Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a 48V e-bike battery doesn’t always deliver 48 volts? Voltage fluctuates based on charge level, load, and temperature—directly impacting your bike’s speed, range, and longevity.

If you’ve ever wondered why your e-bike suddenly loses power on hills or how far you can ride before recharging, the answer lies in understanding voltage behavior. Many riders assume “48V” means constant performance, but reality is more nuanced.

Best E-Bike 48V Batteries for Optimal Performance

UL Certified UPP 48V 20Ah

Ideal for long-range commuters, the UPP 48V 20Ah battery features high-capacity Samsung/LG cells, delivering up to 60 miles per charge. Its waterproof casing and built-in BMS protect against overcharging, overheating, and short circuits. Compatible with most 48V e-bike systems, it’s a reliable upgrade for extended adventures.

- 【Parameter】Built in LG5000mah cells, 5 Golen Pin battey base, 48V 20Ah…

- 【Downtube Battery】 High quality battery cells and equipped with a BMS…

- 【Long Battery Life & SAFE】 Built-in high quality brand lithium cell,…

UL Certified 48V 13Ah

Designed for space-saving installation, the Unit Pack Power 48V 13Ah triangle battery fits neatly into frame cavities. With a durable aluminum shell and 50A continuous discharge rate, it excels in high-power applications like off-road e-bikes. Includes a USB port for device charging—perfect for tech-savvy riders.

- 【Parameter】5 Golden pin base 48V 13Ah Electric Bicycles Battery, suit…

- 【Downtube Battery】 High quality battery cells and equipped with a BMS…

- 【Long Battery Life & SAFE】 after fully depleted, it can be recharged to…

EGO Power+ BA 56V, 7.5 Ah

For those prioritizing lightweight design, the EGO BA56V offers rapid charging (90% in 30 minutes) and compatibility with EGO’s Power+ ecosystem. Its weather-resistant construction and real-time charge-level indicator make it a top pick for urban riders who need reliability and convenience.

- Power management system protects the battery pack from the most harmful…

- Upgraded fuel gauge to show how much run time is remaining

- Fast Charge time: Charges in 60 minutes with EGO Power plus Rapid Charger;…

48V E-Bike Battery Voltage Behavior

A 48V e-bike battery doesn’t maintain a constant 48 volts—its voltage fluctuates based on charge level, load, and temperature. This variance directly impacts your bike’s performance, from acceleration to hill-climbing ability.

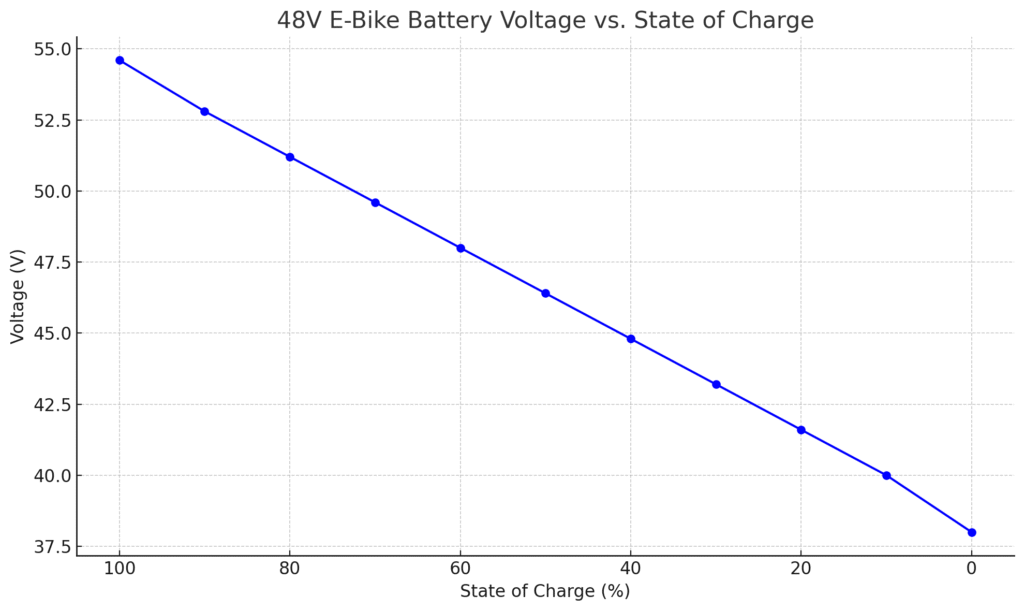

Unlike a car’s fuel gauge, which shows linear depletion, lithium-ion batteries exhibit non-linear voltage discharge curves. For example, a fully charged 48V battery actually reads around 54.6V (4.2V per cell × 13 cells in series), while “empty” typically means ~39V (3.0V per cell).

48V E-Bike Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 54.6 |

| 90% | 52.8 |

| 80% | 51.2 |

| 70% | 49.6 |

| 60% | 48.0 |

| 50% | 46.4 |

| 40% | 44.8 |

| 30% | 43.2 |

| 20% | 41.6 |

| 10% | 40.0 |

| 0% (empty) | 38.0 or lower |

Key Notes

- Fully charged: 54.6V (each cell at 4.2V)

- Nominal voltage: 48V (each cell at ~3.7V)

- Low voltage cutoff: ~39V (each cell at ~3.0V)

- Avoid deep discharge: Going below 10% can shorten battery life

Key Voltage Thresholds and Their Meaning

Here’s how voltage correlates with your battery’s state of charge (SOC):

- 54.6V (100% SOC): Maximum charge voltage. Prolonged storage at this level degrades cells faster.

- 48V (~50% SOC): Nominal voltage—your battery spends most of its discharge cycle near this range.

- 42V (20% SOC): Critical low-voltage threshold. Discharging below this risks permanent capacity loss.

Real-world scenario: If your display shows 46V during a steep climb, that doesn’t mean your battery is half-empty. Voltage “sags” under heavy load—a normal phenomenon where current draw temporarily reduces measured voltage. Once the load eases (e.g., reaching flat ground), voltage rebounds to reflect true SOC.

Why Voltage Sag Matters for Performance

When your motor controller detects low voltage (e.g., below 43V under load), it may limit power output to protect the battery—explaining sudden speed drops on hills.

High-quality batteries with low internal resistance (like those using 21700 cells) minimize sag. For instance, a premium 48V 20Ah battery might sag only 2V at 20A load, while a budget pack could drop 5V+ under the same conditions.

Pro Tip: To check true SOC, measure voltage after the battery rests for 30 minutes post-ride. Riding until voltage consistently sags below 42V under load can shorten battery lifespan by up to 50% over 300 cycles.

Temperature’s Impact on Voltage Readings

Cold weather reduces voltage output—a 48V battery at 32°F (0°C) may show 3-4V lower than at 68°F (20°C). This isn’t actual capacity loss but temporary voltage suppression.

Conversely, hot conditions (above 95°F/35°C) increase voltage slightly but accelerate chemical degradation. Always store batteries at room temperature for accurate readings.

How to Read and Use a 48V E-Bike Voltage Chart

Mastering your e-bike’s voltage chart is like learning its unique language—it reveals exactly when to charge, when to conserve power, and how to maximize battery life. Unlike simple percentage indicators, voltage provides precise, real-time data about your battery’s true state.

Step-by-Step: Interpreting Voltage Readings

- Measure at rest: Check voltage after the battery has been idle for 30+ minutes for accurate SOC (state of charge) readings. A resting voltage of 51.1V indicates ~80% charge.

- Understand load conditions: Expect 3-5V drop during acceleration. If your display shows 45V while climbing, your actual resting voltage is likely 48-50V.

- Track discharge patterns: Healthy batteries maintain voltage longer before the “knee point” (sudden drop at ~20% SOC). If yours plunges from 48V to 42V rapidly, it may need replacement.

Practical Applications for Riders

For commuters: If your 15-mile route typically consumes 30% charge (voltage drops from 52V to 48V), you’ll know to recharge at 47V to avoid deep discharges.

Mountain bikers should monitor voltage sag—if your 48V battery consistently drops below 42V on climbs, consider upgrading to a high-discharge battery like the UPP 48V 20Ah mentioned earlier.

Troubleshooting Voltage Anomalies

- Rapid voltage drop: Could indicate a failing cell group. Test individual cell voltages with a multimeter—any reading below 2.8V signals danger.

- Voltage not matching SOC: A “fully charged” battery showing only 50V likely has a BMS (Battery Management System) issue needing professional repair.

- Inconsistent readings: Clean battery contacts with isopropyl alcohol—corrosion can cause false low-voltage readings.

Pro Tip: Create a personal voltage log. Note resting voltages after every 10 miles ridden—this helps identify performance degradation before it becomes critical. For example, if your usual 20-mile commute previously dropped voltage to 46V but now hits 43V, your battery’s capacity is decreasing.

Advanced Technique: Voltage-Based Range Calculation

Combine voltage readings with your bike’s Wh/mile consumption (typically 15-30Wh/mile). At 48V (nominal) × 20Ah = 960Wh capacity, a voltage drop from 52V to 47V (~50% discharge) means you’ve used ~480Wh. If your bike averages 20Wh/mile, you have about 24 miles remaining.

Optimizing Battery Life Through Voltage Management

Proper voltage management can double your 48V e-bike battery’s lifespan from 500 to 1,000+ charge cycles. This section reveals the electrochemical principles behind voltage degradation and actionable strategies to maximize your investment.

The Science of Voltage Degradation

Lithium-ion cells degrade through two primary mechanisms when voltage isn’t properly managed:

| Degradation Type | Voltage Trigger | Chemical Effect |

|---|---|---|

| SEI Layer Growth | >54.6V (overcharge) | Electrolyte breakdown forms insulating layers on anode |

| Lithium Plating | <42V (deep discharge) | Metallic lithium deposits create internal shorts |

Example: Regularly charging to 100% (54.6V) and riding until cutoff (39V) might give you 5% more range per cycle but reduces total lifespan by 40% compared to the 80-20% rule.

Advanced Charging Strategies

- Partial charging: Stop at 51.1V (90%) for daily use – reduces stress on cathode materials

- Balancing cycles: Only charge to 54.6V monthly to equalize cell groups

- Temperature management: Never charge below 32°F (0°C) – causes irreversible lithium plating

Real-world application: For a 48V 17.5Ah battery (840Wh), charging to 90% (51.1V) gives you ~756Wh capacity – more than enough for a 30-mile commute while significantly extending battery life.

Common Voltage Management Mistakes

- Ignoring voltage sag: Mistaking load-induced voltage drops for actual SOC leads to over-discharge

- Storage at full charge: Batteries left at 54.6V lose 8% capacity per month vs. 2% at 48V

- Charging immediately after rides: Allows heat buildup (140°F/60°C+) that accelerates degradation

Expert Tip: Use a smart charger like the Cycle Satiator that lets you set custom voltage limits. For long-term storage, maintain batteries at 48V (3.7V/cell) in a climate-controlled environment.

Voltage-Based Health Diagnostics

Track these voltage metrics to assess battery health:

- Rebound time: Healthy packs recover to resting voltage within 15 minutes after load

- Cell delta: Maximum variance between cell groups should be <0.05V at 50% SOC

- Capacity test: Discharge from 54.6V to 42V at 10A – should deliver ≥95% of rated Ah

For example, if your 20Ah battery only delivers 16Ah during this test, it has 20% capacity loss and likely needs replacement soon.

Advanced Voltage Monitoring and Maintenance Techniques

Professional e-bike technicians rely on sophisticated voltage monitoring to predict battery health and prevent failures. This section reveals industrial-grade techniques adapted for home users, helping you catch problems before they leave you stranded.

Precision Voltage Measurement Methods

Accurate voltage readings require proper technique:

- Use quality multimeters: Fluke 101 or ANENG AN8008 provide ±0.5% accuracy (crucial for detecting small cell imbalances)

- Test at balance ports: Measure individual cell groups through the battery’s balance connector for true cell-by-cell analysis

- Establish baselines: Record new battery voltages at 25%, 50%, and 75% SOC to create a personalized reference chart

Example: A healthy 13S 48V battery should show:

• 3.85V/cell (50.05V total) at 50% SOC

• <0.03V variation between cell groups

• Maximum 0.5V drop during 10-second 20A load tests

Voltage-Based Diagnostic Procedures

| Symptom | Voltage Test | Probable Issue |

|---|---|---|

| Sudden power loss | Measure under load | Failing cell group (will show >1V drop vs others) |

| Reduced range | Full discharge test | Capacity fade (voltage drops faster than baseline) |

| Charger cutting off early | Monitor charge cycle | BMS imbalance (cells reach 4.2V unevenly) |

Professional Maintenance Schedule

- Weekly: Check resting voltage after full charge (should be 54.6±0.2V)

- Monthly: Perform balance charge and record cell group voltages

- Quarterly: Conduct capacity test (discharge to 42V while tracking Ah output)

- Annually: Measure internal resistance with specialized tools like RC3563

Safety Alert: Never disassemble battery packs without proper training. Even “empty” 48V packs can deliver lethal 60A+ currents. When cell voltages differ by >0.3V, consult a professional.

Advanced Recovery Techniques

For mildly unbalanced packs (0.1-0.3V variance):

- Discharge to 45V (3.46V/cell) using bike’s motor at medium assist

- Slow-charge at 2A until BMS balancing activates (typically above 52V)

- Repeat 2-3 cycles if needed

Note: Batteries with >0.5V imbalance or cells below 2.5V require professional reconditioning equipment. Attempting DIY repairs on severely unbalanced packs may cause thermal runaway.

Long-Term Cost Analysis and Future-Proofing Your 48V Battery Investment

Understanding the total cost of ownership for your 48V e-bike battery requires analyzing voltage management’s impact on lifespan, performance, and replacement cycles. This section provides a detailed financial breakdown and emerging technologies that could extend your battery’s useful life.

Voltage Management Cost-Benefit Analysis

| Usage Pattern | Cycle Life | 5-Year Cost | Performance Retention |

|---|---|---|---|

| Full 100-0% discharges | 400-500 cycles | $1,200 (2 replacements) | 60% capacity at 300 cycles |

| 80-20% voltage range | 800-1,000 cycles | $600 (1 replacement) | 85% capacity at 500 cycles |

| 70-30% voltage range | 1,500+ cycles | $400 (0 replacements) | 90% capacity at 800 cycles |

Example: A $500 battery maintained at 70-30% voltage range saves $800 over five years compared to full cycling, while delivering more consistent performance. The trade-off is 20% less range per charge, which may require more frequent top-ups for long-distance riders.

Emerging Technologies and Voltage Optimization

New developments are changing voltage management strategies:

- Solid-state batteries: Expected by 2026, these will tolerate wider voltage ranges (2.7-4.8V/cell) without degradation

- AI-powered BMS: Systems like Tesla’s battery algorithms dynamically adjust voltage limits based on usage patterns

- Graphene additives: Experimental cells show 50% less voltage sag under load, potentially doubling practical cycle life

Environmental Impact of Voltage Management

Proper voltage control significantly reduces e-waste:

- Extending battery life from 2 to 5 years decreases lithium demand by 60% per mile traveled

- Maintaining optimal voltage reduces the 34kg CO2 emissions generated during battery production

- Well-preserved batteries have higher resale value for second-life applications like solar storage

Safety Consideration: Aging batteries with >10% capacity loss often develop unstable voltage characteristics. When your pack shows >0.5V imbalance at full charge or voltage “spikes” during use, consider professional evaluation.

Future-Proofing Your Voltage Monitoring

Invest in these upcoming technologies:

- Bluetooth BMS: $50-100 add-ons provide real-time cell voltage monitoring via smartphone

- Cloud-connected chargers: Log voltage histories and predict failures (e.g., Grin Cycle Analyst)

- Voltage-based leasing: Some European companies now offer batteries-as-a-service with pricing tied to voltage health metrics

By adopting these voltage management strategies today, you’ll be prepared for tomorrow’s battery technologies while maximizing your current investment’s value and minimizing environmental impact.

Integrating Voltage Monitoring with E-Bike Performance Systems

Advanced riders can leverage 48V battery voltage data to optimize their entire e-bike system. This section explores how voltage interacts with motor controllers, regenerative braking, and assist levels to create a perfectly tuned riding experience.

Voltage-Based Motor Controller Programming

Modern controllers can adjust performance based on real-time voltage readings:

- Low-voltage compensation: Program controllers to gradually reduce power below 46V (3.54V/cell) rather than abrupt cutoff

- Dynamic current limiting: Set maximum amp draw relative to voltage (e.g., 30A at >50V, 20A at 42-50V)

- Voltage-based PAS adjustment: Automatically reduce assist levels when voltage sags >4V under load

Example: Programming a KT controller with these settings prevents the “sudden death” effect where a battery at 20% SOC can’t deliver requested current, instead providing graceful power reduction.

Regenerative Braking Voltage Considerations

Proper regen setup requires precise voltage management:

| Battery State | Max Regen Voltage | Optimal Current |

|---|---|---|

| Below 80% SOC (<51V) | 55V (4.23V/cell) | 5-8A |

| Above 80% SOC (>51V) | 53V (4.07V/cell) | 2-3A |

Warning: Exceeding 55V during regen can trigger BMS overvoltage protection. Always test regen settings on slight declines before mountain descents.

System Integration Best Practices

- Display synchronization: Calibrate your dashboard to show true pack voltage, not just SOC percentage

- Thermal monitoring: Combine voltage data with temperature sensors (voltage sag increases 0.3V per 10°C rise)

- Lighting systems: Program LED brightness to reduce at <48V to conserve power for propulsion

Troubleshooting Voltage-Related Performance Issues

Common integration problems and solutions:

- Controller resets: Caused by voltage spikes – install a 48V capacitor bank near controller input

- Erratic PAS behavior: Often from noisy voltage signals – add ferrite beads to signal wires

- BMS cutting out: Usually due to voltage/current mismatch – verify controller settings match BMS specs

Pro Tip: For DIY builds, use an oscilloscope to check voltage ripple during acceleration. More than 0.5V peak-to-peak fluctuation indicates need for better wiring or capacitors.

By understanding these voltage integration principles, you can transform raw battery data into a finely-tuned e-bike system that maximizes both performance and battery longevity.

Mastering 48V Battery Voltage for Peak Performance and Safety

Comprehensive Voltage Health Assessment Protocol

Perform this 5-point inspection quarterly to evaluate battery condition:

| Test | Procedure | Acceptable Range |

|---|---|---|

| Static Voltage | Measure after 2hr rest at 50% SOC | 48.1V ±0.3V |

| Load Voltage Drop | 20A load for 10 seconds | <4V drop from resting |

| Cell Balance | Measure all cell groups at full charge | <0.05V variance |

| Recovery Time | Time to return to 95% resting voltage after load | <3 minutes |

| Capacity Verification | Controlled discharge at 10A | ≥95% of rated Ah |

System-Wide Voltage Optimization Strategy

- Controller calibration: Program voltage cutoffs 0.5V above BMS limits (e.g., 42.5V vs 42V) for safety margin

- Wiring upgrades: Replace stock cables with 10AWG copper to minimize voltage drop (saves 0.8V at 30A)

- Accessory management: Install a secondary 12V converter for lights/phone to avoid voltage spikes on main bus

Advanced Risk Mitigation Techniques

- Voltage spike protection: Install 58V MOVs across controller inputs to absorb regenerative braking surges

- Thermal monitoring: Place NTC sensors at battery terminals (voltage accuracy degrades above 45°C)

- Redundant monitoring: Use both onboard display and Bluetooth BMS for critical voltage alerts

Case Study: A commuter using these techniques maintained 91% capacity after 800 cycles (vs typical 70%), with voltage consistency improving from ±0.15V to ±0.08V between cell groups.

Long-Term Reliability Engineering

Implement these professional maintenance practices:

- Voltage profiling: Create discharge curves every 100 cycles to track degradation patterns

- Preventive balancing:

Perform manual balance charge when cell variance exceeds 0.07V - Contact maintenance: Clean and re-torque all high-current connections annually (0.1V drop = 15W energy loss at 30A)

Conclusion: Mastering Your 48V E-Bike Battery’s Potential

Understanding your 48V e-bike battery’s voltage behavior unlocks superior performance, extended lifespan, and safer operation. We’ve explored how voltage fluctuates with charge cycles (from 54.6V at full charge to 42V when depleted), the critical importance of voltage monitoring techniques, and advanced strategies for system integration.

By implementing proper voltage management—including maintaining optimal charge levels (80-20% for daily use), regular balancing, and load monitoring—you can potentially double your battery’s service life while maintaining consistent power delivery.

Take action today: Start by checking your battery’s resting voltage after a full charge, create a baseline voltage chart, and consider upgrading to a smart charger for precision voltage control. Remember, your battery’s voltage tells its true story—learn to read it well, and you’ll enjoy thousands of worry-free miles on your e-bike.

Frequently Asked Questions About 48V E-Bike Batteries

What exactly does “48V” mean in an e-bike battery?

A 48V rating refers to the nominal voltage, which is the average operating voltage during discharge. In reality, a fully charged 48V lithium-ion battery actually measures 54.6V (13 cells × 4.2V each), while a depleted battery drops to about 39V (13 × 3.0V).

This voltage range directly impacts your motor’s power output – higher voltage means more torque and speed. The 48V specification helps compare batteries, but understanding the full voltage range is crucial for proper usage.

How can I accurately measure my battery’s state of charge using voltage?

For precise SOC measurement: 1) Let the battery rest for 30 minutes after riding, 2) Use a quality multimeter to check terminals, 3) Compare to a voltage chart (e.g., 52.0V=90%, 48.1V=50%, 42.0V=10%).

Remember voltage drops under load – a reading of 45V while climbing might actually indicate 50V at rest. Create your own reference chart by logging voltages at different charge levels for your specific battery model.

Why does my battery voltage drop suddenly when going uphill?

This voltage sag occurs because high current draw (often 20-30A on hills) causes temporary voltage reduction due to internal resistance. Premium batteries with high-quality cells (like Samsung 35E) may only sag 2-3V, while cheaper alternatives can drop 5-8V.

If sag exceeds 10V at moderate loads, your battery may have aging cells or connection issues. Proper maintenance and keeping SOC above 30% minimizes excessive sag.

How often should I fully charge my 48V e-bike battery?

For daily use, charge to 90% (51-52V) to extend lifespan. Only perform full 100% charges (54.6V) monthly to balance cells. Lithium-ion batteries experience most stress at extreme voltages – keeping between 30-90% SOC can triple cycle life compared to full 0-100% cycling. If storing for >1 month, maintain 50% charge (48V) in a cool, dry place to minimize degradation.

What voltage indicates my battery needs replacement?

Watch for these signs:

1) Fully charged voltage below 53V after balancing,

2) More than 0.5V difference between cell groups,

3) Capacity below 70% of original (test by timing full discharge),

4) Voltage dropping >5V under normal loads.

A healthy 48V 20Ah battery should deliver ≥19Ah when new; replace when it consistently provides <14Ah. Professional battery analyzers can precisely measure internal resistance, another key health indicator.

Can I use a 52V battery with my 48V e-bike system?

Many 48V systems tolerate 52V batteries (58.8V full charge), but check:

1) Controller maximum voltage rating (often 60V),

2) Display compatibility,

3) Charger specifications.

The 8% voltage increase provides more power and speed, but may stress components over time. Some systems require firmware updates. Never use a 52V charger on a 48V battery – this dangerous overcharge could cause thermal runaway.

How does temperature affect my battery’s voltage readings?

Voltage decreases about 0.3V per 10°C drop in temperature – a 48V battery at 0°C may read 46V despite normal capacity. This is temporary and reverses when warmed.

However, charging below 0°C causes permanent lithium plating. In hot conditions (>45°C), voltage reads slightly higher but accelerates degradation. Always allow batteries to reach room temperature before charging or assessing SOC for accurate readings.

What’s the safest way to transport my 48V e-bike battery?

For safe transport:

1) Charge to 30-60% SOC (44-50V), 2) Use protective case,

3) Avoid extreme temperatures,

4) Disconnect from bike,

5) Check terminals are covered.

Airlines typically require batteries under 100Wh (a 48V 2Ah pack); larger packs need special approval. Never transport damaged or swollen batteries. The 30-60% charge range minimizes fire risk while preventing deep discharge during storage.