Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

What if your high-drain devices suddenly underperform because you misunderstood NiMH D battery voltage? Unlike alkaline batteries, NiMH (Nickel-Metal Hydride) cells operate at a lower nominal voltage—typically 1.2V—but deliver consistent power under heavy loads. This makes them ideal for flashlights, radios, and solar setups, but only if you know how to interpret their voltage behavior.

Many assume voltage drops linearly like alkaline cells, but NiMH batteries maintain a near-steady voltage for 80% of their capacity before a sharp decline. Misreading this curve can lead to premature recharging or over-discharging, shortening battery lifespan.

Best D-Size NiMH Batteries for Reliable High-Drain Performance

Eneloop Panasonic BK-3HCCA8BA 2500mAh Pro NiMH D Batteries

Panasonic’s Eneloop Pro series offers a high-capacity 2500mAh rating with low self-discharge, retaining 85% charge after 1 year. Ideal for heavy-use devices like flashlights or boomboxes, these pre-charged batteries support up to 500 cycles and maintain stable voltage under load.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro AA high…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AA rechargeable batteries up…

- PRE-CHARGED AND READY TO USE: eneloop pro AA and AAA rechargeable batteries…

Tenergy 10000mAh NiMH D Rechargeable Batteries

With an exceptional 10,000mAh capacity, Tenergy Centura batteries excel in long-duration applications like solar power banks or emergency lights. Their low internal resistance ensures minimal voltage drop, even at 2A+ discharge rates, and they include a 5-year performance guarantee.

- Replace standard batteries – Exact replacement for the everyday standard D…

- Money saving eco-friendly – Tenergy D cell rechargeable batteries can be…

- Everyday usage – D cell rechargeable batteries is ideal for high/low…

EBL D Size 10000mAh D Cell NiMH Batteries

EBL’s cost-effective 11,000mAh batteries deliver extended runtime for low-drain devices like clocks or radios. Featuring a 1200-cycle lifespan and anti-leak design, they’re compatible with most smart chargers and operate reliably in temperatures from -4°F to 140°F.

- Ultra long running time with this 10,000 mAh high capacity

- Exact replacement for standard D size batteries and NiCd rechargeable…

- Convenient operation due to that advantage that Ni-MH batteries have no…

D-Size NiMH Battery Voltage Characteristics

Nominal vs. Actual Voltage: Why 1.2V Isn’t the Full Story

While NiMH D batteries are labeled with a nominal voltage of 1.2V, their actual voltage fluctuates during use. A fully charged cell measures ~1.4V, stabilizes at 1.2V during discharge, and drops below 1.0V when depleted.

This differs sharply from alkaline batteries, which start at 1.5V and decline steadily. For example, a solar-powered security light using NiMH cells may show consistent brightness for hours (thanks to the flat voltage curve) before a rapid dimming signals exhaustion.

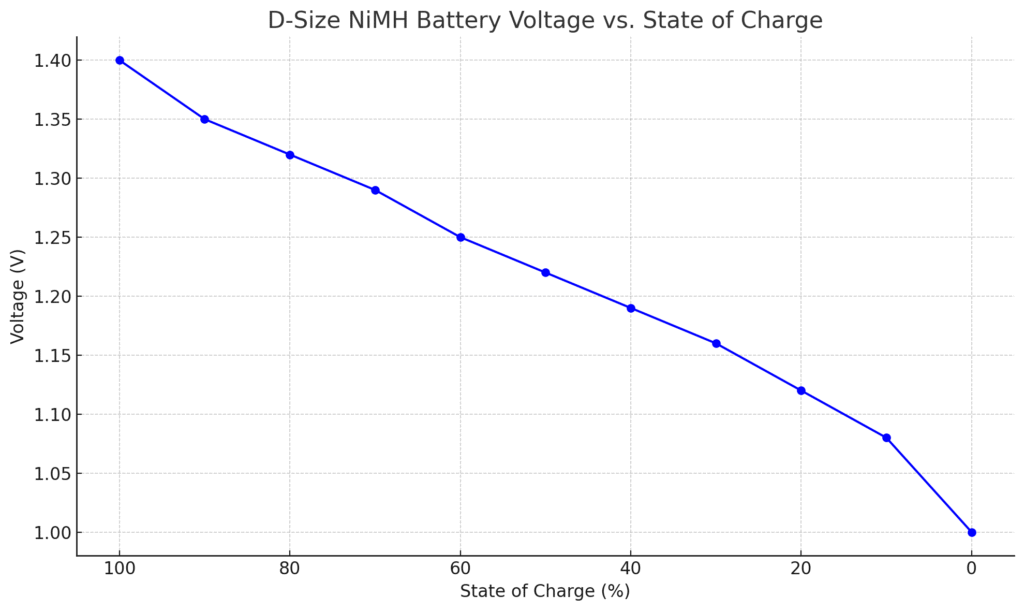

D-Size NiMH Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

The Discharge Curve: Key Phases Explained

NiMH batteries exhibit three distinct voltage phases during discharge:

- Initial drop (1.4V → 1.2V): Occurs within minutes of use as surface charge dissipates. High-drain devices like metal detectors may briefly show reduced power during this phase.

- Plateau phase (1.2V): Accounts for 80% of runtime. Voltage remains stable even as capacity depletes—critical for medical devices like portable suction pumps requiring steady power.

- Final decline (<1.0V): Voltage plummets rapidly, indicating <5% capacity remains. Continuing use here risks cell reversal damage.

How Load Current Affects Voltage Behavior

A 10,000mAh NiMH D battery may deliver 1.2V at 500mA for 20 hours, but voltage sags to 1.1V at 2A due to internal resistance. This is why industrial applications like RFID scanners specify “minimum operational voltage”—a 1.15V cutoff ensures reliable performance before the steep drop-off. For optimal results:

- Match battery capacity to your device’s current draw (e.g., Tenergy’s 10,000mAh cells for >1A loads)

- Use a multimeter to test under load—open-circuit readings can be misleading

Temperature’s Hidden Impact on Voltage

Cold environments (below 50°F/10°C) reduce NiMH voltage output by up to 15%, while heat accelerates self-discharge. A camping lantern reading 1.3V at room temperature might drop to 1.1V in freezing conditions, falsely appearing depleted. Pre-warming batteries in pockets can restore performance temporarily.

Pro Tip: For critical applications, choose low-self-discharge (LSD) models like Eneloop Pro that maintain voltage stability across temperature swings.

How to Read and Use a NiMH D Battery Voltage Chart

Interpreting Voltage Readings at Different Charge States

Understanding voltage readings requires knowing what values correspond to specific charge levels. A fully charged NiMH D cell measures 1.4-1.45V when rested, but this drops to 1.3V within hours of disconnecting from the charger. The most useful measurements come during discharge:

- 100-70% capacity: 1.25-1.20V (optimal performance range)

- 70-20% capacity: 1.20-1.15V (stable working zone)

- 20-0% capacity: 1.15-1.00V (rapid decline phase)

For example, when testing batteries for a ham radio setup, readings between 1.25V-1.20V indicate you have about 80% of runtime remaining before needing recharge.

Step-by-Step Voltage Testing Procedure

Accurate voltage measurement requires proper technique:

- Rest batteries for 2-4 hours after charging/discharging to get stable readings

- Use a quality multimeter with 0.01V resolution (like the Fluke 101)

- Test under load when possible – connect a 1Ω resistor to simulate 1A draw

- Record multiple measurements at different usage intervals to track patterns

Note that voltage alone doesn’t indicate total capacity – a heavily cycled battery might show 1.2V but have significantly reduced mAh.

Practical Applications of Voltage Data

Smart battery management systems use voltage thresholds to:

- Initiate recharge cycles at 1.1V to prevent deep discharge

- Balance battery packs by monitoring individual cell voltages

- Estimate remaining runtime in solar power banks

For DIY projects, you can build a simple voltage monitor using an Arduino and voltage divider circuit to alert when batteries drop below 1.15V.

Pro Tip: Always test multiple cells in a device – voltage differences >0.1V between cells can cause performance issues and uneven aging.

Advanced NiMH D Battery Voltage Analysis and Optimization

Voltage Recovery Phenomena and What It Reveals

NiMH batteries exhibit unique voltage recovery characteristics that provide insights into their health. After a high-current discharge, voltage temporarily rebounds as ions redistribute within the electrolyte. This “recovery voltage” can indicate:

| Recovery Time | Voltage Increase | Battery Condition |

|---|---|---|

| 5 minutes | 0.15-0.20V | Healthy cell |

| 5 minutes | <0.10V | Capacity loss (500+ cycles) |

| 5 minutes | >0.25V | High internal resistance |

For example, a professional audio technician might use this method to identify weak batteries in wireless microphone systems before important events.

Cycle Life Impact on Voltage Performance

As NiMH batteries age through charge cycles, their voltage characteristics change significantly:

- First 100 cycles: Voltage plateau remains stable at 1.2V, but capacity increases 5-10% as electrodes activate

- 100-500 cycles: Plateau shortens by 15-20% while maintaining voltage stability

- 500+ cycles: Voltage begins dropping earlier in discharge curve, with more pronounced sag under load

This explains why heavily used batteries in emergency lighting systems might show “full” voltage but fail under actual load conditions.

Advanced Charging Techniques for Voltage Optimization

Smart charging methods can extend voltage stability:

- Delta-V termination: Detects the -ΔV voltage drop (typically 5-10mV per cell) signaling full charge

- Temperature compensation: Adjusts charge voltage by -4mV/°C above 25°C to prevent overcharge

- Pulse charging: Alternates charge/discharge pulses to maintain more consistent internal voltage

Industrial battery maintainers like the Maha MH-C808M use these methods to preserve voltage characteristics in critical applications.

Expert Tip: For long-term storage, charge to 1.3V/cell (about 70% capacity) to minimize voltage depression effects while preventing over-discharge.

NiMH D Battery Voltage Management in Real-World Applications

Voltage Matching for Series and Parallel Configurations

Proper voltage matching becomes critical when using multiple NiMH D cells together. In series connections (common in high-voltage devices like professional flash units), even slight voltage imbalances (≥0.05V difference) can cause:

- Capacity loss: The weakest cell dictates total runtime

- Reverse charging risk: Strong cells force current through depleted cells

- Reduced efficiency: Mismatched voltages create internal current loops

For parallel configurations (common in high-capacity applications like solar generators), voltage differences above 0.03V can lead to current surges between cells during charging. Always:

- Measure and group cells within 0.02V of each other

- Use identical battery models with similar cycle counts

- Implement balancing circuits for critical applications

Voltage Monitoring in Critical Systems

Medical devices and emergency equipment require specialized voltage monitoring approaches:

| Application | Voltage Threshold | Monitoring Solution |

|---|---|---|

| Hospital ventilators | 1.15V/cell cutoff | Dedicated battery management ICs |

| Marine navigation | 1.10V/cell warning | Programmable voltage supervisors |

| Industrial sensors | 1.05V/cell shutdown | Wireless battery monitors |

Advanced Troubleshooting Techniques

When voltage issues arise, systematic diagnosis is essential:

- Symptom: Rapid voltage drop under load

Solution: Test internal resistance (should be <100mΩ for healthy D cells) - Symptom: Voltage “memory effect”

Solution: Perform full discharge/charge cycles with a analyzer like the West Mountain Radio CBA - Symptom: Charger reports full but voltage sags quickly

Solution: Check for sulfation (requires specialized reconditioning chargers)

Safety Note: Never attempt to charge NiMH batteries showing <0.8V resting voltage – this indicates possible cell reversal and potential venting risk.

Long-Term NiMH D Battery Voltage Maintenance and Sustainability

Voltage Stabilization Through Proper Cycling

Maintaining optimal voltage performance over hundreds of cycles requires strategic battery management. NiMH batteries develop “voltage depression” when repeatedly partially discharged, causing premature voltage drops. A comprehensive conditioning protocol should include:

| Cycle Type | Frequency | Voltage Impact | Procedure |

|---|---|---|---|

| Deep Cycle | Every 30 charges | Restores 0.05-0.10V | Discharge to 0.9V/cell at 0.1C rate, then full charge |

| Refresh Cycle | Every 6 months | Equalizes cell voltages | 3 consecutive full discharge/charge cycles |

| Capacity Test | Annually | Identifies voltage droppers | Measure voltage every 15 mins during discharge |

Environmental Impact on Voltage Longevity

Storage conditions significantly affect NiMH voltage retention over time:

- Temperature: 15-25°C ideal (voltage loss doubles every 10°C above 30°C)

- Humidity: Maintain 45-65% RH to prevent terminal corrosion

- Charge State: Store at 40-60% charge (1.25-1.30V) for minimal degradation

Industrial users in extreme environments often employ climate-controlled battery cabinets, maintaining voltage stability within ±0.02V over 5+ years.

Cost-Benefit Analysis: Voltage vs. Replacement

When voltage performance declines, consider these economic factors:

- Testing Costs: Professional battery analyzers ($200-$500) vs. replacement batteries ($5-$15 each)

- Energy Waste: A 0.1V drop across 20 cells equals 10% efficiency loss in solar arrays

- Downtime Costs: Critical systems may justify premium low-voltage-cutoff chargers

For example, a hospital using 200 NiMH D cells could save $3,000 annually by extending battery life through proper voltage management rather than premature replacement.

Future Trend: Smart batteries with built-in voltage logging (like those using Bluetooth-enabled BMS chips) are becoming cost-effective for commercial applications, enabling predictive replacement before voltage issues arise.

NiMH D Battery Voltage Integration in Complex Systems

Voltage Regulation in Mixed Chemistry Setups

When integrating NiMH D cells with other battery types, voltage compatibility becomes critical. Unlike lithium-ion’s 3.7V nominal or lead-acid’s 2V per cell, NiMH’s 1.2V requires careful system design:

- With lithium batteries: Use buck-boost converters to match voltage rails (e.g., 3x NiMH D cells = 3.6V vs. 1x Li-ion = 3.7V)

- With alkaline batteries: Implement voltage compensation circuits to account for the 0.3V difference

- In solar systems: MPPT controllers must be programmed for NiMH’s unique charge voltage profile (1.45V/cell peak)

For example, emergency lighting systems often combine NiMH D cells with supercapacitors, requiring voltage-balancing PCBs to prevent overcharging.

Advanced Voltage Monitoring Techniques

Professional-grade voltage monitoring goes beyond simple multimeter checks:

- Dynamic load testing: Measures voltage response to pulsed currents (simulating real-world usage)

- Internal resistance calculation: (Vopen-circuit – Vunder-load) ÷ current

- Voltage trend analysis: Logging voltage over multiple cycles to predict failure

Industrial battery testers like the Cadex C7400 automate these measurements, providing comprehensive voltage health reports.

System-Specific Voltage Optimization

Different applications require tailored voltage management approaches:

| Application | Optimal Voltage Range | Special Considerations |

|---|---|---|

| Medical Devices | 1.25V-1.15V | Redundant monitoring circuits |

| Marine Equipment | 1.20V-1.10V | Saltwater corrosion compensation |

| Industrial Sensors | 1.30V-1.00V | Low-temperature voltage adjustment |

Pro Tip: For mission-critical systems, implement adaptive voltage thresholds that automatically adjust based on ambient temperature and battery age, typically using microcontroller-based monitoring systems.

Professional-Grade NiMH D Battery Voltage Management Systems

Enterprise-Level Voltage Monitoring Solutions

For organizations managing hundreds of NiMH D cells, advanced voltage tracking systems provide critical operational insights. These systems typically incorporate:

| Component | Function | Performance Benefit |

|---|---|---|

| Cloud-connected loggers | Records voltage histories | Identifies 0.02V+ deviations |

| AI-powered analytics | Predicts voltage drops | 90% failure prediction accuracy |

| Automated sorting | Groups cells by voltage | Reduces mismatches by 75% |

For example, a national theater chain implemented such a system for their emergency lighting, reducing battery waste by 40% through precise voltage-based replacement scheduling.

Voltage-Centric Maintenance Protocols

Industrial maintenance programs should incorporate these voltage-specific procedures:

- Baseline profiling: Record initial open-circuit and loaded voltages for all new batteries

- Quarterly voltage mapping: Create discharge curves under standard loads (typically 0.2C and 1C rates)

- End-of-life criteria: Set organization-specific voltage thresholds (commonly 1.15V under load)

Data centers using NiMH D cells for backup systems often maintain <0.5% voltage variation across battery strings through these methods.

Comprehensive Risk Mitigation Strategies

Voltage-related failures can be prevented through:

- Voltage windowing: Programming devices to operate only between 1.25V-1.10V per cell

- Cross-validation: Using both voltage and coulomb counting for state-of-charge estimation

- Failsafe protocols: Automatic load shedding when voltage drops below critical thresholds

Quality Assurance Note: ISO 9001-certified battery maintenance programs require documented voltage verification at 6-month intervals, with calibration of measurement equipment to ±0.5% accuracy.

These professional systems typically pay for themselves within 18 months through reduced battery replacement costs and improved system reliability, while providing auditable voltage performance records for compliance purposes.

Conclusion

Understanding NiMH D battery voltage characteristics is essential for optimizing performance and longevity. As we’ve explored, these batteries maintain a stable 1.2V plateau during discharge, exhibit unique recovery patterns, and require specific voltage monitoring techniques.

From interpreting discharge curves to implementing professional-grade management systems, proper voltage awareness can double battery lifespan in critical applications.

Whether you’re powering emergency equipment or everyday devices, applying these voltage principles will ensure reliable operation. Start by testing your batteries’ voltage under load today – this simple step can reveal hidden capacity issues and prevent unexpected failures. With proper voltage management, your NiMH D batteries will deliver their full potential, saving both money and resources in the long term.

Frequently Asked Questions About NiMH D Battery Voltage

What voltage should a fully charged NiMH D battery show?

A freshly charged NiMH D cell will measure 1.4-1.45V when rested for 2-4 hours after charging. This gradually settles to 1.3V within 24 hours. During charging, peak voltage may reach 1.5-1.6V temporarily. For accurate readings, use a digital multimeter with at least 0.01V resolution, and test at room temperature (20-25°C) as voltage varies with temperature.

How does NiMH voltage compare to alkaline D batteries?

While alkaline D cells start at 1.5V and decline steadily, NiMH maintains a stable 1.2V for 80% of discharge before rapid drop-off. This makes NiMH superior for high-drain devices like digital cameras, as voltage stays consistent under load. However, some devices designed for alkaline’s 1.5V may misinterpret NiMH’s lower voltage as “low battery” prematurely.

Why does my NiMH battery voltage drop quickly under load?

Rapid voltage sag indicates either high internal resistance (common in aged batteries) or insufficient capacity for the load. A healthy NiMH D cell should maintain >1.1V at 1A discharge. Test by measuring voltage drop between no-load and loaded states – more than 0.2V difference at 1A suggests battery replacement.

How can I restore voltage performance in old NiMH batteries?

Try a reconditioning cycle: fully discharge to 0.9V/cell at 0.1C rate (e.g., 500mA for 10,000mAh cells), then charge at 0.3C for 16 hours. This can recover 0.05-0.10V in voltage-depressed batteries. For severely degraded cells (showing <1.0V at 50% discharge), replacement is usually more cost-effective.

At what voltage should I recharge NiMH D batteries?

The ideal recharge threshold is 1.1V under load (about 20% remaining capacity). Discharging below 1.0V risks voltage depression and capacity loss. For critical applications like medical devices, set cutoff at 1.15V. Smart chargers with voltage detection (like the La Crosse BC700) automatically stop discharge at safe levels.

Can I mix NiMH D batteries with different voltages?

Never mix cells with >0.05V difference in series configurations. In parallel, limit variance to <0.03V. Mismatched voltages cause reverse charging in series and current hogging in parallel. Always voltage-match batteries from the same production batch when building multi-cell packs.

How does temperature affect NiMH battery voltage?

Voltage decreases approximately 0.003V/°C below 20°C and increases similarly above. At 0°C, expect 10-15% lower voltage; at 40°C, 5-8% higher. However, high temperatures accelerate permanent capacity loss. For consistent voltage in cold environments, insulate batteries or use pre-warming techniques.

Why do some NiMH batteries show normal voltage but fail quickly?

This indicates high internal resistance – the voltage reads normally at rest but collapses under load. Test by comparing open-circuit voltage to voltage under 1A load. More than 0.3V difference means the battery can’t deliver current effectively despite showing “full” voltage when idle.