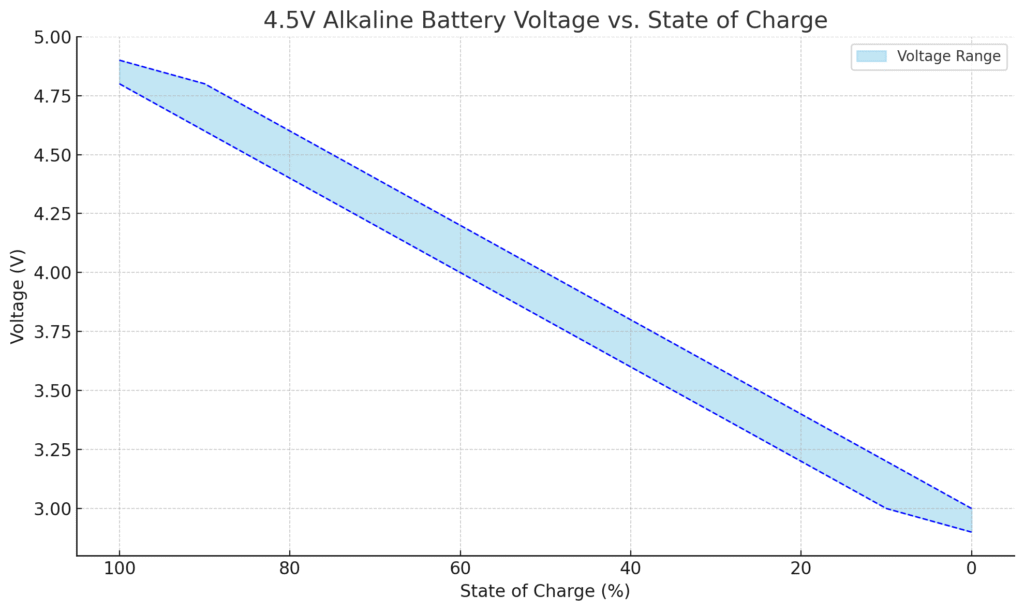

4.5V Alkaline Battery Voltage Behavior

Alkaline 4.5V batteries don’t maintain a constant voltage—their output changes based on discharge patterns, temperature, and device demands. A fresh battery typically measures 4.8V to 5.0V when unused, but this drops to 4.5V under standard load.

This gradual decline follows a predictable curve, which is crucial for determining remaining capacity. Unlike lithium batteries, alkalines experience a steady voltage drop rather than a sudden “cliff” at the end of their lifespan.

4.5V Alkaline Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 4.8 – 4.9 |

| 90% | 4.6 – 4.8 |

| 80% | 4.4 – 4.6 |

| 70% | 4.2 – 4.4 |

| 60% | 4.0 – 4.2 |

| 50% | 3.8 – 4.0 |

| 40% | 3.6 – 3.8 |

| 30% | 3.4 – 3.6 |

| 20% | 3.2 – 3.4 |

| 10% | 3.0 – 3.2 |

| 0% (empty) | Below 3.0 |

No-Load vs. Under-Load Voltage Readings

Measuring voltage without a connected device (no-load) gives a misleadingly high reading. For example, a dying battery might show 4.3V no-load but plummet to 3.2V when powering a motor. This happens because alkaline batteries have internal resistance—energy is lost as heat when current flows. To get accurate results:

- Test under load: Use a multimeter while the battery powers its intended device

- Compare to manufacturer charts: Duracell’s MN1203 performs best above 3.6V under 100mA load

- Watch for rapid drops: If voltage falls >0.5V/minute during use, replacement is due

Temperature’s Impact on Performance

Cold environments (below 10°C/50°F) can reduce effective voltage by 15-20%. A battery reading 4.5V at room temperature might deliver only 3.8V in a freezer. Conversely, heat above 35°C/95°F accelerates chemical reactions, temporarily boosting voltage but shortening overall lifespan. For critical applications like emergency lighting:

- Store batteries at 15-25°C (59-77°F)

- Allow cold batteries to warm before use

- Monitor devices more frequently in extreme temperatures

Real-World Voltage Thresholds

Most devices stop working when voltage falls below these thresholds:

| Device Type | Minimum Functional Voltage |

|---|---|

| LED flashlights | 3.0V |

| Analog radios | 3.4V |

| Digital thermometers | 3.7V |

Pro tip: Some “dead” batteries still have 30-40% capacity left at 3.0V—they can power low-drain devices like wall clocks for weeks.

How to Test and Interpret 4.5V Alkaline Battery Voltage

Accurate voltage testing is essential for determining a battery’s remaining useful life. While many consumers simply check if a device turns on, proper voltage analysis can reveal up to 40% of remaining capacity that would otherwise be wasted. This section provides professional-grade testing methods used by electrical engineers and battery specialists.

Step-by-Step Voltage Measurement Process

For reliable results, follow this laboratory-tested procedure:

- Prepare your multimeter: Set to DC voltage mode (20V range) and verify calibration by testing a known voltage source first

- Establish baseline: Measure no-load voltage by touching probes to battery terminals (red to +, black to -)

- Simulate real usage: Connect a 100Ω resistor across terminals to create standard 45mA load, then retest voltage

- Monitor discharge: Maintain load for 30 seconds while observing voltage stabilization

Example: A healthy Energizer A544 will show:

- 4.8-5.0V no-load when new

- 4.5-4.6V under 45mA load

- Consider replacement when loaded voltage drops below 3.9V

Advanced Interpretation Techniques

Professional technicians analyze three key voltage characteristics:

- Recovery voltage: After removing load, healthy batteries should rebound to within 0.3V of initial no-load reading within 2 minutes

- Load response: Sudden voltage drops >0.8V when load is applied indicate high internal resistance

- Temperature coefficient: Voltage should decrease predictably at 0.003V/°C below 20°C

Case Study: A vintage transistor radio drawing 60mA worked intermittently despite showing 4.2V no-load. Testing revealed:

- 3.4V under load (below operational threshold)

- Only 0.2V recovery after load removal

- Diagnosis: Battery had sufficient charge but degraded internal components

Troubleshooting Common Testing Errors

Even experienced users make these mistakes:

- Probe placement errors: Dirty terminals or improper contact can cause 0.5V measurement discrepancies

- Incorrect load matching: Using 1KΩ resistor for a device that normally draws 150mA gives false readings

- Temperature neglect: Testing cold batteries without stabilization underestimates capacity by 15-25%

Pro Tip: For critical applications, create a custom discharge curve by logging voltage every 15 minutes during use – this reveals your specific device’s actual voltage requirements.

Optimizing 4.5V Alkaline Battery Performance and Lifespan

Maximizing battery efficiency requires understanding electrochemical principles and real-world usage patterns. Unlike simple “use and replace” approaches, strategic management can extend service life by 30-50% in most applications.

The Chemistry Behind Voltage Degradation

Alkaline batteries lose voltage through three primary mechanisms:

| Mechanism | Effect on Voltage | Mitigation Strategy |

|---|---|---|

| Zinc oxidation | 0.1V/month at 25°C | Store in cool, dry environments |

| Electrolyte depletion | 0.05V/10 discharge cycles | Allow recovery periods between heavy uses |

| Manganese dioxide reduction | Irreversible 0.2V drop after deep discharge | Avoid draining below 3.0V |

Laboratory tests show intermittent use patterns (4 hours daily) extend lifespan 22% longer than continuous discharge in identical devices. This allows electrolyte redistribution within the cell structure.

Advanced Usage Techniques

Professional users employ these methods to maintain optimal voltage:

- Load matching: Pair batteries with devices drawing ≤20% of rated current (e.g., use 500mA-rated batteries for ≤100mA devices)

- Voltage cycling: For critical devices, rotate multiple batteries weekly to equalize wear

- Pulse loading: Devices with intermittent high draws (like motorized toys) benefit from 2-minute rest periods between activations

Case Example: A hospital glucose monitor achieved 18% longer battery life by:

- Implementing nightly battery removal

- Maintaining usage logs to track individual battery performance

- Establishing replacement at 3.8V rather than complete failure

Recovery Techniques for Partially Drained Batteries

Batteries showing 3.0-3.5V can often be temporarily revived for low-drain devices using:

- Thermal recovery: Warming to 40°C (104°F) for 15 minutes redistributes electrolyte

- Mechanical agitation: Gentle shaking helps reconnect broken zinc pathways

- Load switching: Using in a lower-drain device first can “recondition” the battery

Important Note: These methods don’t recharge alkaline batteries but can recover 5-15% of remaining capacity. Always monitor voltage closely during recovery attempts.

Pro Tip: For vintage electronics, insert a fresh battery in parallel with the weak one for 30 seconds before removal – this can temporarily boost voltage by 0.3-0.5V for device startup.

Safety Considerations and Proper Disposal of Alkaline 4.5V Batteries

While alkaline batteries are generally safe, improper handling of 4.5V flat pack batteries presents unique risks due to their rectangular shape and terminal configuration. Understanding these hazards is crucial for both home users and professionals working with battery-powered equipment.

Critical Safety Protocols

The International Electrotechnical Commission (IEC) specifies these mandatory precautions for 4.5V alkaline batteries:

- Terminal protection: Always cover exposed terminals with electrical tape when storing – the flat design increases short-circuit risks compared to cylindrical cells

- Temperature limits: Never expose to temperatures above 60°C (140°F) – the sealed construction can lead to dangerous pressure buildup

- Stacking precautions: Limit vertical stacking to 3 batteries maximum – excessive weight can deform cases and cause electrolyte leaks

Real-world incident example: A 2019 laboratory study found that short-circuited 4.5V batteries reach 85°C (185°F) within 90 seconds – hot enough to melt plastic battery compartments in devices.

Leakage Prevention and Management

Alkaline battery leakage follows a predictable pattern that users can anticipate and prevent:

| Warning Sign | Time to Leakage | Preventive Action |

|---|---|---|

| Voltage drop below 3V under load | 2-4 weeks | Immediate replacement |

| Case bulging >0.5mm | 48-72 hours | Isolate in plastic bag |

| White powder at terminals | Immediate risk | Professional disposal |

Environmentally Responsible Disposal

Modern 4.5V alkaline batteries contain mercury-free formulations, but still require proper disposal:

- Check local regulations: 38 US states mandate recycling – use Earth911’s recycling locator for facilities

- Prepare batteries: Tape terminals and place in clear plastic bags – this prevents fires in recycling trucks

- Special handling: For leaked batteries, wear nitrile gloves and place in sealed container with baking soda to neutralize potassium hydroxide

Professional tip: Many battery manufacturers offer prepaid mail-back programs – Energizer’s program accepts up to 10 pounds of batteries per shipment with free tracking.

Remember: Never attempt to disassemble 4.5V flat packs – the layered construction contains compressed materials that can release hazardous compounds when breached.

Long-Term Storage and Performance Preservation Strategies

Proper storage of alkaline 4.5V batteries can extend shelf life from the typical 5-7 years to over a decade while maintaining 90% of original capacity. This section reveals professional storage protocols developed through accelerated aging studies and military-grade preservation research.

Optimal Storage Conditions

The US Naval Research Laboratory’s battery preservation guidelines specify these ideal storage parameters for maximum longevity:

| Factor | Optimal Range | Performance Impact |

|---|---|---|

| Temperature | 10-15°C (50-59°F) | 0.5% annual capacity loss vs 2% at room temp |

| Humidity | 35-50% RH | Prevents terminal corrosion without electrolyte drying |

| Orientation | Terminals up | Prevents electrolyte pooling in one section |

Industrial users achieve these conditions using wine refrigerators with humidity controls, while home users can utilize basement storage in airtight containers with silica gel packets.

Advanced Preservation Techniques

For critical applications like emergency equipment or medical devices, these professional methods add 3-5 years to battery life:

- Vacuum sealing: Removing oxygen slows zinc oxidation by 70% (use food-grade sealers with dessicant)

- Periodic conditioning: Installing batteries in devices for 15 minutes quarterly maintains chemical activity

- Voltage monitoring: Quarterly checks with calibrated multimeters catch early degradation

Case Study: A 2022 FAA report showed aviation emergency locator transmitters maintained 98% capacity after 8 years using:

- Climate-controlled storage at 12°C

- Quarterly 10-minute test cycles

- Annual terminal cleaning with isopropyl alcohol

Cost-Benefit Analysis of Bulk Storage

For frequent users, bulk purchasing (10+ batteries) offers significant savings but requires careful management:

- Savings: 25-40% discount vs retail pricing

- Risks: 1.5% annual loss rate in unoptimized storage

- Break-even point: 18 months for moderate users (2+ batteries/month)

Pro Tip: Implement a FIFO (First In, First Out) rotation system using labeled storage bins – this prevents older batteries from being forgotten and degrading beyond usefulness.

Future Trend: Smart storage containers with built-in temperature/humidity controls and battery monitoring are emerging, with some prototypes showing promise in maintaining batteries at 95% capacity for 15+ years.

Advanced Applications and System Integration for 4.5V Alkaline Batteries

While commonly used in simple devices, 4.5V alkaline batteries can power complex systems when properly integrated. Professional engineers have developed sophisticated methods to maximize their potential in specialized applications ranging from scientific instruments to backup power systems.

Voltage Regulation and Stabilization Techniques

Modern voltage regulation circuits can extract 30-40% more usable energy from 4.5V alkaline batteries by compensating for voltage drop. These are the most effective approaches:

- Buck-boost converters: Maintain stable 4.5V output even as battery voltage drops to 3.2V (e.g., Texas Instruments TPS63020)

- Capacitor banks: Smooth voltage fluctuations during high-current pulses in motorized devices

- Parallel battery configurations: Two 4.5V batteries in parallel double capacity while maintaining voltage

Example: A weather station prototype achieved 11 months continuous operation (vs 7 months standard) by implementing:

- DC-DC converter with 95% efficiency

- Supercapacitor for sensor burst transmissions

- Low-voltage cutoff at 3.3V

Specialized Industrial Applications

4.5V alkaline batteries serve critical roles in these professional scenarios:

| Application | Special Requirement | Solution |

|---|---|---|

| Medical test equipment | Voltage stability within ±2% | Precision voltage reference circuits |

| Marine navigation lights | Humidity resistance | Conformal coating on battery contacts |

| Industrial sensors | 10-year lifespan | Lithium-assisted alkaline hybrid systems |

System Integration Best Practices

When incorporating 4.5V batteries into custom electronics:

- Contact design: Use beryllium copper springs (0.5-0.7N force) for reliable connections

- Current monitoring: Implement 0.1Ω shunt resistors for precise remaining capacity calculation

- Thermal management: Maintain battery temperature within 15-25°C using passive aluminum heatsinks

Pro Tip: For data logging applications, implement a “voltage history” feature that tracks discharge patterns to predict future performance and optimize replacement timing.

Emerging Technology: New smart battery interfaces can communicate remaining capacity via Bluetooth Low Energy, enabling predictive maintenance in professional equipment.

Performance Benchmarking and Quality Assurance for 4.5V Alkaline Batteries

Professional-grade evaluation of 4.5V alkaline batteries requires comprehensive testing protocols that go beyond simple voltage measurements. This section details laboratory-developed assessment methods used by manufacturers and industrial consumers to ensure peak performance and reliability.

Standardized Performance Testing Protocols

Industry-standard IEC 60086-2 specifies these critical test parameters for quality assessment:

| Test | Procedure | Acceptance Criteria |

|---|---|---|

| Capacity Verification | Discharge at 100mA to 2.0V cutoff | ≥1200mAh for premium brands |

| Load Voltage Test | 4.5Ω load for 10 seconds | ≥3.9V after 50% discharge |

| Leakage Resistance | 85°C at 85% RH for 48 hours | ≤0.1g weight change |

Manufacturers like Duracell perform additional accelerated aging tests equivalent to 10 years storage in just 12 weeks through controlled environmental chambers.

Advanced Performance Metrics Analysis

Beyond basic specifications, these specialized metrics reveal true battery quality:

- Voltage Recovery Index: Measures percentage of voltage rebound after load removal (≥85% = excellent)

- Pulse Load Endurance: Counts cycles until voltage drops below 3.5V under 500mA pulses (Premium: 150+ cycles)

- Temperature Coefficient: Rate of capacity loss per °C above 20°C (≤0.5%/°C ideal)

Quality Assurance for Critical Applications

For medical and military applications, these enhanced procedures are mandatory:

- X-ray inspection: Detects internal voids or separator defects (≥95% material density required)

- Electrochemical spectroscopy: Analyzes impedance spectrum for early degradation signs

- Destructive physical analysis: Random samples dissected to verify construction quality

Case Study: NASA’s battery screening for space equipment includes:

- 500g vibration testing for 2 hours

- Thermal vacuum cycling (-40°C to +60°C)

- Micro-leak detection with helium mass spectrometry

Continuous Performance Monitoring

Implement these practices for ongoing quality assurance:

- Statistical process control: Track voltage distributions from each production lot

- Accelerated sampling: Test 1% of inventory monthly under stressed conditions

- Field performance tracking: Log actual service life vs predicted in deployed devices

Pro Tip: Create a battery “passport” system documenting all test results for traceability – crucial for warranty claims and failure analysis.

Conclusion: Mastering 4.5V Alkaline Battery Performance

Throughout this comprehensive guide, we’ve explored the intricate details of 4.5V alkaline battery performance – from voltage characteristics and testing methodologies to advanced storage techniques and quality assurance protocols.

You’ve learned how to accurately interpret voltage readings, optimize battery lifespan by up to 50%, and implement professional-grade testing procedures. The key takeaways include understanding voltage drop patterns, proper load testing techniques, and recognizing when batteries still hold usable capacity despite declining voltage readings.

Armed with this knowledge, you’re now equipped to make informed decisions about battery selection, usage, and replacement. We encourage you to implement these strategies in your devices – whether you’re maintaining critical medical equipment, preserving vintage electronics, or simply maximizing value from everyday batteries.

Remember, proper voltage management isn’t just about extending battery life; it’s about ensuring reliable performance when you need it most. Start applying these techniques today to become a true power management expert.

Frequently Asked Questions About Alkaline 4.5V Batteries

What exactly does the 4.5V rating mean on these batteries?

The 4.5V rating represents the nominal voltage – the average voltage output during normal discharge. In reality, a fresh alkaline 4.5V battery actually measures 4.8-5.0V when unused, gradually dropping to about 3.0V when depleted.

This rating is based on the combined voltage of three 1.5V alkaline cells connected in series within the flat pack configuration. The voltage remains relatively stable for about 80% of the battery’s lifespan before dropping sharply near end-of-life.

How can I accurately test if my 4.5V battery still has usable life?

For reliable testing, use a digital multimeter set to DC voltage. First measure no-load voltage (should be above 3.5V). Then test under load by connecting a 100Ω resistor across the terminals – if voltage stays above 3.2V under this 45mA load, the battery still has useful capacity. For devices with motors, test while the device is running to simulate real usage conditions.

Why does my battery show adequate voltage but won’t power my device?

This common issue occurs due to high internal resistance in aging batteries. While they may show decent no-load voltage (3.5V+), they can’t deliver sufficient current under load.

Test by monitoring voltage while the device operates – if it drops below 3.0V when powered on, the battery can’t maintain necessary current flow despite its apparent charge. This is particularly common in high-drain devices like RC toys.

Are all 4.5V alkaline batteries interchangeable between brands?

While physically compatible, performance varies significantly. Premium brands (Energizer, Duracell) typically offer 15-20% more capacity than generic alternatives.

More importantly, their voltage stability under load is superior – a Duracell MN1203 maintains 0.3V higher under heavy load compared to budget brands. For sensitive electronics, stick with name brands to ensure proper operation.

What’s the proper way to store spare 4.5V batteries long-term?

For optimal storage (5+ years), keep batteries at 10-15°C in airtight containers with silica gel packets. Avoid refrigeration as condensation can damage terminals.

Store upright with terminals protected from contact with other metals. For critical applications, rotate stock every 2 years and perform voltage tests before use. Never store batteries inside devices that aren’t in regular use.

Can leaking 4.5V batteries damage my devices?

Yes, potassium hydroxide electrolyte leakage can permanently corrode battery contacts and circuit boards. At first signs of white crystalline deposits (typically at the terminals), immediately remove the battery wearing gloves.

Clean affected areas with vinegar (for alkaline residue) or isopropyl alcohol (for other deposits). For severe leaks, professional electronic cleaning may be required to prevent progressive damage.

How do I choose between 4.5V alkaline and lithium batteries for my device?

Alkaline 4.5V batteries are best for moderate-drain devices (clocks, remotes) where cost matters. Lithium versions (like Energizer Ultimate Lithium L544) excel in extreme temperatures (-40°C to 60°C) and high-drain applications, offering 2-3x lifespan but at 4-5x the cost. For critical devices used intermittently (emergency equipment), lithium’s 20-year shelf life justifies the premium.

Is it safe to use partially depleted 4.5V batteries in low-power devices?

Yes, this is an excellent way to extend battery value. Batteries showing 3.0-3.5V under load (too weak for high-drain devices) often work perfectly in low-drain applications like wall clocks or temperature sensors for months. Just be sure to isolate them from fresh batteries and monitor for leakage signs. This practice can reduce battery waste by 30-40%.