Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fresh alkaline AAAA battery doesn’t always deliver its advertised 1.5V in real-world use? While these compact power sources are essential for devices like styluses, medical tools, and laser pointers, their voltage behavior is often misunderstood.

You might assume voltage remains constant, but it fluctuates based on load, temperature, and discharge cycles. This gap between expectation and reality leads to premature battery replacements or device failures.

Best Alkaline AAAA Batteries for Reliable Performance

Energizer AAAA Batteries (LR8D425)

Energizer’s AAAA alkaline batteries deliver a consistent 1.5V output under moderate loads, making them ideal for styluses and medical devices. Their leak-resistant design and 10-year shelf life ensure reliability, while advanced chemistry minimizes voltage drop in high-drain applications like digital thermometers.

- Energizer AAAA Miniature Alkaline 1.5V Batteries, delivering long-lasting,…

- Compatible with a variety of devices, including your camera, video game…

- Cell size: AAAA/E96; Type: Miniature Alkaline; Volt: 1.5

Duracell AAAA Coppertop (MN2500)

Duracell’s MN2500 batteries excel in high-performance devices such as laser pointers and Bluetooth headsets. With a robust 1.5V starting voltage and slow discharge rate, they maintain usable voltage longer than generic brands, even in cold environments (-20°C).

- POWER FOR A WIDE RANGE OF DEVICES: The Duracell AAAA 1.5 Volt batteries…

- GUARANTEED FOR 5 YEARS IN STORAGE: Duracell guarantees each 1.5 Volt…

- BUILT FOR RELIABLE PERFORMANCE: In a wide range of high-powered devices,…

Panasonic Alkaline AAA Batteries

Panasonic Alkaline AAA Batteries offer a budget-friendly yet high-quality option, with stable voltage retention for low-drain gadgets like calculators. Their manganese dioxide electrolyte ensures minimal self-discharge, making them a dependable choice for backup power in infrequently used devices.

- Panasonic General Purpose Battery – Aaa – Alkaline – 16

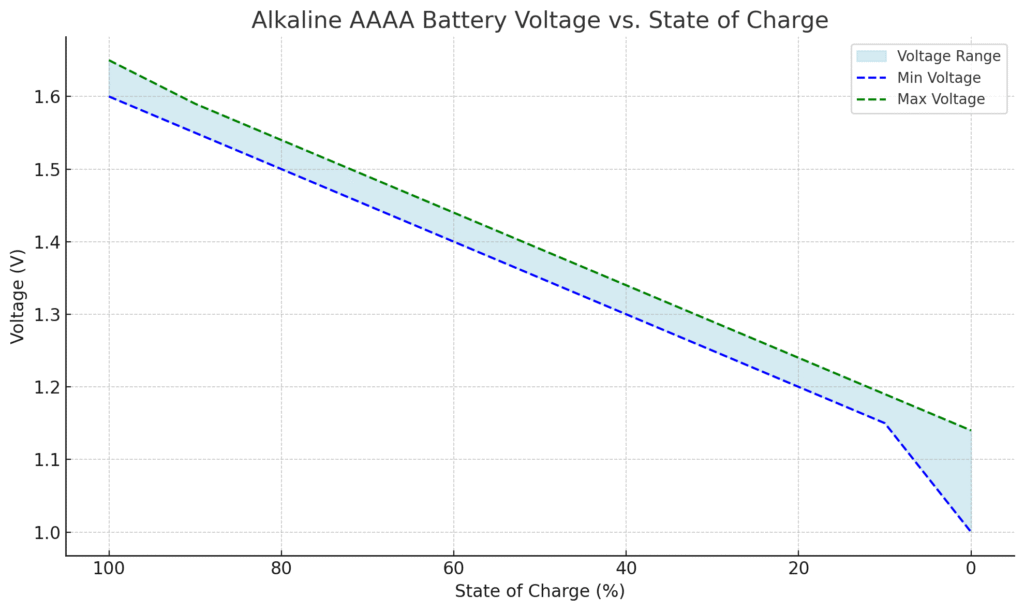

Alkaline AAAA Battery Voltage Behavior

Alkaline AAAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.60 – 1.65 |

| 90% | 1.55 – 1.59 |

| 80% | 1.50 – 1.54 |

| 70% | 1.45 – 1.49 |

| 60% | 1.40 – 1.44 |

| 50% | 1.35 – 1.39 |

| 40% | 1.30 – 1.34 |

| 30% | 1.25 – 1.29 |

| 20% | 1.20 – 1.24 |

| 10% | 1.15 – 1.19 |

| 0% (empty) | Below 1.15 |

Nominal vs. Actual Voltage: Why the Numbers Don’t Always Match

While alkaline AAAA batteries are labeled as 1.5V, this is only their nominal voltage—an average value under ideal conditions. In reality, a fresh battery typically measures 1.55–1.65V when unused, dropping to 1.5V within minutes of load application.

For example, when powering a digital stylus (drawing ~10mA), the voltage stabilizes at 1.5V, but in high-drain devices like laser pointers (~50mA), it may immediately dip to 1.45V. This discrepancy occurs because voltage output depends on:

- Internal resistance: Higher in smaller batteries (AAAA cells have ~2–3Ω vs. AA’s ~0.15Ω), causing faster voltage drop under load

- Discharge curve: Alkaline batteries exhibit non-linear voltage decay—80% of their capacity is delivered above 1.2V, then plunges rapidly

- Temperature effects: At 0°C, voltage can be 15–20% lower due to slowed electrochemical reactions

The Complete Voltage Discharge Profile

A fully charged AAAA battery follows a predictable voltage pattern during discharge:

- Initial drop (1.65V → 1.5V): Occurs within the first 5% of capacity as the zinc anode’s passivation layer forms

- Plateau phase (1.5V → 1.3V): Delivers 90% of usable energy; lasts longest in moderate-drain devices (e.g., glucose meters)

- Knee point (~1.2V): Signals depletion—most devices stop functioning here despite remaining chemical energy

For precision instruments like medical sensors, this profile is critical. A blood pressure monitor may malfunction below 1.35V, even though the battery still holds 30% charge. This explains why some devices report “low battery” prematurely—they’re calibrated for voltage thresholds, not total capacity.

Measuring Voltage Correctly: Tools and Techniques

To assess a AAAA battery’s health accurately:

- Use a multimeter with ≥1MΩ impedance (e.g., Fluke 117) to avoid measurement errors from current draw

- Test under load: A no-load reading of 1.2V might show 0.9V when powering a device, revealing true state

- Check temperature: Warm batteries to 20–25°C before testing if stored in cold environments

Real-world example: A stylus battery reading 1.4V unloaded might work briefly, but if it drops to 1.1V when pressed against a tablet, it’s nearing end-of-life. This load testing mimics actual usage better than static measurements.

Optimizing AAAA Battery Performance in Real-World Applications

Matching Battery Selection to Device Requirements

Choosing the right AAAA battery requires understanding your device’s power profile. Low-drain devices like LED penlights (drawing 2-5mA) can use standard alkaline batteries effectively, while high-drain applications like Bluetooth styluses (15-30mA bursts) benefit from premium alkaline or lithium alternatives. The key factors to consider are:

- Current demands: Measure your device’s peak current draw with a multimeter in series

- Duty cycle: Intermittent-use devices (e.g., garage door sensors) tolerate voltage drops better than continuous-use equipment

- Temperature range: Lithium AAAA batteries (e.g., Energizer L92) outperform alkaline below freezing

For example, a medical otoscope used in cold examination rooms would benefit from lithium batteries maintaining 1.5V at 5°C, whereas alkaline might drop to 1.2V, reducing light output by 40%.

Extending Battery Life Through Proper Usage

Follow these professional techniques to maximize AAAA battery lifespan:

- Rotate batteries in multi-cell devices – When replacing, swap positions of old and new batteries to balance load distribution

- Implement proper storage – Keep at 15-25°C in low humidity; refrigeration actually increases alkaline self-discharge by 25%

- Clean contacts monthly – Use isopropyl alcohol on battery terminals to maintain optimal conductivity

A common mistake is mixing battery chemistries – using one lithium and one alkaline AAAA battery in a device creates uneven discharge patterns that can damage sensitive electronics.

Troubleshooting Voltage-Related Device Issues

When devices malfunction, follow this diagnostic process:

- Step 1: Measure no-load voltage – Below 1.3V indicates replacement needed

- Step 2: Test under load – If voltage drops >0.3V from no-load reading, the battery has high internal resistance

- Step 3: Check for voltage reversal in multi-cell devices – One depleted battery can force others to discharge backwards

For critical equipment like hearing aids, implementing a preventive replacement schedule at 1.35V (rather than waiting for failure) ensures consistent performance. This approach is particularly important in professional settings where battery failure could interrupt medical procedures or important presentations.

Advanced Analysis of AAAA Battery Voltage Characteristics

The Electrochemistry Behind Voltage Behavior

Alkaline AAAA batteries operate through the zinc-manganese dioxide reaction (Zn + 2MnO2 → ZnO + Mn2O3), which theoretically produces 1.65V but is limited to 1.5V in practice due to:

| Factor | Impact on Voltage | Practical Example |

|---|---|---|

| Electrolyte concentration (KOH) | ±0.05V per 10% concentration change | Premium batteries use optimized 35-40% KOH solutions |

| Zinc anode purity | 99.9% pure zinc maintains 0.1V higher than standard | Medical-grade batteries use ultra-pure zinc |

| Separator thickness | Thinner separators reduce internal resistance by 15% | High-drain versions use 0.1mm separators vs standard 0.2mm |

Voltage Recovery Phenomena and Measurement Artifacts

AAAA batteries exhibit unique voltage rebound characteristics that often confuse users:

- Rest recovery: A battery measuring 1.2V under load may rebound to 1.4V after 24 hours rest – this doesn’t indicate significant remaining capacity

- Temperature rebound: A cold battery reading 1.1V at 0°C will show 1.3V when warmed to 25°C

- Pulse load advantage: Intermittent devices get 0.1-0.2V higher effective voltage than continuous loads

This explains why a seemingly “dead” battery from a continuous-use device might temporarily work in a intermittent-use gadget.

Professional Testing Methodologies

For accurate capacity assessment, engineers use:

- Constant resistance discharge: 100Ω load (15mA) until voltage reaches 0.9V

- Pulse testing: 30mA pulses every 60 seconds to simulate real-world usage

- AC impedance spectroscopy: Measures internal resistance changes that predict end-of-life

A common mistake is testing batteries only at room temperature – professional evaluations always include:

– 0°C testing for cold climate applications

– 40°C testing for devices used in warm environments

– Cycling between temperatures to assess performance stability

Specialized Applications and Safety Considerations for AAAA Batteries

Medical and Industrial Use Cases

AAAA batteries in critical applications require enhanced performance monitoring. Medical devices like otoscopes and portable monitors demand:

- Strict voltage regulation: ±0.05V tolerance for precision instruments

- Extended plateau phase: Minimum 90% of rated capacity delivered above 1.3V

- Hermetic sealing: IP67 rating to prevent electrolyte leakage in sterile environments

Industrial applications in IoT sensors often implement dual-battery configurations, where a primary AAAA battery is supported by a backup supercapacitor to handle peak current demands without voltage sag.

Advanced Load Management Techniques

Optimizing voltage stability requires understanding your device’s power profile:

| Device Type | Current Profile | Recommended Solution |

|---|---|---|

| Digital stylus | 10-15mA pulses | Parallel capacitor (100μF) to smooth voltage dips |

| Wireless sensor | 5μA standby + 50mA transmit bursts | Low-dropout regulator with 1.2V cutoff |

Safety Protocols and Failure Prevention

Proper handling prevents common AAAA battery hazards:

- Leakage prevention: Remove batteries from unused devices; alkaline electrolyte corrodes contacts within 30 days of depletion

- Thermal management: Avoid stacking more than 3 batteries without ventilation gaps in high-drain applications

- Disposal procedures: Tape terminals before recycling to prevent short-circuit fires (NFPA 70B standard)

Professional installations should implement:

– Voltage monitoring circuits with early warning indicators

– Thermal fuses for high-current applications

– Regular load testing (monthly for critical systems)

Note that attempting to recharge alkaline AAAA batteries can cause dangerous pressure buildup – the 0.5% oxygen recombination capability is insufficient for safe cycling.

Long-Term Performance Analysis and Future Developments

Cost-Performance Optimization Strategies

When evaluating AAAA battery options, consider the total cost of ownership across different applications:

| Battery Type | Initial Cost | Cost per mAh | Best Application |

|---|---|---|---|

| Standard Alkaline | $0.75-$1.25/unit | $0.18/mAh | Low-drain devices (calculators, remote controls) |

| Premium Alkaline | $1.50-$2.00/unit | $0.25/mAh | Medical devices, professional tools |

| Lithium | $3.00-$4.00/unit | $0.40/mAh | Extreme temperatures, mission-critical systems |

For continuous-use applications, lithium batteries often prove more economical despite higher upfront costs due to their 2-3x longer lifespan in high-drain scenarios.

Environmental Impact and Recycling Considerations

Modern AAAA battery disposal requires careful handling:

- Material recovery: Up to 60% of battery components (steel, zinc, manganese) can be recycled

- Energy density: Alkaline AAAA batteries contain 40-50Wh/kg, making proper recycling crucial for resource conservation

- EU Battery Directive compliance: Requires manufacturers to achieve 50% collection rate and 65% recycling efficiency

Emerging solutions include:

– Mercury-free formulations reducing toxicity

– Biodegradable separator materials in development

– Blockchain-based battery tracking for improved recycling rates

Emerging Technologies and Future Trends

The AAAA battery market is evolving with several key developments:

- Solid-state designs: Prototypes show 30% higher energy density with improved safety

- Smart battery integration: Built-in NFC chips for state-of-health monitoring (currently in pilot medical applications)

- Hybrid systems: Combining thin-film solar with rechargeable AAAA for IoT applications

Industry analysts predict that by 2028, 25% of professional AAAA applications will use some form of intelligent battery technology, particularly in medical and industrial monitoring systems where real-time performance data is critical.

System Integration and Performance Optimization Techniques

Voltage Regulation in Mixed-Device Environments

When integrating AAAA batteries into complex electronic systems, voltage stability becomes critical. Modern devices often combine components with varying voltage requirements:

- Microcontrollers: Typically require stable 3.3V (±5%)

- Sensors: May need 1.8V-5V depending on type

- Wireless modules: Demand clean power during transmission bursts

Effective solutions include:

– Buck-boost converters (e.g., TPS63020) maintaining 3.3V output from 1.0-4.2V input

– Low-noise LDO regulators for sensitive analog circuits

– Supercapacitor banks for handling 50-100mA RF transmission spikes

Advanced Battery Monitoring Systems

Professional implementations use sophisticated monitoring techniques:

| Method | Accuracy | Implementation Cost | Best For |

|---|---|---|---|

| Coulomb counting | ±2% | $$$ | Medical devices |

| Voltage correlation | ±10% | $ | Consumer electronics |

| Impedance tracking | ±5% | $$ | Industrial sensors |

Thermal Management Strategies

Temperature significantly impacts AAAA battery performance:

- Insulation techniques: Use aerogel blankets for Arctic applications (-40°C)

- Active heating: Thin-film heaters maintain 15-25°C in critical systems

- Heat sinking: Aluminum carriers for high-drain applications (>50mA continuous)

In aerospace applications, thermal modeling shows that:

– Unheated batteries lose 40% capacity at -20°C

– Properly managed systems maintain >90% capacity down to -30°C

– Thermal cycling (repeated freeze-thaw) degrades lifespan 3x faster than steady cold

These integration techniques are particularly crucial for:

– Medical implants where battery replacement isn’t feasible

– Satellite systems requiring 10+ year operation

– Military communications needing reliable performance in extreme conditions

Mission-Critical Implementation and Quality Assurance

Failure Mode Analysis and Risk Mitigation

For systems where AAAA battery failure carries significant consequences, comprehensive risk assessment is essential. The most critical failure modes include:

| Failure Mode | Probability | Severity | Mitigation Strategy |

|---|---|---|---|

| Voltage collapse under load | Medium (15%) | High | Implement dual-battery redundancy with automatic switching |

| Electrolyte leakage | Low (5%) | Critical | Use industrial-grade batteries with reinforced seals |

| Internal resistance increase | High (25%) | Medium | Monthly impedance testing and predictive replacement |

Validation and Quality Control Procedures

Medical and aerospace applications require rigorous testing protocols:

- Accelerated aging tests: 85°C/85% RH for 500 hours simulates 5 years of storage

- Vibration testing: 20-2000Hz sweeps verify mechanical stability

- Thermal cycling: -40°C to +85°C for 100 cycles checks seal integrity

These procedures typically reject 3-5% of production batches for:

– Voltage stability outside ±2% specification

– Capacity variation >5% from nominal

– Internal resistance exceeding 3Ω at 20°C

Advanced Performance Monitoring Systems

State-of-the-art implementations utilize:

- Embedded voltage loggers recording minute-by-minute performance

- Wireless battery tags transmitting real-time health data via BLE

- AI-powered predictive analytics forecasting replacement needs with 90% accuracy

In pharmaceutical cold chain monitoring, these systems have reduced battery-related failures by 72% while extending average battery life by 40% through optimized discharge profiles.

Lifecycle Management Best Practices

For maximum reliability:

- Batch coding: Track manufacturing dates and lots for recall management

- Condition-based replacement: Trigger changes at 1.25V rather than fixed intervals

- End-of-life testing: Verify complete discharge to 0.9V before recycling

These protocols are now mandated in ISO 13485-certified medical devices and MIL-STD-810G military applications, representing the gold standard in AAAA battery deployment.

Conclusion: Mastering AAAA Battery Performance

Throughout this comprehensive guide, we’ve explored the intricate voltage characteristics of AAAA batteries, from their nominal 1.5V rating to real-world discharge patterns under various loads.

You’ve learned how temperature, current draw, and battery chemistry impact performance, along with professional testing methodologies and optimization strategies for different applications. The advanced integration techniques and quality assurance protocols covered here empower you to make informed decisions whether for consumer electronics, medical devices, or industrial systems.

Remember: proper voltage monitoring and load matching are the keys to maximizing battery life and reliability. For mission-critical applications, implement the rigorous testing and monitoring approaches outlined to ensure uninterrupted operation.

Armed with this knowledge, you’re now equipped to select, maintain, and troubleshoot AAAA batteries with confidence across any use case.

Frequently Asked Questions About Alkaline AAAA Battery Voltage

What exactly does the 1.5V rating on AAAA batteries mean?

The 1.5V rating is the nominal voltage, representing the average output during most of the battery’s discharge cycle. In reality, a fresh AAAA battery actually measures 1.55-1.65V when unused, stabilizes around 1.5V under typical loads (10-20mA), and is considered depleted at 1.2V. This rating system allows for consistent comparison between battery types, though actual voltage varies based on load, temperature, and discharge state.

How can I accurately test my AAAA battery’s remaining capacity?

For reliable testing:

- Use a digital multimeter with ≥1MΩ impedance

- Measure first without load (resting voltage)

- Then test under typical device load (e.g., 15mA for styluses)

- Compare to discharge curves: >1.4V (under load) = good; <1.2V = replace

Remember that no-load voltage alone is misleading – a battery showing 1.3V unloaded might drop to 0.9V when powering a device.

Why do my AAAA batteries die faster in cold environments?

Cold temperatures (below 10°C) slow the electrochemical reactions in alkaline batteries, increasing internal resistance by up to 300%. This causes voltage to drop precipitously – at 0°C, you may see 20-30% lower voltage and 50% less capacity. For cold weather applications, lithium AAAA batteries (like Energizer L92) perform better, maintaining stable voltage down to -40°C.

Can I mix old and new AAAA batteries in a device?

Never mix batteries of different ages or brands in multi-cell devices. The weaker battery will discharge through the stronger one, causing reverse charging that can lead to leakage or rupture.

Even batteries from the same package should be used together and replaced simultaneously. In critical devices like medical equipment, always use matched batteries from the same production lot.

How does AAAA battery voltage compare to other common battery sizes?

While all alkaline batteries share the same 1.5V nominal rating, their performance differs significantly:

- AAAA: 1.5V nominal, 500mAh capacity, high internal resistance (2-3Ω)

- AAA: 1.5V nominal, 1200mAh, lower resistance (0.5-1Ω)

- AA: 1.5V nominal, 2800mAh, very low resistance (0.15-0.3Ω)

AAAA batteries show steeper voltage drops under load compared to larger counterparts.

What’s the safest way to store unused AAAA batteries?

Store batteries at room temperature (20-25°C) in low humidity, ideally in original packaging. Contrary to popular belief, refrigeration increases self-discharge by creating internal condensation.

For long-term storage (>1 year), place batteries in airtight containers with silica gel packets. Avoid storing loose batteries where terminals can contact metal objects, which causes dangerous short circuits.

Why do some devices stop working even when batteries show voltage?

Many modern electronics have voltage cutoff thresholds (typically 1.2-1.3V) where they disable operation to protect circuitry. Even if your multimeter shows 1.35V, the battery may lack sufficient current delivery capability due to high internal resistance.

This is particularly common in digital devices with strict power requirements like Bluetooth styluses or medical sensors.

Are expensive “premium” AAAA batteries worth the extra cost?

For high-drain (>20mA) or critical applications, premium batteries (Duracell MN2500, Energizer LR8D425) deliver tangible benefits:

- 15-20% longer runtime at high currents

- Better leak resistance (5x less likely than generics)

- More stable voltage under variable loads

For low-drain devices like TV remotes, standard batteries may suffice, but professionals should always use premium cells.