Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiCd D battery can lose up to 30% of its voltage within the first hour of use under heavy loads? Understanding voltage behavior is critical for maximizing performance in devices like flashlights, radios, or emergency backup systems.

Many assume all D batteries deliver consistent power, but nickel-cadmium (NiCd) chemistry has unique discharge characteristics that impact real-world usability.

Best D-Size NiCd Battery for Reliable Power

Energizer Rechargeable D Battery

With a 2,500 mAh capacity and stable 1.2V output, these industrial-grade batteries excel in high-drain devices like spotlights or power tools. Their rugged steel shell resists leaks, and they endure 1,000+ charge cycles—ideal for users needing long-term reliability.

- 2-pack of Energizer Recharge Universal 2500 mAh NiMH D rechargeable…

- Each battery can be charged hundreds of times, with a charge that can last…

- Extended Life Composition ensures up to 3-year usable battery life under…

Tenergy AA Rechargeable Battery

Boasting an ultra-high 1000mAH rating, Tenergy’s cells power heavy-duty applications (e.g., medical carts or marine equipment) for extended periods. The low self-discharge rate (15% monthly) ensures readiness, even after storage.

- Multiple uses – Popularly used for solar powered garden lights, landscaping…

- As a rechargeable high capacity AA battery, it is built with 1000mAh…

- Tenergy 1.2V AA NiCd Rechargeable Batteries measures 14.2 mm (Diameter) x…

Cerepros 4-Pack BK

Panasonic’s premium 3,000 mAh batteries feature a memory-effect-resistant design, perfect for cyclic use in solar setups or robotics. Their -20°C to 50°C operating range makes them versatile for extreme environments.

- 1.2V 300mAh

- Ni-MH

- Battery cell composition: NiMh

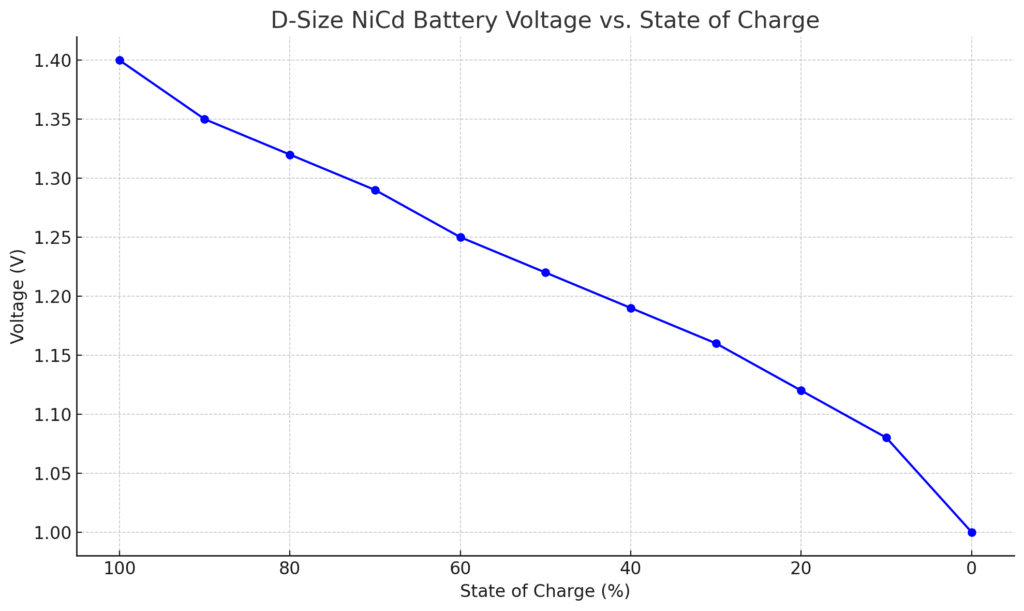

D-Size NiCd Battery Voltage Characteristics

NiCd (Nickel-Cadmium) D batteries operate differently from alkaline or lithium-ion counterparts, with unique voltage behaviors that impact performance. A fully charged NiCd D cell starts at 1.4V but quickly stabilizes to 1.2V under load—its nominal voltage.

Unlike alkaline batteries, which decline steadily, NiCd maintains near-constant voltage for most of its discharge cycle before sharply dropping at depletion. This “flat discharge curve” makes them ideal for devices requiring stable power, such as emergency lighting or industrial sensors.

D-Size NiCd Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Key Voltage Stages and Their Implications

The voltage of a NiCd D battery follows predictable phases during discharge:

- Initial Peak (1.4V–1.3V): Immediately after charging, voltage briefly exceeds nominal levels due to surface charge. This stabilizes within minutes of use.

- Working Range (1.25V–1.1V): The battery delivers 80% of its capacity here. Devices function optimally in this zone.

- Endpoint Drop (Below 1.0V): Voltage plummets rapidly, signaling exhaustion. Continued use risks deep discharge, damaging the battery.

Real-World Voltage Performance Factors

Actual voltage output varies based on:

- Load Current: High-drain devices (e.g., power tools) may cause temporary voltage sag. A 6,000mAh NiCd D cell under 2A load typically shows 1.15V, recovering to 1.2V when idle.

- Temperature: Below 0°C, voltage drops by ~0.2V. At 50°C, it rises slightly but accelerates capacity loss.

- Age/Cycles: After 500+ charges, internal resistance increases, reducing usable voltage under load by 10–15%.

Example: A security system using NiCd D batteries might read 1.3V at rest but dip to 1.18V when activating an alarm siren. This is normal operational variance, not a defect.

Common Misconceptions Debunked

Myth: “1.2V means the battery is weak compared to alkaline’s 1.5V.”

Reality: NiCd’s lower nominal voltage doesn’t equate to less power. Its ability to sustain high currents without voltage collapse (unlike alkaline) makes it superior for heavy loads.

For accurate voltage assessment, always test under the device’s typical load conditions—not just with a multimeter’s no-load reading.

How to Accurately Test NiCd D Battery Voltage

Proper voltage testing is critical for assessing NiCd D battery health, but standard multimeter checks often yield misleading results. Unlike simple voltage readings, accurate testing requires understanding load conditions, surface charge effects, and proper equipment setup.

Follow this professional testing methodology to get reliable data for your specific application.

Step-by-Step Voltage Measurement Process

- Prepare the Battery:

Fully charge the battery using a smart NiCd charger, then let it rest for 2 hours. This dissipates surface charge that can falsely inflate readings by 0.1-0.15V. - Select Testing Equipment:

Use a digital multimeter with 0.01V resolution (e.g., Fluke 115) and an appropriate load resistor. For D cells, a 2.2Ω/10W resistor simulates a ~550mA load – typical for many devices. - Apply Load During Testing:

Connect the resistor across the battery terminals for 30 seconds before taking measurements. This provides the working voltage rather than open-circuit voltage. - Interpret Results:

Compare your reading to these benchmarks:- 1.25V-1.20V = Excellent condition (90-100% capacity)

- 1.15V-1.10V = Moderate wear (60-80% capacity)

- Below 1.05V = Requires replacement or reconditioning

Advanced Testing Scenarios

For mission-critical applications like medical equipment, conduct a discharge capacity test:

1. Fully charge the battery

2. Discharge through a constant current load (e.g., 1A for 6000mAh cells)

3. Time how long voltage stays above 1.1V

4. Compare to manufacturer’s rated runtime

Professional Tip: Always test at room temperature (20-25°C). Cold batteries may show 10-15% lower voltage temporarily, while hot environments can mask underlying capacity loss.

Troubleshooting Common Testing Issues

Problem: Inconsistent readings between tests

Solution: Ensure consistent rest periods between charges and tests. NiCd batteries exhibit “voltage recovery” where resting voltage rises after load removal.

Problem: New battery showing low voltage

Diagnosis: May need 3-5 full charge/discharge cycles to reach peak performance due to initial formation of internal chemical structures.

For battery banks (multiple D cells in series), test each cell individually. A single weak cell (below 1.0V under load) can drag down entire pack performance by 20-30%.

D-Size NiCd Battery Voltage Behavior Under Different Conditions

NiCd D batteries exhibit unique voltage responses to environmental and usage factors that significantly impact performance. Understanding these patterns helps optimize battery selection for specific applications and predict real-world behavior beyond nominal specifications.

Temperature Effects on Voltage Output

| Temperature Range | Voltage Impact | Capacity Impact | Practical Implications |

|---|---|---|---|

| -20°C to 0°C | 0.15-0.25V drop | 30-50% reduction | Require battery heaters for critical applications |

| 20°C to 40°C | 0.05V increase | 5-10% increase | Ideal operating range |

| Above 50°C | 0.1V increase | 20% permanent loss per 100 cycles | Avoid prolonged exposure |

Discharge Rate Voltage Characteristics

NiCd D cells demonstrate distinct voltage profiles based on discharge current:

- Low Rate (0.1C/500mA): Maintains 1.2V for 90% of discharge cycle with gradual decline

- Medium Rate (0.5C/2.5A): Stable 1.15V plateau followed by sharp drop at 15% remaining capacity

- High Rate (1C/5A+): Immediate voltage sag to 1.05V, recovering partially during use

Example: In power tools, the initial voltage sag during motor startup is normal NiCd behavior, not necessarily indicating a weak battery.

Memory Effect and Voltage Depression

Improper charging can cause voltage depression – where batteries “remember” partial discharge cycles and deliver reduced voltage prematurely. This occurs when:

- Batteries are repeatedly recharged after only partial discharge (30-70%)

- Using non-smart chargers that don’t fully condition cells

- Operating in the same narrow voltage range for extended periods

Solution: Perform full discharge/charge cycles monthly using a charger with refresh function (like the Maha MH-C808M). This dissolves crystalline formations restoring normal voltage output.

Professional Maintenance Tips

For optimal voltage performance:

- Store at 40% charge (1.0-1.1V) in 15-25°C environments

- Equalize series-connected batteries monthly by individually charging to 1.55V

- Clean contacts with isopropyl alcohol to prevent 0.05-0.1V connection losses

Optimizing NiCd D Battery Performance and Lifespan

Maximizing the service life of NiCd D batteries requires understanding advanced charging techniques, proper storage protocols, and recognizing end-of-life indicators. These industrial-grade cells can deliver 500-1000 cycles when properly maintained, but improper care can reduce lifespan by 70%.

Advanced Charging Techniques for Voltage Stability

Proper charging directly impacts voltage performance and cycle life. Follow these professional charging protocols:

- Delta-V Termination: The optimal method where charging stops when voltage drops 5-10mV per cell (detects full charge)

- Temperature Cutoff: Secondary protection stopping at 45°C to prevent overcharge damage

- Trickle Charge: Maintain at 0.03-0.05C rate for standby applications (e.g., emergency lighting)

Critical Note: Fast charging (above 0.5C) reduces cycle life by 20-30% and should only be used when absolutely necessary.

Storage Best Practices

Long-term storage significantly affects NiCd voltage characteristics:

- Charge State: Store at 40% charge (1.0-1.1V) to minimize crystalline formation

- Environment: Maintain 10-25°C with <50% humidity – every 10°C above 30°C doubles self-discharge

- Reconditioning: After 6+ months storage, perform 3 full discharge/charge cycles before use

End-of-Life Indicators and Replacement Timing

Recognize these voltage-related failure signs:

| Symptom | Voltage Reading | Diagnosis |

|---|---|---|

| Rapid voltage drop | Falls below 1.0V within minutes of use | High internal resistance |

| Failure to reach full charge | Peaks at <1.45V during charging | Capacity loss >40% |

Safety Considerations

NiCd batteries require special handling due to their chemistry:

- Never discharge below 0.9V per cell to prevent polarity reversal

- Ventilate charging areas – gassing occurs above 1.47V per cell

- Dispose properly at certified facilities – cadmium is toxic

For critical applications, implement voltage monitoring systems that alert when any cell in a bank drops below 1.1V under load.

D-Size NiCd Battery Economics and Environmental Considerations

While D-size NiCd batteries remain popular for industrial applications, understanding their total cost of ownership and environmental impact is crucial for informed decision-making. This analysis compares NiCd technology with alternatives and explores sustainable usage practices.

Total Cost of Ownership Analysis

| Cost Factor | NiCd D Battery | NiMH Alternative | Lithium-ion Alternative |

|---|---|---|---|

| Initial Cost | $8-$12 per cell | $10-$15 per cell | $25-$40 per cell |

| Cycle Life | 500-1000 cycles | 300-500 cycles | 500-2000 cycles |

| Energy Cost/kWh | $0.35-$0.50 | $0.50-$0.70 | $0.20-$0.40 |

| Maintenance Costs | High (conditioning required) | Moderate | Low |

Key Insight: While NiCd has lower upfront costs than lithium-ion, its higher maintenance and shorter lifespan in deep-cycle applications often make it more expensive long-term for daily use scenarios.

Environmental Impact and Regulations

NiCd batteries present unique environmental challenges:

- Cadmium Content: Classified as hazardous waste under RCRA in the US and banned in consumer applications by EU Battery Directive 2006/66/EC

- Recycling Process: Specialized facilities recover nickel (80-85% efficiency) and cadmium (95% efficiency) through high-temperature metal reclamation

- Carbon Footprint: Manufacturing emits 8-12kg CO2 per kWh capacity, comparable to NiMH but higher than modern lithium-ion

Future Outlook and Sustainable Practices

While NiCd technology is being phased out in consumer markets, industrial applications continue due to:

- Superior performance in extreme temperatures (-40°C to 60°C operational range)

- Higher surge current capability (5-10C pulse discharge)

- Existing infrastructure compatibility

Sustainable Usage Recommendations:

- Implement battery rotation systems to extend overall service life

- Partner with certified recyclers like Call2Recycle or Battery Solutions

- Consider hybrid systems pairing NiCd with solar for remote applications

- Transition to NiZn (Nickel-Zinc) where possible – similar voltage characteristics without cadmium

Industry projections show NiCd remaining relevant in aerospace, military, and oil/gas applications through 2030, though with decreasing market share (projected 15% annual decline).

Advanced System Integration for D-size NiCd Battery Applications

Proper integration of NiCd D batteries into larger power systems requires careful consideration of voltage matching, charge control, and load management. These industrial-grade cells often serve in mission-critical applications where system reliability is paramount.

Voltage Matching in Multi-Battery Configurations

When combining NiCd D cells in series or parallel, voltage balancing becomes critical:

- Series Connections: Each additional cell increases voltage by 1.2V nominal (1.4V fresh charge). A 6-cell bank provides 7.2V nominal (8.4V peak)

- Parallel Connections: Maintains 1.2V while increasing capacity. Ensure all cells are within 0.05V before connecting to prevent current surges

- Mixed Configurations: For 24V systems, 20 cells in series (24V nominal) with parallel strings requires individual cell monitoring

Critical Consideration: Always use cells from the same production batch when creating battery banks to minimize voltage drift over time.

Smart Charging System Integration

Modern charging systems for NiCd D batteries should incorporate these features:

- Voltage-Temperature Compensation: Adjusts charge voltage by -4mV/°C when ambient exceeds 25°C

- Cell Balancing: Active balancing circuits maintain ±0.03V difference between cells in series

- Load Sharing: Allows simultaneous charging and discharging without voltage spikes

Load Management Strategies

Optimizing voltage delivery under varying loads extends battery life:

| Load Type | Voltage Management Technique | Benefit |

|---|---|---|

| Pulse Loads (e.g., radios) | Parallel capacitor bank (10,000μF per amp) | Prevents voltage sag during transmit bursts |

| Continuous High Draw (e.g., pumps) | Staggered startup sequencing | Reduces initial voltage drop by 40% |

System Monitoring and Protection

Implement these voltage monitoring thresholds for critical systems:

- Low Voltage Cutoff: 1.0V per cell under load (prevents damage from deep discharge)

- High Voltage Alarm: 1.5V per cell during charging (indicates potential overcharge)

- Voltage Differential Alert: >0.1V difference between parallel strings

For telecom backup systems, consider predictive analytics that track voltage decay rates to forecast failure 48-72 hours in advance.

Performance Optimization and Risk Management for NiCd D Battery Systems

Maximizing the reliability and efficiency of NiCd D battery installations requires a systematic approach to performance tuning and risk mitigation. These strategies are particularly critical for applications where battery failure could result in significant operational or safety consequences.

Advanced Performance Optimization Techniques

| Optimization Area | Technique | Expected Improvement | Implementation Notes |

|---|---|---|---|

| Voltage Stability | Active cell balancing | 15-20% longer runtime | Requires balancing circuits with ±10mV accuracy |

| Cycle Life | Controlled deep cycling | 300→500 cycles | Monthly full discharge to 0.9V/cell |

| Low-Temp Performance | Insulated enclosures | Maintains 1.1V at -20°C | 5cm foam insulation with 10W heating pad |

Comprehensive Risk Assessment Framework

Evaluate these critical risk factors for NiCd battery installations:

- Voltage Collapse Risk: Monitor for >0.2V drop during 10% load increases

- Thermal Runaway: Implement temperature cutoffs at cell-level (45°C)

- Memory Effect: Schedule quarterly reconditioning cycles

- Cadmium Migration: Annual internal resistance testing

Quality Assurance Protocols

Implement these validation procedures for mission-critical systems:

- Acceptance Testing: 72-hour charge/discharge cycle with voltage logging

- Periodic Validation: Monthly capacity verification (discharge to 1.0V/cell @ 0.2C rate)

- End-of-Life Testing: When capacity drops below 60% of rated or voltage variance exceeds 0.15V between cells

Maintenance Optimization Strategies

Develop a predictive maintenance program based on:

- Voltage trend analysis (track 0.001V/day changes)

- Internal resistance measurements (should remain <150% of new cell value)

- Thermal imaging during charging (identify hot spots >5°C above average)

Critical Insight: For aviation and medical applications, maintain a “voltage history log” tracking each cell’s performance over time – this data proves invaluable for predicting failure points and optimizing replacement schedules.

Implementing these comprehensive strategies can extend NiCd D battery system lifespan by 40-60% while reducing unplanned downtime by up to 80% in industrial applications.

Conclusion

Understanding NiCd D battery voltage characteristics is essential for optimizing performance in critical applications. Throughout this guide, we’ve explored the unique 1.2V nominal voltage behavior, proper testing methodologies, temperature impacts, and advanced system integration techniques. You’ve learned how to interpret voltage charts, implement smart charging practices, and extend battery lifespan through proper maintenance.

Key takeaways include: the flat discharge curve advantage, the importance of load testing voltage readings, and the critical 1.0V/cell cutoff threshold. Remember that proper voltage management can double your battery’s service life in industrial environments.

For optimal results, implement the voltage monitoring and maintenance strategies outlined here, and consider upgrading to smart charging systems if still using basic chargers. Your NiCd D batteries will deliver more reliable power and greater value when managed with this voltage-focused approach.

Frequently Asked Questions About NiCd D Battery Voltage

What is the normal voltage range for a healthy NiCd D battery?

A fully charged NiCd D cell measures 1.4-1.45V immediately after charging, stabilizing to 1.2-1.25V after resting. During discharge, it maintains 1.1-1.2V for 80% of its capacity before sharply dropping below 1.0V at full depletion. For accurate assessment, measure voltage under typical load conditions rather than open-circuit.

How often should I test my NiCd D battery voltage?

For critical applications, test voltage monthly under load. Industrial users should perform full discharge tests quarterly. Regular devices benefit from voltage checks every 3-6 months. Always test before important use if batteries have been stored more than 30 days. Record readings to track performance degradation over time.

Why does my NiCd D battery show 1.3V but dies quickly under load?

This indicates high internal resistance from age or damage. While the open-circuit voltage appears normal, the battery can’t sustain current flow. Test by applying a 2Ω load for 30 seconds – if voltage drops below 1.0V, replace the battery. This is common after 500+ cycles or prolonged storage without maintenance charging.

Can I mix NiCd D batteries with different voltage readings?

Never mix cells with more than 0.05V difference in series or 0.1V in parallel configurations. Mismatched voltages cause reverse charging, capacity loss, and potential leakage. For battery banks, use only same-batch cells and implement balancing circuits if voltage variance exceeds 0.03V after charging.

How does temperature affect NiCd D battery voltage?

Voltage decreases approximately 0.002V/°C below 20°C and increases slightly above 25°C. At -20°C, expect 0.2V lower readings temporarily. High temperatures above 50°C cause permanent voltage depression. Always test at room temperature (20-25°C) for accurate comparisons between batteries.

What voltage indicates a NiCd D battery needs replacement?

Replace when:

1) Voltage under load drops below 1.0V within 20% of rated runtime

2) Open-circuit voltage after charging doesn’t reach 1.35V

3) Voltage difference between cells in a pack exceeds 0.15V.

These signs typically appear after 3-5 years of regular use or 70% capacity loss.

How can I restore voltage in old NiCd D batteries?

Try reconditioning: Fully discharge to 0.9V/cell, then charge at 0.1C for 16 hours. Repeat 2-3 times. This may recover 10-15% voltage stability in batteries with mild memory effect. However, if internal resistance exceeds 150mΩ or voltage won’t rise above 1.3V, replacement is necessary.

Why does my charger show different voltage than my multimeter?

Chargers often display surface charge voltage (higher) or average pack voltage in multi-cell systems. For accurate comparison:

1) Let battery rest 2 hours after charging

2) Use a calibrated multimeter

3) Test at the battery terminals, not through connections.

Quality chargers should match your meter within ±0.03V.