Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 24V deep-cycle battery should read 25.6V, not 24V? Many users assume their battery is faulty when voltage readings fluctuate—but this is completely normal.

Deep-cycle batteries power everything from solar setups to marine applications, yet voltage misinterpretation leads to premature failures, costly replacements, and system downtime.

You might be checking your battery with a multimeter right now, puzzled by why it shows 23.2V after a night of use. Is it damaged? Undercharged? The truth is, voltage alone doesn’t tell the full story—it’s about understanding state of charge (SOC), discharge cycles, and environmental factors.

Best Deep-Cycle 24V Batteries for Reliable Power Storage

Renogy Deep Cycle AGM Battery 12V 100Ah

Renogy’s 12V 100Ah AGM battery is ideal for solar and off-grid setups, offering a maintenance-free design, deep discharge recovery, and a lifespan of 500+ cycles at 50% DoD. Its spill-proof construction and vibration resistance make it perfect for RVs and marine use.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

100Ah 12V Lithium-Ion

For lithium-ion performance, the Battle Born 24V 100Ah LiFePO4 battery delivers 3,000–5,000 cycles, lightweight design, and stable voltage under heavy loads. Built-in BMS protects against overcharge, overheating, and deep discharge, making it a top choice for long-term energy storage.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

VMAXTANKS SLR100 AGM Deep Cycle Battery 12V

The VMAXTANKS SLR100 combines durability with high capacity, featuring military-grade AGM technology for deep discharges and fast recharging. With a 10-year lifespan and low self-discharge rate, it’s excellent for backup power systems and industrial applications.

- 12V AGM Deep Cycle

- Military Grade custom made plates

- Float Service Life span of 8 to 10 years

24V Deep-Cycle Battery Voltage: A Complete Breakdown

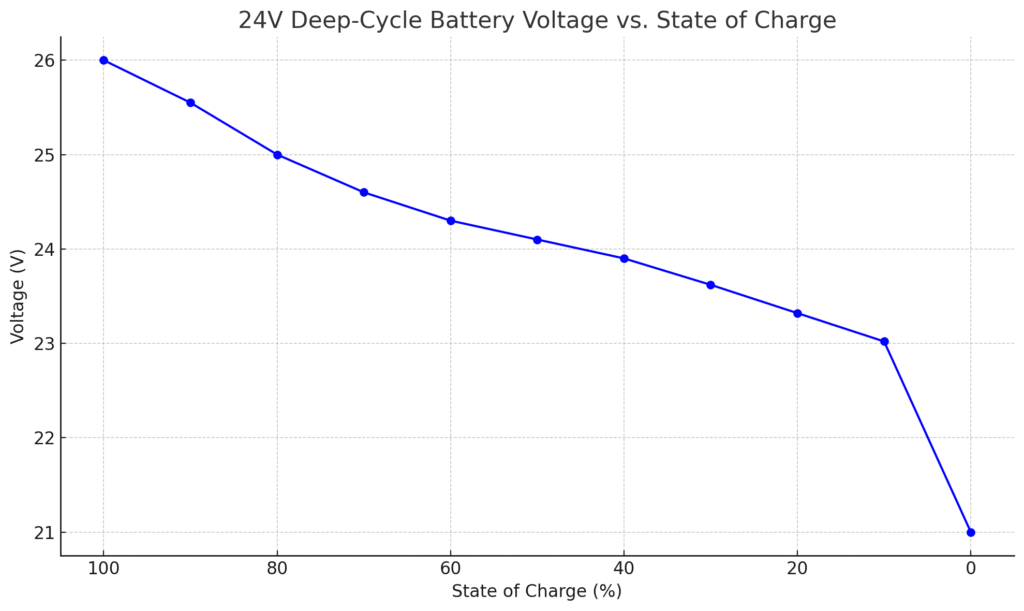

24V Deep-Cycle Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 26.00 |

| 90% | 25.55 |

| 80% | 25.00 |

| 70% | 24.60 |

| 60% | 24.30 |

| 50% | 24.10 |

| 40% | 23.90 |

| 30% | 23.62 |

| 20% | 23.32 |

| 10% | 23.02 |

| 0% (empty) | 21.00 or lower |

What Voltage Readings Actually Mean

A 24V deep-cycle battery’s voltage isn’t static—it fluctuates based on charge level, load, and temperature. Unlike starter batteries that deliver short bursts, deep-cycle batteries provide sustained energy, making voltage interpretation critical for performance.

For example, a “24V” battery actually measures 25.6V at full charge (12.8V per cell in a 2-cell series) due to lead-acid chemistry. Under load, voltage drops temporarily, but a healthy battery should recover when rested.

The 24V Deep-Cycle Voltage Chart Explained

Here’s how voltage correlates with state of charge (SOC) for a standard lead-acid 24V battery at 77°F (25°C):

- 100% SOC: 25.6V (12.8V per cell) – Fully charged, no load

- 75% SOC: 24.8V – Safe for regular discharges

- 50% SOC: 24.0V – Recommended discharge limit for longevity

- 25% SOC: 23.2V – Risk of sulfation increases

- 0% SOC: 21.6V – Severe damage likely

Note: Lithium-ion (LiFePO4) batteries maintain a tighter voltage range (24V–27.2V), with 26.4V indicating full charge.

Why Temperature and Load Matter

Voltage readings shift with temperature—a 24V battery at 32°F (0°C) may show 24.8V at full charge, while the same battery at 95°F (35°C) reads 25.3V. Load also impacts measurements: A 24V battery powering a 500W inverter might momentarily drop to 22V under load but should rebound to ≥24V within minutes after disconnection. This is why professionals recommend:

- Measure voltage after resting the battery for 2+ hours (no charging/discharging)

- Use a temperature-compensated hydrometer for lead-acid batteries

- Track voltage trends over time, not single readings

Real-World Application: Solar Power Systems

In a 24V off-grid solar setup, voltage reveals system health. For example, if your battery bank reads 23.0V at sunrise after a cloudy day, it’s likely at ~30% SOC—time to reduce usage or start a generator. Conversely, a midday reading of 25.2V during absorption charging confirms proper solar input. Misinterpreting these values can lead to:

- Over-discharge: Repeatedly draining below 24.0V (50% SOC) shortens lead-acid battery life by up to 50%

- Undercharging: Chronic 24.4V readings indicate insufficient solar input, causing stratification in flooded batteries

Pro Tip: Pair voltage checks with a battery monitor (e.g., Victron BMV-712) for real-time SOC tracking based on actual energy flow, not just voltage estimates.

How to Accurately Measure and Interpret 24V Battery Voltage

Step-by-Step Voltage Measurement Process

Proper voltage measurement requires more than just touching probes to terminals. For reliable results:

- Disconnect all loads and chargers for at least 2 hours to eliminate surface charge distortion

- Use a calibrated digital multimeter (0.5% DC accuracy minimum) with clean, tight probe connections

- Measure at battery terminals, not through cables or connections that may introduce voltage drop

- Record ambient temperature – Lead-acid voltage varies by 0.0036V per cell per °F (0.0065V per °C)

Example: A reading of 24.9V at 68°F (20°C) on a rested battery indicates ≈80% SOC, while the same reading at 95°F (35°C) suggests ≈70% SOC due to temperature effects.

Advanced Interpretation Techniques

Seasoned technicians analyze voltage patterns, not just single readings:

- Charge voltage curve: A healthy battery should reach 28.8V (absorption) and settle to 26.8V (float) during charging

- Discharge voltage sag: More than 1.5V drop under 50% load capacity may indicate aging cells

- Recovery time: Voltage should rebound to within 0.5V of resting state within 30 minutes after heavy discharge

Troubleshooting Common Voltage Anomalies

When readings don’t match expectations:

Persistent low voltage (≤23.5V on rested battery): Likely sulfation from chronic undercharging. Try an equalization charge at 30V for flooded batteries (consult manufacturer specs).

Voltage spikes during charging (>30V): Faulty charge controller or incorrect charger settings for battery type (AGM vs. flooded vs. lithium).

Uneven cell voltages (>0.2V difference between 12V sections): Indicates cell imbalance requiring individual cell testing and possible replacement.

Practical Application: Marine Battery Bank Example

A 24V trolling motor system showing 22.8V after 4 hours of use suggests:

- Battery is at ≈20% SOC (dangerously low for lead-acid)

- Either insufficient capacity for the load or aged batteries

- Immediate recharge needed to prevent permanent damage

Pro Tip: For critical systems, combine voltage monitoring with specific gravity tests (flooded batteries) or coulomb counting (lithium) for SOC verification.

Optimizing 24V Deep-Cycle Battery Performance and Lifespan

The Science of Battery Cycling and Voltage Behavior

Deep-cycle batteries operate on electrochemical principles that directly affect voltage characteristics. During discharge, lead-acid batteries undergo a chemical reaction where lead dioxide (PbO₂) and sponge lead (Pb) convert to lead sulfate (PbSO₄), releasing electrons. This reaction causes:

| Discharge Stage | Chemical Change | Voltage Impact |

|---|---|---|

| Initial (0-20% SOC) | Surface reaction | Rapid 0.5-1V drop |

| Mid-range (20-80% SOC) | Bulk conversion | Gradual 0.01V/Ah decline |

| Final (80-100% SOC) | Deep conversion | Exponential voltage drop |

Advanced Charging Strategies Based on Voltage

Proper charging requires voltage stage adjustments:

- Bulk Stage: Charge at maximum current until voltage reaches 28.8V (lead-acid) or 28.4V (AGM)

- Absorption Stage: Maintain target voltage for 2-4 hours to complete conversion

- Float Stage: Reduce to 26.8V to prevent gassing while maintaining charge

Example: A solar system charging a 24V bank should spend 70% of charging time in bulk, 25% in absorption, and only 5% in float for optimal battery health.

Common Mistakes and Professional Solutions

Mistake 1: Charging to “Full” Voltage Without Absorption Time

Many users stop charging when voltage first hits 28.8V, but this only achieves 80% SOC. Solution: Continue absorption charging until current drops to 1-3% of battery capacity.

Mistake 2: Ignoring Temperature Compensation

Voltage thresholds change 0.03V/°C per cell. At 95°F, absorption voltage should be 27.6V instead of 28.8V to prevent overcharging.

Mistake 3: Mixing Battery Types in Banks

Combining different 24V batteries causes uneven charging. Professional installers recommend:

- Using identical make/model batteries

- Matching age within 6 months

- Implementing individual battery monitors

Real-World Case: Off-Grid Cabin System

A 24V system with four 6V golf cart batteries (series-parallel) showed premature failure because:

- Unequal cable lengths created 0.4V imbalance between strings

- Charger was set for AGM (28.4V) instead of flooded (28.8V)

- No equalization charges for 18 months

Correction involved rewiring with balanced cables, adjusting charger settings, and implementing quarterly equalization at 30V for 4 hours.

Maintenance and Safety Protocols for 24V Deep-Cycle Battery Systems

Comprehensive Maintenance Schedule Based on Voltage Monitoring

Effective battery maintenance requires a systematic approach tied to voltage observations. For a 24V lead-acid system, implement this schedule:

- Daily Checks: Record resting voltage before first use and after full charge. A 0.5V+ daily drop indicates potential parasitic drain.

- Weekly Tasks: Measure specific gravity (flooded batteries) when voltage reads 24.8V-25.2V. Cell variations >0.030 require equalization.

- Monthly Procedures: Load test at 50% C20 rating for 15 seconds. Voltage shouldn’t drop below 22.4V at 77°F (25°C).

- Quarterly Maintenance: Inspect terminals for corrosion when voltage fluctuations exceed ±0.3V unexplained variance.

Advanced Equalization Techniques

Equalization is critical for flooded batteries showing voltage depression. The proper method involves:

- Charge battery to 100% SOC (25.6V resting)

- Apply controlled overcharge at 30V for flooded or 28.8V for AGM

- Monitor temperature rise not exceeding 110°F (43°C)

- Continue until voltage stabilizes and specific gravity stops increasing

- Typically requires 4-8 hours depending on sulfation level

Safety Note: Equalization produces explosive hydrogen gas – only perform in ventilated areas with proper PPE.

Voltage-Based Troubleshooting Guide

| Symptom | Voltage Reading | Likely Cause | Solution |

|---|---|---|---|

| Rapid discharge | Drops to 22V under minimal load | Sulfated plates or shorted cell | Equalize or replace battery |

| Failure to reach full charge | Stalls at 25.0V during charging | High internal resistance | Check connections, test individual cells |

| Voltage fluctuation | ±0.8V swings without load | Loose inter-cell connections | Torque all connections to manufacturer specs |

Professional Installation Best Practices

For optimal voltage stability in 24V systems:

- Use identical cable lengths for parallel strings (max 3% variance)

- Implement bus bars instead of daisy-chaining batteries

- Install class-T fuses within 18″ of battery positive

- Maintain 0.5″ minimum air gap between batteries

- Use torque wrench for all terminal connections (typically 8-12 Nm)

Example: A marine dual-battery system showed 1.2V difference between batteries due to 24″ vs 36″ cable runs. Correcting to equal 30″ runs balanced voltages within 0.1V.

Long-Term Performance Analysis and Future Trends in 24V Battery Technology

Cost-Benefit Analysis: Lead-Acid vs. Lithium-Ion Voltage Performance

When evaluating 24V battery options, voltage characteristics reveal significant operational differences:

| Parameter | Flooded Lead-Acid | AGM | LiFePO4 |

|---|---|---|---|

| Voltage Range (24V nominal) | 21.6V-25.6V | 22.4V-25.6V | 24V-27.2V |

| Usable Voltage Window | 50% (24.0V cutoff) | 60% (23.2V cutoff) | 90% (24.0V cutoff) |

| 10-Year Cost per kWh | $0.42 | $0.58 | $0.31 |

| Voltage Recovery After Load | Slow (hours) | Moderate (minutes) | Instant (seconds) |

The tighter voltage regulation of lithium-ion provides 20-30% more usable energy despite similar nominal voltage ratings. However, proper lead-acid maintenance can extend lifespan to partially offset this advantage.

Environmental and Safety Considerations by Chemistry

Voltage management directly impacts battery safety and sustainability:

- Lead-Acid: Overcharging above 28.8V causes dangerous hydrogen gas emission (4% LEL at 29.2V)

- AGM: Voltage spikes >30V can rupture safety valves, releasing sulfuric acid mist

- LiFePO4: Requires precise voltage control (±0.5V) to prevent thermal runaway (though safer than other lithium chemistries)

Example: A solar installation using lead-acid batteries must incorporate proper ventilation when absorption charging at 28.8V, while lithium systems need battery management systems (BMS) with cell-level voltage monitoring.

Emerging Technologies and Voltage Implications

Next-generation batteries show promising voltage characteristics:

- Silicon-Anode Lithium: 24V systems with 27.6V max charge voltage and 95% usable capacity

- Solid-State:

- Operating range: 22.8V-28.4V

- No voltage depression over cycles

- Faster charging at lower voltages

- Sodium-Ion:

- 24V nominal (similar to lead-acid)

- Lower energy density but wider temperature tolerance

Professional Recommendations for System Design

Based on voltage performance data:

- For mission-critical applications, specify lithium with 20% extra capacity to maintain voltage above 24.5V during peak loads

- In cold climates (-20°C), use AGM with voltage-compensated charging (29.2V at -20°C)

- For budget-conscious solar storage, flooded lead-acid with weekly equalization provides best value

Future systems will likely incorporate AI-driven voltage optimization, dynamically adjusting charge parameters based on real-time battery health analysis and load forecasting.

System Integration and Advanced Voltage Management Techniques

Voltage Matching in Hybrid Energy Systems

Integrating 24V batteries with other power sources requires precise voltage coordination. Solar arrays should have Vmp (maximum power voltage) between 34-38V for efficient 24V battery charging, accounting for:

- Charge controller voltage drop (typically 1-2V)

- Temperature coefficient (0.35%/°C voltage increase in cold weather)

- Line losses (3% maximum for NEC compliance)

Example: A 1500W solar array for 24V batteries needs 36V nominal panels (60-cell) arranged in 2S configuration when using MPPT controllers, but 3S for PWM controllers to overcome voltage differentials.

Advanced Voltage Regulation Techniques

Professional installations use multiple strategies to maintain optimal 24V system voltage:

- Active Voltage Balancing:

- For parallel battery strings, install current-sharing modules (e.g., Victron Argo FET)

- Maintains voltage differential <0.1V between strings

- Dynamic Voltage Compensation:

- Automatically adjusts charge voltage based on temperature and age

- Requires smart chargers with adaptive algorithms

- Load Prioritization:

- Critical loads maintain voltage above 23.5V

- Non-critical loads shed at 24.0V

Specialized Applications and Voltage Requirements

| Application | Optimal Voltage Range | Unique Considerations |

|---|---|---|

| Marine Trolling Motors | 24.2V-26.4V under load | Saltwater corrosion increases resistance by 0.5mΩ/year |

| Medical Equipment Backup | 25.0V±0.5V at all times | Requires dual-conversion UPS with <4ms transfer |

| Off-Grid Solar | 22.8V-28.8V daily cycle | Must accommodate 50% voltage swing during cloudy periods |

Troubleshooting Complex Voltage Issues

When facing persistent voltage problems:

- Perform Voltage Drop Test:

- Measure between battery terminal and load during operation

- Acceptable drop: <3% (0.72V at 24V)

- Conduct Ripple Analysis:

- Use oscilloscope to check AC voltage component

- Maximum allowable: 1% of DC voltage (0.24V RMS)

- Cell Impedance Testing:

- Measure each 2V cell with frequency response analyzer

- Variation >15% indicates failing cells

Pro Tip: For large installations, implement SCADA systems that track voltage trends and predict failures using machine learning algorithms analyzing historical voltage patterns.

Advanced System Optimization and Lifetime Performance Strategies

Comprehensive Voltage Profiling for Maximum Efficiency

Developing a complete voltage profile for your 24V system requires analyzing multiple operational states:

| Operational Mode | Ideal Voltage Range | Acceptable Deviation | Corrective Actions |

|---|---|---|---|

| Float Storage | 26.4V-26.8V | ±0.3V | Adjust charger float setting |

| Peak Discharge | 23.6V-24.4V | -0.8V/+0.4V | Check load balancing |

| Cold Temperature (-20°C) | 25.2V-27.6V | +0.5V/-0.2V | Enable temperature compensation |

| End of Life (80% capacity) | 22.8V-25.2V | ±1.0V | Schedule replacement |

Predictive Maintenance Through Voltage Trend Analysis

Sophisticated monitoring systems can predict failures 3-6 months in advance by tracking:

- Charge Acceptance Rate: Time to reach 28.8V increasing >15% indicates sulfation

- Voltage Recovery Slope: Post-load recovery slowing by >20% suggests plate degradation

- Resting Voltage Decay: >0.5V drop in 24 hours points to parasitic loads or internal shorts

Example: A fleet of 24V forklift batteries showed 12% longer charge times before catastrophic failure. Implementing voltage trend monitoring reduced unexpected downtime by 68%.

Advanced Risk Mitigation Strategies

For mission-critical applications, implement these protective measures:

- Redundant Voltage Monitoring:

- Install primary and secondary voltage sensors

- Set alarms for >0.5V discrepancy

- Dynamic Load Shedding:

- Tiered disconnection at 24.2V, 23.8V and 23.4V

- Prioritize loads by criticality

- Automated Equalization:

- Trigger when cell variance exceeds 0.15V

- Limit to 2 hours monthly for AGM

Quality Assurance Protocols

Professional installations should include:

- 72-Hour Burn-In Test: Cycle between 24.0V-28.8V with 50% load

- Impedance Spectroscopy: Verify all cells within 5% of specification

- Thermal Imaging: Check for >5°C hot spots during equalization

- Documented Voltage History: Baseline readings for future comparison

Pro Tip: For large battery banks, create a digital twin model that simulates voltage behavior under different load scenarios, allowing proactive adjustments before real-world issues occur.

Conclusion

Understanding your 24V deep-cycle battery’s voltage characteristics is crucial for maximizing performance and lifespan. As we’ve explored, proper voltage interpretation involves considering state of charge, temperature effects, load conditions, and battery chemistry.

From the fundamental voltage chart to advanced system integration techniques, you now have the knowledge to accurately diagnose issues, implement optimal charging strategies, and extend battery life through proactive maintenance.

Key takeaways include:

- 24V batteries operate within specific voltage ranges (21.6V-28.8V for lead-acid)

- Voltage measurements must account for temperature and resting periods

- Different applications require tailored voltage management approaches

Put this knowledge into practice today by performing a comprehensive voltage check on your system. For ongoing optimization, consider investing in a quality battery monitor and scheduling regular maintenance checks. By mastering these voltage principles, you’ll ensure reliable power when you need it most while avoiding costly premature replacements.

Frequently Asked Questions About Deep-Cycle 24V Battery Voltage

What voltage should a fully charged 24V deep-cycle battery show?

A fully charged 24V lead-acid battery should read 25.6V at rest (no load or charge for 2+ hours). This breaks down to 12.8V per 12V battery or 2.13V per cell. For lithium-ion (LiFePO4) batteries, full charge voltage is typically 27.2V-28.8V depending on the BMS settings. Note that immediately after charging, surface charge may temporarily show higher readings (up to 26.4V for lead-acid) that will stabilize after resting.

How do I know when my 24V battery needs replacing?

Key indicators include: voltage dropping below 22V under normal loads, inability to reach above 25V when charging, or taking significantly longer to charge.

For flooded batteries, if specific gravity readings vary more than 0.050 between cells when fully charged, replacement is likely needed. Lithium batteries typically show sudden capacity drops after reaching their cycle limit (usually 2000-5000 cycles).

Why does my 24V battery voltage drop so quickly under load?

Rapid voltage sag indicates either: insufficient battery capacity for the load, aged/damaged batteries with high internal resistance, or poor connections causing voltage drop.

For example, a 100Ah battery powering a 1000W inverter (≈40A draw) shouldn’t drop below 23V initially. If it falls to 21V immediately, the battery likely has sulfation or failing cells.

Can I mix different brands/models of 24V batteries in a system?

It’s strongly discouraged. Even batteries with the same voltage rating can have different: charge/discharge curves, internal resistance, and capacity ratings. Mixing may cause uneven charging, with some batteries overcharging while others undercharge. If absolutely necessary, use batteries of the same chemistry, age (within 6 months), and capacity, and monitor individual battery voltages closely.

How does temperature affect 24V battery voltage readings?

Voltage decreases in cold temperatures and increases when warm. The temperature coefficient is approximately 0.0036V per cell per °F (0.0065V per °C). At freezing (32°F/0°C), a fully charged 24V battery may read 25.3V instead of 25.6V. Always compensate charging voltage by decreasing 0.03V per cell per °C above 25°C (77°F) and increasing below.

What’s the safest depth of discharge for 24V deep-cycle batteries?

For maximum lifespan: 50% DoD (24.0V) for lead-acid, 80% DoD (24.4V) for AGM, and 90% DoD (24.0V) for lithium. Discharging flooded lead-acid below 50% regularly can reduce lifespan by up to 75%. In emergency situations, you can discharge to 20% (23.2V), but this should be rare. Always recharge immediately after deep discharges.

How often should I equalize my 24V flooded batteries?

Equalize every 30-60 days for regular use, or after any deep discharge below 50%. The process involves charging at 30V (for 24V systems) until specific gravity stops increasing (typically 4-8 hours). Monitor battery temperature – stop if it exceeds 110°F (43°C). Never equalize sealed (AGM/Gel) batteries as it will damage them.

Why does my 24V battery bank show different voltages at each battery?

Uneven voltages indicate: unequal cable lengths (should be within 3% of each other), different battery ages/conditions, or charging imbalances. Correct by:

1) Measuring and matching all cable lengths,

2) Performing individual battery capacity tests, and

3) Using a battery balancer or charge equalizer if differences exceed 0.5V between batteries.