Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

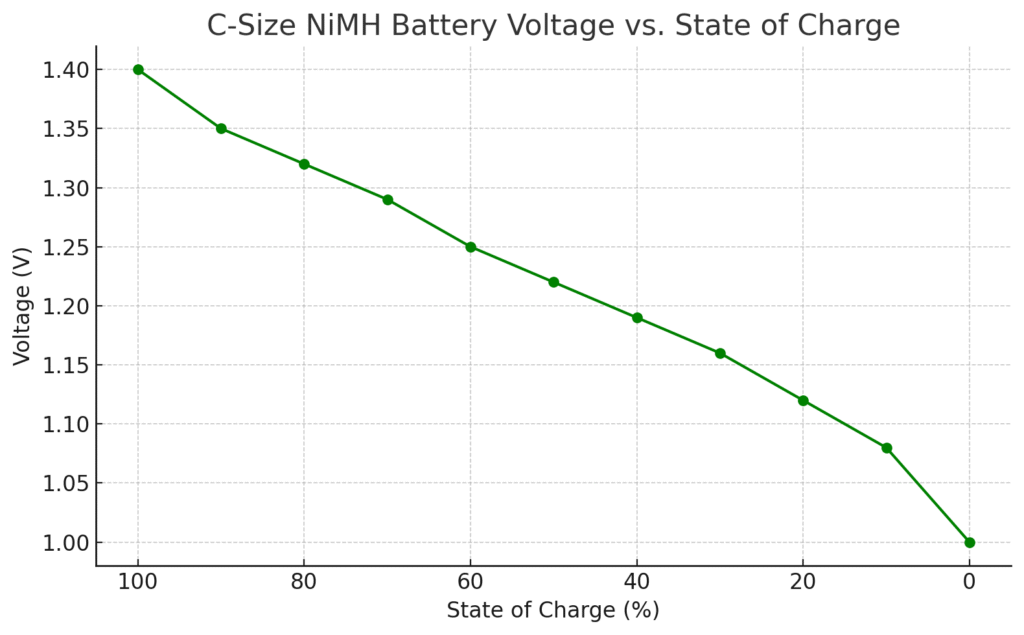

Did you know a fully charged NiMH C battery holds 1.4V, but its voltage drops rapidly under load? Understanding voltage behavior is critical for optimizing battery life and device performance.

Many assume all rechargeable batteries behave like alkalines, but NiMH chemistry has unique voltage characteristics that impact everything from runtime to charging efficiency. Whether you’re powering flashlights, toys, or medical devices, misinterpreting voltage can lead to premature failures or wasted energy.

Best C-Size NiMH Batteries for Reliable Power

Eneloop Panasonic BK-3HCCA8BA 3000mAh NiMH C Batteries

Panasonic’s Eneloop Pro series offers high-capacity 3000mAh cells with low self-discharge, retaining 85% charge after 1 year. Pre-charged with solar energy, these batteries deliver consistent voltage for high-drain devices like flashlights and RC toys. Their 15-year lifespan makes them a sustainable choice.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro AA high…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AA rechargeable batteries up…

- PRE-CHARGED AND READY TO USE: eneloop pro AA and AAA rechargeable batteries…

Amazon Basics Pre-Charged Rechargeable C Batteries (2500mAh)

With 2500mAh capacity and 1000+ recharge cycles, these budget-friendly NiMH C cells are ideal for household gadgets. They maintain a stable 1.2V output under moderate loads and come pre-charged for immediate use. Perfect for clocks, remotes, and low-drain electronics.

- One 4-pack of pre-charged C-cell rechargeable batteries (5000mAh/Ni-MH)

- Long battery life; extremely gradual self-discharge; maintains 80% capacity…

- Comes pre-charged and ready to use; can be recharged 1000 times with…

Tenergy Premium 5000mAh NiMH C Batteries

Engineered for extreme performance, Tenergy’s 5000mAh cells excel in high-demand applications like professional audio equipment and medical devices. Their flat discharge curve ensures prolonged voltage stability, while the industrial-grade construction resists overheating during rapid charging.

- HIGH POWER ENERGY – Tenergy’s Premium rechargeable NiMH C Battery Packs…

- HIGH-TECH RELIABILITY – These Premium C batteries consistently deliver high…

- PREMIUM POWER ANYWHERE – These rechargeable C cell batteries are enhanced…

Pro Tip: Pair these with a smart charger (like the La Crosse BC700) to monitor voltage trends and maximize battery health.

C-Size NiMH Battery Voltage Characteristics

C-Size NiMH Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal vs. Actual Voltage: What Your Devices Really Need

While NiMH C batteries are labeled with a 1.2V nominal voltage, their actual voltage fluctuates significantly during use. A freshly charged cell measures 1.4-1.45V, which quickly stabilizes to 1.2-1.3V under load.

This contrasts with alkaline batteries that start at 1.5V but experience steady voltage drop. Devices designed for alkalines may misinterpret NiMH voltage levels, causing early “low battery” warnings even when substantial capacity remains.

The Complete Voltage Discharge Curve

A typical NiMH C battery follows this voltage pattern during discharge:

- Initial peak (1.4V): Lasts only minutes after full charge

- Working plateau (1.25-1.3V): Where 80% of capacity is delivered

- Knee point (~1.1V): Signals imminent depletion

- Cutoff voltage (0.9V): Minimum safe level to prevent cell damage

For example, a 3000mAh NiMH C battery powering a 500mA load will maintain above 1.2V for approximately 5 hours before the steep drop-off.

Temperature’s Impact on Voltage Performance

NiMH batteries exhibit unique voltage responses to temperature changes:

- Cold environments (0-10°C): Voltage appears artificially high but capacity drops up to 30%

- Room temperature (20°C): Delivers rated voltage and capacity

- Hot conditions (35°C+): Voltage sags faster, reducing effective runtime

This explains why flashlight performance varies between winter camping (shorter runtime despite normal voltage readings) and summer use (rapid voltage decline in heat).

Voltage Recovery: The “Resting” Phenomenon

NiMH batteries exhibit temporary voltage rebound when loads are removed—a discharged cell showing 0.9V under load might read 1.1V after 30 minutes rest. This characteristic is crucial when:

- Testing batteries (always check under load)

- Designing battery cutoff circuits

- Troubleshooting intermittent device shutdowns

Smart battery testers account for this by applying simulated loads during measurement.

Practical Tip: For critical applications like emergency lighting, measure voltage under typical operating current rather than relying on open-circuit readings.

How to Read and Use a C-Size NiMH Battery Voltage Chart

Interpreting Voltage vs. Capacity Relationships

Professional battery voltage charts reveal more than just numbers – they tell the story of your battery’s health and remaining capacity. A high-quality NiMH C battery will show:

- 100% capacity: 1.4V (fresh off charger), stabilizing to 1.3V within 15 minutes

- 50% capacity: 1.2V under moderate load (500mA for standard C cells)

- 20% capacity: 1.1V – the critical point where recharge should begin

For example, when testing a Tenergy 5000mAh cell powering a 2W LED light drawing 1.67A, you’d expect these voltage readings at room temperature.

Step-by-Step Voltage Measurement Protocol

- Prepare your tools: Use a digital multimeter with 0.01V resolution (like the Fluke 115)

- Simulate real conditions: Measure during actual use or connect a load resistor matching your device’s current draw

- Record properly: Take readings at 15-minute intervals for discharge curves

- Account for temperature: Add 0.03V to readings for every 10°C below 20°C

Common Voltage Chart Misinterpretations

Many users make these critical mistakes when consulting voltage charts:

- Mixing charge states: Comparing resting voltage (no load) to loaded voltage readings

- Ignoring load current: A battery showing 1.2V at 100mA may drop to 1.0V at 2A

- Overlooking cycle count: After 500+ cycles, a battery’s voltage may drop 0.1V across all states

Advanced Application: Predicting Runtime

Using voltage charts, you can calculate remaining runtime with this formula:

(Current Voltage – Cutoff Voltage) × Capacity / Load Current

For a 4000mAh cell at 1.25V powering a 800mA device: (1.25V-0.9V) × 4000mAh/800mA = 1.75 hours remaining.

Pro Tip: Create custom voltage charts for your specific devices by logging voltage during controlled discharge tests – this accounts for your exact usage patterns.

Advanced C-Size NiMH Battery Voltage Analysis and Optimization

Voltage Behavior Under Different Load Conditions

NiMH C batteries exhibit distinct voltage responses based on current demands:

| Load Current | Voltage Behavior | Practical Implications |

|---|---|---|

| Low (≤200mA) | Stable 1.25-1.3V for 90% of discharge | Ideal for clocks/remote controls |

| Medium (500-1000mA) | Gradual drop from 1.3V to 1.1V | Common in portable radios |

| High (≥2000mA) | Rapid initial drop to 1.15V, steep decline | Affects power tools performance |

Memory Effect vs. Voltage Depression

While often confused, these phenomena impact voltage differently:

- Memory Effect: Occurs from repeated partial discharges, causing voltage to “remember” the discharge point (rare in modern NiMH)

- Voltage Depression: Temporary voltage drop from crystalline formation, reversible with deep cycling

Example: A battery consistently recharged at 50% may show 0.1V lower output until fully discharged/recharged.

Precision Charging Based on Voltage Signatures

Smart chargers use voltage characteristics to determine charge completion:

- -ΔV Detection: Looks for 5-10mV voltage drop after peak

- dT/dt Method: Monitors temperature rise rate

- Zero ΔV: For slow charging (0.1C rate)

Voltage-Based Battery Health Assessment

Diagnose aging batteries through voltage patterns:

- Healthy Cell: Maintains >1.2V under load for 80% of capacity

- Aging Cell: Voltage sags below 1.1V early in discharge

- Failed Cell: Can’t sustain 0.9V under minimal load

Expert Tip: For critical applications, measure internal resistance (using a YR1035+ tester) alongside voltage – resistance above 150mΩ indicates impending failure regardless of voltage readings.

C-Size NiMH Battery Voltage Management in Real-World Applications

Voltage Matching for Series and Parallel Configurations

When combining NiMH C batteries, voltage behavior becomes critical:

- Series connections: Voltage adds (3 cells = 3.6V nominal) but the weakest cell dictates performance. A 0.1V mismatch can cause 20% capacity loss

- Parallel connections: Maintains voltage (1.2V) but requires matched internal resistance (±5%) to prevent current hogging

Example: In a 4-cell flashlight, one depleted cell at 1.0V will drag the entire string down prematurely.

Voltage-Based Charging Protocols

Different charging methods use voltage characteristics differently:

- Fast Charge (1C rate): Terminates at -ΔV detection (5-10mV drop from peak voltage)

- Trickle Charge (0.05C): Maintains constant voltage (1.45V/cell) after full charge

- Pulse Charge: Monitors voltage recovery between pulses for state-of-charge analysis

Voltage Thresholds for Common Devices

Understanding device cutoff voltages prevents premature replacements:

- LED Flashlights: Typically cut off at 0.9V per cell

- RC Vehicles: Often set at 1.0V per cell under load

- Medical Devices: May have strict 1.1V minimums for safety

Temperature Compensation Techniques

Advanced users adjust voltage readings for temperature:

- Cold environments: Add 0.003V/°C below 20°C to readings

- Hot environments: Subtract 0.005V/°C above 30°C

Example: A battery reading 1.25V at 5°C actually has equivalent performance to 1.19V at 20°C.

Professional Insight: For mission-critical applications, implement voltage logging (using devices like the BatteryMINDer) to track long-term performance degradation and predict failure points before they occur.

Long-Term C-Size NiMH Battery Voltage Maintenance and Future Trends

Voltage Stabilization Through Proper Cycling

Maintaining optimal voltage performance requires strategic cycling:

| Cycle Type | Voltage Impact | Recommended Frequency |

|---|---|---|

| Deep Discharge (to 0.9V) | Resets voltage depression, +0.1V recovery | Every 20-30 cycles |

| Refresh Cycle (discharge/charge) | Balances cell voltages in packs | Every 3-6 months |

| Conditioning (0.05C slow charge) | Improves voltage stability | Annually for storage |

Voltage-Based Storage Strategies

Proper storage voltage significantly impacts longevity:

- Short-term (1-3 months): Store at 1.3V/cell (40% charge)

- Medium-term (3-12 months): Store at 1.25V/cell (30% charge)

- Long-term (1+ years): Store at 1.2V/cell (20% charge) with temperature control

Example: Batteries stored at full charge lose 0.1V/month, while properly stored cells maintain voltage within 0.02V/month.

Emerging Voltage Management Technologies

Future developments in NiMH voltage control include:

- Smart voltage regulators: Active balancing circuits that maintain optimal voltage under varying loads

- AI-powered charging: Algorithms that predict voltage drop patterns based on usage history

- Nano-coated electrodes: New materials that reduce voltage sag during high-current discharges

Environmental and Safety Considerations

Voltage monitoring impacts sustainability and safety:

- Over-discharge prevention: Maintaining >0.9V prevents harmful copper dendrite formation

- Recycling indicators: Voltage below 0.5V after charging signals end-of-life

- Temperature correlation: Every 10°C above 25°C doubles voltage decay rate

Expert Recommendation: Implement a voltage logbook tracking each cell’s performance over time – this historical data reveals degradation patterns and helps predict optimal replacement timing before critical failures occur.

Advanced C-Size NiMH Battery Voltage Monitoring and System Integration

Precision Voltage Measurement Techniques

Accurate voltage monitoring requires specialized approaches:

- 4-wire Kelvin measurement: Eliminates lead resistance errors for lab-grade precision (±0.1%)

- Dynamic load testing: Measures voltage under pulsed loads (e.g., 1A pulses every 5 seconds)

- Peak detection circuits: Captures instantaneous voltage drops during high-current surges

Example: When testing for RC car applications, pulsed measurements reveal voltage behavior during acceleration spikes that steady-state tests miss.

Voltage Monitoring in Battery Management Systems

Modern BMS solutions handle NiMH voltage characteristics through:

- Adaptive voltage thresholds: Adjusts cutoff points based on temperature and cycle count

- Per-cell monitoring: Tracks individual cell voltages in series configurations

- Drift compensation: Automatically adjusts for long-term voltage sensor calibration drift

Integration with Power Systems

NiMH voltage profiles affect system design considerations:

- DC-DC converter matching: Must accommodate 1.4V-0.9V input range

- Voltage hysteresis: Power path designs must account for voltage rebound effects

- Mixed chemistry systems: Special circuits required when combining with lithium buffers

Diagnostic Voltage Patterns

Characteristic voltage signatures indicate specific issues:

| Voltage Pattern | Diagnosis | Solution |

|---|---|---|

| Rapid initial drop >0.3V | High internal resistance | Replace battery |

| Stair-step discharge | Memory effect | Deep cycle refresh |

| Unstable fluctuations | Damaged separator | Immediate replacement |

Professional Tip: For critical systems, implement redundant voltage monitoring with at least two independent measurement circuits to prevent single-point failures in state-of-charge calculations.

Comprehensive C-Size NiMH Battery Voltage Management Framework

System-Wide Voltage Optimization Strategies

Implementing a holistic voltage management approach requires addressing multiple interdependent factors:

| Component | Voltage Consideration | Optimization Technique |

|---|---|---|

| Charging System | Termination voltage accuracy (±10mV) | Use precision voltage references with 0.1% tolerance |

| Load Circuit | Minimum operating voltage | Implement buck-boost regulators with 0.8V input capability |

| Monitoring System | Voltage sampling rate | 10Hz minimum for dynamic load applications |

Advanced Performance Validation Protocol

Professional-grade voltage validation involves:

- Baseline characterization: 72-hour voltage decay test at controlled 20°C

- Load profile simulation: Replicating actual device current patterns

- Temperature cycling: -20°C to +50°C voltage stability assessment

- Cycle life testing: Tracking voltage drop per 100 cycles

Risk Assessment Matrix

Critical voltage-related failure modes and mitigations:

- Overcharge risk (≥1.48V/cell): Implement redundant voltage cutoff

- Voltage reversal in series strings: Add parallel balancing circuits

- Deep discharge (≤0.8V): Use latching protection circuits

- Voltage drift: Annual calibration of monitoring equipment

Quality Assurance Standards

Industrial voltage performance benchmarks:

- Initial voltage consistency: ±2% cell-to-cell variation

- Cycle life voltage retention: ≤15% drop after 500 cycles

- Load regulation: ≤5% voltage dip during current spikes

- Temperature coefficient: ≤0.05%/°C voltage variation

Enterprise-Level Recommendation: Deploy automated voltage tracking systems that log every charge/discharge cycle with environmental data, enabling predictive maintenance and early detection of performance degradation patterns before they impact operations.

Conclusion

Understanding NiMH C battery voltage characteristics is essential for optimizing performance and maximizing battery life. Throughout this guide, we’ve explored voltage discharge curves, load behaviors, temperature effects, and advanced monitoring techniques.

From interpreting voltage charts to implementing system-wide management strategies, proper voltage awareness enables smarter battery usage across all applications.

Remember these key takeaways: NiMH cells deliver stable 1.2V nominal voltage but require different handling than alkalines; voltage monitoring under load provides the most accurate state-of-charge assessment; and proper storage voltages significantly impact longevity. Whether you’re powering household devices or critical equipment, applying these voltage principles will ensure reliable operation.

Take action today: Start by testing your batteries’ voltage under typical load conditions and create a baseline performance log. This simple practice will help you detect early signs of degradation and make informed decisions about maintenance and replacement.

Frequently Asked Questions About NiMH C Battery Voltage

What voltage should a fully charged NiMH C battery show?

A freshly charged NiMH C cell will measure 1.4-1.45V immediately after charging, settling to 1.35V within 30 minutes. This differs from the nominal 1.2V rating, which represents the average voltage during discharge.

For accurate readings, measure voltage 2 hours post-charge at room temperature (20-25°C). High-quality chargers like the Panasonic BQ-CC17 maintain precise termination voltages to prevent overcharging.

How does NiMH voltage compare to alkaline batteries?

While alkaline C cells start at 1.5V and gradually decline, NiMH batteries begin higher (1.4V) but quickly stabilize at 1.2-1.3V for most of their discharge cycle. This voltage profile means devices designed for alkalines may show “low battery” warnings prematurely.

Some electronics compensate for this difference, while others may require voltage-boosting circuits for optimal performance with NiMH batteries.

Why does my NiMH battery voltage drop quickly under load?

Rapid voltage sag indicates either high internal resistance (common in aged batteries) or excessive current draw. A healthy 5000mAh NiMH C cell should maintain >1.1V at 2A loads.

If voltage plunges below 1V immediately, test capacity with a controlled discharge cycle. For high-drain devices like RC cars, use low-resistance cells like the Tenergy Centura with optimized electrode design.

How can I accurately measure remaining capacity using voltage?

Create a discharge curve chart for your specific batteries by:

- Fully charging then resting cells for 2 hours

- Applying constant current (e.g., 500mA for standard C cells)

- Recording voltage every 15 minutes until reaching 0.9V

Match field measurements to your chart, remembering that 1.25V typically indicates ~50% capacity remaining at moderate loads.

At what voltage should I recharge NiMH C batteries?

Recharge when cells reach 1.1V under typical operating loads. Deep discharges below 0.9V cause permanent damage by creating copper dendrites. For critical applications, set device cutoffs at 1.15V. Smart chargers like the Opus BT-C3100 automatically detect voltage thresholds and apply appropriate charging algorithms based on cell condition.

Can I mix NiMH C batteries with different voltages?

Never mix cells with >0.05V difference in open-circuit voltage. In series configurations, weaker cells reverse charge when depleted, causing permanent damage.

For parallel use, voltage differences >0.02V create current imbalances. Always capacity-match and voltage-match cells when building battery packs, using professional analyzers like the West Mountain Radio CBA for precise measurements.

Why do my NiMH batteries show different voltages after charging?

Voltage variations up to 0.03V are normal, but larger differences indicate:

- Uneven aging (cycle older cells separately)

- Temperature variations during charging (keep cells at equal spacing)

- Charger channel inconsistencies (verify with multimeter)

For premium cells like Eneloop Pros, expect ≤0.01V variation when new.

How does temperature affect NiMH battery voltage?

Voltage decreases approximately 0.003V/°C below 20°C and increases similarly above. However, cold temperatures simultaneously increase internal resistance, creating apparent voltage “recovery” when load is removed.

In sub-zero conditions, keep batteries insulated and expect 20-30% capacity reduction despite normal voltage readings. High-quality cells like AmazonBasics perform better in extreme temperatures than generic brands.