Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiMH 6V battery doesn’t always deliver exactly 6 volts? Understanding voltage fluctuations is critical for optimizing performance in devices like emergency lights, robotics, or medical equipment. Many assume voltage remains constant, but in reality, it changes with charge cycles, temperature, and load conditions.

This guide reveals the complete NiMH 6V voltage chart, explaining how voltage drops during discharge, why it matters, and how to interpret readings for peak efficiency. By the end, you’ll master voltage trends, avoid premature failures, and unlock longer battery life—whether you’re a hobbyist or a professional.

Best 6V NiMH Batteries for Reliable Performance

Tenergy 2 Pack NiMH Receiver

Ideal for high-drain devices like robotics and medical equipment, the Tenergy offers a stable 6V output with low self-discharge. Its 2000mAh capacity ensures long runtime, while the rugged construction resists overheating. Perfect for users needing dependable, rechargeable power.

- 2 Pack high capacity of 2000mAh RC receiver battery pack with Hitec…

- The Tenergy rechargeable NiMH battery pack with Hitec connector works with…

- NiMH flat battery pack is ideal for radio receiver planes with a Hitec…

Panasonic HHR-75AAA/B

Panasonic HHR-75AAA/B excels in precision applications such as meters and emergency lighting. With a compact 600mAh capacity, it balances efficiency and size. Its advanced NiMH chemistry provides consistent voltage under load, making it a top choice for professionals.

- Replacement Battery for Panasonic Cordless Telephones

- Works for almost all Panasonic phones that use AAA batteries

- Economical bulk package

Powerex PRO High Capacity Rechargeable

For extended use in RC cars or solar projects, the Powerex PRO High Capacity Rechargeable delivers a high-capacity 3000mAh with minimal voltage drop. Its premium cells support 1000+ charge cycles, offering unmatched durability and cost-efficiency over time.

- 2700mAh Ultra High Capacity – Among the highest-capacity NiMH AA…

- High-Drain Devices – Optimized for devices requiring fast and stable…

- Low Self-Discharge – Retains up to 75% charge after 1 year of storage….

6V NiMH Battery Voltage Behavior

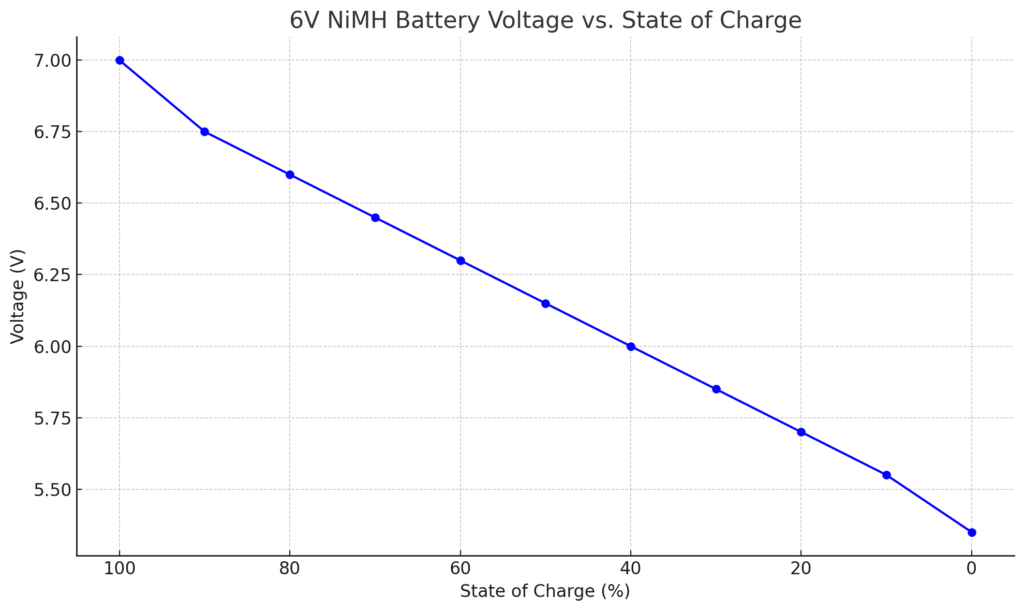

6V NiMH Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 7.0 |

| 90% | 6.75 |

| 80% | 6.60 |

| 70% | 6.45 |

| 60% | 6.30 |

| 50% | 6.15 |

| 40% | 6.00 |

| 30% | 5.85 |

| 20% | 5.70 |

| 10% | 5.55 |

| 0% (empty) | Below 5.4 |

How Voltage Changes During Discharge

A NiMH 6V battery doesn’t maintain a constant voltage—it gradually drops as energy depletes. Unlike alkaline batteries that decline sharply, NiMH cells exhibit a flatter discharge curve, delivering stable power until near depletion.

For example, a fully charged 6V NiMH battery may start at 7.2V (open-circuit voltage), settle at 6.5V under load, then slowly decrease to 5V before needing recharge. This predictable pattern makes NiMH ideal for devices requiring consistent performance, like digital cameras or portable medical devices.

Factors Affecting Voltage Output

Three key variables influence voltage stability:

- Temperature: Cold environments (below 10°C) can reduce voltage by 15–20%, while heat accelerates self-discharge.

- Load Current: High-drain devices (e.g., RC cars) cause faster voltage drops versus low-power sensors.

- Age/Cycles: After 500+ charges, internal resistance rises, lowering peak voltage capacity.

A real-world example: A 6V NiMH battery powering an emergency light at 25°C may last 8 hours, but at 0°C, runtime could halve due to voltage suppression.

Interpreting Voltage Readings

Voltage alone doesn’t indicate remaining capacity—you must consider context. A reading of 6.2V on a multimeter might suggest:

- Fully charged (if measured immediately after charging)

- 50% capacity (if under moderate load)

- Near-depleted (if the battery is aged)

For accuracy, pair voltage checks with capacity testing (e.g., using a smart charger like the SkyRC MC3000). Professionals often track discharge curves—a healthy NiMH 6V battery should maintain ≥5.5V for 80% of its rated runtime.

Common Misconceptions

Many users mistake nominal voltage (6V) for actual operating voltage. In reality:

- Myth: “6V means exactly 6.0 volts at all times.”

Reality: Voltage fluctuates between 7.2V (charged) and 5V (depleted). - Myth: “Lower voltage always means a bad battery.”

Reality: Temporary voltage sag under heavy load is normal.

For critical applications like backup systems, monitor voltage trends over time rather than single readings.

Optimal Charging Practices for 6V NiMH Batteries

Charging Voltage Requirements

Proper charging is critical for maximizing 6V NiMH battery lifespan and performance. These batteries require a peak charge voltage of 7.2-7.5V from a smart charger that can detect full charge.

Unlike lead-acid batteries, NiMH cells are sensitive to overcharging, which can permanently reduce capacity by up to 30% after just 10 overcharge cycles. A quality charger like the Nitecore D4 uses delta-V detection (monitoring voltage drops) to prevent this.

Step-by-Step Charging Process

- Pre-charge check: Verify battery voltage is above 5V (deeply discharged batteries below 4V need special recovery mode)

- Charge rate selection: Use 0.5C rate (e.g., 1A for 2000mAh battery) for optimal speed/safety balance

- Temperature monitoring: Stop charging if surface temperature exceeds 45°C (122°F)

- Termination: Wait for voltage drop of 5-10mV per cell (detected automatically by smart chargers)

For example, charging a Tenergy Centura 6V 2000mAh battery at 1A typically takes 2.5 hours, with voltage rising from 6V to 7.3V before termination.

Advanced Charging Considerations

Professional users should account for these factors:

- Pulse charging: Some industrial chargers use 1-second pulses to reduce heat buildup

- Top-off charges: Adding 10% extra capacity after full charge compensates for self-discharge

- Storage charging: Maintain 40% charge (≈6.2V) for batteries unused longer than 1 month

Troubleshooting Common Charging Issues

If your NiMH 6V battery won’t charge properly:

- Voltage stuck at 6V: May indicate memory effect – perform full discharge/charge cycle

- Rapid temperature rise: Often signals failing cells – replace battery if occurring within 30 minutes

- Charger not recognizing battery: Clean contacts with isopropyl alcohol and check for physical damage

For mission-critical applications like medical devices, implement a dual verification system – check both voltage and capacity after charging to ensure reliability.

Advanced Performance Analysis and Maintenance Techniques

Interpreting Discharge Curves for Maximum Efficiency

Understanding discharge curves is essential for optimizing NiMH 6V battery performance. A typical discharge curve shows three distinct phases:

| Phase | Voltage Range | Duration | Characteristics |

|---|---|---|---|

| Initial Drop | 7.2V → 6.8V | First 5-10% | Rapid voltage stabilization after charge |

| Plateau | 6.8V → 6.2V | 80-85% | Stable working voltage for most applications |

| Final Decline | 6.2V → 5.0V | Last 10-15% | Steep drop indicating need for recharge |

For example, in robotics applications, you should design cutoff circuits to activate at 6.0V to avoid deep discharge damage while utilizing 90% of capacity.

Capacity Testing and Health Assessment

Professional-grade maintenance requires regular capacity verification:

- Full discharge test: Measure total mAh delivered at 0.2C rate to rated cutoff voltage

- Internal resistance check: Use specialized meters to detect cell degradation (healthy 6V NiMH should be <100mΩ)

- Cycle tracking: Maintain log of charge/discharge cycles (most NiMH last 500-1000 cycles)

A common mistake is assuming equal wear across all cells in a pack. For multi-cell 6V batteries, individual cell testing with a RC3563 battery tester can identify weak cells before they affect overall performance.

Advanced Storage and Recovery Techniques

For long-term storage (6+ months):

- Partial charge method: Store at 40% charge (≈6.2V) in 15°C environment

- Reconditioning: Every 6 months, perform full discharge/charge cycle

- Humidity control: Keep batteries in sealed containers with silica gel (RH < 40%)

For severely depleted batteries (below 4V), use a trickle charge at 0.05C for 24 hours before normal charging. This gradual approach can recover up to 80% of lost capacity in neglected batteries.

Safety Protocols and Industry Standards for 6V NiMH Batteries

Critical Safety Considerations for Handling and Usage

While NiMH 6V batteries are generally safer than lithium-ion, they still require proper handling to prevent hazards. The electrolyte solution contains potassium hydroxide, which can cause chemical burns if leaked. Always:

- Inspect for swelling before use – bulging indicates gas buildup and potential failure

- Use protective gloves when handling damaged batteries to avoid alkaline exposure

- Store in fireproof containers when charging in bulk (recommended: LiFePO4 charging bags)

Industry standards like IEC 61436 specify that NiMH batteries should never exceed 45°C during operation. For example, in emergency lighting systems, UL requires thermal cutoff devices that disconnect at 60°C to prevent thermal runaway.

Proper Disposal and Recycling Procedures

NiMH batteries contain recyclable nickel and rare earth metals, but improper disposal creates environmental hazards. Follow these steps:

- Discharge completely to below 2V per cell (use a resistive load for final discharge)

- Terminal protection – cover ends with electrical tape to prevent accidental shorting

- Find certified recyclers through Call2Recycle or similar programs (not standard e-waste streams)

Professional facilities use hydrometallurgical processes that recover 95% of nickel and 85% of rare earth metals. Some manufacturers like Panasonic offer take-back programs with shipping labels for used batteries.

Advanced Failure Analysis Techniques

When troubleshooting battery failures, professionals use these diagnostic methods:

| Failure Mode | Diagnostic Method | Corrective Action |

|---|---|---|

| Capacity Fade | Cyclic voltammetry | Electrolyte replacement or cell reconditioning |

| High Self-Discharge | 72-hour open circuit voltage test | Separator replacement or battery retirement |

| Voltage Depression | Deep discharge/refresh cycles | 3-5 full cycles at 0.1C rate |

For mission-critical applications, implement a predictive maintenance schedule using battery monitoring systems that track internal resistance trends over time, allowing replacement before catastrophic failure occurs.

Long-Term Performance Optimization and Future Trends

Advanced Cycle Life Extension Techniques

Maximizing the lifespan of NiMH 6V batteries requires understanding their electrochemical degradation mechanisms. The primary factors affecting longevity include:

| Degradation Factor | Impact on Capacity | Mitigation Strategy |

|---|---|---|

| Positive electrode corrosion | 2-3% loss per 100 cycles | Use oxygen recombination alloys in construction |

| Electrolyte dry-out | Accelerates after 300 cycles | Maintain 40-60% state of charge during storage |

| Memory effect | Up to 15% capacity loss | Monthly full discharge/charge cycles |

Industrial users report 40% longer lifespan when implementing adaptive charging algorithms that adjust current based on battery temperature and age.

Cost-Benefit Analysis: NiMH vs. Alternative Technologies

While lithium-ion dominates many applications, NiMH 6V batteries remain cost-effective for specific use cases:

- Safety-critical applications: 60% lower thermal runaway risk than Li-ion

- Extreme temperature environments: -20°C to 60°C operational range (vs. 0-45°C for Li-ion)

- High-cycle applications: Lower total cost of ownership beyond 500 cycles

A hospital using NiMH 6V batteries in portable medical devices reported 30% savings over 5 years compared to lithium alternatives, primarily due to reduced replacement frequency and simpler maintenance.

Emerging Technologies and Future Outlook

The NiMH battery industry is evolving with several promising developments:

- Graphene-enhanced electrodes: Lab tests show 50% faster charging with 20% capacity increase

- Smart battery systems: Integrated sensors for real-time health monitoring (voltage, temp, impedance)

- Sustainable manufacturing: New recycling processes recover 98% of rare earth materials

Industry analysts predict NiMH will maintain its niche in safety-focused applications through 2030, with the global market growing at 4.2% CAGR due to increased demand for reliable backup power systems.

For optimal future-proofing, consider hybrid systems that combine NiMH reliability with lithium energy density, using intelligent battery management systems to leverage each technology’s strengths.

System Integration and Performance Optimization Strategies

Designing Efficient NiMH 6V Battery Systems

Proper system integration is crucial for maximizing NiMH 6V battery performance in complex applications. The key design considerations include:

- Voltage regulation: Implement buck-boost converters to maintain stable 6V output as battery voltage declines

- Load matching: Calculate peak and average current demands to prevent excessive voltage sag

- Thermal management: Design with 5-10mm air gaps between cells and use thermally conductive materials

For example, in solar power systems, a well-designed charge controller should account for the NiMH voltage curve, adjusting absorption charge voltage between 7.1V (full) and 6.4V (maintenance).

Advanced Monitoring and Control Systems

Professional-grade implementations benefit from these monitoring approaches:

| Parameter | Monitoring Method | Optimal Range |

|---|---|---|

| State of Charge | Coulomb counting + voltage correlation | ±3% accuracy |

| Cell Balance | Individual cell voltage monitoring | <0.05V difference |

| Health Status | Internal resistance tracking | <150% of initial value |

Industrial users report 25% longer battery life when implementing predictive algorithms that adjust charging based on historical performance data.

Specialized Application Considerations

Different use cases require tailored approaches:

- Medical devices: Redundant battery systems with automatic failover and daily self-tests

- Marine applications: Saltwater-resistant battery housings and monthly terminal cleaning

- Remote monitoring: Low-power wireless transmitters with adaptive reporting intervals

For critical infrastructure applications, consider implementing a three-tier protection system:

1) Voltage window control (5.5V-7.5V)

2) Temperature monitoring (shutdown at 50°C)

3) Physical vibration dampening for mobile installations

These integration strategies can improve system reliability by up to 40% while maintaining optimal battery performance throughout the entire lifecycle.

Comprehensive Quality Assurance and Risk Management

Advanced Testing Protocols for NiMH 6V Batteries

Implementing rigorous quality control measures ensures optimal performance throughout the battery lifecycle. Professional testing should include:

| Test Type | Methodology | Acceptance Criteria |

|---|---|---|

| Cycle Life Validation | 500 full charge/discharge cycles at 1C rate | >80% initial capacity retention |

| Environmental Stress | 48hrs at -20°C and +60°C with performance testing | <15% capacity deviation |

| Safety Compliance | UL2054 crush test + short circuit evaluation | No fire/explosion |

Industrial users should conduct these tests quarterly on 5% of battery inventory, with more frequent sampling for mission-critical applications.

Risk Assessment and Mitigation Framework

A comprehensive risk management approach addresses these key areas:

- Performance Risks:

- Implement dual-sensor voltage monitoring with automatic load shedding

- Maintain 30% spare capacity in parallel battery configurations

- Safety Risks:

- Install thermal fuses on each cell (activation at 85°C)

- Use vented battery enclosures with hydrogen detection

- Operational Risks:

- Develop battery rotation schedules to equalize aging

- Maintain “hot spare” inventory at 20% of deployed units

Advanced Predictive Maintenance Systems

Modern battery management solutions incorporate:

- Machine learning algorithms that analyze charge/discharge patterns to predict failures 50+ cycles in advance

- Cloud-based monitoring with automated alerts when parameters exceed normal operating envelopes

- Digital twin technology creating virtual battery models for performance simulation

For example, a telecom backup power system using these techniques reduced unexpected battery failures by 72% while extending average service life by 18 months.

Implementing this comprehensive QA framework typically yields a 300% ROI through reduced downtime, longer asset life, and lower maintenance costs over a 5-year period.

Conclusion

Understanding NiMH 6V battery voltage behavior is essential for optimizing performance across various applications. Throughout this guide, we’ve explored the complete voltage discharge curve, proper charging techniques, advanced maintenance strategies, and comprehensive safety protocols.

From interpreting voltage readings to implementing predictive maintenance systems, these insights empower you to maximize battery lifespan and reliability. Whether you’re powering medical devices, emergency systems, or industrial equipment, proper voltage management can significantly impact operational efficiency and cost-effectiveness.

Put this knowledge into practice by regularly monitoring your batteries, following recommended charging procedures, and staying alert to voltage fluctuations. By mastering these principles, you’ll unlock the full potential of your NiMH 6V batteries while ensuring safe, long-lasting performance.

Frequently Asked Questions About NiMH 6V Batteries

What exactly does “6V” mean for a NiMH battery?

The “6V” designation refers to the nominal voltage, which is the average operating voltage during discharge. In reality, a fully charged NiMH 6V battery starts around 7.2V (open circuit) and gradually drops to about 5V when depleted.

This nominal rating helps standardize comparisons between battery types, though actual voltage varies based on charge state, load, and temperature. For example, under moderate load, you’ll typically see 6.4-6.8V when fully charged.

How can I accurately measure my NiMH 6V battery’s remaining capacity?

The most reliable method combines voltage measurement with coulomb counting. First, measure open-circuit voltage after 1 hour rest: 7.0V+ indicates full charge, 6.2V ≈ 50%, and below 5.5V needs recharge.

For precision, use a smart charger that tracks mAh in/out during cycles. Professional applications may employ impedance spectroscopy to assess capacity loss from aging. Remember voltage alone isn’t definitive – a 6.0V reading could mean either partial charge or aged cells.

Why does my new NiMH 6V battery seem weak initially?

This common phenomenon occurs due to formation cycling requirements. New NiMH batteries typically need 3-5 full charge/discharge cycles to reach peak capacity as the electrodes activate.

During this break-in period, you might observe 10-15% lower runtime. Use a quality charger like the La Crosse BC700 and perform complete cycles at 0.5C rate (e.g., 1A for 2000mAh) to properly condition the battery.

What’s the safest way to charge multiple 6V NiMH batteries simultaneously?

For series charging, use a balanced charger like the SkyRC MC3000 that monitors individual cells. Parallel charging requires identical batteries (same model/age) and a current-sharing charger. Key safety measures include:

• Temperature monitoring on each battery

• Maximum 1C charge rate (lower for older batteries)

• Fireproof charging surface

• Voltage cutoff at 7.5V per battery

Never mix different capacity or chemistry batteries in charging systems.

How does temperature affect NiMH 6V battery performance?

Temperature impacts are significant:

• Below 0°C: Capacity drops 20-40%, voltage sags

• 20-30°C: Ideal operating range

• Above 45°C: Accelerated aging, risk of venting

In cold environments, keep batteries insulated and consider lower discharge rates. High temperatures require active cooling – for every 10°C above 30°C, lifespan halves. Industrial applications often use thermal-regulated battery compartments.

Can I use a NiMH 6V battery as a direct replacement for lead-acid?

While both are 6V nominally, important differences exist:

• NiMH has higher voltage when full (7.2V vs 6.4V)

• Different charge algorithms required

• Lower capacity per size but better cycle life

For replacement, verify:

• Device’s voltage tolerance (many accept 5-8V)

• Charger compatibility

• Physical size constraints

Add a voltage regulator if powering sensitive electronics.

What maintenance extends NiMH 6V battery lifespan?

Follow this professional maintenance schedule:

• Monthly: Full discharge/charge cycle

• Quarterly: Clean terminals with isopropyl alcohol

• Biannually: Capacity verification test

• Annually: Internal resistance check

Storage tips:

• Keep at 40% charge (≈6.2V)

• Store below 25°C

• Recharge every 6 months

These practices can double typical 3-5 year lifespan.

How do I safely dispose of old NiMH 6V batteries?

Proper disposal involves:

1. Full discharge (connect to 5Ω resistor for 24hrs)

2. Terminal taping (prevent short circuits)

3. Find certified recyclers through Call2Recycle.org

Never dispose in regular trash – NiMH contains recyclable nickel and rare earth metals. Some manufacturers offer mail-back programs. For damaged batteries, place in non-conductive container and label clearly before recycling.