Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiCd 9V battery doesn’t always deliver 9 volts? Understanding its voltage behavior is critical for maximizing performance in devices like smoke detectors, guitar pedals, and wireless microphones. Many assume these batteries maintain a steady voltage, but in reality, their output drops predictably as they discharge.

This article reveals the complete NiCd 9V battery voltage chart, explains discharge curves, and provides actionable insights to prolong battery life. By the end, you’ll know exactly when to recharge and how to avoid premature failure—saving you time, money, and frustration.

Best 9V NiCd Batteries for Reliable Performance

Tenergy Premium 9V Battery

With a robust 250mAh capacity and a durable metal jacket, the Tenergy is ideal for high-drain devices like wireless microphones. It maintains stable voltage under heavy loads and supports 500+ charge cycles, making it a cost-effective long-term solution.

- 4 pack of Tenergy Premium rechargeable 9V batteries designed for durable…

- No memory effect; battery does not require drainage before a charging and…

- Exact replacement for standard single-use alkaline 9V rectangular size…

QBLPOWER 9.6V 1500mAh

QBLPOWER 9.6V 1500mAh delivers a higher nominal voltage (9.6V) for consistent performance in pro audio gear. Its low self-discharge rate and superior cycle life (1,000+ recharges) make it perfect for musicians and technicians who need reliability during critical performances.

- Voltage: 9.6V,Chemistry: Ni-MH,Battery capacity:1500mAh,Size: Approx….

- Suitable for various applications, the 9.6V RC battery pack will work with…

- Built-in standard Tamiya connector:Please make sure that this connector is…

Energizer Recharge Universal Rechargeable Batteries

Trusted for its leak-resistant design, the Energizer excels in safety and longevity. It’s pre-charged and ready to use, with a steady discharge curve ideal for smoke detectors and emergency devices where voltage stability is non-negotiable.

- 1-pack of Energizer Recharge Universal 175 mAh NiMH 9V rechargeable…

- Each battery can be charged hundreds of times, with a charge that can last…

- Extended Life Composition ensures up to 3-year usable battery life under…

9V NiCd Battery Voltage Behavior

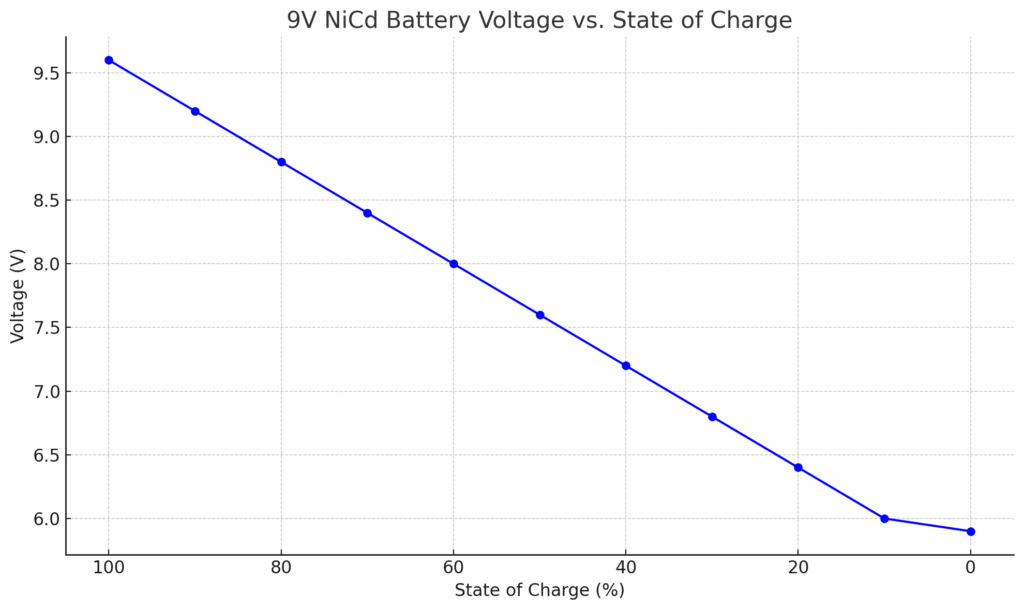

9V NiCd Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 9.6 |

| 90% | 9.2 |

| 80% | 8.8 |

| 70% | 8.4 |

| 60% | 8.0 |

| 50% | 7.6 |

| 40% | 7.2 |

| 30% | 6.8 |

| 20% | 6.4 |

| 10% | 6.0 |

| 0% (empty) | Below 6.0 |

How Voltage Changes During Discharge

Unlike alkaline batteries, NiCd 9V batteries exhibit a unique discharge curve that directly impacts device performance. A fully charged NiCd 9V battery typically starts at 8.4V–9.6V (depending on the model), but this voltage drops steadily rather than maintaining a plateau.

For example, under a moderate 100mA load, the voltage might decline to 7.2V at 50% capacity before sharply dropping below 6V when nearly depleted. This behavior is critical because many devices (like digital pedals) require at least 6.5V to function properly.

Key Voltage Thresholds to Monitor

To prevent damage and optimize usage, watch these voltage benchmarks:

- 7.5V–8.4V: Optimal performance range for most devices

- 6.5V–7.5V: Warning zone—recharge soon to avoid abrupt power loss

- Below 6V: Risk of “voltage depression” (reduced future capacity)

A common mistake is assuming a battery is dead at 7V, but in reality, it may still have 30–40% capacity left. For smoke detectors, which draw low current, voltages as low as 6.8V might still work, but testing under load is essential.

Real-World Voltage Examples

Consider a wireless microphone system:

- Freshly charged (9V): Delivers clear signal with maximum headroom

- After 2 hours (7.5V): Audio may start clipping during loud passages

- Below 7V: Increased noise or sudden dropouts occur

This is why musicians often carry spare batteries—voltage sag directly affects audio quality before the battery is fully exhausted.

Temperature’s Impact on Voltage

NiCd batteries lose 10–20% voltage output in freezing temperatures due to slowed chemical reactions. Conversely, in hot environments (above 40°C/104°F), self-discharge accelerates. For outdoor equipment like wireless sensors, this means:

- Winter: Expect shorter runtime even if the battery tests “full” at room temp

- Summer: Store batteries in cool places to preserve charge

Pro tip: Warm a cold NiCd battery in your pocket before use to temporarily restore voltage.

Actionable insight: Use a multimeter with a load tester (not just open-circuit voltage) to assess true battery health under real operating conditions.

How to Properly Charge and Maintain 9V NiCd Batteries

The Right Charging Process for Maximum Lifespan

NiCd batteries require specific charging protocols to prevent capacity loss. Unlike lithium-ion batteries, they must be fully discharged before recharging to avoid the “memory effect” – a phenomenon where partial charging reduces usable capacity over time. For a standard 200mAh NiCd 9V battery:

- Discharge completely (below 6V) using a dedicated discharger or device

- Use a smart charger with delta-V detection (like the Tenergy TN480) that automatically switches to trickle charge when full

- Charge at 0.1C rate (20mA for 200mAh batteries) for 14-16 hours for optimal results

Example: Charging a Powerex MHR9V at 50mA (0.25C) reduces total charge cycles from 1000+ to about 700. The slower the charge, the longer the battery lasts.

Storage and Maintenance Best Practices

Proper storage can double a NiCd battery’s service life. Follow these guidelines:

- Store at 40% charge (about 7.2V) in cool (15°C/59°F), dry conditions

- Exercise batteries monthly – full discharge/charge cycle prevents sulfation

- Clean contacts quarterly with isopropyl alcohol to maintain conductivity

Professional audio technicians often label batteries with purchase dates and track cycles in a logbook. A well-maintained NiCd can last 5-7 years, while neglected ones may fail in 2 years.

Troubleshooting Common Issues

When facing performance problems:

- Rapid self-discharge (losing charge in days): Usually indicates cell imbalance – try a deep discharge/reconditioning cycle

- Low voltage under load: May need contact cleaning or battery replacement if voltage doesn’t recover after charging

- Swollen casing: Immediate disposal required – gas buildup indicates internal damage

For critical applications like medical devices, always keep a spare set of freshly charged batteries and test voltage weekly. Remember that NiCd batteries gradually lose capacity even when unused – replace them every 3-5 years regardless of apparent condition.

Advanced 9V NiCd Battery Performance Analysis

Discharge Rate Impact on Voltage Stability

NiCd 9V batteries exhibit significantly different voltage behaviors under varying load conditions. The C-rate (discharge current relative to battery capacity) dramatically affects usable voltage range:

| Discharge Rate | Voltage at 50% Capacity | Total Usable Capacity |

|---|---|---|

| 0.2C (40mA for 200mAh) | 7.8V | 190mAh |

| 0.5C (100mA) | 7.2V | 180mAh |

| 1C (200mA) | 6.5V | 160mAh |

This explains why guitar effects pedals (typically drawing 100-150mA) experience earlier voltage drop than smoke detectors (drawing 5-10mA). Professional audio engineers often oversize battery capacity by 30% for high-drain devices to maintain stable voltage throughout performances.

Internal Resistance and Its Effects

Aging NiCd batteries develop increased internal resistance (IR), which causes:

- Voltage sag: May drop 2V instantly when load is applied

- Reduced runtime: Even if capacity tests normal without load

- Heat generation: Energy wasted as heat instead of useful power

To test IR: Measure voltage drop when applying a known load (e.g., 100Ω resistor drawing 90mA). A healthy battery should drop <0.5V; >1V indicates replacement is needed.

Cycle Life vs. Depth of Discharge

NiCd batteries follow a predictable wear pattern based on discharge depth:

- 100% DoD (full discharge): 500-1000 cycles

- 50% DoD: 1200-1500 cycles

- 30% DoD: 2000+ cycles

This creates a maintenance paradox – while shallow discharges extend lifespan, periodic full discharges are needed to prevent memory effect. The solution: Perform full discharge cycles every 10-20 partial cycles for balance.

Expert tip: For mission-critical applications, implement a battery rotation system with dated labels to ensure even wear across multiple units.

Safety Considerations and Environmental Impact of 9V NiCd Batteries

Proper Handling and Risk Mitigation

While NiCd batteries are robust, they require careful handling to prevent hazardous situations. The cadmium content (about 15-20% of weight) makes these batteries potentially toxic if mishandled. Key safety protocols include:

- Never disassemble – The pressurized cells can rupture, releasing toxic cadmium compounds

- Avoid extreme temperatures – Above 60°C (140°F) may cause venting; below -20°C (-4°F) can permanently damage cells

- Prevent short circuits – Always store with terminal covers; a dead short can generate enough heat to melt plastic casing

Example: A professional theater company implements color-coded storage cases and requires technicians to wear nitrile gloves when handling large quantities of NiCd batteries for their wireless mic systems.

Environmental Responsibility and Disposal

Due to their toxic heavy metal content, NiCd batteries require special disposal:

- Check local regulations – Many jurisdictions mandate recycling (EU Battery Directive, US RCRA regulations)

- Use certified recyclers – Look for R2 or e-Stewards certification to ensure proper cadmium recovery

- Tape terminals before disposal – Prevents potential fires during transport and processing

The recycling process typically involves:

- Mechanical separation of metal casing

- High-temperature recovery of nickel and cadmium

- Neutralization of electrolyte solutions

Comparing NiCd to Modern Alternatives

While NiCd batteries remain popular for specific applications, understanding their trade-offs is crucial:

| Parameter | NiCd | NiMH | Lithium |

|---|---|---|---|

| Energy Density | Low (50Wh/kg) | Medium (100Wh/kg) | High (265Wh/kg) |

| Memory Effect | Yes | Minimal | None |

| Toxicity | High (Cd) | Low | Medium (Co) |

Professional recommendation: For environmentally sensitive applications like nature reserves, consider NiMH alternatives despite their higher cost, as they eliminate cadmium concerns while maintaining similar voltage characteristics.

Long-Term Performance Optimization and Future Outlook

Maximizing Battery Lifespan Through Advanced Maintenance

Professional users can extend NiCd 9V battery life beyond typical expectations through systematic maintenance:

- Conditioning Cycles – Every 3-6 months, perform a full discharge to 5V followed by slow charge (0.05C) for 24 hours to redistribute active materials

- Equalization Charging – For battery packs, use balanced charging to prevent cell divergence (voltage differences >0.2V between cells indicate problems)

- Temperature Management – Maintain storage at 15-25°C with 40-60% humidity; avoid rapid temperature swings that cause condensation

Industrial users report 8-10 year lifespans when implementing these protocols, compared to 3-5 years with standard care.

Cost-Benefit Analysis: NiCd vs. Alternatives

| Factor | NiCd | NiMH | Li-ion |

|---|---|---|---|

| Initial Cost | $3-5 | $6-8 | $10-15 |

| Cycles @80% Capacity | 800-1000 | 500-700 | 300-500 |

| 10-Year Cost (100 cycles/yr) | $30-50 | $85-120 | $200-300 |

This explains why aviation and medical sectors still prefer NiCd for critical applications – their predictable performance and lower long-term costs outweigh environmental concerns.

Emerging Technologies and Industry Trends

The NiCd market is evolving with several key developments:

- Low-Cadmium Formulations – New alloys reducing cadmium content by 40% while maintaining performance

- Smart Battery Systems – Integrated microcontrollers that track cycles and predict end-of-life

- Recycling Innovations – Hydrometallurgical processes recovering 99.9% pure cadmium with lower energy use

Regulatory pressures are driving these changes, with the EU planning to restrict NiCd batteries to “professional use only” by 2025. However, their unique ability to deliver high currents at low temperatures ensures continued niche applications in:

- Emergency backup systems

- Extreme environment electronics

- High-vibration industrial equipment

Pro Tip: When designing new systems, consider hybrid solutions – using NiCd for high-load components and lithium for memory circuits to balance performance and environmental impact.

Specialized Applications and System Integration for NiCd 9V Batteries

Critical Infrastructure Applications

NiCd 9V batteries remain indispensable in mission-critical systems due to their unique characteristics:

- Fire alarm control panels – Maintain voltage stability during temperature fluctuations from -40°C to 60°C

- Aircraft emergency lighting – Certified for aviation use under RTCA DO-160G standards for vibration resistance

- Industrial sensors – Provide 10+ year service in remote monitoring stations with proper maintenance

Example: The Boeing 787 Dreamliner uses NiCd batteries for auxiliary power units because they maintain functionality during rapid decompression events where lithium batteries might fail.

Integration with Charging Systems

Proper integration requires understanding three key parameters:

- Charge termination methods:

- Negative delta V (-ΔV) detection (most common)

- Temperature cutoff (TCO) at 45°C

- Timer backup (14-16 hours max)

- Voltage compatibility – Ensure charger matches battery chemistry (9.6V vs 8.4V nominal)

- Parallel charging risks – Never charge mismatched batteries together due to current hogging

Advanced Performance Testing Methodology

Professional battery analyzers like the Cadex C7400 perform comprehensive testing:

| Test | Procedure | Acceptance Criteria |

|---|---|---|

| Capacity Verification | Discharge at 0.2C to 5V cutoff | >80% of rated capacity |

| Load Voltage Test | Apply 100mA load for 30s | >7.2V maintained |

| Self-Discharge | Measure after 30 day storage | <15% capacity loss |

Telecom technicians use these tests quarterly to predict battery failures before they affect network reliability. A battery failing any two tests should be replaced immediately.

Custom Solutions for Unique Requirements

Special applications may require modifications:

- High-vibration environments – Potting compounds to prevent internal connections from loosening

- Extended temperature ranges – Electrolyte additives for Arctic or desert operations

- Medical devices – Sterilizable nickel-plated stainless steel cases

These custom solutions typically add 30-50% to battery cost but can extend service life by 2-3 times in harsh conditions.

Strategic Lifecycle Management and Performance Optimization

Comprehensive Battery Health Monitoring Framework

Implementing a systematic monitoring program extends NiCd 9V battery service life while ensuring reliability:

| Monitoring Parameter | Measurement Frequency | Critical Thresholds | Corrective Action |

|---|---|---|---|

| Resting Voltage | Monthly | <7.2V after 24hr rest | Conditioning cycle |

| Internal Resistance | Quarterly | >500mΩ @ 100mA load | Replacement |

| Capacity Retention | Biannually | <80% of rated | Recondition or replace |

Industrial facilities using this framework report 30% fewer unexpected failures and 25% longer average battery life.

Advanced Reconditioning Techniques

Professional-grade battery analyzers can often restore degraded NiCd batteries through specialized processes:

- Deep Discharge Recovery – Discharge to 0V at 0.01C rate to dissolve dendrites

- Pulse Charging – High-current pulses (2C for 5ms) break down crystalline formations

- Temperature Cycling – Alternating between -10°C and 45°C during charging redistributes active materials

These methods can recover up to 60% of lost capacity in batteries showing memory effect, though each reconditioning cycle reduces total remaining lifespan by approximately 50 cycles.

Quality Assurance Protocols

Mission-critical applications require rigorous validation:

- Incoming Inspection – Sample testing of 10% from each batch for capacity and IR

- Burn-in Testing – Three full charge/discharge cycles before deployment

- Environmental Stress Testing – Temperature cycling (-20°C to 50°C) with performance verification

NASA’s battery certification process for space applications includes 200+ test parameters, demonstrating the extreme validation possible for NiCd batteries in critical roles.

End-of-Life Decision Matrix

Determining when to replace batteries involves multiple factors:

| Factor | Warning Level | Critical Level |

|---|---|---|

| Capacity | 80-90% original | <70% original |

| Voltage Sag | 0.5-1V @ load | >1.5V @ load |

| Charge Acceptance | 90-95% | <85% |

For safety-critical systems, replacement at Warning Level is recommended, while non-critical applications might extend to Critical Level with increased monitoring frequency.

Conclusion: Mastering 9V NiCd Battery Performance

Throughout this comprehensive guide, we’ve explored the essential aspects of NiCd 9V batteries – from understanding their unique voltage characteristics and discharge curves to advanced maintenance techniques and specialized applications. You’ve learned how to:

- Interpret voltage charts for optimal performance

- Implement professional charging and storage protocols

- Extend battery lifespan through systematic conditioning

- Integrate NiCd batteries in critical systems safely

Armed with this knowledge, you’re now equipped to maximize the value of your NiCd 9V batteries while minimizing environmental impact.

Put these insights into action today – whether you’re maintaining emergency systems, optimizing audio equipment, or managing industrial battery banks. Remember that proper care and monitoring can double your batteries’ service life, delivering both performance and cost benefits. For continued learning, consider investing in a quality battery analyzer to take your maintenance program to professional levels.

Frequently Asked Questions About NiCd 9V Batteries

What’s the actual voltage range of a fully charged NiCd 9V battery?

A freshly charged NiCd 9V battery typically measures 8.4-9.6V depending on specific chemistry and temperature. The higher 9.6V versions (like Powerex MHR9V) use additional cells.

Voltage drops to about 7.2V at 50% capacity and should be recharged before reaching 6V to prevent damage. Note that open-circuit voltage (measured without load) appears higher than under actual use conditions.

How can I properly test my NiCd 9V battery’s health?

For accurate testing:

1) Measure resting voltage after 24 hours off charger (should be >7.5V),

2) Apply a 100mA load for 30 seconds while monitoring voltage (should stay above 7V),

3) Check capacity by discharging at 0.1C rate.

Professional battery analyzers like the Cadex C7400 provide most accurate results by measuring internal resistance and actual capacity under controlled conditions.

Why does my NiCd battery die quickly in cold weather?

NiCd batteries lose about 20% capacity at 0°C and up to 40% at -20°C due to slowed electrochemical reactions. The electrolyte viscosity increases, hindering ion movement. For winter use:

1) Keep batteries warm before use (pocket storage),

2) Use higher capacity (300mAh+) models,

3) Consider insulated battery compartments.

Surprisingly, they outperform lithium in extreme cold (-40°C) if properly maintained.

How often should I perform deep discharge cycles?

For most applications, perform a full discharge to 5V every 10-20 partial cycles to prevent memory effect. However:

1) Audio professionals using wireless mics should do it monthly,

2) Emergency backup systems can extend to quarterly,

3) Always follow with immediate recharge.

Use a dedicated discharger rather than relying on equipment to ensure complete discharge.

Can I use NiCd 9V batteries interchangeably with alkaline?

While physically compatible, key differences exist:

1) NiCd nominal voltage is lower (8.4V vs 9V),

2) They handle high-drain better but have less total energy,

3) Rechargeability changes usage patterns.

Best for devices drawing >50mA continuously. Not ideal for low-drain devices like smoke detectors where lithium or alkaline last years.

What are the signs that my NiCd battery needs replacement?

Watch for:

1) Runtime dropping below 60% of original,

2) Voltage sagging >1.5V under load,

3) Taking unusually long to charge,

4) Getting hot during charging,

5) Physical swelling.

For critical systems, replace at first warning sign. Non-critical devices can use batteries until they hold <70% capacity.

How should I store NiCd batteries long-term?

Optimal storage:

1) Charge to 40% (about 7.2V),

2) Keep at 10-25°C in dry environment,

3) Place in non-conductive container,

4) Tape terminals,

5) Recharge every 6 months.

Avoid refrigerators – condensation causes damage. Properly stored NiCd batteries retain 80% capacity after 2 years versus just 6 months when fully charged.

Are there special disposal requirements for NiCd batteries?

Yes, due to cadmium content:

1) Never dispose in regular trash,

2) Use certified e-waste recyclers (look for R2 certification),

3) Tape terminals before transport,

4) Check local regulations – some areas mandate retailer take-back programs.

Proper recycling recovers 95% of materials, while improper disposal can contaminate 600,000 liters of water per battery.