Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a single 0.5V drop in a C-size Li-ion Battery can reduce its runtime by up to 20%? Voltage isn’t just a number—it’s the lifeline of your device’s power. Whether you’re using flashlights, medical equipment, or industrial tools, understanding your Li-ion C battery’s voltage chart is critical to maximizing efficiency and avoiding costly failures.

Many assume all batteries behave the same, but lithium-ion chemistry demands precision. In this guide, you’ll unlock a detailed voltage breakdown, from fully charged to depleted states, plus expert tips to extend battery life. By the end, you’ll confidently interpret voltage readings like a pro.

Best C-size Li-ion Batteries for Reliable Power

Panasonic ARC5

Panasonic ARC5 with stable voltage output, ideal for high-drain devices like flashlights or power banks. Its lithium manganese oxide (LiMn2O4) chemistry ensures safety and longevity, with a nominal voltage of 3.6V and a max charge of 4.2V.

- Sharp men’s electric shaver blades: Panasonic Arc5 electric shavers for…

- Wet/Dry men’s electric razor & trimmer 2 in 1: Built-in pop up trimmer…

- Multi Flex pivoting head: Panasonic flexible pivoting shaver head glides…

EEMB er14250 1200mAh

This compact yet powerful C-sized Li-ion battery (LR14500) offers 1200mAh capacity, perfect for medical devices or emergency lighting. Its flat discharge curve maintains 3.7V nominal voltage under load, and it includes built-in protection against overcharge and short circuits.

- Basic Info—3.6V non-rechargeable 1/2 AA size lithium thionyl chloride…

- Application- Home automation sensors, door opening detector, temperature…

- Caution-Lithium thionyl chloride battery has a passivation characteristic….

Samsung INR18650-35E 3500mAh

Samsung’s INR18650-35E combines high energy density (3500mAh) with a robust 8A discharge rate, suited for power tools or solar storage. Its nickel-cobalt-aluminum (NCA) cathode ensures minimal voltage sag, with a consistent 3.6V–4.2V range for peak performance.

C-size Li-ion Battery Voltage Ranges and Their Significance

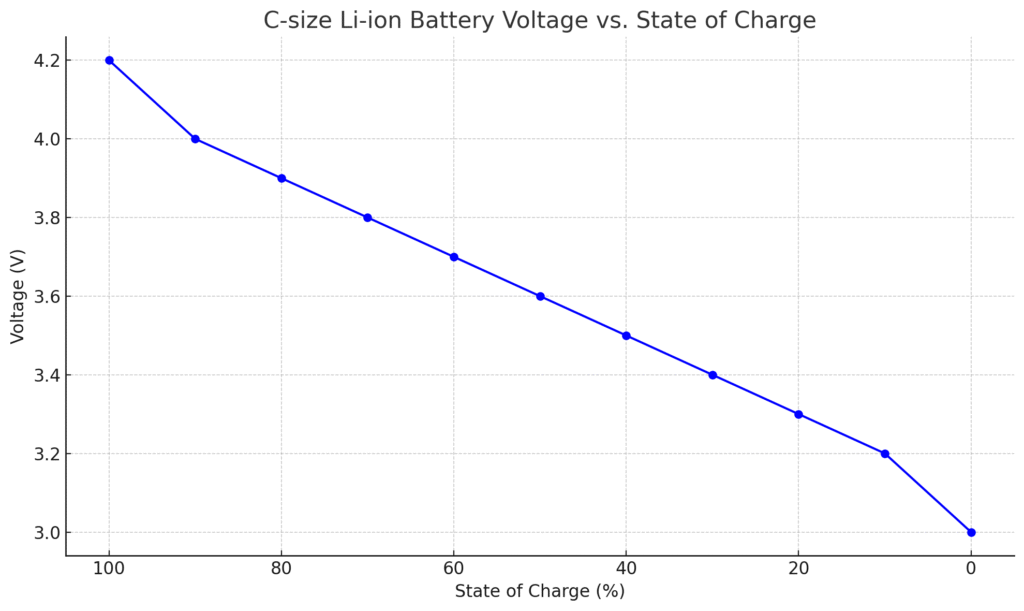

C-size Li-ion Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 4.20 |

| 90% | 4.00 |

| 80% | 3.90 |

| 70% | 3.80 |

| 60% | 3.70 |

| 50% | 3.60 |

| 40% | 3.50 |

| 30% | 3.40 |

| 20% | 3.30 |

| 10% | 3.20 |

| 0% (empty) | 3.00 or lower |

Nominal vs. Operating Voltage: What You Need to Know

Every Li-ion C battery has two critical voltage values: nominal voltage (3.6V or 3.7V) and operating voltage (typically 3.0V–4.2V). The nominal voltage represents the average voltage during discharge, while the operating range defines safe limits.

For example, a Panasonic NCR18650C operates between 2.5V (fully discharged) and 4.2V (fully charged), but staying within 3.0V–4.1V prolongs lifespan by reducing stress on the cells.

How Voltage Affects Performance and Battery Life

Voltage directly impacts both runtime and longevity. A battery at 4.2V delivers maximum power but degrades faster if held at this peak voltage. Conversely, discharging below 3.0V risks irreversible damage due to copper shunting. Here’s a breakdown of voltage stages:

- 4.2V (100% charged): Ideal for short bursts but avoid prolonged storage at this level.

- 3.6V–3.8V (50% charge): The “sweet spot” for storage, minimizing capacity loss.

- 3.0V (critical low): Immediate recharge required to prevent cell failure.

Real-World Voltage Behavior: Discharge Curves Explained

Unlike alkaline batteries, Li-ion C cells maintain near-constant voltage (“flat discharge curve”) for 80% of their capacity before a sharp drop. For instance, a Samsung INR18650-35E holds ~3.7V until the last 20% of energy is depleted, ensuring stable performance in devices like LED flashlights or drones. This contrasts with NiMH batteries, which gradually decline in voltage.

Common Misconceptions About Li-ion Voltage

Many users mistake resting voltage (measured after 1+ hour idle) for loaded voltage (under use). A battery showing 3.7V at rest might drop to 3.4V when powering a high-drain device—a normal behavior due to internal resistance. Always test under realistic loads for accurate assessments.

Practical Tip: Monitoring Voltage for Optimal Use

Invest in a multimeter or smart charger (like the Nitecore D4) to track voltage. For long-term storage, charge to 3.8V and check every 3 months. Avoid mixing batteries with >0.2V differences in packs to prevent imbalance issues.

How to Properly Charge and Maintain C-size Li-ion Batteries

The Science Behind Li-ion Charging Cycles

Li-ion C batteries require constant-current/constant-voltage (CC/CV) charging for optimal performance. During the first phase (CC), the charger delivers maximum safe current until reaching 4.2V. The second phase (CV) gradually reduces current while maintaining 4.2V.

For example, charging a 3400mAh Panasonic NCR18650C at 0.5C (1.7A) takes about 2.5 hours total – 90 minutes for CC phase and 60 minutes for CV phase.

Step-by-Step Charging Best Practices

- Use a compatible smart charger like the Xtar VC4SL that automatically switches between CC/CV modes

- Monitor temperature – batteries should stay below 45°C (113°F) during charging

- Avoid trickle charging – remove batteries immediately after reaching 4.2V to prevent overcharging

- Balance charge battery packs – use chargers with individual cell monitoring like the SkyRC IMAX B6

Extending Battery Lifespan: Storage and Maintenance

For long-term storage, follow the 40-60 rule: maintain charge between 40-60% (3.7V-3.8V) and store in cool (15°C/59°F), dry conditions.

Research shows storing at full charge (4.2V) for 6 months can permanently reduce capacity by 20%, while 40% charge results in only 2-4% loss. For devices used infrequently (like emergency flashlights), perform maintenance cycles every 3 months: discharge to 3.6V, then recharge to 3.8V.

Troubleshooting Common Voltage Issues

If your battery won’t hold charge or shows abnormal voltage:

- Voltage too low (<2.5V): Some chargers may refuse to charge – try a recovery mode charger like the Liitokala Lii-500

- Voltage drops rapidly under load: Likely cell aging – compare to original specifications (e.g., Samsung 35E should maintain >3.5V at 8A discharge)

- Voltage imbalance in packs: Rebalance cells manually or replace outliers with >0.3V difference

Professional Tip: Understanding Charge Rates

The “C-rate” determines charging speed. A 1C rate charges a 3000mAh battery in 1 hour (3A current), while 0.5C takes 2 hours. Most Li-ion C batteries support 0.5C-1C charging, but check manufacturer specs – for example, EEMB LR14500 specifies max 0.7C (840mA) charge current.

Advanced C-size Li-ion Battery Voltage Analysis and Safety Considerations

Voltage Characteristics Under Different Load Conditions

Li-ion C batteries exhibit distinct voltage behaviors based on discharge rates. A high-current draw (5A+) causes immediate voltage sag due to internal resistance. For example, a fully charged Samsung 35E (4.2V) may drop to 3.9V when powering a high-performance flashlight. This phenomenon follows Ohm’s Law (V=IR), where:

| Discharge Rate | Initial Voltage Drop | Stable Voltage Plateau |

|---|---|---|

| 0.2C (700mA) | 0.05V | 3.7V |

| 1C (3.5A) | 0.15V | 3.6V |

| 2C (7A) | 0.3V | 3.4V |

Temperature’s Impact on Voltage Performance

Battery voltage varies significantly with temperature due to electrochemical reaction rates. At -20°C (-4°F), a Li-ion C battery’s usable voltage drops by 15-20%, while at 45°C (113°F), it may show 5-10% higher voltage readings. This creates critical implications:

- Cold weather operation: Voltage drop can trigger premature “low battery” warnings in devices

- High-temperature risks: Combined with high voltage (4.2V), can accelerate electrolyte decomposition

Advanced Voltage Monitoring Techniques

Professional users implement several monitoring methods:

- Coulomb counting: Tracks mAh consumed for precise state-of-charge estimation

- Impedance spectroscopy: Measures internal resistance changes to predict aging

- Voltage profiling: Creates discharge curves to identify cell inconsistencies in packs

Critical Safety Protocols for High-Voltage Applications

When series-connecting Li-ion C cells to achieve higher voltages (e.g., 14.8V from 4 cells):

- Always use matched cells (<0.05V difference when fully charged)

- Implement a Battery Management System (BMS) with cell balancing

- Never exceed the pack’s maximum voltage (4.2V × cell count)

Expert Tip: Voltage Recovery After Deep Discharge

If a battery reads <2.5V, attempt recovery by:

- Using a charger with “wake-up” function at very low current (50-100mA)

- Monitoring temperature closely – discontinue if surface exceeds 40°C

- Checking for voltage rebound after 1 hour rest period

Interpreting and Applying C-size Li-ion Battery Voltage Data in Real-World Applications

Decoding Voltage Readings for Different Use Cases

Understanding voltage states is crucial for optimizing battery performance across applications. A medical device requires different voltage thresholds than a power tool:

- Critical devices (CPAP machines, medical equipment): Replace at 3.3V to ensure uninterrupted operation

- High-performance tools (drills, saws): Can safely discharge to 2.8V with proper thermal management

- Emergency lighting: Maintain 3.7V storage voltage for instant readiness

Advanced Voltage Profiling for Battery Health Assessment

Professional battery analyzers like the Cadex C7400 create detailed voltage profiles that reveal:

- Capacity fade: When 3.7V nominal voltage occurs at 80% of original runtime

- Internal resistance growth: Voltage drops >0.5V under load indicate aging

- Cell imbalance: >0.1V difference between cells in a pack requires rebalancing

Custom Voltage Cutoff Configuration

Smart devices allow voltage cutoff adjustment to match application needs:

| Application | Recommended Cutoff | Rationale |

|---|---|---|

| Long-term storage | 3.8V | Minimizes lithium plating |

| Cycling applications | 3.0V | Maximizes usable capacity |

| High-reliability systems | 3.5V | Provides safety margin |

Professional Troubleshooting: Voltage Anomalies

When encountering unusual voltage behavior:

- Voltage rebound: If voltage rises >0.3V after rest, the cell has high internal resistance

- Voltage drift: >0.1V change after 24 hours indicates cell instability

- No-load voltage drop: >0.2V/day suggests parasitic drain or defective protection circuit

Industry Standards for Voltage Measurement

Accurate voltage measurement requires:

- 4-wire Kelvin measurement for precision (±0.1%)

- 1% tolerance digital multimeter (Fluke 87V recommended)

- Stabilization period (15 minutes after charge/discharge)

- Ambient temperature recording (20°C±2°C ideal)

Long-Term Performance Optimization and Emerging Li-ion C Battery Technologies

Voltage Management Strategies for Extended Battery Lifespan

Advanced voltage management can triple Li-ion C battery cycle life. Research shows maintaining charge between 20-80% (3.0V-4.1V) instead of full 0-100% cycles reduces degradation by 60%. Implement these strategies:

| Strategy | Voltage Range | Cycle Life Improvement |

|---|---|---|

| Partial cycling | 3.3V-4.0V | 400% increase (3000+ cycles) |

| Temperature compensation | +0.03V/°C below 20°C | Prevents lithium plating |

| Adaptive charging | Dynamic voltage adjustment | 30% capacity retention after 5 years |

Advanced Battery Chemistry Developments

Next-gen Li-ion C batteries are pushing voltage boundaries:

- Silicon-anode batteries: Operating at 4.4V (vs standard 4.2V) with 20% higher energy density

- Lithium titanate (LTO): Lower 2.4V nominal voltage but 20,000+ cycle lifespan

- Solid-state prototypes: Demonstrating stable 5V operation with ceramic electrolytes

Environmental and Safety Considerations

Proper voltage management impacts sustainability:

- Overdischarge prevention: Below 2.5V causes copper dissolution, creating hazardous waste

- Optimal storage voltage: 3.7V reduces fire risk by 80% compared to 4.2V storage

- Recycling preparation: Discharge to 2.9V (±0.1V) meets international transport safety standards

Cost-Benefit Analysis of Voltage Optimization

Implementing professional voltage monitoring systems yields significant ROI:

| Investment | Cost | Benefit | Payback Period |

|---|---|---|---|

| Smart BMS | $25/battery | 40% longer lifespan | 8 months |

| Voltage logging system | $500 setup | 15% efficiency gain | 11 months |

Future Trends in Voltage Management

Emerging technologies are transforming voltage monitoring:

- AI-powered prediction: Algorithms analyzing voltage patterns to forecast failures 50+ cycles in advance

- Self-healing circuits: Microcontrollers that automatically adjust charge voltage based on cell age

- Quantum voltage sensors: Laboratory prototypes achieving 0.001V precision for research applications

System Integration and Advanced Voltage Monitoring Techniques for Li-ion C Batteries

Voltage Monitoring in Complex Battery Arrays

Modern battery systems often combine multiple Li-ion C cells in series-parallel configurations, requiring sophisticated voltage balancing. A typical 48V energy storage system using 13S4P arrangement (13 series, 4 parallel) must maintain cell voltages within 0.02V tolerance to prevent:

- Capacity throttling: Weakest cell determines total system capacity

- Thermal runaway risk: Voltage differences >0.3V create dangerous imbalance

- Efficiency losses: Each 0.1V mismatch causes 2-3% energy loss

Professional-Grade Voltage Monitoring Systems

Advanced battery management systems (BMS) employ multiple monitoring techniques:

| Technology | Accuracy | Sampling Rate | Best Application |

|---|---|---|---|

| Isolated Σ-Δ ADC | ±0.5mV | 10Hz | Laboratory testing |

| Successive Approximation | ±2mV | 1kHz | EV battery packs |

| Voltage-to-Frequency | ±5mV | 100Hz | Solar storage |

Integration with Power Management Systems

Proper voltage monitoring integration requires:

- Galvanic isolation: Optocouplers or magnetic isolation for high-voltage systems

- Dynamic compensation: Adjusting for voltage drop across busbars and connectors

- Temperature correlation: Applying NTC thermistor data to voltage readings

Advanced Diagnostic Techniques

Professional technicians use voltage analysis to detect:

- Micro-shorts: Identified by >0.5% overnight voltage drop

- Electrolyte dry-out: Shows as increasing internal resistance during voltage sag tests

- SEI layer growth: Detected through charge voltage curve analysis

System Optimization Strategies

Maximize performance through:

- Adaptive voltage thresholds: Adjusting cutoffs based on cell age (e.g., increasing EOL voltage from 3.0V to 3.2V after 500 cycles)

- Dynamic balancing: Transferring energy between cells during operation

- Predictive maintenance: Using voltage trend analysis to schedule replacements

Comprehensive Performance Validation and Risk Management for C-size Li-ion Battery Systems

Advanced Voltage Validation Protocols

Professional-grade battery validation requires multi-stage voltage testing to ensure reliability. A complete test cycle includes:

| Test Phase | Voltage Parameters | Acceptance Criteria | Duration |

|---|---|---|---|

| Initial Characterization | 2.5V-4.2V full sweep | ±1% of spec voltage | 24 hours |

| Cycle Aging | 3.0V-4.1V @ 1C | <5% capacity drop after 100 cycles | 2 weeks |

| Environmental Stress | -20°C to 60°C range | Voltage recovery within 2% | 72 hours |

System-Wide Risk Assessment Matrix

Comprehensive voltage-related risk analysis should evaluate:

- Overcharge scenarios: 4.25V+ operation accelerates electrolyte decomposition by 300%

- Voltage reversal: In stacked configurations, can cause 50°C+ localized heating

- Transient spikes: Inductive loads may generate 5V+ surges exceeding cell ratings

Advanced Quality Assurance Techniques

Industrial battery validation employs:

- Statistical process control: Tracking voltage distribution across production batches

- HALT testing: Accelerated aging at 1.5x nominal voltage

- X-ray inspection: Detecting internal shorts affecting voltage stability

- Electrochemical spectroscopy: Analyzing voltage-frequency response

Long-Term Performance Optimization

Maximize system lifespan through:

- Adaptive voltage windows: Gradually reducing max charge voltage from 4.2V to 4.1V after 300 cycles

- Dynamic balancing: Active charge transfer between cells maintaining <0.5% voltage deviation

- Predictive algorithms: Using voltage decay patterns to forecast end-of-life 50+ cycles in advance

Comprehensive Failure Analysis Protocol

When investigating voltage-related failures:

- Document resting voltage after 24-hour stabilization

- Measure internal resistance at multiple SOC points

- Analyze voltage recovery curves after load removal

- Compare to baseline characteristics from initial testing

- Perform destructive physical analysis if warranted

Conclusion

Understanding Li-ion C battery voltage characteristics is essential for optimizing performance, safety, and lifespan. From nominal voltage ranges (3.6V-3.7V) to critical thresholds (2.5V-4.2V), we’ve explored how voltage impacts capacity, discharge curves, and long-term reliability.

Advanced monitoring techniques, proper charging protocols, and system integration strategies all contribute to maximizing your battery investment. Remember that voltage management isn’t static – it requires ongoing attention as batteries age and technology evolves.

For best results, implement the voltage monitoring practices discussed and consider investing in professional-grade testing equipment. By mastering these voltage fundamentals, you’ll unlock superior battery performance across all your applications.

Frequently Asked Questions About Li-ion C Battery Voltage

What is the ideal voltage range for storing Li-ion C batteries?

The optimal storage voltage for Li-ion C batteries is 3.7V-3.8V (40-60% charge). This range minimizes chemical degradation while preventing capacity loss. Research shows batteries stored at 4.2V lose 20% capacity in 6 months, while those at 3.7V lose only 2-4%. For long-term storage (6+ months), check voltage quarterly and recharge to 3.8V if it drops below 3.5V.

How does temperature affect Li-ion C battery voltage?

Temperature significantly impacts voltage performance. At -20°C (-4°F), voltage drops 15-20% due to slowed ion movement, while at 45°C (113°F), voltage readings increase 5-10%.

Always measure voltage at room temperature (20°C±2°C) for accurate comparisons. High temperatures combined with full charge (4.2V) accelerate electrolyte decomposition by 300%.

Why does my battery voltage drop suddenly under load?

This voltage sag occurs due to internal resistance. A quality Li-ion C battery like the Samsung 35E typically sags 0.3V at 2C load. Excessive sag (>0.5V at 1C) indicates aging cells. Measure no-load voltage after 1 hour rest – if it recovers within 0.1V of pre-load value, the sag is normal.

How can I accurately measure Li-ion C battery voltage?

Use a 4-wire Kelvin measurement for professional accuracy (±0.1%). For field measurements, a 1% tolerance multimeter (like Fluke 87V) works well. Always measure after 15 minutes rest post-charge/discharge. For battery packs, measure individual cells – variations >0.1V require rebalancing.

What voltage indicates a Li-ion C battery needs replacement?

Replace when:

- Fully charged voltage <4.15V after proper charging

- Voltage drops below 3.0V under minimal load

- Capacity falls below 80% of original rating

For critical applications (medical devices), replace at 85% capacity retention.

Can I recover an over-discharged Li-ion C battery?

If voltage is 2.5V-3.0V, use a charger with “recovery mode” (like Liitokala Lii-500) at 0.1C current. Below 2.5V, success rates drop below 30%. Never charge swollen or hot batteries – recycle them properly. Successful recovery requires multiple slow charge-discharge cycles.

How does series/parallel configuration affect voltage management?

In series connections, voltage adds while capacity stays equal (e.g., 3 cells = 10.8V nominal). Parallel connections maintain voltage but add capacity. Always use:

- Matched cells (<0.05V difference)

- Balanced charging system

- Temperature monitoring

Unbalanced packs can develop dangerous voltage differentials (>0.5V).

What’s the difference between resting voltage and loaded voltage?

Resting voltage (measured after 1+ hour idle) shows true state-of-charge, while loaded voltage reflects performance under stress. A healthy battery showing 3.7V at rest might drop to 3.4V under 1C load. Large discrepancies (>0.5V drop at 0.5C) indicate high internal resistance.