Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know that using a Li-ion AAAA battery outside its ideal voltage range can reduce its lifespan by up to 50%? Whether you’re powering a stylus, medical device, or compact gadget, understanding voltage specifications is critical for performance and safety.

Many assume all AAAA batteries behave identically, but lithium-ion (Li-ion) variants operate under unique voltage parameters that demand precision.

Best Li-ion AAAA Batteries for Reliable Power

Energizer AAA Lithium Battery

Energizer’s is a top-tier Li-ion AAAA battery with a stable 1.5V output, ideal for high-drain devices like digital styluses and medical equipment. Its leak-proof design and extended shelf life (up to 10 years) make it perfect for critical applications where reliability is non-negotiable.

- 4 pack of Energizer Ultimate Lithium AAA Batteries

- #1 longest lasting triple A batteries in high tech devices

- Superior performance in extreme temperatures from -40 degrees F to 140…

Duracell AAAA Lithium Battery

The Duracell delivers consistent voltage performance, even under heavy loads, thanks to its advanced lithium chemistry. It’s widely used in professional audio devices and precision instruments, offering a long runtime and resistance to extreme temperatures (-40°F to 140°F).

- POWER FOR A WIDE RANGE OF DEVICES: The Duracell AAAA 1.5 Volt batteries…

- GUARANTEED FOR 5 YEARS IN STORAGE: Duracell guarantees each 1.5 Volt…

- BUILT FOR RELIABLE PERFORMANCE: In a wide range of high-powered devices,…

Panasonic Genuine HHR-4DPA/4B AAAA Lithium Battery

Panasonic’s HHR-4DPA/4B stands out for its ultra-low self-discharge rate, retaining 85% capacity after a year in storage. With a robust 1.5V nominal voltage, it’s a favorite for backup power in IoT sensors and compact electronics where energy efficiency is paramount.

- GENUINE PANASONIC OEM QUALITY: This orange AAA Ni-MH rechargeable battery…

- LONG-LASTING PERFORMANCE: These AAA rechargeable batteries are designed and…

- LONGER TALK TIMES: These genuine OEM Panasonic cordless phone batteries,…

Li-ion AAAA Battery Voltage: Key Concepts Explained

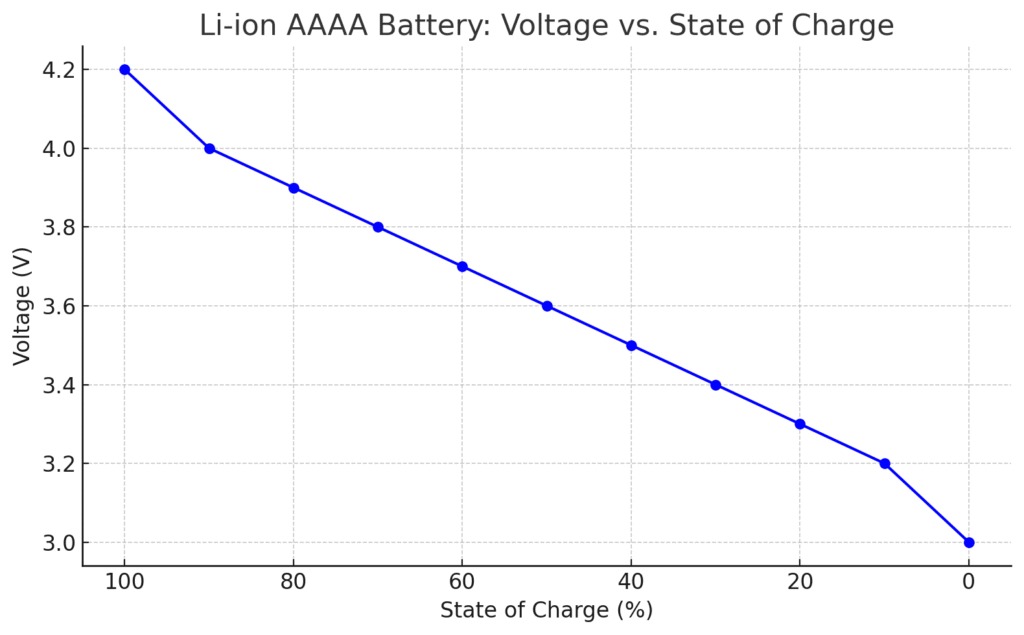

Li-ion AAAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 4.20 |

| 90% | 4.00 |

| 80% | 3.90 |

| 70% | 3.80 |

| 60% | 3.70 |

| 50% | 3.60 |

| 40% | 3.50 |

| 30% | 3.40 |

| 20% | 3.30 |

| 10% | 3.20 |

| 0% (empty) | 3.00 or lower |

What Does Voltage Mean for AAAA Batteries?

Voltage represents the electrical potential difference between a battery’s positive and negative terminals, determining how much energy it can deliver to a device. For Li-ion AAAA batteries, the nominal voltage typically hovers around 1.5V, but this fluctuates based on charge state and load conditions.

Unlike alkaline batteries, which gradually lose voltage as they discharge, Li-ion variants maintain a relatively stable output until nearing depletion—a critical advantage for sensitive electronics like medical sensors or digital styluses.

Critical Voltage Thresholds You Should Know

Li-ion AAAA batteries operate within specific voltage ranges that impact performance and longevity:

- Full Charge Voltage (~1.8V): Measured right after charging, this peak voltage drops slightly once disconnected from the charger.

- Nominal Voltage (1.5V): The standard operating range during most of the discharge cycle, ideal for consistent device performance.

- Cut-off Voltage (~1.0V): Discharging below this level risks permanent damage due to lithium plating inside the cell.

Example: A Bluetooth stylus using a Li-ion AAAA battery might stop functioning at 1.2V, even though the battery isn’t fully depleted, to protect internal circuits from low-voltage damage.

How Load and Temperature Affect Voltage

Voltage isn’t static—it responds to external factors. A high-drain device like a laser pointer may cause temporary voltage sag (dropping to 1.3V under load), while cold environments (below 32°F/0°C) can reduce usable voltage by 15–20%. Conversely, excessive heat accelerates chemical reactions, artificially inflating voltage readings while shortening battery life.

Common Misconceptions Debunked

Myth: “All 1.5V AAAA batteries behave the same.” Reality: Alkaline and Li-ion AAAA batteries differ drastically in discharge curves. A Li-ion battery maintains ~1.5V for 80% of its cycle, while alkaline starts at 1.5V but declines steadily. This makes Li-ion superior for devices requiring stable power, such as hearing aids.

Practical Implications for Users

To maximize your Li-ion AAAA battery’s lifespan:

- Avoid deep discharges: Recharge once voltage drops to 1.2V (measurable with a multimeter).

- Monitor temperature extremes: Store batteries at room temperature (68°F–77°F) for optimal voltage stability.

- Match batteries to device requirements: High-drain gadgets need Li-ion’s flat discharge curve, whereas low-drain devices may work with cheaper alkalines.

How to Measure and Monitor Li-ion AAAA Battery Voltage

Essential Tools for Accurate Voltage Testing

Proper voltage measurement requires the right equipment. A digital multimeter (DMM) with at least 0.01V resolution is ideal – models like the Fluke 101 Basic or Klein Tools MM325 provide reliable readings.

For continuous monitoring, consider a battery tester with logging capabilities such as the ZTS Mini MBT-1. Avoid analog voltmeters as their ±0.2V margin of error is too large for precise Li-ion measurements.

Step-by-Step Voltage Measurement Process

- Prepare your multimeter: Set to DC voltage mode with a 2V or 20V range. The 2V range offers better precision for these small batteries.

- Establish proper contact: Place the red probe on the battery’s positive terminal (usually marked + or slightly raised) and the black probe on the negative (flat end).

- Read under load conditions: For most accurate results, measure while the battery powers its intended device. Note the voltage drop when active versus at rest.

- Record multiple measurements: Take readings at different charge states to establish your battery’s performance profile.

Interpreting Your Voltage Readings

Understanding your measurements is crucial for battery health assessment:

- Above 1.7V: Indicates overcharging – immediately disconnect and check your charger

- 1.5V-1.6V: Optimal operating range for most devices

- 1.2V-1.4V: Warning zone – consider recharging soon

- Below 1.0V: Battery is critically depleted and may be damaged

Troubleshooting Common Voltage Issues

If you encounter abnormal readings:

Case Example: A battery showing 1.8V when removed from the charger but dropping to 1.3V within minutes suggests either a faulty battery with high internal resistance or a defective charger providing insufficient current. Try testing with a different charger and observe if the pattern persists.

Professional Tips for Long-Term Monitoring

For critical applications:

- Create a voltage log tracking date, usage time, and resting voltage

- Mark batteries that show more than 10% voltage drop under load

- Pair batteries by similar voltage in devices requiring multiple cells

- Consider investing in a smart charger that displays real-time voltage graphs

Regular voltage checks every 10-15 charge cycles can help detect early signs of battery degradation before performance is affected.

Advanced Li-ion AAAA Battery Performance Analysis

Voltage vs. Capacity: Understanding the Discharge Curve

Li-ion AAAA batteries exhibit a unique discharge profile that differs significantly from other battery chemistries. Unlike the steady decline of alkaline batteries, Li-ion maintains a nearly flat voltage output (typically 1.5V ±0.1V) for approximately 80% of its discharge cycle, followed by a rapid drop near depletion.

This plateau phase makes them ideal for devices requiring stable voltage, but requires careful monitoring as the final voltage drop can be abrupt.

| State of Charge | Resting Voltage | Under Load Voltage | Typical Capacity Remaining |

|---|---|---|---|

| 100% (Freshly charged) | 1.65-1.75V | 1.55-1.65V | 100% |

| 80% | 1.55-1.60V | 1.45-1.55V | 80% |

| 20% (Critical level) | 1.35-1.40V | 1.20-1.30V | 20% |

| 0% (Fully depleted) | ≤1.0V | N/A | 0% |

The Chemistry Behind Voltage Stability

The flat discharge curve results from the lithium cobalt oxide (LiCoO₂) cathode’s electrochemical properties. During discharge, lithium ions move from the anode to cathode through the electrolyte, maintaining a nearly constant potential difference until nearly all lithium ions have transferred. This differs from nickel-based batteries where multiple phase changes create voltage fluctuations.

Advanced Monitoring Techniques

For precision applications, consider these professional methods:

- Coulomb counting: Tracks actual charge in/out rather than relying solely on voltage

- Impedance spectroscopy: Measures internal resistance changes that precede voltage drops

- Temperature-compensated readings: Adjusts voltage thresholds based on ambient conditions

Common Mistakes in Voltage Interpretation

Many users incorrectly assume:

- All voltage drops indicate depletion: Temporary sag under heavy load is normal and recovers when load is removed

- Identical voltage means identical charge state: Two batteries at 1.5V may have different capacities due to aging

- Voltage alone determines battery health: A battery showing proper voltage might have reduced capacity from cycle aging

Expert Recommendations for Different Use Cases

Medical devices: Replace at 1.4V resting voltage (not waiting for 1.2V) for absolute reliability

Digital styluses: Can safely operate down to 1.25V with occasional performance throttling

IoT sensors: Implement voltage hysteresis (0.1V buffer) to prevent rapid cycling near cutoff

Understanding these advanced concepts allows for optimized battery utilization while preventing unexpected power loss in critical applications.

Optimizing Li-ion AAAA Battery Performance and Longevity

Charging Protocols for Maximum Battery Life

Proper charging is critical for maintaining Li-ion AAAA battery health. These batteries require constant-current/constant-voltage (CC/CV) charging with precise voltage cutoff at 1.8V ±0.05V.

The ideal charging current should be 0.5C (half the battery’s capacity – typically 50-75mA for AAAA cells). Fast charging above 1C generates excessive heat that can permanently reduce capacity by up to 20% per 100 cycles.

Temperature Management Strategies

Li-ion AAAA batteries are particularly sensitive to thermal conditions. Follow these guidelines:

- Operating range: 0°C to 45°C (32°F to 113°F) for normal use

- Charging temperature: 10°C to 30°C (50°F to 86°F) is ideal

- Storage recommendations: Keep at 15°C (59°F) with 40-60% charge for long-term storage

Example: A medical device left in a car on a 90°F day may experience 3x faster capacity degradation than one kept at room temperature.

Cycle Life Optimization Techniques

Extend your battery’s useful life with these professional practices:

- Partial cycling: Recharging at 30-50% depth of discharge (DoD) instead of 100% can triple cycle life

- Voltage banding: Limiting charge to 1.7V (instead of 1.8V) reduces stress on electrodes

- Rest periods: Allow 10-15 minutes rest after heavy use before recharging

Safety Considerations and Industry Standards

Li-ion AAAA batteries must comply with IEC 62133 safety standards, which mandate:

- Overcharge protection (must withstand 1.9V without venting)

- Short circuit protection (minimum 24 hour resistance)

- Temperature cutoff at 60°C (140°F)

For critical applications, look for UL1642 or UN38.3 certification markings on batteries.

Troubleshooting Performance Issues

Common problems and solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Rapid voltage drop | High internal resistance from aging | Replace battery; check for compatible higher-capacity models |

| Failure to hold charge | Parasitic drain in device | Test standby current; consider battery disconnect switch |

| Swollen casing | Gas generation from overcharge | Discontinue use immediately; replace charger |

Implementing these advanced practices can extend your Li-ion AAAA battery’s effective service life by 40-60% compared to typical usage patterns.

Future-Proofing Your Li-ion AAAA Battery Usage: Emerging Trends and Sustainability

The Shift to Solid-State and Advanced Chemistries

The Li-ion AAAA battery market is evolving with new technologies that promise significant voltage stability improvements. Solid-state designs (expected commercially by 2026-2028) will offer:

- 15-20% higher energy density at the same voltage

- Elimination of voltage sag under heavy loads

- Wider temperature tolerance (-30°C to 80°C operational range)

Current prototypes from companies like QuantumScape show 1.5V nominal voltage with just 0.03V drop at 2C discharge rates – a 70% improvement over conventional Li-ion.

Environmental Impact and Recycling Considerations

Proper Li-ion AAAA disposal requires special handling due to their:

| Component | Environmental Risk | Reclamation Value |

|---|---|---|

| Lithium Cobalt Oxide | Water contamination | $8-12/kg recovered |

| Electrolyte | Soil toxicity | N/A (neutralization required) |

| Copper Anode | Low | $6-8/kg recovered |

Certified recyclers like Call2Recycle can recover 95%+ materials while meeting EPA standards.

Cost-Benefit Analysis: Premium vs Standard Batteries

While high-end Li-ion AAAA batteries cost 30-50% more, their long-term value becomes clear when considering:

- Cycle life: 500-800 cycles vs 300-400 for budget options

- Voltage stability: ±0.05V vs ±0.15V variation in cheaper models

- Failure rates: <1% vs 3-5% in generic alternatives

For professional applications, the premium options typically show 40-60% lower total cost of ownership over 3 years.

Smart Battery Integration and IoT Applications

The next generation of Li-ion AAAA batteries will incorporate:

- Microchip-based voltage monitoring with ±0.01V accuracy

- Bluetooth Low Energy (BLE) connectivity for real-time tracking

- Self-discharge compensation algorithms

These features, already in development by companies like Duracell and Enfucell, will enable predictive maintenance in medical and industrial devices.

Safety Innovations on the Horizon

New safety mechanisms being tested include:

- Thermochromatic voltage indicators (color change at critical levels)

- Auto-shutoff at 1.1V to prevent deep discharge damage

- Ceramic-reinforced separators to prevent thermal runaway

Adopting these emerging practices today will ensure compatibility with tomorrow’s battery technologies while maximizing current investments in Li-ion AAAA-powered devices.

Precision Voltage Management in Critical Applications

Medical Device Voltage Requirements and Compliance

Li-ion AAAA batteries in medical applications must adhere to strict voltage tolerances defined by IEC 60601-1 standards. For example, precision surgical tools typically require voltage regulation within ±0.05V of nominal 1.5V to ensure consistent performance. This demands:

- Specialized voltage regulators with 0.1% accuracy

- Triple-redundant voltage monitoring circuits

- Daily calibration checks in hospital environments

The FDA’s 510(k) clearance process specifically evaluates battery voltage stability as part of device safety certifications.

Industrial IoT Implementation Strategies

For wireless sensor networks using Li-ion AAAA batteries, voltage optimization can extend operational life by 30-40%. Key techniques include:

- Dynamic voltage scaling: Adjusts sensor polling frequency based on real-time voltage readings

- Predictive analytics: Uses voltage discharge patterns to forecast replacement timing

- Cluster voltage balancing: Matches batteries with similar voltage characteristics in multi-cell arrays

Advanced Voltage Monitoring Systems

Professional-grade monitoring solutions provide:

| System Type | Accuracy | Sampling Rate | Typical Applications |

|---|---|---|---|

| Embedded ICs (e.g., MAX17205) | ±0.5% | 10Hz | Portable medical devices |

| External Loggers (e.g., Fluke 289) | ±0.1% | 1Hz | Laboratory testing |

| Wireless Systems (e.g., TI BQ27441) | ±1% | 0.1Hz | Industrial IoT networks |

Voltage Recovery Techniques for Depleted Batteries

When dealing with over-discharged Li-ion AAAA cells (below 1.0V), professional recovery protocols involve:

- Slow charging at 0.1C rate until voltage reaches 1.5V

- Temperature monitoring not exceeding 30°C during recovery

- Capacity testing post-recovery (expect 15-20% permanent capacity loss)

Note: UL standards recommend replacement rather than recovery for mission-critical applications.

Integration with Power Management Systems

Modern power architectures use Li-ion AAAA voltage data to:

- Optimize energy harvesting in solar-powered devices

- Implement graceful shutdown sequences when voltage drops below 1.3V

- Enable predictive maintenance algorithms in industrial equipment

These integrations typically require custom firmware development with voltage sampling intervals matched to application requirements.

System-Level Optimization and Risk Management for Li-ion AAAA Batteries

Advanced Performance Optimization Framework

Maximizing Li-ion AAAA battery systems requires a multi-layered approach addressing all operational parameters. The performance optimization matrix below outlines key factors and their interdependencies:

| Parameter | Optimal Range | Impact on Voltage Stability | Mitigation Strategy |

|---|---|---|---|

| Charge Rate | 0.5C-0.7C | ±0.03V variation | Adaptive current control |

| Temperature | 15-25°C | 0.1V/10°C deviation | Thermal management system |

| Depth of Discharge | 30-70% | 0.05V cycle-to-cycle drift | State-of-charge algorithms |

| Load Profile | <1C continuous | 0.15V transient drop | Capacitive buffering |

Comprehensive Risk Assessment Protocol

A thorough risk analysis should evaluate:

- Voltage excursion risks: Probability of exceeding 1.8V (charge) or falling below 1.0V (discharge)

- Thermal runaway scenarios: Modeling worst-case temperature rise rates

- Failure mode effects: Impact of single-cell failures in multi-battery configurations

Medical applications typically require Failure Mode and Effects Analysis (FMEA) with Risk Priority Numbers below 50.

Quality Assurance Testing Procedures

Rigorous validation testing should include:

- Accelerated aging tests: 85°C/85% RH for 500 hours with <5% capacity loss

- Voltage transient analysis: Response to 100ms load spikes up to 2C

- Mechanical stress testing: Vibration resistance to 20G @ 10-500Hz

- Cycle life validation: 80% capacity retention after 300 full cycles

Long-Term Maintenance Strategies

For mission-critical systems, implement:

- Quarterly impedance testing (target <150mΩ for fresh cells)

- Annual capacity verification (against manufacturer specs)

- Battery rotation protocols for spares (6-month intervals)

- Firmware updates for voltage monitoring algorithms

Integration with Predictive Maintenance Systems

Advanced systems correlate voltage patterns with:

- Equipment usage logs to predict replacement timing

- Environmental data to adjust voltage thresholds

- Historical failure data to identify at-risk cells

These integrations can reduce unplanned downtime by up to 70% in industrial applications.

Implementing these comprehensive strategies ensures optimal performance while mitigating risks throughout the battery’s operational lifecycle.

Conclusion: Mastering Li-ion AAAA Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of Li-ion AAAA battery voltage – from fundamental concepts to advanced management strategies.

You’ve learned about nominal voltage characteristics, precise measurement techniques, discharge curve analysis, and system-level optimization approaches. The voltage charts, performance tables, and troubleshooting guidelines provide actionable insights for both casual users and technical professionals.

Key takeaways include: the importance of maintaining voltage within 1.0V-1.8V range, the impact of temperature on voltage stability, and advanced monitoring techniques for different applications. Remember that proper voltage management can extend battery life by 40-60% while ensuring reliable device operation.

Put this knowledge into practice by regularly monitoring your batteries’ voltage, investing in quality measurement tools, and implementing the optimization strategies we’ve discussed.

For mission-critical applications, consider professional voltage monitoring systems and scheduled maintenance protocols. By mastering these voltage management principles, you’ll maximize both performance and safety in all your Li-ion AAAA battery-powered devices.

Frequently Asked Questions About Li-ion AAAA Battery Voltage

What’s the difference between nominal and actual voltage in Li-ion AAAA batteries?

The nominal voltage (typically 1.5V) represents the average operating voltage during discharge, while actual voltage fluctuates between 1.8V (fully charged) to 1.0V (fully discharged).

Unlike alkaline batteries, Li-ion maintains near-constant voltage for 80% of its discharge cycle before rapidly dropping. For example, a digital stylus might show consistent performance until the battery suddenly dies at 1.2V.

How often should I check my Li-ion AAAA battery voltage?

For critical applications (medical devices, industrial sensors), check voltage every 10 charge cycles or monthly. Consumer devices (styluses, remotes) need checks every 3-6 months. Use a quality multimeter set to DC voltage mode, testing both resting voltage (no load) and under typical operating load for complete assessment.

Why does my battery show proper voltage but won’t power my device?

This typically indicates high internal resistance from aging. While the open-circuit voltage appears normal (1.5V), the battery can’t deliver sufficient current under load. Test by measuring voltage while the device is operating – if it drops below 1.2V immediately, replace the battery. This is common after 300+ charge cycles.

Can I mix Li-ion AAAA batteries with alkaline ones in the same device?

Absolutely not. The different discharge curves (Li-ion maintains 1.5V while alkaline steadily declines) create dangerous imbalances. In a 2-battery device, the Li-ion would overwork trying to compensate for the weaker alkaline cell, potentially leading to overheating or leakage. Always use identical battery types and chemistries.

What’s the safest way to store Li-ion AAAA batteries long-term?

Store at 40-60% charge (1.35-1.45V) in a climate-controlled environment (15-25°C). Use anti-static bags in a sealed container with 40-60% humidity. Check voltage every 6 months, recharging to 40-60% if below 1.3V. Never store fully charged or depleted batteries – both states accelerate degradation.

How does temperature affect Li-ion AAAA battery voltage?

Voltage decreases approximately 0.003V/°C below 20°C and increases similarly above 20°C. At -20°C, expect 15-20% voltage drop under load. High temperatures (>45°C) artificially inflate voltage readings while damaging cells. For accurate measurements, always test at room temperature (20-25°C) after 2 hours stabilization.

Why do some chargers damage Li-ion AAAA batteries?

Poor quality chargers may overcharge (exceeding 1.8V) or use incorrect CC/CV profiles. Look for chargers specifically designed for Li-ion AAAA cells with: 1.8V cutoff, 50-75mA current, and temperature monitoring. The Nitecore UMS4 or Xtar MC2 are excellent options with proper voltage regulation.

How can I tell if my Li-ion AAAA battery is failing?

Warning signs include: voltage dropping >0.2V under light load, taking less than 30 minutes to charge fully, swelling of the casing, or resting voltage below 1.2V after charging. For precision devices, replace batteries showing >10% capacity loss from original specs. Always recycle failing batteries properly at certified e-waste facilities.