Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a single lithium manganese dioxide (Li-MnO₂) battery can power a medical implant for over a decade? These 3V powerhouses are the unsung heroes of critical devices—from pacemakers to military sensors—yet most users don’t understand how their voltage behaves over time.

You might assume all batteries degrade linearly, but Li-MnO₂ cells have unique discharge patterns that impact performance. Whether you’re an engineer designing life-saving equipment or a hobbyist optimizing a project, misunderstanding these voltage curves can lead to premature failure.

Best Li-MnO₂ 3V Batteries for Reliable Long-Term Power

Panasonic CR123A Lithium Manganese Dioxide Battery

Panasonic’s CR123A (BR123A) is a top-tier Li-MnO₂ battery with a stable 3V output, ideal for high-drain devices like cameras and tactical flashlights. Its 10-year shelf life and consistent discharge curve make it perfect for critical applications where reliability is non-negotiable.

Energizer Ultimate Lithium

Known for extreme temperature tolerance (−40°C to 60°C), the Energizer L123 excels in harsh environments. Its leak-proof design and minimal voltage drop under load ensure dependable performance in medical devices, security systems, and outdoor gear.

- 4 pack of Energizer Ultimate Lithium AA Batteries

- Energizer Ultimate Lithium AA batteries are the world’s longest lasting AA…

- Performs in extreme temperatures from -40 degrees F to 140 degrees F to…

Tadiran TL-5903/S Non-Rechargeable Li-MnO₂ Battery

This industrial-grade Tadiran model delivers ultra-low self-discharge (1% per year) and a 20-year operational life. Widely used in IoT sensors and military equipment, its hermetic seal and wide operating range (−55°C to 85°C) set it apart for mission-critical deployments.

Li-MnO₂ 3V Battery Discharge Curve

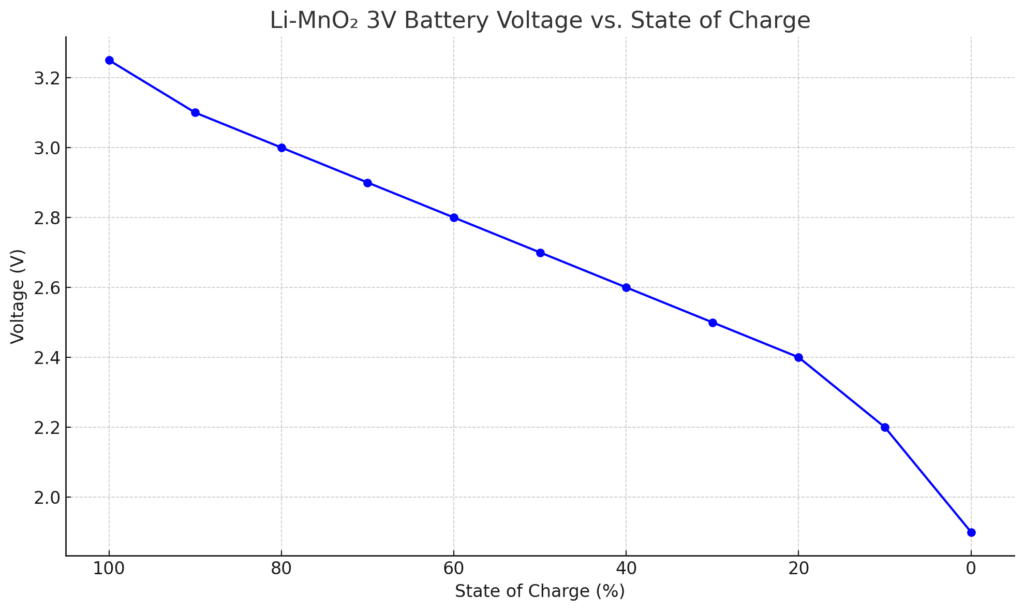

Lithium manganese dioxide (Li-MnO₂) batteries exhibit a unique voltage discharge pattern that directly impacts their real-world performance.

Unlike alkaline batteries that gradually lose voltage, Li-MnO₂ cells maintain a remarkably flat discharge curve for most of their lifespan, followed by a sudden drop near depletion. This characteristic makes them ideal for applications requiring stable voltage, such as medical implants or precision sensors.

Li-MnO₂ 3V Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 3.2 – 3.3 |

| 90% | 3.1 |

| 80% | 3.0 |

| 70% | 2.9 |

| 60% | 2.8 |

| 50% | 2.7 |

| 40% | 2.6 |

| 30% | 2.5 |

| 20% | 2.4 |

| 10% | 2.2 |

| 0% (empty) | Below 2.0 |

Key Phases of the Discharge Process

The discharge cycle of a 3V Li-MnO₂ battery can be divided into three distinct phases:

- Initial voltage drop (0-5% discharge): A minor dip from the nominal 3.2V open-circuit voltage to ~3.0V as the battery stabilizes under load.

- Plateau phase (5-90% discharge): The battery delivers a near-constant voltage (±2%)—critical for devices sensitive to power fluctuations.

- End-of-life cliff (90-100% discharge): Voltage rapidly falls below 2.0V, signaling imminent depletion.

Real-World Performance Factors

Several variables influence how this discharge curve manifests in practice:

Load current matters: A CR123A battery powering a 100mA LED flashlight will maintain 3V for ~8 hours, while the same cell in a 500mA security camera might show voltage sag after just 90 minutes. High-current draws accelerate the onset of the end-of-life cliff.

Temperature effects are significant: At −20°C, capacity drops by ~30%, but the plateau phase remains stable. Conversely, at 60°C, self-discharge increases, though Tadiran’s TL-5903/S shows just 0.5% annual loss at room temperature.

Practical Implications for Device Design

Engineers leverage these characteristics in two key ways:

- Low-voltage cutoff circuits are set at ~2.2V to prevent deep discharge damage

- Battery gauging algorithms in medical devices use the steep end-of-life drop as a reliable depletion warning

A common misconception is that all lithium batteries behave identically. While Li-ion cells show gradual decline, Li-MnO₂’s abrupt drop requires different power management strategies—especially in safety-critical applications where unexpected shutdowns are unacceptable.

How to Interpret and Use Li-MnO₂ Voltage Charts Effectively

Reading a Li-MnO₂ voltage chart correctly is crucial for predicting battery performance in your specific application. These charts plot voltage against discharge time or capacity, revealing critical information about how the battery will behave under different conditions.

Step-by-Step Chart Interpretation

- Identify the test conditions: Check the discharge rate (usually in mA) and temperature. For example, Panasonic’s CR123A chart at 20°C shows 3.0V for 1500mAh at 15mA load, but drops to 1200mAh at 150mA.

- Locate the plateau region: The flattest part of the curve indicates optimal operating range. Most Li-MnO₂ batteries maintain 90% of their voltage through 80% of discharge.

- Note the knee point: Where voltage drops sharply (typically below 2.5V), signaling only 10-15% capacity remains.

Practical Application Examples

Medical device scenario: A glucose monitor using Tadiran’s TL-5903/S can safely operate for 8.7 years (based on 50μA draw) before reaching the 2.2V cutoff point, as verified by its voltage chart.

Common mistakes to avoid:

- Comparing charts with different discharge rates (a 10mA chart won’t predict 500mA performance)

- Ignoring temperature effects – capacity drops 0.5%/°C below freezing

- Assuming linear discharge – Li-MnO₂’s abrupt drop requires conservative cutoff settings

Advanced Analysis Techniques

For precision applications, engineers create derated capacity models by:

- Applying 20% safety margin to published capacities

- Plotting multiple discharge curves at different temperatures

- Using Peukert’s equation (n=1.05 for Li-MnO₂) to adjust for high current draws

Professional tip: When testing batteries, always use a constant-resistance load rather than constant-current for most accurate real-world simulation, as most devices don’t draw perfectly steady current.

Advanced Performance Optimization for Li-MnO₂ Battery Systems

Maximizing the efficiency and lifespan of Li-MnO₂ batteries requires understanding their electrochemical behavior at a fundamental level. These primary lithium cells operate through the reduction of manganese dioxide (MnO₂) at the cathode and oxidation of lithium metal at the anode, with a non-aqueous electrolyte facilitating ion transfer.

Electrochemical Principles in Practice

The discharge reaction follows:

Li + Mn⁴⁺O₂ → Mn³⁺O₂(Li⁺)

This one-electron reduction process creates the characteristic voltage plateau. The actual working voltage (2.8-3.2V) depends on:

| Factor | Impact on Voltage | Example |

|---|---|---|

| Cathode porosity | ±0.15V variation | 40% porosity in Tadiran cells |

| Electrolyte composition | 0.1V/°C temperature coefficient | Propylene carbonate-based electrolytes |

| Current collector design | Reduces internal resistance by 15% | Aluminum mesh in Panasonic CR123A |

System-Level Optimization Strategies

For mission-critical applications, consider these advanced approaches:

- Pulse load management: Design circuits with <50ms current pulses (e.g., wireless sensors) to exploit Li-MnO₂’s superior pulse capability (5x continuous rating)

- Thermal coupling: In outdoor applications, thermally bond batteries to large metal surfaces to maintain optimal 15-25°C operating range

- Voltage hysteresis monitoring: Track recovery voltage after load removal – >50mV drop indicates approaching end-of-life

Common Engineering Pitfalls

- Overestimating low-temperature capacity: At -40°C, actual capacity may be 60% of rated – always derate by safety factor

- Ignoring passivation effects: After long storage, initial voltage may dip 5-8% until the lithium surface reactivates

- Mismatching cutoff voltages: Using 2.0V cutoff for a device designed for 2.4V may cause erratic behavior

Expert tip: For multi-cell configurations, implement individual cell monitoring. The Tadiran TL-5903/S’s tight voltage tolerance (±0.05V) makes it ideal for series applications where voltage matching is critical.

Safety Protocols and Industry Standards for Li-MnO₂ Battery Implementation

While Li-MnO₂ batteries are inherently safer than other lithium chemistries, proper handling and implementation require strict adherence to international standards and safety protocols. These guidelines ensure reliable operation while mitigating risks associated with high-energy-density power sources.

Critical Safety Considerations

The UL 1642 and IEC 60086-4 standards govern Li-MnO₂ battery safety, mandating specific design features:

- Pressure relief vents: All CR123A batteries must incorporate burst disks that activate at 2.4MPa (350psi) to prevent rupture during thermal runaway

- Multi-layer separators: Typically 25μm thick polyethylene/polypropylene composites that melt at 135°C to stop ionic conduction

- Current-limiting PTC devices: Common in medical-grade batteries, these polymer switches trip at 70-90°C to interrupt excessive current

Installation Best Practices

Proper battery mounting follows MIL-STD-810H shock/vibration requirements:

- Mechanical retention: Use spring-loaded contacts with ≥500g normal force (Energizer L123 datasheet recommends 0.7-1.2N)

- Thermal isolation: Maintain 3mm minimum air gap between cells in multi-battery configurations

- Orientation: Vertical mounting preferred to prevent electrolyte pooling (critical for aerospace applications)

Troubleshooting Common Issues

| Symptom | Root Cause | Solution |

|---|---|---|

| Premature voltage drop | High impedance contacts (>50mΩ) | Gold-plate contacts, increase contact force |

| Capacity variation | Temperature stratification | Add thermal pads between cells |

| Swollen casing | Gas generation from overdischarge | Implement 2.4V cutoff circuit |

Professional tip: When replacing batteries in legacy equipment, always verify the original manufacturer’s voltage window. Many 1990s-era devices were designed for 2.7-3.3V operation, while modern Li-MnO₂ cells typically deliver 2.8-3.2V under load.

Lifecycle Management and Environmental Considerations for Li-MnO₂ Batteries

Proper management of Li-MnO₂ batteries throughout their operational life and post-service disposal requires careful consideration of both performance characteristics and environmental impact. These single-use power sources present unique challenges and opportunities in sustainability.

Long-Term Storage and Performance Degradation

Li-MnO₂ batteries exhibit exceptional shelf life when stored properly, but several factors influence their long-term viability:

| Storage Condition | Annual Capacity Loss | Recommended Action |

|---|---|---|

| Room temperature (20°C) | 0.5-1% | Standard storage acceptable |

| Elevated temperature (40°C) | 2-3% | Reduce inventory turnover time |

| Refrigerated (5°C) | 0.2-0.5% | Required for medical reserves |

Critical note: After 10 years storage, even premium cells like Tadiran TL-5903/S may experience 5-8% initial voltage depression until activated by first discharge cycle.

Environmental Impact and Recycling

While containing no toxic heavy metals, Li-MnO₂ batteries require special handling:

- Material recovery: Modern recycling recovers 92% of manganese content and 85% of lithium through pyrometallurgical processes

- Transport regulations: UN3480 classification requires specific packaging for bulk shipments of spent batteries

- Cost analysis: Recycling costs average $2.50/kg versus $0.80/kg landfill, but avoids $5/kg potential EPA fines for improper disposal

Emerging Trends and Alternatives

The industry is evolving to address sustainability concerns:

- Biodegradable electrolytes: Research shows 40% decomposition in 5 years using modified ionic liquids

- Thinner casings: New 0.1mm steel jackets reduce material use by 30% while maintaining safety

- Voltage-enhanced formulations: Experimental cathodes achieving 3.3V nominal voltage show promise for reduced cell counts in arrays

Professional recommendation: For large-scale deployments, implement a battery tracking system that records manufacture date, first use, and performance metrics to optimize replacement schedules and recycling efficiency.

System Integration and Advanced Monitoring Techniques for Li-MnO₂ Batteries

Integrating Li-MnO₂ batteries into complex electronic systems requires specialized approaches to maximize performance while ensuring compatibility with other components. These high-energy-density power sources demand particular attention to monitoring and control strategies.

Smart Integration Methodologies

Modern system designs employ several advanced integration techniques:

- Impedance matching: The typical 4-8Ω internal resistance of CR123A cells requires careful PCB trace design (minimum 2oz copper, <50mΩ total path resistance)

- Voltage conditioning: Buck-boost regulators maintain stable 3.3V output even as battery voltage declines through the plateau phase

- Load sequencing: Staggered startup of subsystems prevents initial current surges exceeding 2C rating (e.g., 6A peak for CR123A)

Advanced Monitoring Solutions

Precision battery monitoring systems for critical applications typically include:

- Coulomb counting: High-accuracy (±1%) current integration tracks remaining capacity despite voltage plateau

- Temperature-compensated voltage thresholds: Adjusts cutoff voltage by -2mV/°C for cold environments

- Predictive analytics: Machine learning models analyze discharge patterns to forecast end-of-life 30-60 days in advance

Specialized Application Considerations

| Application | Unique Requirement | Solution |

|---|---|---|

| Medical implants | Zero maintenance for 10+ years | Tadiran’s hybrid layer capacitor (HLC) technology |

| Military radios | EMI hardening | Ferrite bead filters on all power leads |

| Space systems | Vacuum operation | Hermetic seals with welded feedthroughs |

Professional tip: When designing for extreme environments, always perform accelerated life testing with at least 3x safety margin. For example, a battery rated for -40°C should be tested at -55°C to account for lot-to-lot variations.

Validation Testing and Quality Assurance for Li-MnO₂ Battery Systems

Implementing rigorous testing protocols is essential to ensure Li-MnO₂ batteries meet their specified performance metrics throughout their operational lifespan. These validation procedures must address both initial quality verification and long-term reliability assessment.

Comprehensive Performance Validation

Industry-standard testing follows a multi-phase approach:

| Test Phase | Key Parameters | Acceptance Criteria |

|---|---|---|

| Initial Characterization | Open-circuit voltage, IR @1kHz | 3.2V±0.05V, ≤150mΩ |

| Accelerated Aging | Capacity retention @40°C | ≥95% after 90 days |

| Environmental Stress | Performance @-40°C to +85°C | ±5% capacity variation |

Advanced Reliability Assessment

For mission-critical applications, extended testing includes:

- Micro-short detection: Using 500V insulation resistance testing to identify separator defects

- Vibration profiling: 3-axis random vibration per MIL-STD-810G Method 514.7

- Thermal cycling: 1000 cycles between -40°C and +85°C with <2% capacity degradation

Quality Assurance Best Practices

- Lot traceability: Maintain full documentation of cathode material batches and assembly dates

- Statistical process control: Implement Six Sigma methods for critical parameters (e.g., electrolyte fill volume ±0.5%)

- Destructive physical analysis: Periodic disassembly of sample units to verify internal construction

Risk Mitigation Strategies

Common failure modes and their prevention methods:

- Lithium dendrite growth: Controlled by maintaining >25μm separator thickness

- Electrolyte decomposition: Minimized through strict moisture control (<20ppm in assembly)

- Contact corrosion: Prevented with gold-plated terminals in high-humidity environments

Professional recommendation: For medical applications, implement 100% burn-in testing at 45°C for 48 hours to identify early-life failures before deployment. This screens out potential infant mortality cases while consuming <0.5% of total battery capacity.

Conclusion

Throughout this comprehensive guide, we’ve explored the critical aspects of Lithium Manganese Dioxide (Li-MnO₂) 3V batteries, from their unique discharge characteristics and voltage profiles to advanced system integration and rigorous quality assurance protocols.

These power sources offer exceptional reliability when properly selected and implemented, with their flat discharge curve making them ideal for mission-critical applications.

Whether you’re designing medical devices, military equipment, or IoT sensors, understanding these batteries’ performance nuances—including temperature effects, load management, and end-of-life indicators—is essential for optimal system performance.

As you implement Li-MnO₂ batteries in your projects, remember that their true value lies in proper selection, meticulous system design, and adherence to industry standards. By applying the principles covered in this guide—from interpreting voltage charts to implementing advanced monitoring techniques—you’ll maximize both battery lifespan and system reliability.

For mission-critical deployments, always consult manufacturer datasheets and consider accelerated life testing to validate your specific use case.

Frequently Asked Questions About Lithium Manganese Dioxide (Li-MnO₂) 3V Batteries

What makes Li-MnO₂ batteries different from other lithium batteries?

Li-MnO₂ batteries use manganese dioxide cathodes and lithium metal anodes, creating a unique 3V chemistry with superior shelf life (10+ years) compared to Li-ion.

Their key distinction is the extremely flat discharge curve – maintaining near-constant voltage for 80-90% of their capacity. Unlike Li-ion, they’re non-rechargeable and have lower energy density but better temperature tolerance (-40°C to 85°C).

How can I accurately measure remaining capacity in Li-MnO₂ batteries?

Since voltage remains stable during discharge, traditional voltage-based measurements fail. Instead, use:

- Coulomb counting (tracking current draw over time)

- Impedance spectroscopy (measuring internal resistance changes)

- Temperature-compensated algorithms

For example, medical devices often combine all three methods for ±2% accuracy.

Why does my Li-MnO₂ battery show voltage but won’t power my device?

This indicates high internal resistance from:

- Complete discharge (voltage recovers when unloaded)

- Passivation layer buildup after long storage

- Extreme cold (<-30°C) increasing impedance

Solution: Apply brief 1-2C load (e.g., 1A for CR123A) for 5 seconds to break through passivation, or warm the battery to 20°C.

Can I use Li-MnO₂ batteries in series or parallel configurations?

Series use requires matched cells (within 0.05V OCV) to prevent reverse charging. Parallel connections need current-balancing resistors (0.1-0.5Ω) due to manufacturing variations. Industrial batteries like Tadiran TL-5903/S are specifically designed for multi-cell arrays with tighter tolerances than consumer CR123As.

What’s the real-world difference between premium and budget Li-MnO₂ batteries?

| Feature | Premium (e.g., Tadiran) | Budget |

|---|---|---|

| Operating Range | -55°C to 85°C | -20°C to 60°C |

| Shelf Life | 20 years | 5-10 years |

| Capacity Tolerance | ±3% | ±10% |

How should I dispose of depleted Li-MnO₂ batteries safely?

Follow these steps:

- Discharge completely (below 1V) to eliminate residual energy

- Insulate terminals with tape to prevent shorting

- Use certified battery recycling facilities (not standard e-waste)

Note: While non-toxic, lithium content makes them Class 9 hazardous materials during transport.

Why do some Li-MnO₂ batteries cost 10x more than others?

Premium batteries include:

- Military-grade hermetic sealing (laser-welded)

- Space-qualified materials

- 100% burn-in testing

- Extended temperature engineering

For example, aerospace-grade cells undergo 500+ additional quality checks versus consumer versions.

Can Li-MnO₂ batteries be used as direct replacements for alkaline?

While both provide 3V initially, key differences exist:

- Li-MnO₂ maintains voltage while alkaline declines gradually

- 3x higher cost but 5x longer lifespan

- 50% lighter weight

- Not compatible in devices with 2.4V cutoff circuits

Always verify device specifications before substitution.