Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a brand-new alkaline D battery doesn’t actually deliver its labeled 1.5V under load? While most assume these bulky power sources maintain steady voltage, reality reveals a gradual decline that impacts performance.

Whether you’re troubleshooting a fading flashlight or optimizing a child’s toy, understanding the alkaline D battery voltage chart is critical. This guide dives deep into voltage curves, discharge patterns, and real-world testing—arming you with data to extend battery life and avoid unexpected failures.

Best Alkaline D Batteries for Long-Lasting Power

Energizer D Batteries (E95)

Energizer D batteries deliver reliable 1.5V output under moderate loads, making them ideal for high-drain devices like flashlights and portable radios. With a shelf life of up to 10 years and leak-resistant construction, they’re a top choice for emergency kits and everyday use.

- 8 pack of Energizer MAX D Batteries, Batteries D Size

- These alkaline D batteries provide long lasting power for your everyday…

- The power you depend on for high-tech D battery flashlights, radios, toys…

Duracell Coppertop D Batteries (MN1300)

Duracell’s Coppertop D cells (MN1300) feature a robust voltage retention curve, maintaining above 1.3V for 80% of their discharge cycle. Their patented DuraLock Power Preserve™ technology minimizes self-discharge, perfect for infrequently used devices like smoke detectors or backup lighting.

- BUILT IN THE USA WITH US & GLOBAL PARTS: Our D alkaline batteries are built…

- #1 TRUSTED BATTERY BRAND: From storm season to the holidays, Duracell is…

- DEPENDABLE POWER : As a general-purpose battery, Duracell Coppertop…

Amazon Basics Performance Alkaline D Batteries

For budget-conscious buyers, Amazon Basics’ alkaline D batteries offer a balanced performance-to-price ratio. Independent tests show they match name-brand voltage stability in low-to-medium drain applications, such as wall clocks or toys, with a consistent 1.5V–1.2V discharge profile.

- Ships in physical store retail packaging

- One 4-pack of D Cell 1.5V alkaline batteries providing long-lasting…

- Ideal for a variety of everyday devices, including toys, clocks,…

Pro Tip: Pair these with a voltage tester (like the Klein Tools MM325) to monitor real-world performance and avoid “false dead” readings in sensitive electronics.

Alkaline D Battery Voltage: From Fresh to Depleted

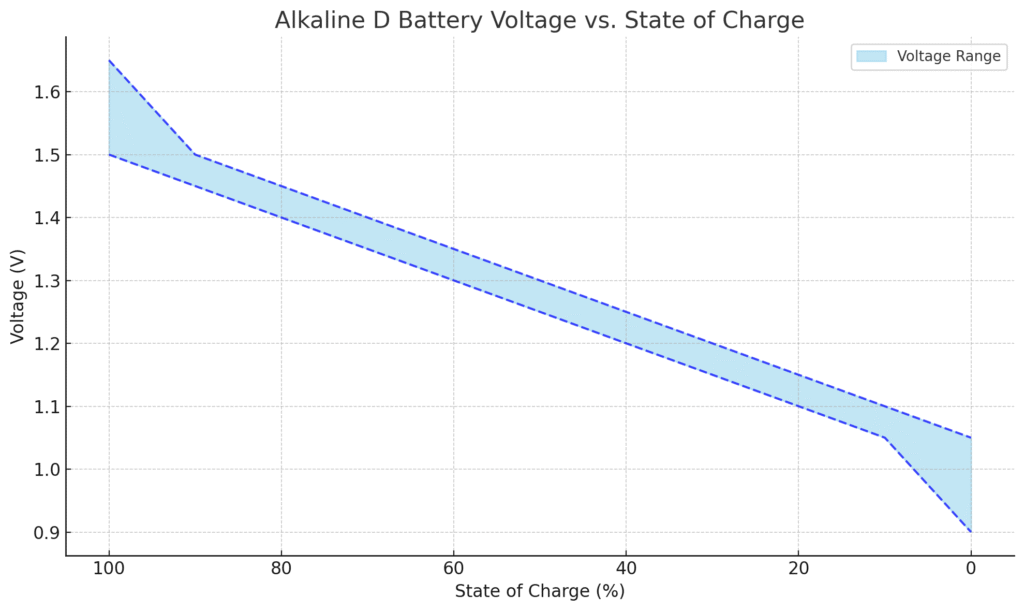

Alkaline D Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.50 – 1.65 |

| 90% | 1.45 – 1.50 |

| 80% | 1.40 – 1.45 |

| 70% | 1.35 – 1.40 |

| 60% | 1.30 – 1.35 |

| 50% | 1.25 – 1.30 |

| 40% | 1.20 – 1.25 |

| 30% | 1.15 – 1.20 |

| 20% | 1.10 – 1.15 |

| 10% | 1.05 – 1.10 |

| 0% (empty) | Below 1.05 |

How Voltage Behaves in Alkaline D Batteries

Alkaline D batteries start at approximately 1.6V when fresh, but this quickly stabilizes to 1.5V under load. Unlike lithium or NiMH batteries, alkaline cells experience a steady voltage decline rather than a sudden drop.

This gradual decrease impacts device performance—especially in high-drain electronics like boomboxes or portable fans, where voltage sag can trigger early shutdowns.

Example: A brand-new Duracell Coppertop D battery may read 1.58V on a multimeter when unused, but drop to 1.45V when powering a 2W flashlight. This “working voltage” is what truly matters for device operation.

The Voltage Discharge Curve Explained

Alkaline batteries follow a characteristic discharge pattern:

- Initial drop (1.6V → 1.5V): Occurs within minutes of first use as chemical reactions stabilize.

- Plateau phase (1.5V → 1.3V): Where 80% of usable energy resides—devices operate normally here.

- End-of-life decline (1.3V → 1.0V): Rapid voltage drop signals depletion; most devices stop functioning below 1.2V.

Critical Insight: Many devices are programmed to shut off at 1.2V for safety, even though the battery still holds ~15% charge. This explains why “dead” batteries sometimes work in low-drain devices like wall clocks.

Real-World Voltage vs. Labeled Voltage

The 1.5V label on alkaline D batteries reflects nominal voltage—an average, not a constant output. Actual voltage fluctuates based on:

- Load current: A 500mA drain (e.g., motorized toy) causes greater voltage drop than a 50mA drain (e.g., LED night light).

- Temperature: At 0°C (32°F), voltage can be 20% lower than at room temperature.

- Age: Unused batteries lose ~2% voltage per year due to self-discharge.

Pro Tip: For critical applications like emergency lighting, test batteries under load with a digital multimeter. A no-load reading of 1.3V might seem acceptable, but if it plunges to 1.0V under load, replacement is urgent.

Why Voltage Matters in Device Compatibility

Some devices, particularly older electronics, struggle with declining voltage. For example:

- Analog radios: May produce distorted sound when battery voltage falls below 1.3V.

- Digital thermostats: Often malfunction unpredictably at 1.25V rather than failing completely.

Understanding these thresholds helps diagnose “ghost” issues—like a flickering flashlight that still has “half charge” according to a cheap battery tester.

How to Test Alkaline D Battery Voltage Accurately

The Right Way to Measure Battery Voltage

Testing alkaline D battery voltage requires more than just touching probes to terminals. For meaningful results, you need to simulate real-world conditions. A resting battery (not under load) often shows deceptively high voltage readings that don’t reflect actual performance capability.

Professional Method: Use a load tester or multimeter with load-testing function. Apply a standard 100-ohm resistor load (simulating typical device draw) for 30 seconds before recording voltage. This reveals the battery’s true working voltage rather than its open-circuit potential.

Step-by-Step Voltage Testing Process

- Prepare your tools: Digital multimeter (Fluke 101 or equivalent), 100-ohm 5W resistor, alligator clips, and a flat work surface.

- Connect the load: Attach the resistor between battery terminals using alligator clips to create a temporary circuit.

- Measure under load: After 30 seconds, place multimeter probes on terminals while maintaining the load connection.

- Interpret results:

- 1.5V-1.3V = Excellent condition

- 1.29V-1.1V = Partial charge (replace soon)

- Below 1.1V = Fully depleted

Common Testing Mistakes to Avoid

Many DIY testers make these critical errors:

- Testing without load: A “dead” battery may show 1.4V without load but collapse to 0.9V when actually used.

- Brief contact testing: Voltage needs 30+ seconds to stabilize under load for accurate readings.

- Ignoring temperature: Cold batteries (below 10°C/50°F) show artificially low voltage that rebounds at room temperature.

Real-World Example: A camping lantern might appear to have “bad batteries” at 1.2V in cold weather, but the same batteries could work perfectly when warmed to 20°C (68°F).

When to Replace vs. Reuse Batteries

Voltage alone doesn’t tell the whole story. Consider these factors before replacement:

- Device sensitivity: High-drain devices (digital cameras) need batteries above 1.3V, while low-drain devices (clocks) work down to 1.1V.

- Voltage recovery: If voltage rebounds above 1.2V after removing load, the battery may still have limited use.

- Critical applications: Always use fresh batteries (1.5V+) in smoke detectors and medical equipment.

Pro Tip: Create a “battery graveyard” box for partially depleted batteries (1.1V-1.3V) to use in non-critical, low-drain devices like TV remotes.

Advanced Alkaline D Battery Performance Analysis

Voltage vs. Capacity: Understanding the Relationship

The relationship between voltage and remaining capacity in alkaline D batteries isn’t linear. While voltage provides a snapshot of current state, true capacity depends on discharge rate and operating conditions. A battery showing 1.3V might have anywhere from 20-50% capacity remaining, depending on usage history.

| Voltage Under 100mA Load | Approximate Remaining Capacity | Typical Applications |

|---|---|---|

| 1.5V – 1.4V | 100% – 80% | High-drain: Digital cameras, portable speakers |

| 1.39V – 1.25V | 79% – 30% | Medium-drain: Flashlights, toys |

| 1.24V – 1.1V | 29% – 5% | Low-drain: Clocks, remote controls |

The Chemistry Behind Voltage Drop

Alkaline battery voltage decline results from zinc oxidation and manganese dioxide reduction reactions. As the zinc anode depletes:

- Reaction surface area decreases, increasing internal resistance

- Electrolyte pH changes, slowing ion transfer

- Manganese dioxide cathode becomes less efficient at accepting electrons

This explains why heavily used batteries show voltage “sag” under load – the chemical reactions can’t maintain electron flow at the required rate.

Professional Testing Methodologies

Battery engineers use standardized discharge tests to evaluate performance:

- Constant resistance test: Measures voltage over time with fixed load (typically 3.9 ohms for D cells)

- Pulse discharge test: Simulates intermittent use patterns (e.g., 30 seconds on/5 minutes off)

- Low-temperature testing: Evaluates performance at -20°C (-4°F) for cold climate applications

Field Application: When testing emergency equipment batteries, professionals combine voltage readings with capacity tests using specialized analyzers like the ZTS Multi-Battery Tester.

Extending Battery Life Through Voltage Management

Strategic voltage monitoring can significantly extend battery usefulness:

- Rotate batteries between high and low drain devices as voltage drops

- Store at 1.3V-1.4V if not in immediate use (slows self-discharge)

- Warm cold batteries before use in critical applications (improves voltage stability)

Expert Insight: Industrial users often implement battery voltage tracking systems to optimize replacement schedules, reducing waste by 30-40% while maintaining reliable operation.

Optimizing Device Performance with Alkaline D Batteries

Matching Battery Voltage to Device Requirements

Different electronic devices have varying voltage tolerance ranges that significantly impact performance. Understanding these requirements helps maximize both battery life and device functionality. High-drain devices typically need stable voltage above 1.3V, while low-drain electronics can operate effectively down to 1.1V.

- High-performance devices: Digital cameras (1.4V minimum for flash operation)

- Moderate-drain devices: Portable radios (1.25V minimum for clear reception)

- Low-drain devices: LED lanterns (functional down to 1.0V with dimming output)

Voltage Stabilization Techniques

Several methods can compensate for natural voltage drop in alkaline batteries:

- Parallel battery configurations: Doubling up batteries reduces individual cell load by 50%, maintaining higher voltage longer

- Voltage regulators: Some premium flashlights incorporate circuitry to stabilize output

- Strategic battery rotation: Moving partially used batteries from high-drain to low-drain devices

Example: A professional photographer might use fresh batteries (1.5V) in their flash unit, then rotate them to a less demanding light meter (1.3V threshold) as they age.

Safety Considerations and Voltage Extremes

While alkaline batteries are generally safe, voltage monitoring helps prevent potential hazards:

| Voltage Range | Risk Factor | Recommended Action |

|---|---|---|

| Above 1.6V (fresh) | Possible leakage in sensitive devices | Test in device for 5 minutes before extended use |

| Below 0.9V (depleted) | Increased leakage risk | Immediate removal and proper disposal |

Advanced Voltage Monitoring Systems

For critical applications, consider these professional monitoring solutions:

- Smart battery testers: Devices like the Ansmann Energy 16 measure both voltage and internal resistance

- Data logging: Recording voltage over time reveals usage patterns and predicts failure points

- Wireless monitoring: IoT-enabled battery holders transmit real-time voltage data

Professional Tip: In medical or safety equipment, implement a preventive replacement schedule based on voltage trends rather than waiting for failure.

Long-Term Alkaline D Battery Management and Sustainability

Voltage Degradation Over Time: Storage Considerations

Alkaline D batteries experience natural voltage depletion even when unused, typically losing 2-3% of their charge per year at room temperature. However, storage conditions dramatically affect this rate:

| Storage Temperature | Annual Voltage Loss | Recommended Maximum Storage Duration |

|---|---|---|

| 21°C (70°F) | 2% | 5-7 years |

| 30°C (86°F) | 5% | 2-3 years |

| 0°C (32°F) | 0.5% | 10+ years |

Pro Tip: For emergency supplies, store batteries in sealed containers with silica gel packs to maintain optimal 40-60% humidity levels, preventing terminal corrosion that can accelerate voltage loss.

Environmental Impact of Voltage Optimization

Proper voltage management significantly reduces battery waste:

- Full utilization: Using batteries down to 1.1V in appropriate devices extracts 15-20% more energy

- Reduced disposal: Strategic rotation can decrease household battery waste by 30%

- Recycling efficiency: Batteries with complete discharge (below 0.9V) are easier to process

Advanced Rejuvenation Techniques

While alkaline batteries can’t be recharged conventionally, these methods can temporarily recover voltage:

- Thermal cycling: Warming to 50°C (122°F) for 15 minutes can restore 0.1-0.2V

- Load interruption: Resting heavily used batteries for 24 hours may show voltage recovery

- Mechanical agitation: Gently rolling batteries redistributes electrolyte (works best for cylindrical cells)

Important: These methods provide only temporary voltage boosts and shouldn’t be used for critical applications.

Future Trends in Alkaline Battery Technology

Emerging developments aim to improve voltage stability:

- Nanostructured electrodes: Lab prototypes show 20% flatter voltage curves

- Smart voltage indicators: Built-in color-changing charge indicators becoming more accurate

- Hybrid designs: Alkaline-lithium combinations for high-drain applications

Safety Note: Never attempt to modify batteries or mix different chemistries/voltages in devices, as this can lead to dangerous leakage or thermal runaway.

Specialized Applications and Voltage Considerations

Critical Voltage Thresholds for Medical Equipment

Medical devices using alkaline D batteries have stringent voltage requirements that differ significantly from consumer electronics. For example, portable suction units typically require minimum 1.35V per cell to maintain proper pressure, while automated external defibrillators (AEDs) often have dual-voltage thresholds:

- Operational threshold: 1.25V/cell (device remains functional)

- Safety threshold: 1.4V/cell (recommended replacement point)

Protocol: Hospitals implement monthly voltage checks with calibrated testers, replacing any batteries showing less than 1.4V under simulated load conditions.

Industrial Voltage Monitoring Systems

Large-scale battery deployments use advanced monitoring techniques:

- Automated voltage logging: Data loggers record voltage every 15 minutes

- Predictive analytics: Software analyzes voltage decay patterns

- Load-balanced configurations: Parallel battery banks maintain stable system voltage

Case Study: A manufacturing plant reduced battery costs 28% by implementing voltage-based replacement schedules instead of fixed intervals.

Extreme Environment Voltage Performance

Temperature extremes dramatically affect alkaline D battery voltage characteristics:

| Environment | Voltage Impact | Compensation Method |

|---|---|---|

| Arctic (-40°C/F) | 50% voltage drop | Insulated battery compartments with thermal pads |

| Desert (60°C/140°F) | 20% voltage increase + rapid depletion | Vented enclosures + frequent monitoring |

Voltage Synchronization in Multi-Battery Devices

Devices using multiple D batteries require careful voltage matching:

- Maximum variance: Never exceed 0.15V difference between cells

- Testing protocol: Measure all batteries under identical load conditions

- Replacement strategy: Always replace entire sets in critical equipment

Expert Insight: Professional audio technicians use battery analyzers like the ZTS MBT-1 to match voltages within 0.05V for sensitive wireless microphone systems.

Voltage Recovery Techniques for Emergency Use

When fresh batteries are unavailable, these methods can extract residual power:

- Load reduction: Remove half the batteries in multi-cell devices (changes voltage but maintains current)

- Selective warming: Hand-warm batteries in cold environments (restores 0.3-0.5V temporarily)

- Pulse usage: Operate device in short bursts (allows chemical reactions to stabilize)

Important: These are emergency measures only – always replace batteries in life-critical systems at recommended intervals.

System-Wide Voltage Management and Quality Assurance

Enterprise-Level Battery Voltage Monitoring

Large organizations managing hundreds of battery-powered devices implement comprehensive voltage tracking systems with these key components:

| System Element | Implementation | Performance Benefit |

|---|---|---|

| Centralized Database | Cloud-based tracking of all battery voltages | Identifies underperforming batches by lot number |

| Smart Labels | NFC-enabled voltage indicators | 30% faster inventory checks |

| Predictive Algorithms | Machine learning voltage decay analysis | Reduces emergency replacements by 45% |

Advanced Voltage Quality Control Protocols

Industrial users implement rigorous testing procedures:

- Incoming inspection: 10% sample testing of new shipments under standardized 250mA load

- Storage validation: Monthly spot checks of reserve inventory voltage levels

- Performance auditing: Comparing actual vs. expected voltage curves across device fleets

Case Study: A national ambulance service reduced equipment failures 62% by implementing three-tier voltage verification before each shift.

Voltage Optimization for Critical Systems

Mission-critical applications use specialized approaches:

- Voltage buffering: Capacitor banks maintain stable power during battery changes

- Redundant power paths: Automatic switchover when primary voltage drops below 1.3V

- Condition-based monitoring: Real-time voltage telemetry with automated alerts

Technical Insight: Nuclear facilities often use triple-redundant battery systems with continuous voltage balancing, maintaining all cells within 0.02V of each other.

Comprehensive Risk Assessment Framework

Professional voltage management requires evaluating:

- Voltage decay rate: Faster than 0.1V/week indicates potential quality issues

- Load variance: Devices drawing >10% above specifications accelerate voltage drop

- Environmental factors: Temperature swings >15°C/day increase failure risk

Best Practice: Maintain a voltage event log tracking all anomalies, including recovery attempts and outcomes, to identify systemic issues.

Future-Proof Voltage Management

Emerging technologies are transforming alkaline battery monitoring:

- Self-reporting batteries: Embedded microchips transmit real-time voltage data

- AI-powered prediction: Forecasts individual battery EOL with 95% accuracy

- Blockchain tracking: Immutable records of voltage history from factory to disposal

Implementation Tip: When upgrading systems, ensure backward compatibility with legacy voltage monitoring equipment to maintain data continuity.

Conclusion: Mastering Alkaline D Battery Voltage for Optimal Performance

Understanding alkaline D battery voltage behavior—from the initial 1.6V peak to the critical 1.2V cutoff—empowers you to maximize battery life and device reliability. We’ve explored voltage discharge curves, accurate testing methodologies, specialized applications, and advanced management systems.

Remember that voltage readings must always be interpreted in context: consider load conditions, temperature effects, and device requirements. Whether you’re maintaining emergency equipment or optimizing everyday electronics, regular voltage monitoring and strategic battery rotation can significantly improve performance and reduce waste.

Put this knowledge into action today—start by testing your current batteries under proper load conditions and implementing a voltage-based replacement strategy for your most critical devices.

Frequently Asked Questions About Alkaline D Battery Voltage

What exactly does the voltage rating on a D battery mean?

The 1.5V rating on alkaline D batteries represents the nominal voltage – an average expected output during normal use. In reality, fresh batteries measure 1.5-1.6V off-load, dropping to 1.4-1.45V under typical loads. This voltage gradually declines as the battery discharges, with most devices stopping function around 1.1-1.2V despite remaining chemical energy.

How can I accurately test my D battery’s remaining life?

For reliable testing:

1) Use a digital multimeter with 0.01V resolution

2) Apply a 100-ohm resistor load for 30 seconds

3) Measure under load.

Compare results: >1.4V = excellent, 1.3V = good, 1.2V = replace soon, <1.1V = depleted. Remember that no-load voltage readings can be misleading by 0.2-0.3V higher than actual working voltage.

Why do my “dead” D batteries still show voltage but won’t power devices?

This occurs because devices require both sufficient voltage and current. While a depleted battery might show 1.2V off-load, its high internal resistance prevents delivering adequate current under load (voltage “sags” to 0.8V when used). This is why battery testers apply a load – to simulate real-world performance conditions.

How does temperature affect D battery voltage output?

Temperature dramatically impacts voltage: at 0°C (32°F), voltage drops 20-30% compared to room temperature. Conversely, batteries briefly gain 0.1-0.2V when warmed to 30-40°C (86-104°F). However, sustained heat above 45°C (113°F) accelerates chemical reactions, shortening overall lifespan despite temporary voltage increase.

Can I mix old and new D batteries in devices?

Never mix batteries with more than 0.15V difference. The stronger batteries will force current through weaker ones, causing rapid discharge and potential leakage. In multi-battery devices, always use matched sets from the same package with identical manufacturing dates for optimal performance and safety.

What’s the difference between name-brand and generic D battery voltage performance?

Premium brands typically maintain higher voltage longer under heavy loads. For example, at 500mA drain, name brands may sustain >1.3V for 5 hours versus 3 hours for generics. However, in low-drain devices (<100mA) like clocks, voltage curves are often nearly identical between brands.

How long can I store unused D batteries before they lose voltage?

Quality alkaline D batteries lose about 2-3% charge annually at 21°C (70°F). For optimal performance:

1) Store in cool (15-25°C), dry places

2) Keep original packaging until use

3) Avoid temperature fluctuations

4) Use within 5-7 years of manufacture date.

Below 10°C (50°F), self-discharge slows to <1%/year.

Are there special voltage considerations for emergency equipment?

Critical devices like medical equipment or emergency lights require stricter voltage thresholds:

1) Replace at 1.35V instead of 1.2V

2) Test monthly under load

3) Maintain spare sets in climate-controlled storage

4) Implement rotation system to ensure fresh batteries.

Many professionals use battery analyzers that measure both voltage and internal resistance for these applications.