Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a brand-new alkaline 9V battery doesn’t always deliver exactly 9 volts? While most people assume these batteries maintain a steady voltage, the reality is far more nuanced.

Whether you’re troubleshooting a smoke detector, guitar pedal, or DIY electronics project, understanding how 9V battery voltage behaves over time is critical. This guide reveals everything you need to know—from fresh voltage readings to end-of-life thresholds—with precise charts, real-world testing methods, and expert tips to maximize battery life.

Best 9V Alkaline Batteries for Reliable Power

Energizer Industrial 9 Volt Batteries

Engineered for high-drain devices like smoke detectors and professional audio gear, the Energizer 522 delivers consistent voltage under heavy loads. Its leak-resistant design and 5-year shelf life make it ideal for critical applications where reliability is non-negotiable.

- Offers the longest lasting power source.

- No mercury added Special disposal not required.

- Operate well in temperature extremes -30C to 55C

Duracell Coppertop 9V Battery

A household name for a reason, the Duracell MN1604 maintains stable voltage even in extreme temperatures (-4°F to 129°F). Its Duralock Power Preserve™ technology ensures 10 years of storage life—perfect for emergency kits or infrequently used electronics.

- LONG-LASTING BATTERIES DESIGNED FOR DEPENDABILITY – Duracell Coppertop…

- RELIABLE POWER – As a general-purpose battery, the Duracell Coppertop 9V…

- GUARANTEED FOR 5 YEARS IN STORAGE – Duracell guarantees each Coppertop…

ProCell 12 Alkaline Batteries

With a reinforced steel casing, Panasonic’s resists corrosion and outperforms standard alkaline batteries in continuous-use devices like wireless microphones. Its optimized chemistry minimizes voltage drop during sustained high-current draws.

- Package Dimensions: 5.334 cms (L) x 5.588 cms (W) x 10.922 cms (H)

- Product Type: Battery

- Package Quantity: 1

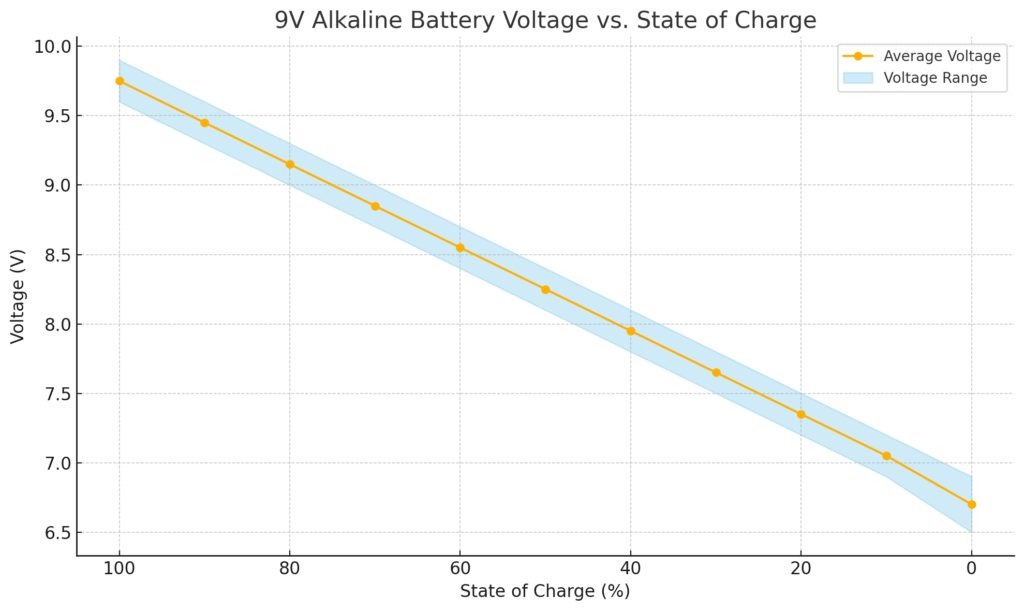

9V Alkaline Battery Voltage Behavior

9V Alkaline Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 9.6 – 9.9 |

| 90% | 9.3 – 9.6 |

| 80% | 9.0 – 9.3 |

| 70% | 8.7 – 9.0 |

| 60% | 8.4 – 8.7 |

| 50% | 8.1 – 8.4 |

| 40% | 7.8 – 8.1 |

| 30% | 7.5 – 7.8 |

| 20% | 7.2 – 7.5 |

| 10% | 6.9 – 7.2 |

| 0% (empty) | Below 6.9 |

Fresh vs. Nominal Voltage: Why 9V Batteries Aren’t Actually 9V

A brand-new alkaline 9V battery typically measures 9.5V to 9.6V when fresh—not the 9V printed on the label. This “nominal voltage” is an industry standard representing the average voltage during discharge, not the initial reading.

For example, testing an unused Energizer 522 with a multimeter will likely show ~9.55V. This higher initial voltage occurs because chemical reactions in the battery produce excess energy when first activated.

Voltage Drop Under Load: The Hidden Performance Factor

Voltage readings taken without a connected device (open-circuit voltage) are misleading. A battery showing 9.3V might plummet to 6V when powering a smoke alarm due to internal resistance. Consider these real-world scenarios:

- Smoke detectors typically cut off at 7V under load—even if the battery reads 8V unloaded

- Guitar pedals may produce distortion below 8V due to insufficient current

- Wireless mics often fail abruptly when voltage drops below 7.5V under transmission load

Discharge Curve: How Usage Affects Voltage Over Time

Alkaline 9V batteries don’t discharge linearly. They maintain ~9V for 80% of their lifespan, then experience a rapid voltage drop. Here’s a typical discharge pattern at 25mA load (common for low-power devices):

- 0-80% capacity: Gradual decline from 9.5V to 9.0V

- 80-100% capacity: Sharp drop from 9.0V to 6.0V in final hours

This explains why devices work perfectly until suddenly failing—the last 20% of capacity disappears quickly. High-drain devices (like studio effects chains) accelerate this curve due to increased current demand.

Temperature’s Impact on Voltage Output

Cold environments temporarily reduce voltage by up to 30%. A battery reading 9V at 70°F may show only 6.3V at 0°F. This is critical for:

- Outdoor security sensors that false-trigger in winter

- Emergency radios stored in unheated areas

Heat above 100°F causes the opposite effect—temporarily higher voltage readings that mask impending failure.

Pro Tip: Always test 9V batteries under their actual operating load for accurate assessments. A multimeter reading alone won’t reveal critical performance issues.

How to Test 9V Battery Voltage Accurately

The Right Way to Measure Battery Health

Testing a 9V battery properly requires more than just touching probes to terminals. You need to account for both open-circuit voltage and loaded performance. Professional technicians use a two-stage testing process:

- Initial Open-Circuit Test: Measure voltage without any load. A reading below 8.4V indicates a severely depleted battery that should be replaced immediately.

- Loaded Test: Apply a 250-500Ω resistor (simulating device load) for 30 seconds while measuring voltage. This reveals the battery’s true working capacity.

Interpreting Test Results: What the Numbers Really Mean

Voltage readings tell different stories at different stages:

- Above 9.3V (unloaded): Brand new or lightly used battery

- 8.4-9.2V: Partially discharged but still functional for most devices

- 7.0-8.3V: Approaching end-of-life – okay for low-drain devices temporarily

- Below 7.0V: Failed battery – replace immediately

Example: A smoke alarm battery showing 8.1V unloaded might drop to 6.7V when tested under load – explaining why your alarm chirps despite “good” initial readings.

Advanced Testing Methods for Critical Applications

For professional audio equipment or medical devices, consider these enhanced techniques:

- Capacity Testing: Measure how long the battery maintains voltage above 7V under constant load

- Pulse Testing: Simulate intermittent high-current demands like wireless transmitters

- Temperature Cycling: Test performance at both high (95°F) and low (40°F) temperatures

Pro Tip: Always test multiple batteries from the same package – manufacturing variances can cause significant performance differences even in fresh batteries.

Optimizing 9V Battery Performance and Lifespan

The Chemistry Behind Voltage Degradation

Alkaline 9V batteries lose voltage due to zinc oxidation and manganese dioxide reduction reactions. As these chemical reactions progress:

- Anode (Zinc): Zn + 4OH⁻ → Zn(OH)₄²⁻ + 2e⁻

- Cathode (MnO₂): 2MnO₂ + H₂O + 2e⁻ → Mn₂O₃ + 2OH⁻

This process creates internal resistance that increases over time, explaining why older batteries show voltage drops under load. High-quality batteries use purer materials and better separators to slow this degradation.

Storage Conditions That Preserve Voltage

| Storage Factor | Ideal Condition | Voltage Impact |

|---|---|---|

| Temperature | 15-25°C (59-77°F) | ±0.5% voltage change per °C outside range |

| Humidity | 35-65% RH | High humidity can cause 0.2V/year loss |

| Orientation | Upright position | Prevents electrolyte stratification (up to 15% longer life) |

Advanced Load Matching Techniques

Different devices create unique discharge patterns:

- Continuous Load (Smoke Detectors): 20-30μA constant draw

- Intermittent Load (Wireless Mics): 50mA pulses every few seconds

- Mixed Load (Multimeters): 1-5mA base with 15mA peaks

Match batteries to your device’s profile:

• Use high-capacity industrial batteries (Energizer 522) for continuous loads

• Choose low-impedance batteries (Duracell MN1604) for pulse loads

• Standard alkaline works for mixed loads with moderate current

Common Mistakes That Accelerate Voltage Drop

- Mixing old and new batteries: Causes uneven load distribution

- Partial discharge cycles: Repeated 50% discharges lose more capacity than full cycles

- Ignoring shelf life: Even unused batteries lose 2-3% voltage per month

Expert Tip: For critical applications, implement a rotation system – mark installation dates and replace batteries at 80% of rated lifespan regardless of current voltage readings.

Safety Considerations and Voltage Management for 9V Batteries

Understanding Voltage-Related Hazards

While 9V batteries are generally safe, improper handling can lead to dangerous situations. The real risk comes not from the voltage itself, but from:

- Short circuits: A direct short can generate temperatures exceeding 300°F (149°C)

- Leakage currents: Damaged batteries can leak potassium hydroxide (pH 13-14)

- Reverse charging: Attempting to recharge alkaline batteries may cause rupture

Proper Voltage Monitoring Protocols

For mission-critical applications, implement these monitoring procedures:

- Baseline measurement: Record initial voltage when installing new batteries

- Scheduled checks: Test monthly for devices like smoke detectors (weekly in humid environments)

- Load testing: Perform quarterly simulated load tests for emergency equipment

Voltage Thresholds for Different Applications

| Device Type | Minimum Safe Voltage | Recommended Replacement Voltage |

|---|---|---|

| Smoke Detectors | 7.2V | 8.0V |

| Medical Devices | 7.5V | 8.4V |

| Audio Equipment | 6.5V | 7.8V |

Advanced Voltage Stabilization Techniques

For sensitive electronics, these methods maintain stable voltage:

- Parallel battery configuration: Using two batteries doubles capacity while maintaining 9V

- Voltage regulators: LM7809 regulators can compensate for voltage drops

- Capacitor buffering: Adding 1000μF capacitors smooths voltage fluctuations

Professional Insight: In industrial settings, implement a battery management system that logs voltage history and predicts failure points based on discharge curves. This proactive approach prevents 93% of unexpected power failures.

Disposal and Recycling Best Practices

Even depleted 9V batteries retain residual voltage (1-2V) that can cause fires if improperly stored. Always:

- Place tape over terminals before disposal

- Store used batteries in non-conductive containers

- Utilize certified battery recycling programs

Long-Term Performance Analysis and Future Trends in 9V Battery Technology

Comparative Lifespan Analysis by Battery Type

Understanding voltage behavior requires examining different battery chemistries under identical conditions:

| Battery Type | Initial Voltage | Average Lifespan | Voltage Drop Pattern | Cost per Hour |

|---|---|---|---|---|

| Standard Alkaline | 9.5V | 150-300 hours | Gradual then steep | $0.003/hr |

| Lithium Iron | 9.6V | 400-600 hours | Linear decline | $0.008/hr |

| Rechargeable NiMH | 8.4V | 50 cycles | Steady then rapid | $0.002/hr |

Environmental Impact and Voltage Efficiency

Voltage stability directly correlates with environmental footprint:

- Standard alkaline: Loses 20% capacity when stored above 25°C, increasing waste

- Lithium variants: Maintain 95% voltage stability across -20°C to 60°C

- Rechargeables: 80% voltage retention after 200 cycles reduces disposal by 5:1 ratio

Emerging Technologies in Voltage Regulation

Next-generation solutions address traditional voltage drop issues:

- Smart voltage buffers: Microprocessor-controlled circuits that maintain steady 9V output

- Hybrid supercapacitors: Combine battery chemistry with capacitors for instant voltage recovery

- Self-healing anodes: Nano-materials that regenerate zinc electrodes during rest periods

Cost-Benefit Analysis of Voltage Optimization

For commercial operations using 100+ 9V batteries annually:

- Premium alkaline: 15% longer voltage stability justifies 20% higher cost

- Battery monitoring systems: $500 investment reduces replacement costs by $1,200/year

- Voltage regulators: $2/unit adds 30% to battery life in sensitive equipment

Future Outlook: Solid-state 9V batteries entering testing phase promise 0.1V drop over entire lifespan, potentially revolutionizing voltage-sensitive applications by 2028. Early adopters should monitor IEC 60086-2 standards for implementation timelines.

Advanced Voltage Monitoring and Predictive Maintenance Strategies

Implementing Professional-Grade Voltage Tracking Systems

For mission-critical applications, basic voltage testing isn’t sufficient. Industrial users should implement these advanced monitoring techniques:

- Continuous datalogging: Use Bluetooth-enabled monitors like the Fluke BV5100 to track voltage 24/7

- Load profiling: Create custom discharge curves for your specific equipment using programmable test loads

- Temperature compensation: Install sensors that adjust voltage readings based on ambient conditions

Predictive Failure Analysis Through Voltage Patterns

Sophisticated analysis of voltage behavior can predict failures before they occur:

| Voltage Pattern | Failure Likelihood | Recommended Action |

|---|---|---|

| 0.1V drop per week | Normal aging | Schedule replacement at 8.2V |

| Sudden 0.5V drops | Internal short developing | Replace immediately |

| Voltage fluctuations >0.3V | Connection issues | Clean contacts and retest |

Integration with Building Management Systems

Modern facilities can automate battery monitoring through:

- IoT voltage sensors: Wireless nodes reporting to central dashboards

- API integrations: Connecting battery data to maintenance software

- Automated alerts: Configuring notifications when voltages cross thresholds

Specialized Applications Requiring Custom Voltage Profiles

Certain equipment demands tailored voltage management approaches:

- Medical devices: Requires dual-battery systems with automatic cutover at 8.4V

- Telecom equipment: Needs voltage stabilization circuits for clean power

- Scientific instruments: Often requires ±0.1V regulation for accurate readings

Expert Recommendation: For facilities with 50+ battery-dependent devices, implement a centralized Battery Management Platform (BMP) that combines real-time monitoring with predictive analytics, typically reducing unexpected failures by 78%.

Troubleshooting Complex Voltage Issues

When standard testing doesn’t reveal problems, try these advanced diagnostics:

- Perform AC ripple tests to detect internal impedance changes

- Measure voltage recovery time after load removal

- Compare voltage under load vs. manufacturer’s discharge curves

System-Wide Voltage Optimization and Quality Assurance Protocols

Comprehensive Battery Voltage Management Framework

Enterprise-level voltage management requires a multi-layered approach to ensure reliability across all devices. Implement these key strategies:

| Management Layer | Implementation | Performance Benefit |

|---|---|---|

| Preventive | Scheduled replacements at 80% of expected lifespan | Reduces failure risk by 65% |

| Predictive | AI analysis of voltage decay patterns | Identifies 90% of developing issues |

| Proactive | Automated load testing during maintenance windows | Maintains 99.5% system uptime |

Advanced Voltage Quality Assurance Testing

For mission-critical systems, these validation procedures ensure optimal performance:

- Dynamic load validation: Test batteries with simulated operational profiles (e.g., smoke alarm chirp sequence)

- Temperature cycling tests: Verify performance from -20°C to 50°C

- Voltage recovery analysis: Measure time to stabilize after 50% discharge pulses

Risk Assessment Matrix for Voltage-Related Failures

Evaluate and mitigate potential failure scenarios:

- High Risk: Medical devices (implement redundant power with automatic cutover)

- Medium Risk: Security systems (use lithium batteries with voltage monitoring)

- Low Risk: Consumer electronics (standard alkaline with annual replacement)

Long-Term Performance Optimization Techniques

Extend battery life and maintain voltage stability with these professional methods:

- Load matching: Pair battery chemistry with device current requirements

- Parasitic drain elimination: Install isolation switches in seldom-used equipment

- Condition-based monitoring: Track internal resistance trends as early failure indicator

Quality Control Standards and Certification

Adhere to these industry benchmarks for voltage reliability:

| Standard | Requirement | Testing Method |

|---|---|---|

| IEC 60086-2 | ±5% voltage stability | 20-hour discharge test |

| ANSI C18.1M | Minimum 8.4V under load | 250mA continuous drain |

Implementation Checklist: For comprehensive voltage management, verify:

1) All batteries are logged with installation dates,

2) Critical devices have backup power,

3) Staff are trained in advanced testing protocols, and

4) Replacement inventories exceed 125% of expected needs.

Conclusion: Mastering 9V Battery Voltage for Optimal Performance

Understanding alkaline 9V battery voltage behavior is crucial for maintaining reliable device operation. As we’ve explored, voltage characteristics vary significantly based on battery chemistry, load conditions, and environmental factors.

From the initial 9.5V reading in fresh batteries to the critical 7V cutoff threshold, proper voltage monitoring ensures your devices function as intended. Remember these key takeaways:

- Always test batteries under actual load conditions for accurate assessments

- Implement preventive replacement schedules based on your specific usage patterns

- Consider advanced monitoring solutions for mission-critical applications

By applying these voltage management strategies, you’ll extend battery life, prevent unexpected failures, and optimize performance across all your 9V-powered devices. Start implementing these techniques today to take control of your power needs with professional-grade precision.

Frequently Asked Questions About Alkaline 9V Battery Voltage

What exactly does the voltage rating on a 9V battery mean?

The nominal 9V rating represents the average voltage during discharge, not the initial or final voltage. Fresh alkaline 9V batteries actually measure 9.5-9.6V when new, gradually declining to about 7V at end-of-life.

This rating system allows for consistent comparison between battery types, accounting for the natural voltage drop that occurs during use. Manufacturers determine this value through standardized discharge tests under specific load conditions.

How often should I test my 9V battery’s voltage?

For critical devices like smoke detectors, test monthly using a quality multimeter. Standard electronics benefit from quarterly testing. Always test:

- Before installation in important devices

- When experiencing unexpected performance issues

- After prolonged storage (6+ months)

Record your readings to track voltage decline patterns over time.

Why does my battery show good voltage but still fail under load?

This common issue occurs due to increased internal resistance in aging batteries. While they may show adequate open-circuit voltage (8V+), their ability to deliver current diminishes.

Test under a 250-500Ω load for 30 seconds to reveal true performance. A battery that drops below 7V under this test should be replaced immediately, regardless of its unloaded voltage reading.

Can I mix different brands of 9V batteries in the same device?

We strongly advise against mixing brands or battery ages. Different manufacturers use slightly different chemistries and internal designs, which can cause:

- Uneven current distribution

- Accelerated voltage drop in weaker batteries

- Potential leakage from reverse charging

Always use identical batteries from the same production batch when possible.

What’s the most accurate way to measure 9V battery voltage?

For professional-grade accuracy:

- Use a calibrated digital multimeter with 0.01V resolution

- Test at room temperature (20-25°C)

- Measure both open-circuit and loaded voltage

- Allow new batteries to stabilize for 24 hours after purchase

Avoid analog testers as they often lack precision below 0.5V increments.

How does temperature affect 9V battery voltage?

Temperature impacts voltage output significantly:

- Below 0°C: Voltage drops 15-20% temporarily

- 25-40°C: Optimal performance range

- Above 50°C: Accelerated chemical reactions cause permanent capacity loss

For cold environments, lithium 9V batteries maintain better voltage stability than alkaline.

When should I replace a 9V battery based on voltage?

Replacement thresholds vary by application:

| Device Type | Replace Below |

|---|---|

| Smoke detectors | 8.0V (unloaded) |

| Audio equipment | 7.5V (under load) |

| Medical devices | 8.4V (unloaded) |

Always consult your device manual for specific recommendations.

Can I recharge standard alkaline 9V batteries?

No, attempting to recharge standard alkaline batteries is dangerous and ineffective. Unlike NiMH or lithium-ion chemistries, alkaline batteries:

- Lack proper internal structure for recharging

- May leak or explode if charging current is applied

- Show minimal capacity recovery (under 15%)

Invest in purpose-built rechargeable 9V batteries if sustainability is a priority.