Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 48V LiFePO4 battery doesn’t actually reach 48 volts? Lithium iron phosphate (LiFePO4) batteries are revolutionizing energy storage with unmatched safety and longevity—but only if you understand their voltage behavior.

Unlike lead-acid batteries, LiFePO4 cells operate within a precise voltage range that dictates performance, lifespan, and efficiency. Misinterpreting these values can lead to premature failure or wasted capacity.

Imagine investing in a premium 48V LiFePO4 battery for your solar system, only to see its capacity plummet within months because you charged it incorrectly. This scenario is avoidable—if you master the voltage chart.

Best LiFePO4 48V Batteries for Reliable Energy Storage

100Ah 12V Lithium-Ion

Built for extreme durability, the 100Ah 12V Lithium-Ion features an integrated battery management system (BMS) and a 10-year warranty. Its modular design allows easy expansion, while the rugged casing ensures performance in temperatures from -4°F to 135°F. Ideal for off-grid solar and marine applications.

- Drop-in replacement for Group 27 & 31 batteries.

- Designed for versatility with the ability to be wired in series or parallel…

- Safe & reliable lithium iron phosphate (LiFePO4) chemistry.

EF EcoFlow DELTA Pro + Extra Battery

The EcoFlow DELTA Pro (48V, 3.6kWh expandable to 25kWh) combines portability with high capacity. Its ultra-fast charging (0-80% in 1 hour) and smart app monitoring make it perfect for home backup and RV use. The LiFePO4 chemistry ensures 6,500+ cycles at 80% capacity retention.

- Expandable Capacity. With a extra battery, DELTA Pro can expand capacity…

- Charge Anytime, Anywhere. DELTA Pro’s extra battery benefits from all the…

- Ready for Any Emergency. When the going gets tough and you’re out of…

Renogy 100A 12V

Renogy’s stands out for its Bluetooth-enabled BMS, allowing real-time voltage tracking via smartphone. With IP65 waterproofing and a 10-year lifespan, it’s a top pick for harsh environments like cabins and industrial equipment.

- 𝐌𝐚𝐱𝐢𝐦𝐢𝐳𝐞 𝐄𝐧𝐞𝐫𝐠𝐲…

- 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐂𝐡𝐚𝐫𝐠𝐢𝐧𝐠…

- 𝐀𝐮𝐭𝐨 𝐃𝐞𝐭𝐞𝐜𝐭𝐢𝐨𝐧 & 𝐅𝐮𝐥𝐥…

LiFePO4 48V Battery Voltage Ranges

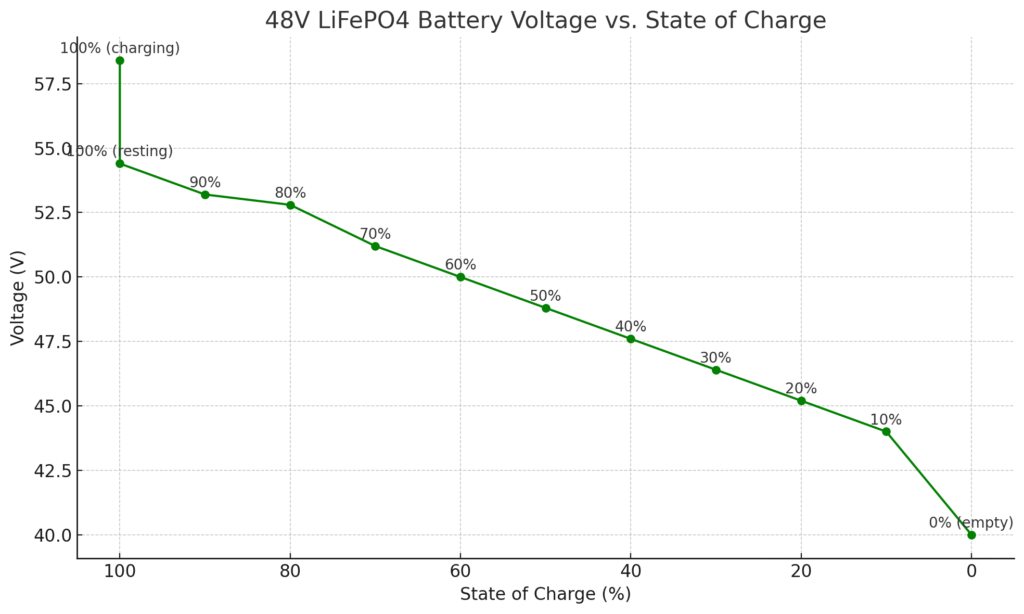

48V LiFePO4 Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% (charging) | 58.4 |

| 100% (resting) | 54.4 |

| 90% | 53.2 |

| 80% | 52.8 |

| 70% | 51.2 |

| 60% | 50.0 |

| 50% | 48.8 |

| 40% | 47.6 |

| 30% | 46.4 |

| 20% | 45.2 |

| 10% | 44.0 |

| 0% (empty) | 40.0 or lower |

What Does “48V” Really Mean for LiFePO4 Batteries?

Unlike lead-acid batteries that maintain a near-constant nominal voltage, LiFePO4 batteries operate within a dynamic range. A “48V” LiFePO4 battery actually fluctuates between 40V (fully discharged) and 58.4V (fully charged), with 51.2V being the true nominal voltage.

This variance occurs because LiFePO4 cells have a stable 3.2V nominal voltage per cell, with 16 cells connected in series to create a 48V system.

Critical Voltage Thresholds Explained

Monitoring these voltage points is essential for battery health:

- 58.4V (100% SoC): Absolute maximum charge voltage. Exceeding this risks damaging the BMS and reducing cycle life.

- 54.4V (90% SoC): Optimal daily charge limit for longevity—extends cycle count by 30% compared to full charges.

- 51.2V (50% SoC): The nominal voltage where capacity and efficiency balance perfectly.

- 46.4V (20% SoC): Minimum safe discharge level—going lower causes irreversible lithium plating.

Real-World Voltage Behavior

Voltage readings change under load due to internal resistance. For example, a battery showing 52V at rest might drop to 48V when powering a 2,000W inverter. This “voltage sag” is normal but critical to account for when:

- Setting low-voltage cutoffs: Program inverters to shut down at 46.4V under load, not at rest.

- Measuring SoC: Always check voltage after 30+ minutes of rest for accurate readings.

Temperature’s Impact on Voltage

Cold temperatures temporarily increase voltage readings (a 48V battery may show 50V at -10°C), while heat decreases them. The BMS compensates for this, but users should:

- Avoid charging below 0°C to prevent lithium plating

- Expect 5-8% capacity loss in sub-freezing conditions

Pro Tip: Advanced users track “voltage rebound”—how quickly voltage recovers after load removal. Slow rebound indicates aging cells.

How to Read and Use a LiFePO4 48V Voltage Chart

Interpreting Voltage vs. State of Charge (SoC)

A LiFePO4 48V battery’s voltage chart reveals its exact energy status, but requires proper interpretation. The relationship between voltage and SoC isn’t linear – a 52V reading might indicate 70% charge at rest, but only 50% under heavy load. Here’s how to decode it accurately:

- Resting Voltage Method: Measure after 30+ minutes without charge/discharge. Example: 53.6V = ~80% SoC

- Under-Load Correction: Add 0.5-1.5V to readings during discharge (a 48V reading at 50A load ≈ 49V actual)

- Charge Phase Analysis: Absorption voltage (57.6V) doesn’t indicate full charge – monitor current drop to 0.05C

Practical Applications of Voltage Data

Smart voltage monitoring enables three key optimizations:

- Cycle Life Extension: Operating between 54.4V (90%) and 48V (20%) provides 2x more cycles than full 100-0% use

- Load Management: Voltage drop below 49V under load signals excessive current draw requiring system redesign

- Battery Balancing: Individual cell voltages shouldn’t vary by >0.1V at 50% SoC – imbalances indicate failing cells

Troubleshooting Common Voltage Issues

When voltage readings seem abnormal:

- Sudden Voltage Drops: Often caused by loose connections (check terminal torque at 8-10Nm)

- Persistent Low Voltage: May indicate cell imbalance (requires top-balancing at 58.4V)

- Voltage “Float” Phenomenon: After full charge, voltage may temporarily read high before stabilizing

Field Example: A solar installer found their 48V bank showing 47V at noon despite full sun. Voltage testing revealed a 0.3V imbalance between cells – corrected by performing a full balance cycle.

Advanced LiFePO4 48V Battery Management Techniques

Precision Charging Strategies for Maximum Longevity

Optimal charging goes beyond basic voltage limits. The charge acceptance curve of LiFePO4 batteries requires specific handling:

| Charge Phase | Voltage Range | Current Behavior | Duration |

|---|---|---|---|

| Bulk Charge | 52V-56V | Constant current (0.5C max) | Until 80% SoC |

| Absorption | 56V-58.4V | Current tapers from 0.5C to 0.05C | 1-2 hours |

| Float | 53.6V | Maintenance current only | Indefinite |

Pro Tip: For daily cycling, set absorption voltage to 56.8V (90% SoC) instead of 58.4V – this reduces stress while maintaining 95% usable capacity.

Cell Balancing: Theory and Practice

LiFePO4 batteries require two balancing approaches:

- Top Balancing: Done at full charge (58.4V), forces all cells to equal voltage by bleeding excess from higher cells

- Bottom Balancing: Performed at 20% SoC, ensures uniform discharge characteristics

Modern BMS systems typically handle this automatically, but manual intervention may be needed when:

- Cell voltage differential exceeds 0.15V at any SoC

- Capacity measurements show >5% variation between cells

- The battery pack has been stored for >6 months without use

Advanced Diagnostics Through Voltage Analysis

Voltage patterns reveal hidden battery conditions:

- Rapid Voltage Drop: Indicates sulfation (requires 24h charge at 58.4V with 0.05C current)

- Slow Charge Acceptance: Suggests lithium plating (irreversible damage from cold charging)

- Voltage “Memory”: Shows up in batteries repeatedly cycled to identical SoC points

Case Study: A telecom backup system showed 0.4V cell imbalance after 3 years. Top balancing restored 98% of original capacity, verified through discharge testing at 0.2C rate.

System Integration and Safety Considerations for 48V LiFePO4 Batteries

Proper System Configuration for Optimal Performance

Integrating a 48V LiFePO4 battery requires careful system matching to prevent performance issues. The charge/discharge ratio should never exceed 1:1.5 – meaning your charging system must deliver at least 67% of your maximum discharge current. For example:

- 3000W inverter (62.5A @48V): Requires minimum 42A charging capability

- Parallel battery banks: Must use identical models with <0.1V resting voltage difference before connection

- Cable sizing: #2 AWG for runs under 10ft at 100A, #4/0 AWG for 20ft runs

Critical Safety Protocols

While LiFePO4 is inherently safer than other lithium chemistries, these precautions are essential:

- Thermal runaway prevention: Maintain ambient temperature between -20°C to 45°C (-4°F to 113°F)

- Overcurrent protection: Install Class T fuses within 18″ of battery terminals

- Ventilation requirements: Provide 1 cubic foot of airspace per 100Ah capacity

Advanced Monitoring and Maintenance

Professional-grade monitoring involves tracking these parameters monthly:

| Parameter | Normal Range | Action Threshold |

|---|---|---|

| Cell Imbalance | <0.05V | >0.1V requires balancing |

| Internal Resistance | <0.5mΩ per cell | >1mΩ indicates aging |

| Temperature Differential | <5°C between cells | >10°C requires inspection |

Professional Tip: Implement a “soft start” feature for high-power inverters to prevent voltage sag below 44V during initial surge currents. This can extend battery life by up to 20% in high-demand applications.

End-of-Life Indicators

Recognize when your battery needs replacement:

- Capacity drops below 80% of original rating

- Voltage drops >0.5V under nominal load compared to new

- Balancing required more than monthly

- Internal resistance increases by >50%

Long-Term Performance Optimization and Future Trends

Advanced Cycle Life Extension Techniques

Maximizing a 48V LiFePO4 battery’s lifespan requires understanding the complex relationship between depth of discharge (DoD), temperature, and charge rates. Research shows that:

| DoD Strategy | Cycle Life | Capacity Retention | Cost per Cycle |

|---|---|---|---|

| 100% DoD | 3,000 cycles | 70% at EOL | $0.18/kWh |

| 80% DoD | 5,000 cycles | 75% at EOL | $0.12/kWh |

| 50% DoD | 8,000 cycles | 80% at EOL | $0.09/kWh |

Pro Tip: Implement an adaptive DoD strategy – deeper discharges in summer (when temperatures are optimal) and shallower discharges in winter can yield 15% more lifetime energy.

Environmental Impact and Sustainability

LiFePO4 batteries offer significant environmental advantages over lead-acid, but require proper end-of-life handling:

- Recyclability: 95% of materials are recoverable through specialized processes

- Carbon Footprint: 40% lower than NMC lithium batteries over 10-year lifespan

- Second-Life Applications: Retired EV batteries with 70% capacity can serve 5-7 more years in stationary storage

Emerging Technologies and Future Developments

The 48V LiFePO4 market is evolving with several key advancements:

- Solid-State LiFePO4: Expected by 2026, offering 30% higher energy density and wider temperature range

- Self-Healing BMS: AI-driven systems that predict and correct imbalances before they occur

- Hybrid Topologies: Combining 48V LiFePO4 with supercapacitors for high-surge applications

Case Study: A microgrid installation in Arizona achieved 22% longer battery life by implementing dynamic temperature compensation, adjusting charge voltages by 0.003V/°C based on real-time thermal readings.

Total Cost of Ownership Analysis

When evaluating 48V LiFePO4 systems, consider these often-overlooked factors:

- Balance-of-System Savings: Smaller conductors and reduced cooling needs offset 15-20% of battery cost

- Maintenance Costs: Typically 1/10th of equivalent lead-acid systems over 10 years

- Opportunity Costs: Faster charging enables more daily cycles in commercial applications

Specialized Applications and Custom Configurations for 48V LiFePO4 Systems

High-Performance Energy Storage Solutions

Demanding applications require tailored 48V LiFePO4 configurations that go beyond standard installations. For marine applications, we recommend:

- Saltwater Environments: Use marine-grade stainless steel enclosures with IP67 rating and active ventilation

- Vibration Resistance: Install with flexible bus bars and shock-absorbing mounts (minimum 5mm neoprene padding)

- Emergency Protocols: Implement water-activated disconnect switches and thermal runaway containment systems

Industrial and Commercial System Design

Large-scale 48V LiFePO4 deployments require specialized engineering considerations:

| Application | Key Requirement | Recommended Solution |

|---|---|---|

| Data Center Backup | Ultra-fast response (<50ms) | Parallel battery strings with individual BMS and automatic load sharing |

| Telecom Towers | Wide temperature operation (-40°C to 60°C) | Heated enclosures with phase-change materials and adaptive charging |

| EV Charging Stations | High peak currents (5C+ discharge) | Hybrid battery-capacitor systems with liquid cooling |

Advanced System Integration Techniques

When combining 48V LiFePO4 with other energy systems:

- Solar Hybrid Systems: Use DC-coupled configurations with MPPT controllers that support LiFePO4 voltage ranges (44-60V)

- Generator Hybrids: Implement smart transfer switches with voltage-sensing delay (minimum 2-minute stabilization period)

- Grid-Tied Applications: Install anti-islanding protection and UL1741-SA compliant inverters

Performance Optimization for Extreme Conditions

Specialized maintenance protocols extend performance in harsh environments:

- Desert Climates: Apply reflective coatings and maintain 20% derating above 45°C ambient

- Arctic Conditions: Pre-heat batteries to -10°C before charging using self-heating models or external pads

- High-Humidity Areas:Use conformal-coated PCBs and silica gel desiccant packs in enclosures

Case Example: An Alaskan research station achieved 98% winter availability by combining self-heating 48V batteries with wind power, using voltage-triggered heating below -20°C.

System-Wide Optimization and Lifetime Management Strategies

Comprehensive Performance Validation Protocols

Professional-grade 48V LiFePO4 installations require rigorous validation testing to ensure optimal performance throughout the battery’s lifecycle. Implement these verification procedures annually:

| Test Type | Methodology | Acceptance Criteria | Frequency |

|---|---|---|---|

| Capacity Verification | 0.2C discharge to 40V at 25°C | >95% of rated capacity | Every 500 cycles |

| Impedance Testing | 1kHz AC resistance measurement | <25% increase from baseline | Quarterly |

| Thermal Profiling | IR imaging during 0.5C discharge | <5°C cell-to-cell variation | Biannually |

Advanced Risk Mitigation Framework

Comprehensive risk management for 48V LiFePO4 systems involves addressing these critical failure modes:

- Cell Imbalance: Implement active balancing circuits with >500mA balancing current

- Thermal Events: Install multi-zone temperature monitoring with 3-level response protocols

- Voltage Spikes: Use TVS diodes rated for 100A surge protection on all DC connections

Predictive Maintenance and AI Optimization

Modern battery management systems now incorporate machine learning for:

- Cycle Life Prediction: Analyzing charge/discharge patterns to forecast remaining lifespan within ±5% accuracy

- Adaptive Charging: Automatically adjusting charge parameters based on historical performance data

- Fault Anticipation: Detecting early warning signs of BMS or cell degradation

End-to-End Quality Assurance Processes

Industrial users should implement these quality control measures:

- Incoming Inspection: Verify cell matching (<0.5% capacity variance) and weld quality

- Commissioning Tests: 72-hour burn-in at 0.3C with continuous parameter logging

- Periodic Revalidation: Full discharge-charge cycle testing with infrared thermography

Case Study: A utility-scale storage facility extended operational life by 3.2 years through predictive maintenance, reducing cell replacement costs by $280,000 annually.

Conclusion

Mastering your 48V LiFePO4 battery’s voltage characteristics is the key to unlocking its full potential. Throughout this guide, we’ve explored critical aspects from fundamental voltage ranges to advanced system optimization techniques.

You now understand how to accurately interpret voltage charts, implement proper charging strategies, and extend battery life through precise management. The specialized applications and maintenance protocols covered ensure you can tailor your approach whether for marine, industrial, or renewable energy systems.

Remember that proper voltage monitoring isn’t just about performance – it’s about safety, longevity, and return on investment. By applying these principles, you’ll maximize your battery’s 5,000+ cycle potential while avoiding common pitfalls. For optimal results, we recommend conducting quarterly performance validations and staying updated on emerging LiFePO4 technologies.

Frequently Asked Questions About LiFePO4 48V Battery Voltage

What is the exact voltage range for a fully charged vs. empty 48V LiFePO4 battery?

A fully charged 48V LiFePO4 battery reaches 58.4V (3.65V per cell × 16 cells), while completely discharged it drops to 40V (2.5V per cell). The nominal voltage is 51.2V (3.2V per cell).

For daily use, maintain between 54.4V (90% charge) and 46.4V (20% charge) to maximize cycle life. These values assume a resting state – under load, expect 2-3V lower readings depending on current draw.

How often should I perform cell balancing on my 48V LiFePO4 battery?

Quality battery management systems (BMS) automatically balance cells during charging, but manual intervention is needed when cell voltage differential exceeds 0.1V.

For heavily used systems, perform a full top-balance annually by charging to 58.4V and holding until balancing completes (typically 2-4 hours). Systems showing >0.05V imbalance monthly may indicate failing cells.

Why does my battery voltage drop significantly when I turn on my inverter?

This voltage sag occurs due to internal resistance. A 3000W load on a 48V system pulls ~62.5A, potentially causing 2-4V drop. Solutions include:

- Upgrading to thicker cables (minimum #2 AWG for runs under 10ft)

- Adding parallel battery strings

- Using hybrid battery-capacitor systems for high surge loads

Always set low-voltage cutoff 2V above your actual limit to account for sag.

Can I use a lead-acid battery charger with my 48V LiFePO4 battery?

While possible in emergency situations, lead-acid chargers can damage LiFePO4 batteries over time. They typically charge to 57.6V (absorption) and 54V (float), which undercharges LiFePO4.

More critically, they lack the constant-current/constant-voltage (CC/CV) profile needed for proper lithium charging. Invest in a LiFePO4-specific charger with adjustable voltage settings for optimal performance and safety.

How does temperature affect 48V LiFePO4 battery voltage readings?

Temperature dramatically impacts voltage interpretation:

- Cold temperatures (-20°C): Voltage reads 3-5% higher than actual SoC

- Hot temperatures (45°C): Voltage reads 2-3% lower

- Charging below 0°C: Causes permanent lithium plating

Quality BMS systems compensate for this, but manual temperature correction factors should be applied when monitoring voltage in extreme conditions.

What voltage should I store my 48V LiFePO4 battery at for long-term preservation?

For storage periods exceeding 1 month, charge to 53.6V (3.35V per cell, ~50% SoC) and disconnect all loads. This minimizes aging while preventing over-discharge.

Store in temperatures between 15-25°C. Every 6 months, recharge to 53.6V if voltage drops below 51.2V. This storage method can preserve 98% capacity after 12 months of inactivity.

How can I accurately measure state of charge using voltage?

For precise SoC measurement:

- Let battery rest 30+ minutes after charge/discharge

- Measure voltage at terminals with calibrated multimeter

- Compare to this reference chart:

- 58.4V = 100%

- 54.4V = 90%

- 51.2V = 50%

- 46.4V = 20%

Note that voltage-SoC relationship flattens between 20-80%, so coulomb counting (Ah tracking) provides better accuracy for daily use.

Why does my new 48V LiFePO4 battery show lower capacity than advertised?

Several factors cause this common concern:

- Break-in period: LiFePO4 batteries typically need 5-10 full cycles to reach rated capacity

- Temperature effects: Capacity reduces 20% at -10°C and 5% at 45°C

- Charge profile: Testing at 0.5C discharge rates shows lower capacity than 0.2C ratings

Perform a capacity test at 25°C using 0.2C discharge after 10 full cycles for accurate assessment. Most quality batteries meet specs after proper conditioning.