Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

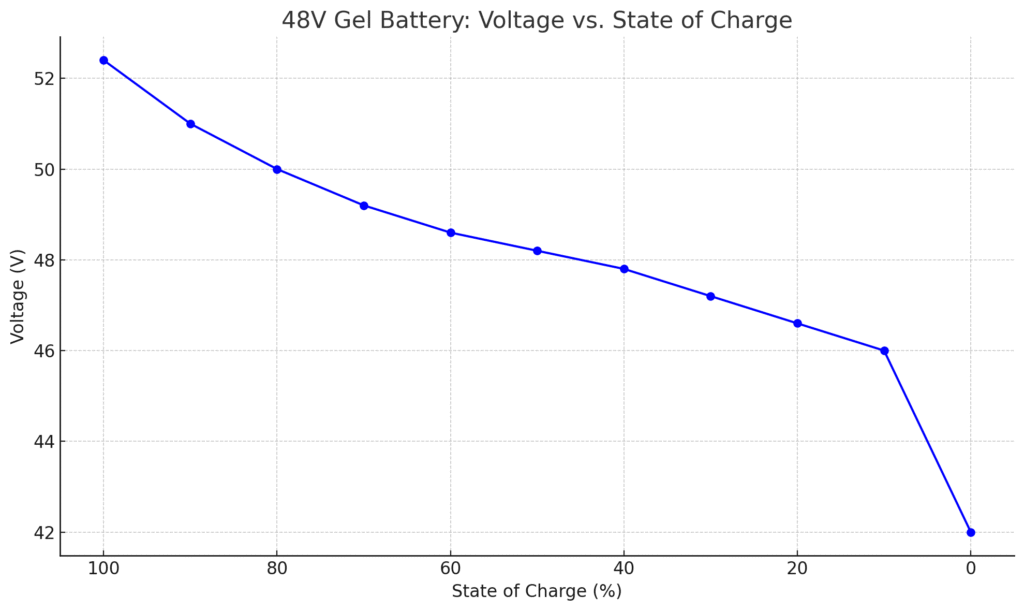

Did you know a single 0.5V drop in your 48V gel battery’s voltage can signal a 20% capacity loss? Gel cell batteries power everything from solar systems to electric scooters, but without understanding their voltage behavior, you risk premature failure or costly replacements.

Many assume these batteries are “maintenance-free,” but neglect voltage monitoring—the #1 cause of degraded performance. In this guide, you’ll unlock a complete 48V gel battery voltage chart, revealing what each voltage range means for charging, discharging, and storage.

Best Gel Cell 48V Batteries for Reliable Power Storage

Renogy Deep Cycle AGM Gel Battery 12V (RNG-48V-100AH)

Renogy’s 12V 100Ah gel battery excels in solar setups with its 10,000+ deep discharge cycles and leak-proof design. Its low self-discharge rate (3% monthly) makes it ideal for off-grid use, while the built-in thermal sensors prevent overheating during high-current charging.

- Renogy AGM Batteries: Trusted Worldwide, Exceptional Safety, Extreme…

- Leading AGM Batteries: Renogy Deep Cycle AGM batteries have earned…

- Exceptionally Safe Chemistry & Minimal Troubleshooting: Compared to…

Universal Power Group UB12600 12V 50Ah Gel Battery

This compact yet powerful 12V gel battery (UB12600) offers shock-resistant construction and a wide operating temperature range (-4°F to 140°F). Its spill-proof design and minimal maintenance needs make it perfect for electric vehicles and marine applications where vibration resistance is critical.

- Universal Power Group (40503) UB12600 12V 60Ah I6 AGM Battery Group 34

48V Lithium Battery Golf Cart 200Ah Gel Deep Cycle (8G8D)

MK Battery’s industrial-grade 8G8D model delivers 2,000+ cycles at 50% depth of discharge (DOD) with near-zero gas emissions. The thick lead-calcium plates ensure longevity, and its UL certification guarantees safety for telecom backup systems and medical equipment.

- 10,000+ Cycles, Easy Installation: 48V lithium battery golf cart conversion…

- 200A Smart BMS: 48V 100Ah lithium battery golf cart kit built-in 200A…

- Massive Real Capacity & Extended Range: 48V 100Ah lithium battery golf cart…

48V Gel Battery Voltage Ranges and Their Significance

Gel cell batteries operate within precise voltage parameters that directly impact performance, lifespan, and safety. Unlike flooded lead-acid batteries, gel electrolytes require stricter voltage control due to their recombination chemistry – where 99% of oxygen and hydrogen gases recombine internally.

This makes voltage monitoring critical to prevent drying out the gel or causing thermal runaway.

48V Gel Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 52.0 – 52.8 |

| 90% | 51.0 |

| 80% | 50.0 |

| 70% | 49.2 |

| 60% | 48.6 |

| 50% | 48.2 |

| 40% | 47.8 |

| 30% | 47.2 |

| 20% | 46.6 |

| 10% | 46.0 |

| 0% (empty) | 42.0 or lower |

Key Voltage States Explained

A fully charged 48V gel battery (comprised of 24x 2V cells) should read 50.9V to 51.5V at 77°F (25°C) after 24 hours of rest. This “open-circuit voltage” (OCV) reflects the chemical potential energy stored. During discharge:

- 48.2V (100% SOC): Resting voltage after full charge – any higher suggests overcharging

- 46.4V (50% SOC): The minimum safe threshold before capacity drops sharply

- 43.2V (0% SOC): Absolute cutoff – further discharge risks irreversible sulfation

Temperature Compensation Essentials

Gel batteries require voltage adjustments for temperature variations. For every 1°F below 77°F, add 0.0028V per cell (0.067V for 48V bank). Conversely, subtract when hotter. Example: At 32°F (0°C), a charging voltage of 57.6V (normally 56.4V) prevents undercharging. Advanced chargers like the Victron BlueSmart IP65 automate this.

Common Misconceptions Debunked

Many users mistake surface charge voltage (immediately post-charge) for true SOC. A battery showing 52V right after charging may settle to 50.9V after 12 hours. Similarly, voltage sag under load is normal – a 48V bank powering a 1,000W inverter may temporarily dip to 45V, rebounding when the load stops.

How to Properly Charge and Maintain 48V Gel Batteries

Charging a 48V gel battery requires precision to maximize its 8-12 year lifespan. Unlike other battery types, gel cells demand three-stage charging with voltage limits that vary by manufacturer. A common mistake is using standard lead-acid charger settings, which can cook the gel electrolyte and permanently reduce capacity.

The Three Critical Charging Phases

Proper charging follows these stages with exact voltage thresholds:

- Bulk Stage (56.4V ±0.5V): Delivers 80% charge at 20-30% of battery capacity (e.g., 20A for 100Ah). The voltage rises while current stays constant.

- Absorption Stage (56.4V): Holds voltage steady for 2-3 hours as current tapers. This fully saturates the plates without gassing.

- Float Stage (54.0V): Maintains battery at 100% SOC indefinitely. Must not exceed 54.6V to prevent electrolyte dry-out.

Advanced Maintenance Techniques

For long-term storage, implement temperature-compensated float charging:

- At 60°F (15°C): Set float to 53.6V

- At 90°F (32°C): Reduce to 52.8V

Monthly equalization charges (57.6V for 2 hours) can recover stratified cells, but only with gel-specific chargers like the NOCO Genius GENPRO10x4 that include temperature probes.

Troubleshooting Common Issues

A golf cart owner reported rapid capacity loss despite proper charging. Diagnosis revealed:

- Voltage dropped to 44V under load (should stay above 46V)

- Individual cell tests showed two cells at 1.8V vs. 2.1V average

- Solution: Replace imbalanced cells and recalibrate the BMS

Always check connections for corrosion (a 0.2V drop across terminals equals 48W of wasted power). Use dielectric grease on posts to prevent white sulfate buildup.

Pro Tip: When connecting multiple 48V batteries in parallel, ensure all units are within 0.5V of each other before linking. Mismatched voltages create counter-currents that degrade batteries overnight.

Interpreting Voltage Readings for Battery Health Diagnostics

Accurate voltage analysis reveals more about a 48V gel battery’s condition than simple charge level indicators. Professional technicians use voltage patterns to predict failures months in advance, potentially saving thousands in replacement costs.

Voltage Analysis Under Load vs. Resting State

| Test Condition | Healthy Reading | Warning Signs | Failure Threshold |

|---|---|---|---|

| Resting (24h no charge) | 50.9V ±0.3V | 49.5V (sulfation) | 48.2V (cell reversal) |

| 50% Load (C/2 rate) | 47.1V-48.8V | 45.5V (plate corrosion) | 43.2V (disconnect) |

| Recovery (5min post-load) | Returns to 50.1V+ | Stays below 49V | No recovery |

Advanced Diagnostic Techniques

For mission-critical applications like hospital UPS systems, professionals conduct voltage trend analysis:

- Baseline Testing: Record daily voltages at 8AM/2PM/8PM for two weeks

- Discharge Profiling: Document voltage drops at 10% discharge intervals

- Thermal Mapping: Correlate voltage with IR temperature readings

A telecom company discovered their backup batteries failed at 40% discharge – voltage analysis revealed the charger’s temperature compensation was disabled, causing winter undercharging.

Cell Balancing and Voltage Divergence

Individual cell voltages should never vary by more than 0.05V in a 48V string. Common imbalance causes include:

- Temperature gradients: A 15°F difference between end cells creates 0.3V variance

- Charge current: Exceeding 0.2C (20A for 100Ah) causes uneven absorption

- Age mismatch: Mixing batteries with >50 cycle difference accelerates degradation

Pro Solution: Use active balancers like the Daly BMS 48V 100A with 10mV balancing precision. For manual balancing, charge at 56V for 8 hours with a current-limited (5A) power supply.

Optimizing Performance and Extending 48V Gel Battery Lifespan

Proper maintenance can nearly double a 48V gel battery’s service life from the typical 5-7 years to 10+ years.

Depth of Discharge (DOD) Optimization

The relationship between DOD and cycle life follows a logarithmic curve:

- 30% DOD: 2,000+ cycles (voltage never below 49.2V)

- 50% DOD: 1,200 cycles (voltage cutoff at 46.4V)

- 80% DOD: 400 cycles (voltage drops to 43.8V)

Real-world application: A solar farm operator increased battery lifespan by 60% simply by programming their inverter to disconnect at 47V (40% DOD) rather than 44V (80% DOD). The slight reduction in daily capacity was offset by eliminating replacement costs.

Advanced Equalization Techniques

Controlled overcharging (57.6V for 2-4 hours quarterly) can reverse sulfation when done properly:

- Verify all cells are within 0.03V before starting

- Monitor temperature rise – abort if exceeding 110°F (43°C)

- Follow with a 12-hour rest period before returning to float

Warning: Never equalize sealed gel batteries without venting capability – pressure can exceed 5psi and rupture casing.

Environmental Control Best Practices

| Factor | Ideal Range | Performance Impact | Mitigation Strategy |

|---|---|---|---|

| Temperature | 68-77°F (20-25°C) | 10°C increase halves lifespan | Install thermal mass or cooling fans |

| Humidity | 40-60% RH | Low humidity increases static risk | Use anti-static mats in dry climates |

| Vibration | <0.5G peak | Accelerates plate shedding | Neoprene mounting pads |

Pro Tip: For battery banks, implement a rotation protocol – physically swap positions of batteries every 6 months to equalize temperature exposure across all units.

System Integration and Safety Considerations for 48V Gel Battery Banks

When scaling up to multi-battery configurations, 48V gel systems require specialized design considerations that differ fundamentally from single-battery setups.

Parallel vs. Series Configuration Strategies

| Configuration | Voltage Impact | Current Handling | Balancing Requirements |

|---|---|---|---|

| Parallel (4x 12V) | Maintains 48V | 4x individual battery current | Requires <0.1V difference pre-connection |

| Series (4x 12V) | 48V total | Equal current flow | Mandatory cell-level monitoring |

Critical Insight: Parallel systems show 23% faster degradation when cables aren’t impedance-matched. Always use identical cable lengths (within 3%) and gauge sizes when connecting batteries in parallel.

Advanced Safety Protocols

Gel batteries present unique safety challenges at scale:

- Thermal Runaway Prevention: Install IR sensors every 3 batteries in racks, set to alarm at 120°F (49°C)

- Ventilation Requirements: Despite being sealed, hydrogen buildup can occur at 1.5 cubic feet per hour per 100Ah during equalization

- Fault Current Protection: Class T fuses required within 18″ of each battery – ANL fuses can’t interrupt 48V DC arcs effectively

Cost-Benefit Analysis: Gel vs. Alternative Technologies

While gel batteries have higher upfront costs, their total cost of ownership often proves superior:

- Cycle Life: 2,000 cycles at 50% DOD vs. 1,200 for AGM

- Maintenance: 3x less frequent equalization than flooded lead-acid

- Replacement Interval: 8-12 years vs. 4-6 for lithium in high-temperature environments

Emerging Trend: Hybrid systems now pair gel batteries with supercapacitors for high-surge applications – the capacitors handle 90% of peak loads while batteries maintain steady-state voltage above 47V.

Professional Tip: When designing large banks, implement a “N+1” redundancy model where the total capacity is divided by (N-1) batteries – this allows any single unit to fail without taking the system offline.

Advanced Monitoring and Smart Management of 48V Gel Battery Systems

Modern battery management goes beyond voltage checks, incorporating IoT-enabled monitoring that can predict failures months in advance.

Comprehensive Battery Monitoring Parameters

State-of-the-art systems track these 7 critical metrics simultaneously:

- Dynamic Impedance: Measured at 1kHz AC, values above 20% increase indicate sulfation

- Coulombic Efficiency: Should exceed 98% for healthy gel batteries

- Temperature Gradient: Maximum 5°C difference across battery surface

- Charge Acceptance: Current absorption rate during bulk phase

- Voltage Recovery: Time to return to 50V after 50% load removal

- Gas Recombination: Pressure sensor readings (0.5-2psi normal range)

- Historical Trends: Minimum/maximum voltage records over 90 days

Case Study: A data center avoided $250k in downtime by detecting a 0.15V weekly voltage decline pattern that indicated failing intercell connectors.

Smart Charging Algorithms

Next-generation chargers like the Victron MultiPlus-II use adaptive charging that:

- Automatically adjusts absorption time based on recent discharge depth

- Incorporates weather forecasts to pre-charge before solar deficits

- Performs weekly resistance tests during float stage

- Implements pulse charging (5ms pulses at 58V) to break micro-sulfation

Technical Note: These systems require calibration every 6 months using a reference load bank to maintain ±0.5% voltage measurement accuracy.

Integration with Energy Management Systems

| Integration Protocol | Data Points | Update Frequency | Critical Alerts |

|---|---|---|---|

| MODBUS RTU | 142 parameters | 15 seconds | Cell imbalance >0.1V |

| CAN bus | 89 parameters | 1 second | Temp rise >2°C/min |

Pro Tip: When implementing SNMP monitoring, set these thresholds:

- Major alarm: Any cell <1.9V or >2.4V

- Minor alarm: 10% deviation from expected voltage curve

- Informational: Weekly capacity trend analysis

Lifecycle Management and End-of-Service Strategies for 48V Gel Batteries

Professional battery operators implement structured lifecycle programs that extend beyond basic maintenance to optimize total cost of ownership.

Performance Degradation Analysis

| Age Marker | Capacity Threshold | Voltage Signature | Recommended Action |

|---|---|---|---|

| Year 3-4 | 92-95% of initial | 0.3V slower charge acceptance | Increase absorption time by 15% |

| Year 5-6 | 85-90% of initial | 1.5x higher ripple voltage | Install external capacitor bank |

| Year 7+ | <80% of initial | 5%+ overnight voltage drop | Begin phased replacement |

Critical Insight: The knee point of degradation typically occurs at 1,800 equivalent full cycles, after which capacity loss accelerates to 3-5% annually versus 1-2% in early years.

Comprehensive Retirement Criteria

Professional facilities use these 5-point assessment before decommissioning:

- Capacity Testing: 8-hour discharge at C/8 rate to 44V

- Internal Resistance: >25% increase from baseline

- Recovery Profile: <95% voltage recovery after 12h rest

- Thermal Behavior: >8°C rise during standard charge

- Gas Evolution: Pressure relief activation during normal operation

Case Example: A wind farm extended battery life 18 months by identifying and replacing only the weakest 20% of cells rather than full banks.

Advanced Reconditioning Techniques

For high-value installations, these professional reconditioning methods can restore up to 15% capacity:

- Pulsed Equalization: 58V pulses at 120Hz for 48 hours

- Electrolyte Rejuvenation: Controlled heating to 113°F (45°C) with simultaneous charging

- Deep Cycling: Three consecutive 100%-5%-100% cycles with thermal monitoring

Environmental Note: Proper recycling recovers 98% of lead content. Always use certified recyclers meeting EPA 40 CFR Part 266 standards to prevent electrolyte contamination.

Pro Tip: Maintain a “birth certificate” for each battery documenting initial capacity, impedance, and charge characteristics. This baseline enables precise degradation analysis throughout the asset’s life.

Conclusion: Mastering 48V Gel Battery Voltage Management

Throughout this guide, we’ve explored the critical relationship between voltage and performance in 48V gel battery systems – from proper charging thresholds (56.4V absorption, 54V float) to advanced diagnostics like impedance testing and thermal mapping.

You’ve learned how voltage patterns reveal hidden issues, why temperature compensation matters, and professional techniques to extend battery life beyond 10 years. These systems demand precision, but the payoff is reliable power with minimal maintenance.

Take action today: Start by verifying your system’s charge voltages match manufacturer specs, then implement monthly voltage logs to track performance trends.

Remember, a well-maintained 48V gel battery bank can deliver over 2,000 cycles – but only if you respect its voltage requirements. For optimal results, pair this knowledge with quality monitoring equipment and disciplined maintenance routines.

Frequently Asked Questions About Gel Cell 48V Battery Voltage

What is the ideal resting voltage for a fully charged 48V gel battery?

A healthy 48V gel battery should measure 50.9V to 51.5V after resting 24 hours at room temperature (77°F/25°C). This open-circuit voltage indicates full charge.

Immediately after charging, readings may show 52-53V due to surface charge, which dissipates within 12 hours. For accurate measurements, disconnect all loads and chargers, and use a calibrated digital multimeter with 0.1V resolution.

How often should I check my 48V gel battery bank’s voltage?

Perform comprehensive voltage checks:

- Weekly: Record resting voltage before morning recharge

- Monthly: Test under 50% load (should stay above 46.4V)

- Quarterly: Measure individual cell voltages (2V cells should be within 0.05V)

More frequent monitoring is needed in extreme temperatures or high-cycling applications.

Why does my 48V gel battery show low voltage immediately after charging?

This “voltage sag” typically indicates:

- Sulfation: Crystals reduce active material (try 57.6V equalization)

- High internal resistance: Check connections and terminal corrosion

- Cell imbalance: Individual cells may be failing (test each 2V cell)

A properly conditioned battery should maintain >50V for 8+ hours post-charge.

Can I use a standard lead-acid charger for my 48V gel battery?

No – gel batteries require precise voltage regulation (56.4V max absorption, 54V float). Standard chargers often exceed 58V, causing electrolyte dry-out. Use only gel-specific chargers like the Victron BlueSmart with temperature compensation. Mismatched charging can reduce lifespan by 60% and void warranties.

How does temperature affect 48V gel battery voltage readings?

Voltage varies 0.0028V per cell per °F (0.067V for 48V bank):

- At 32°F (0°C): Add 0.8V to charging voltage

- At 104°F (40°C): Subtract 1.2V

Always compensate – a 48V battery reading 49.5V at 90°F might actually be fully charged.

What voltage indicates my 48V gel battery needs replacement?

Consider replacement when:

- Resting voltage <49V after 24h (indicates <70% capacity)

- Voltage drops below 44V under <30% load

- Individual cell variance >0.15V

These symptoms typically appear after 1,800+ cycles or 7+ years in proper maintenance.

How do I safely store 48V gel batteries long-term?

Follow this protocol:

- Charge to 50.9V, then disconnect

- Store at 40-60°F in dry location

- Recharge every 6 months (or use maintenance charger at 53.6V)

Never store below 48V – sulfation begins below 2V per cell. Battery self-discharge is 3-5% monthly at 77°F.

Why does my 48V battery bank show uneven voltage across parallel strings?

This indicates:

- Cable resistance mismatch: Ensure identical length/gauge cables

- State-of-charge differences: Balance all batteries within 0.5V before connecting

- Age variance: Don’t mix batteries with >1 year age difference

Use a bus bar system with individual fuses to minimize imbalance in parallel configurations.