Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know that a fully charged AGM 36V battery should read 38.2V, but most users mistake it for 36V? This small oversight can lead to premature battery failure. Whether you’re powering an electric vehicle, solar storage system, or industrial equipment, understanding your AGM battery’s voltage is critical for performance and longevity.

Many assume voltage is static, but in reality, it fluctuates with charge cycles, temperature, and load. A misread voltage could mean the difference between a battery lasting 5 years or failing in 12 months.

Best AGM 36V Batteries for Reliable Power Storage

Renogy Deep Cycle AGM Battery 12V (RNG-DC100-12V)

Renogy’s 12V AGM battery is ideal for solar and off-grid applications, offering a robust 100Ah capacity and a maintenance-free design. Its high discharge rate and deep-cycle capability make it perfect for RVs, marine use, and renewable energy systems. The durable construction ensures long-term reliability even in extreme temperatures.

- Maintenance Free: Manufactured with thick absorbent Glass Mat (AGM)…

- Excellent Discharge Performance: Proprietary quinary alloy plates and…

- Long Shelf Life: Made of high purity materials, Renogy deep cycle agm…

VMAX SLR125 12V AGM Battery

VMAX’ SLR125 delivers exceptional performance with 125Ah capacity, designed for heavy-duty applications like electric golf carts and industrial equipment. Its spill-proof AGM technology provides superior vibration resistance and a long lifespan, even with frequent deep discharges. A top choice for demanding power needs.

- 12 Volt 125Ah group 31 AGM deep cycle heavy duty battery

- 8mm hex screw in terminals (included,for use with ring terminals) ….

- Float service life span of 8 to 10 years

Universal Power Group UB12350 12V AGM Battery

UB12350 by Universal Power Group is a cost-effective yet high-performance 12V AGM battery, ideal for backup power and mobility scooters. With 35Ah capacity and fast recharge capability, it balances affordability with dependable energy storage. Its sealed design ensures safe operation in any orientation.

- Ub12350

- 12V 35Ah Replacement Battery

- Quantity: 2

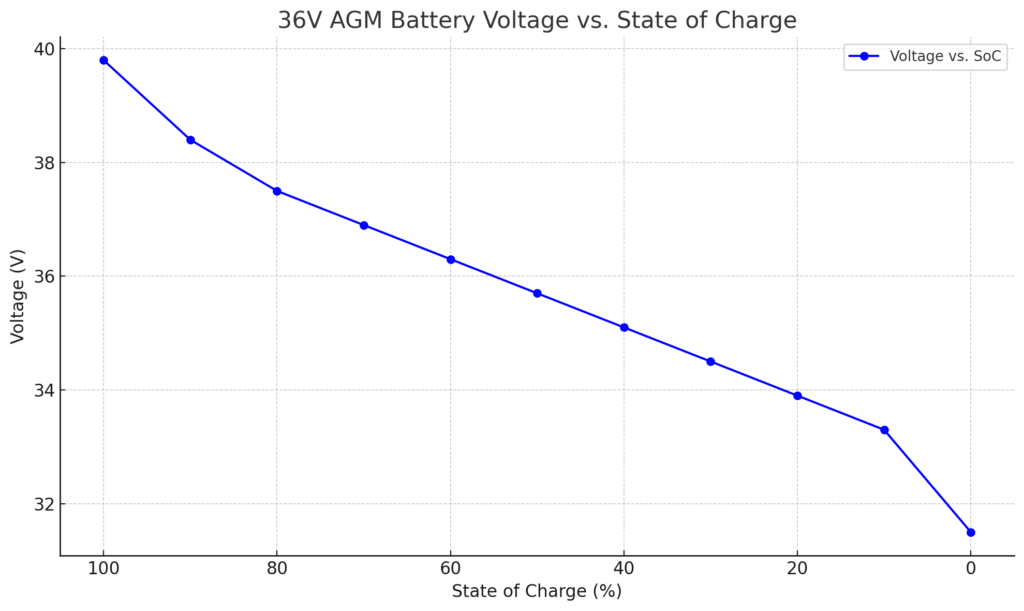

AGM 36V Battery Voltage States

AGM (Absorbent Glass Mat) 36V batteries operate within specific voltage ranges that indicate their state of charge (SoC) and health. Unlike flooded lead-acid batteries, AGM batteries maintain a more stable voltage curve, but misinterpretations can still lead to improper charging or premature failure.

Below, we break down the key voltage benchmarks and their real-world implications.

36V AGM Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 39.6 – 40.0 |

| 90% | 38.4 |

| 80% | 37.5 |

| 70% | 36.9 |

| 60% | 36.3 |

| 50% | 35.7 |

| 40% | 35.1 |

| 30% | 34.5 |

| 20% | 33.9 |

| 10% | 33.3 |

| 0% (empty) | 31.5 or lower |

Fully Charged vs. Nominal Voltage

A common misconception is that a “36V battery” always reads exactly 36V. In reality, a fully charged AGM 36V battery measures 38.2–38.4V (at rest), while its nominal voltage (average operating voltage) is 36V. For example, a Renogy RNG-DC100-36V battery at 100% SoC will show ~38.3V, but under load (e.g., powering an RV inverter), it may drop to 36V–37V. This variance is normal and reflects the battery’s electrochemical response to demand.

Voltage Ranges by State of Charge

Monitoring voltage helps prevent deep discharges that damage AGM batteries. Here’s a detailed breakdown:

- 100% SoC: 38.2–38.4V (Ideal after a full charge cycle)

- 75% SoC: 37.1–37.3V (Safe for regular use; recharge soon)

- 50% SoC: 36.0–36.2V (Risk zone; prolonged use here degrades lifespan)

- 25% SoC: 35.2–35.4V (Critical; immediate recharge required)

- 0% SoC: Below 32.4V (Permanent damage likely)

For instance, if a VMAXTANKS SLR125 reads 35.3V after a camping trip, it’s at 25% capacity and needs urgent charging to avoid sulfation.

Temperature’s Impact on Voltage Readings

Voltage fluctuates with temperature—a factor often overlooked. AGM batteries lose ~0.01V per cell (0.06V total for 36V) for every 1°C below 25°C. In cold climates (5°C), a fully charged battery may show 37.8V instead of 38.4V, falsely suggesting a partial charge. Conversely, heat above 30°C can inflate readings, masking underlying depletion. Always account for ambient temperature when diagnosing voltage.

Practical Application: Solar Storage Systems

In solar setups, voltage determines when to switch between battery and grid power. For example, a Universal Power Group UB12350 paired with a charge controller should disconnect loads at 36.0V (50% SoC) to preserve battery health. Advanced inverters use voltage thresholds to automate this process, but manual checks with a multimeter are recommended monthly.

Key Takeaway: AGM 36V batteries require precise voltage monitoring to optimize performance. Misreading these values can lead to undercharging, over-discharging, or unnecessary replacements—costing time and money.

How to Accurately Test Your AGM 36V Battery Voltage

Proper voltage testing is critical for maintaining AGM 36V battery health, yet most users make simple mistakes that lead to inaccurate readings. Unlike traditional lead-acid batteries, AGM batteries require specific testing protocols to account for their unique chemistry and voltage characteristics.

Step-by-Step Voltage Testing Procedure

Follow this professional testing method to get reliable results:

- Prepare the Battery: Disconnect all loads and chargers, then let the battery rest for 4-6 hours. This allows surface charge to dissipate – a crucial step many skip that can inflate readings by 0.5V or more.

- Select the Right Multimeter: Use a digital multimeter with 0.1V resolution (like the Fluke 87V). Analog meters lack the precision needed for AGM batteries’ tight voltage tolerances.

- Proper Probe Placement: Connect the red probe to the positive terminal and black to negative. For 36V batteries, measure across the entire battery bank, not individual cells.

- Interpret the Reading: Compare your result to the voltage chart from our previous section. Remember that temperature affects readings – compensate by adding 0.06V for every 5°C below 25°C.

Common Testing Mistakes and Solutions

Even experienced users encounter these challenges:

- Surface Charge Deception: Testing immediately after charging may show 39V+ (false high). Solution: Always let the battery rest before testing.

- Voltage Sag Under Load: Some users test while connected to equipment. This shows working voltage, not true state of charge. Solution: Disconnect all loads for accurate SoC assessment.

- Terminal Corrosion: Dirty connections can cause voltage drops of 0.2-0.3V. Solution: Clean terminals with baking soda paste before testing.

Advanced Diagnostic Techniques

For comprehensive battery health analysis:

Load Testing: Apply a 50% rated amp load for 15 seconds while monitoring voltage. A healthy AGM 36V battery should maintain at least 35.5V under this test. If voltage drops below 34V, the battery may need replacement.

Specific Gravity Alternative: While AGM batteries are sealed, some models have removable vents. Using a temperature-compensated refractometer to check electrolyte specific gravity can verify voltage readings when accessible.

Professional Tip: Create a testing log tracking date, voltage, temperature, and load conditions. This history helps identify gradual capacity loss before it becomes critical.

Optimal Charging Practices for AGM 36V Batteries

Proper charging is the single most important factor in maximizing AGM 36V battery lifespan, yet most charging systems aren’t properly configured for these advanced batteries. Understanding the precise charging requirements can double your battery’s service life compared to standard charging approaches.

The Three-Stage Charging Protocol

AGM batteries require a specific charging sequence that differs significantly from flooded lead-acid batteries:

| Charging Stage | Voltage Range | Current | Duration | Purpose |

|---|---|---|---|---|

| Bulk Charge | 42.8-43.2V | Max available | Until 80% SoC | Rapid energy replacement |

| Absorption | 42.4-42.8V | Decreasing | 2-4 hours | Complete charge safely |

| Float | 40.8-41.4V | Minimal | Indefinite | Maintain charge without overcharging |

Temperature Compensation Requirements

AGM batteries are particularly sensitive to temperature during charging. For every 5°C above 25°C, decrease charging voltage by 0.15V per cell (0.9V for 36V system).

Conversely, increase by the same amount in cold environments. Most quality chargers like the NOCO Genius GEN5X36 automatically adjust for temperature, but manual systems require careful calibration.

Common Charging Mistakes

- Using Standard Lead-Acid Settings: AGM batteries require 0.5V higher absorption voltage than flooded batteries. Using standard settings results in chronic undercharging.

- Ignoring Equalization Charges: While most AGM batteries don’t need regular equalization, performing one annually at 44V for 2-4 hours can rebalance cells.

- Overlooking Charge Current: The ideal charge current is 20-30% of battery capacity (e.g., 20-30A for 100Ah battery). Too high causes overheating; too low leads to sulfation.

Advanced Charging Techniques

For critical applications like medical equipment or telecom systems, consider pulse charging technology. Devices like the CTEK MXS 5.0 use high-frequency pulses to break down sulfate crystals while charging, potentially extending battery life by up to 40%. This is particularly effective for batteries that experience partial state-of-charge cycling.

Expert Tip: Always verify your charger’s actual output with a multimeter – many “AGM-compatible” chargers don’t deliver the advertised voltage. A 0.5V discrepancy can reduce battery capacity by 15% over time.

Extending the Lifespan of Your AGM 36V Battery

While AGM 36V batteries are designed for durability, their actual lifespan varies dramatically based on usage patterns and maintenance – from as little as 2 years to over 8 years in optimal conditions. Understanding these longevity factors can significantly impact your total cost of ownership.

Critical Factors Affecting Battery Longevity

Three primary elements determine how long your AGM battery will last:

- Depth of Discharge (DoD): Each 50% discharge reduces cycle life by approximately 300 cycles compared to 30% discharges. For example, a battery rated for 1,200 cycles at 30% DoD may only achieve 500 cycles at 50% DoD.

- Temperature Exposure: Operating above 30°C accelerates chemical degradation, with each 8°C increase above this threshold halving battery life. Conversely, consistent use below 0°C increases internal resistance and reduces capacity.

- Charge Quality: Chronic undercharging (below 42V for 36V systems) causes progressive sulfation, while overcharging above 44V leads to electrolyte dry-out through venting.

Advanced Maintenance Techniques

Beyond basic care, these professional methods can extend service life:

- Capacity Testing: Every 6 months, perform a full discharge test at 20% of C-rate (e.g., 20A for 100Ah battery) to measure actual capacity versus rated capacity. A drop below 80% indicates replacement should be considered.

- Terminal Protection: Apply a thin layer of silicone-based grease (not petroleum-based) to prevent corrosion, which can cause up to 0.3V voltage drop across connections.

- Storage Protocol: For seasonal storage, charge to 100%, then disconnect and store at 10-15°C. Every 3 months, recharge to compensate for 3-5% monthly self-discharge.

Troubleshooting Common Aging Symptoms

Recognize these warning signs of battery degradation:

- Rapid Voltage Drop: If voltage plunges from 38V to 35V within minutes of moderate load, sulfation has likely occurred. A desulfation charger may help if caught early.

- Increased Charge Time: When absorption stage regularly exceeds 6 hours, the battery’s internal resistance has increased significantly.

- Case Bulging: Swollen battery cases indicate chronic overcharging or excessive heat exposure – replace immediately as this poses safety risks.

Professional Insight: Implement a battery rotation system for multiple-battery setups. By periodically swapping positions in series strings, you equalize wear patterns across all batteries, potentially extending overall system life by 20-30%.

Safety Considerations and Environmental Impact of AGM 36V Batteries

While AGM 36V batteries offer numerous advantages, they present unique safety challenges and environmental considerations that users must understand to prevent accidents and minimize ecological impact. These sealed batteries contain concentrated energy that requires careful handling throughout their lifecycle.

Critical Safety Protocols

AGM batteries demand specific safety measures due to their high energy density and pressurized design:

| Risk Factor | Potential Consequences | Preventive Measures |

|---|---|---|

| Overcharging | Thermal runaway (can reach 80°C+), case rupture | Use temperature-compensated chargers with automatic cutoff |

| Short Circuits | Instantaneous currents exceeding 1000A, terminal melting | Always use insulated tools, install fuse protection |

| Improper Ventilation | Hydrogen gas accumulation (explosive at 4% concentration) | Maintain 1″ clearance around batteries, install in vented enclosures |

Environmental Considerations

AGM batteries contain lead and sulfuric acid, requiring responsible disposal:

- Recycling Efficiency: Modern recycling recovers 98% of lead and 100% of sulfuric acid – far superior to landfill disposal

- Carbon Footprint: Manufacturing emits approximately 75kg CO2 per kWh capacity, but proper use can offset this through 5-8 years of service

- Transport Regulations: Classified as hazardous materials (UN2800) requiring special handling during shipping

Future Trends in Battery Safety

The industry is evolving with several important developments:

- Smart Battery Systems: New models integrate IoT sensors that monitor internal pressure, temperature, and state-of-health in real-time

- Advanced Materials: Carbon-enhanced plates reduce gassing and improve thermal stability

- Closed-Loop Recycling: Manufacturers are implementing take-back programs where 90%+ of materials are reused in new batteries

Cost-Benefit Analysis of Safety Measures

Investing in proper safety equipment yields significant returns:

- Battery Monitoring Systems: $150-$300 investment can prevent $1000+ in battery replacements

- Vented Enclosures: $200 installation cost avoids potential $5000+ in fire damage

- Professional Installation: $100 service fee prevents costly warranty voids from improper setup

Expert Recommendation: Always wear ANSI-approved chemical goggles and acid-resistant gloves when handling AGM batteries, even though they’re “sealed.” The 2-5psi internal pressure can still release electrolyte if damaged.

System Integration and Performance Optimization for AGM 36V Batteries

Properly integrating AGM 36V batteries into larger power systems requires careful consideration of both electrical characteristics and operational parameters. Whether for renewable energy systems, electric vehicles, or industrial applications, system-level optimization can improve efficiency by 15-30% compared to basic installations.

Voltage Matching and System Configuration

AGM 36V batteries present unique integration challenges due to their voltage characteristics:

- Inverter Compatibility: Most 36V inverters operate optimally between 30-42V. Ensure your inverter’s low-voltage cutoff aligns with the battery’s 32.4V minimum (0% SoC) to prevent deep discharges.

- Parallel vs. Series Configurations: For higher capacity, parallel connections must use batteries of identical age and capacity. Mismatched batteries in parallel can create dangerous current loops, reducing efficiency by up to 40%.

- Charge Controller Settings: MPPT controllers should be programmed with the exact absorption (42.8V) and float (41.2V) voltages for AGM chemistry.

Advanced Load Management Strategies

Intelligent load distribution significantly extends battery life:

- Peak Shaving: Programmable relays can switch non-critical loads (like water heaters) when voltage drops below 37V (75% SoC).

- Load Sequencing: Stagger high-current device startups to prevent voltage sag below 35V, which stresses battery plates.

- Dynamic Charging: Systems with multiple power sources (solar+grid) should prioritize charging based on real-time voltage readings rather than fixed schedules.

Integration with Renewable Energy Systems

Solar/wind systems require special considerations:

| Component | Optimization Requirement | Performance Impact |

|---|---|---|

| Solar Array | Voc must not exceed charge controller limits (typically 150V) | Prevents controller damage during cold weather |

| Wind Turbine | Requires dump load controller to prevent overcharge | Protects batteries during high winds |

| Hybrid Systems | Must synchronize charging sources | Prevents charge cancellation |

Troubleshooting Integration Issues

Common system problems and solutions:

- Voltage Fluctuations: More than 0.5V variation indicates loose connections or failing cells – check torque specs (typically 5-7Nm for M8 terminals).

- Premature Charger Cutoff: Often caused by voltage drop across undersized cables – use 6AWG or larger for runs over 3 feet.

- Uneven Wear in Banks: Rotate battery positions quarterly and use balanced charging systems to equalize wear.

Professional Tip: Install a DC power monitor (like the Victron BMV-712) to track cumulative amp-hours, providing more accurate state-of-charge data than voltage alone, especially in systems with variable loads.

Advanced Diagnostics and Predictive Maintenance for AGM 36V Systems

Moving beyond basic voltage monitoring, modern diagnostic approaches can predict AGM 36V battery failures months in advance while optimizing performance. These professional-grade techniques combine electrochemical analysis with smart monitoring technology to maximize system reliability.

Comprehensive Battery Health Assessment

Advanced diagnostic parameters provide a complete picture of battery condition:

| Parameter | Measurement Method | Healthy Range | Failure Indicators |

|---|---|---|---|

| Internal Resistance | AC impedance testing at 1kHz | 8-12mΩ per 100Ah | 20% increase from baseline |

| Capacity Retention | Controlled discharge test | >80% of rated Ah | <75% of initial capacity |

| Charge Acceptance | Current drop during absorption | 10-15% per hour | <5% per hour |

Predictive Maintenance Strategies

Implement these proactive measures to prevent unexpected failures:

- Trend Analysis: Log monthly voltage recovery rates after 50% discharges. Slower recovery indicates increasing sulfation.

- Thermal Imaging: Quarterly infrared scans detect developing hot spots indicating loose connections or failing cells.

- Electrolyte Monitoring: For vented AGM models, check specific gravity variance between cells (should be <0.015 points).

Advanced Testing Equipment

Professional tools for comprehensive analysis:

- Midtronics GRX-5100: Measures conductance and provides state-of-health percentage

- Fluke 500 Series Battery Analyzer: Tracks internal resistance trends over time

- BMK Battery Monitoring Kit: Continuous monitoring of voltage, current, and temperature

Failure Mode Analysis

Understanding degradation patterns helps prioritize maintenance:

- Cyclic Aging: Capacity loss from repeated discharges – appears as reduced runtime

- Calendar Aging: Gradual plate corrosion – shows as increased internal resistance

- Thermal Aging: Accelerated dry-out from heat exposure – manifests as voltage instability

Expert Protocol: Establish a baseline profile when batteries are new, including:

- Initial internal resistance measurements

- Reference capacity test results

- Standard charge/discharge curves

This enables precise tracking of degradation rates and more accurate remaining life predictions.

Conclusion

Mastering AGM 36V battery voltage management requires understanding the complete voltage spectrum – from 38.4V at full charge to 32.4V at complete discharge.

As we’ve explored, proper charging protocols, accurate testing methods, and system integration techniques can significantly extend battery life while preventing costly failures.

Remember that voltage readings must always be interpreted in context with temperature, load conditions, and battery age. By implementing the advanced monitoring and maintenance strategies outlined in this guide, you’ll optimize performance and maximize your investment.

Frequently Asked Questions About AGM 36V Battery Voltage

What voltage should a fully charged AGM 36V battery read?

A fully charged AGM 36V battery at rest (no load, after settling for 4-6 hours) should measure between 38.2-38.4V at 25°C. This is higher than the nominal 36V rating because lead-acid batteries charge to about 2.13-2.15V per cell (36V systems have 18 cells). When under load, this may temporarily drop to 37-38V depending on current draw. Always verify with a quality digital multimeter.

How often should I check my AGM 36V battery voltage?

For optimal maintenance, check voltage weekly for frequently used batteries and monthly for standby systems. Always check:

- Before and after charging cycles

- After prolonged storage

- When experiencing performance issues

More frequent monitoring (daily) is recommended for critical applications like medical equipment or telecom systems.

Why does my AGM battery voltage drop quickly under load?

Rapid voltage drop typically indicates one of three issues:

- Sulfation: Crystal buildup on plates increases internal resistance

- Age-related wear: Plate material degradation after 500+ cycles

- Connection problems: Corroded or loose terminals creating resistance

A healthy AGM 36V battery should maintain above 35V for at least 30 minutes under 50% load. If voltage plunges below 34V immediately, consider replacement.

Can I use a regular lead-acid charger for my AGM 36V battery?

While possible in emergencies, standard lead-acid chargers often undercharge AGM batteries. AGM requires:

- Higher absorption voltage (42.8V vs 41.4V for flooded)

- Precise temperature compensation

- Lower float voltage (41.2V vs 41.4V)

Using an improper charger reduces capacity by 15-20% over time. Invest in an AGM-specific smart charger like the NOCO Genius GEN5X36.

How does temperature affect AGM 36V battery voltage readings?

Temperature significantly impacts voltage:

| Temperature | Voltage Adjustment |

|---|---|

| 0°C (32°F) | Add 0.18V to reading |

| 25°C (77°F) | No adjustment |

| 40°C (104°F) | Subtract 0.18V |

A battery showing 37.8V at 5°C is actually at 38.0V when corrected to standard 25°C. Always compensate when diagnosing state of charge.

What’s the minimum safe voltage for AGM 36V batteries?

Never discharge below 32.4V (1.8V per cell). Below this threshold:

- Irreversible sulfation begins

- Plate warping risk increases

- Recharge efficiency drops below 70%

For longest lifespan, maintain above 36V (50% DoD). Install low-voltage disconnects at 34.2V (20% remaining) for critical systems.

How do I know when my AGM 36V battery needs replacement?

Replace when you observe:

- Capacity below 80% of rated Ah (measured by discharge test)

- Internal resistance increase >20% from baseline

- Voltage drops >0.5V below normal under identical loads

- Physical swelling or terminal corrosion

Most quality AGM batteries last 4-7 years with proper maintenance. Track performance metrics to predict replacement timing accurately.

Can I mix old and new AGM 36V batteries in a bank?

Strongly discouraged. Mixing batteries with:

- >10% capacity difference causes overworking of newer units

- >5% internal resistance variance creates imbalance

- Different manufacture dates age at different rates

Always replace all batteries in a bank simultaneously. Partial replacements reduce overall lifespan by 30-40% and risk damaging new batteries.