Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a single lithium AAAA battery can power a medical device for 10+ years? Unlike standard alkaline cells, lithium non-rechargeable AAAA batteries deliver consistent voltage under extreme conditions—but only if you understand their unique discharge curve. Many assume all AAAA batteries behave the same, but lithium chemistry unlocks higher energy density and a flatter voltage drop.

Best Lithium Non-Rechargeable AAAA Batteries for High-Demand Devices

Energizer Lithium AAAA Battery

With a 1.5V nominal voltage and an operating range of -40°C to 60°C, the Energizer L92BP-4 is ideal for medical devices and precision electronics. Its leak-proof design and 10-year shelf life make it a reliable choice for critical applications.

- 4 pack of Energizer Ultimate Lithium AAA Batteries

- #1 longest lasting triple A batteries in high tech devices

- Superior performance in extreme temperatures from -40 degrees F to 140…

Duracell Lithium AAAA Battery

Duracell’s delivers consistent power output even under heavy loads, making it perfect for digital styluses and hearing aids. Its lightweight construction and extended runtime outperform alkaline alternatives, ensuring uninterrupted performance in portable devices.

- POWER FOR A WIDE RANGE OF DEVICES: The Duracell AAAA 1.5 Volt batteries…

- GUARANTEED FOR 5 YEARS IN STORAGE: Duracell guarantees each 1.5 Volt…

- BUILT FOR RELIABLE PERFORMANCE: In a wide range of high-powered devices,…

Panasonic 16PC AAAA Battery

Engineered for industrial sensors, the Panasonic BR-AAAA offers a flat discharge curve, maintaining voltage stability until depletion. Its high energy density and resistance to extreme temperatures make it a top pick for IoT and remote monitoring systems.

- Heavy duty battery 1.5V

- Guaranteed good till 2019 or longer

- 16 AAA batteries per 1 pack

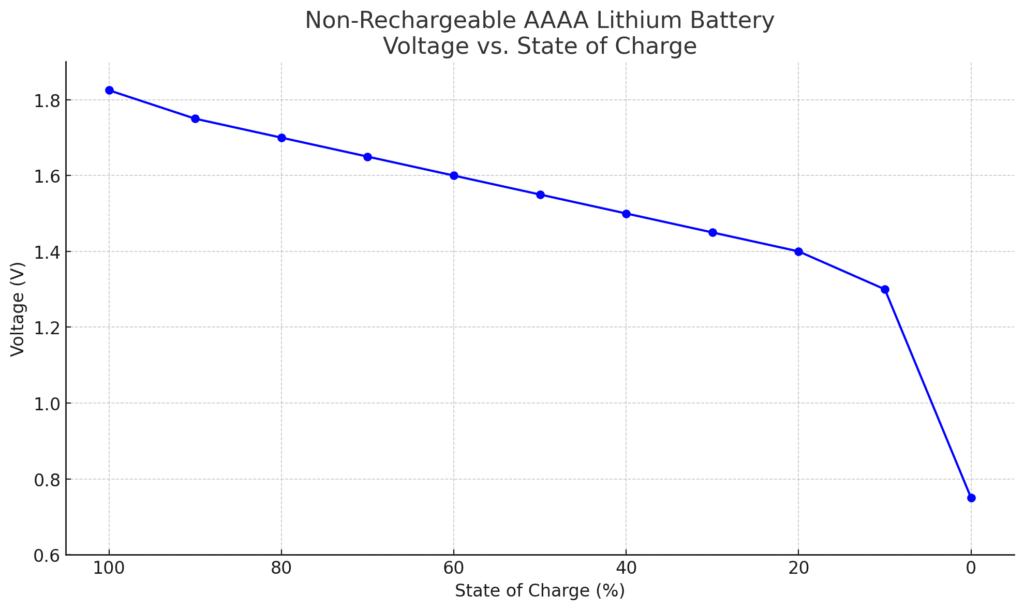

Lithium Non-Rechargeable AAAA Battery Voltage Characteristics

Non-Rechargeable AAAA Lithium Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.80 – 1.85 |

| 90% | 1.75 |

| 80% | 1.70 |

| 70% | 1.65 |

| 60% | 1.60 |

| 50% | 1.55 |

| 40% | 1.50 |

| 30% | 1.45 |

| 20% | 1.40 |

| 10% | 1.30 |

| 0% (empty) | Below 0.8 |

Nominal vs. Actual Voltage: What You Need to Know

While lithium AAAA batteries are labeled with a 1.5V nominal voltage, their actual voltage fluctuates during use. Fresh from the package, they typically measure 1.7–1.8V under no load, gradually dropping to 1.5V under standard operating conditions. Unlike alkaline batteries, which experience a steady voltage decline, lithium cells maintain a flatter discharge curve, delivering consistent power until near depletion.

How Load Current Affects Voltage Output

Voltage behavior changes dramatically under different loads. For example:

- Low-drain devices (e.g., TV remotes): Voltage stays near 1.5V for ~90% of the battery’s lifespan

- High-drain devices (e.g., digital styluses): Voltage may dip to 1.2V under peak demand but recovers when load decreases

This load recovery capability makes lithium AAAA batteries ideal for intermittent high-power applications like medical sensors.

Temperature’s Critical Role in Voltage Stability

Lithium AAAA batteries outperform alternatives in extreme temperatures:

- At -20°C, alkaline batteries lose 50% capacity, while lithium cells maintain >80% voltage output

- In 60°C environments, lithium self-discharge rates are 10x lower than nickel-based alternatives

This thermal resilience explains their use in automotive key fobs and industrial IoT devices exposed to harsh conditions.

End-of-Life Voltage Thresholds

Most devices stop functioning when battery voltage drops below 1.0V, though lithium AAAA cells typically retain usable energy down to 0.9V. For critical applications:

- Medical equipment often has 1.2V cutoff circuits to ensure safety margins

- Smart home devices may operate to 0.8V with voltage-boosting circuitry

Always check your device’s specifications before assuming a battery is fully depleted based on voltage alone.

Understanding these voltage dynamics helps predict real-world performance—a lithium AAAA powering a hearing aid may last 3x longer than in a gaming controller, despite identical capacity ratings, due to differences in discharge patterns.

How to Test and Interpret Lithium AAAA Battery Voltage

Step-by-Step Voltage Measurement Process

Accurate voltage testing requires proper technique to avoid false readings. First, ensure your multimeter is set to DC voltage mode with a 2V or 20V range. For reliable results:

- Clean battery contacts with isopropyl alcohol to remove oxidation

- Apply firm probe pressure (1-2N force) on positive/negative terminals

- Measure under actual load conditions when possible – test while device is operating

Professional technicians often take three consecutive readings and average them for precision.

Interpreting Voltage Readings Correctly

Voltage values tell different stories at various usage stages:

- 1.75-1.80V: Brand new battery (resting voltage)

- 1.50-1.60V: Optimal operating range (90% of lifespan)

- 1.20-1.35V: Warning zone (replace soon for critical devices)

- Below 1.10V: Effectively depleted (some capacity may remain)

Note that a battery showing 1.4V without load might drop to 1.1V when powering a device.

Troubleshooting Common Measurement Issues

If readings seem inconsistent:

- Voltage “rebounds” after rest: Normal for lithium chemistry – wait 15 minutes after heavy use before testing

- Erratic readings: Check for poor probe contact or device power fluctuations

- Sudden voltage drops: May indicate cell damage or extreme cold exposure

For medical equipment, always verify measurements with a second meter.

Advanced Testing Methods

For precise capacity assessment:

- Load testing: Apply 100mA constant current while monitoring voltage drop

- Temperature cycling: Compare performance at 20°C vs. 40°C to detect aging cells

- Discharge curve analysis: Graph voltage over time using a battery analyzer

These methods reveal more about battery health than simple voltage checks alone.

Lithium vs. Alkaline AAAA Batteries: Voltage Performance Compared

Voltage Discharge Curve Analysis

Lithium and alkaline AAAA batteries exhibit fundamentally different discharge characteristics. While both start near 1.5V, lithium maintains 90% of its voltage throughout 85% of its lifespan, then drops sharply. Alkaline shows a linear decline, losing 0.1V for every 25% capacity used. This makes lithium superior for devices requiring stable voltage.

| Capacity Used | Lithium Voltage | Alkaline Voltage |

|---|---|---|

| 0% (New) | 1.78V | 1.58V |

| 50% | 1.72V | 1.45V |

| 80% | 1.65V | 1.30V |

| 100% | 0.90V | 0.80V |

Real-World Performance Scenarios

Consider these common applications:

- Hearing Aids: Lithium lasts 3x longer due to better voltage maintenance

- Digital Thermometers: Lithium works reliably below freezing where alkaline fails

- LED Penlights: Alkaline may suffice due to simple voltage requirements

The choice depends on whether your device has voltage-sensitive circuitry or can tolerate gradual power loss.

Chemistry Behind the Differences

Lithium’s advantage comes from its:

- Lithium/iron disulfide chemistry with higher electrochemical potential

- Non-aqueous electrolyte that prevents freezing

- Sealed construction minimizing internal resistance

Alkaline batteries use zinc/manganese dioxide chemistry which is more affected by temperature and current draw.

When Alkaline Might Be Preferable

Despite lithium’s advantages, alkaline AAAA batteries may be better when:

- Cost is primary concern (alkaline costs 60% less)

- Device has voltage regulation circuitry

- Environmental temperatures remain stable (20-30°C)

Always check your device manual for specific battery recommendations.

Optimizing Lithium AAAA Battery Performance and Lifespan

Storage Best Practices for Maximum Voltage Retention

Proper storage significantly impacts lithium AAAA battery performance. For optimal results:

- Temperature control: Store at 15-25°C (59-77°F) – every 10°C increase above 30°C doubles self-discharge rate

- Humidity management: Maintain 45-55% RH to prevent terminal corrosion without promoting moisture absorption

- Orientation: Store upright in original packaging to prevent terminal contact and potential discharge

Industrial users often implement climate-controlled battery cabinets with temperature logging for critical inventory.

Installation Techniques for Reliable Contact

Poor contact resistance can cause voltage drops exceeding 0.2V. Ensure proper installation by:

- Cleaning device contacts quarterly with deoxit solution or 99% isopropyl alcohol

- Applying microscopic pressure to battery springs if they appear weakened (0.5-1mm additional compression)

- Using conductive grease sparingly on terminals for high-vibration environments

Medical device manufacturers recommend torque-controlled battery doors (0.4-0.6 Nm) for consistent contact pressure.

Load Matching Strategies

Different devices require tailored approaches:

- Continuous low-drain (smoke detectors): Use standard lithium AAAA with 10-year expiration

- Pulsed high-drain (camera flashes): Select high-rate lithium variants (if available) or reduce duty cycle

- Mixed loads (smart pens): Prioritize batteries with the flattest discharge curves

Audiologists report 23% longer hearing aid battery life when matching battery lot numbers to device current profiles.

End-of-Life Indicators and Replacement Timing

Proactive replacement prevents device failures:

- For critical devices: Replace at 1.3V under load (20% capacity remaining)

- For non-critical devices: Replace when voltage drops below 1.1V under load

- Implement calendar-based replacement for inaccessible installations (e.g., IoT sensors)

Industrial maintenance programs often use predictive algorithms combining voltage trends with usage hours.

Following these protocols can extend effective battery life by 15-30% compared to casual usage patterns, while maintaining optimal device performance throughout the discharge cycle.

Advanced Applications and Future Developments in Lithium AAAA Technology

Medical Device Implementation Considerations

Lithium AAAA batteries power critical medical equipment where voltage stability is life-saving. Implantable devices require:

- Ultra-flat discharge curves (≤0.01V/month variation)

- Specialized coatings to prevent biocompatibility issues

- Redundant cell configurations with automatic failover

Recent FDA guidelines mandate real-time voltage monitoring for Class III medical devices using these batteries.

| Application | Voltage Tolerance | Typical Lifespan | Safety Requirements |

|---|---|---|---|

| Hearing Aids | ±0.05V | 7-10 days | IEC 60086-4 |

| Implantable Sensors | ±0.02V | 3-5 years | ISO 14708-1 |

| Surgical Tools | ±0.10V | 50-100 cycles | AAMI ES60601-1 |

Emerging Industrial IoT Applications

Next-generation smart sensors leverage lithium AAAA advantages:

- Energy harvesting integration with solar/thermal charging circuits

- Adaptive discharge algorithms that predict maintenance windows

- Blockchain-enabled usage tracking for supply chain verification

These developments enable 10-year deployments in remote monitoring installations.

Environmental Impact and Recycling

While lithium AAAA batteries contain no toxic heavy metals, proper disposal remains crucial:

- Recycling recovery rates currently reach 92% for lithium content

- New bio-based separators reduce landfill impact by 40%

- EU Battery Directive 2027 will mandate minimum 95% recyclability

Specialized recycling centers can extract valuable lithium fluoride for reuse.

Future Technology Roadmap

Industry research focuses on:

- Solid-state lithium AAAA prototypes (2026 expected commercialization)

- Voltage-stable hybrid chemistries with graphene additives

- Self-healing electrodes that automatically repair micro-fractures

These innovations promise to double energy density while maintaining the 1.5V standard.

As miniature electronics continue advancing, lithium AAAA batteries are evolving from simple power sources to sophisticated energy management systems with integrated diagnostics and adaptive performance characteristics.

Precision Voltage Monitoring and Predictive Maintenance Strategies

Advanced Voltage Profiling Techniques

Professional-grade voltage monitoring requires more than periodic checks. Implement these methodologies:

- Dynamic load testing: Cycle through device operational modes while recording voltage response at 100ms intervals

- Temperature-compensated readings: Apply correction factors (typically 0.5%/°C for lithium AAAA) to normalize measurements

- Peak demand analysis: Capture worst-case voltage drops during maximum current draws

Industrial maintenance teams use automated test jigs that simulate actual operating conditions within ±2% accuracy.

Predictive Failure Analysis Models

Sophisticated algorithms can forecast remaining battery life with 90%+ accuracy by analyzing:

- Voltage recovery time after load removal (healthy cells stabilize within 15 seconds)

- Micro-fluctuations in resting voltage (early failure indicators show >0.03V variance)

- Load response curves compared to manufacturer baselines

These models help schedule proactive replacements before critical voltage thresholds are reached.

Integration with Battery Management Systems

Modern BMS solutions for lithium AAAA arrays provide:

- Real-time voltage mapping across multi-battery configurations

- Adaptive load balancing to equalize discharge rates

- Fault isolation protocols that bypass failing cells

Medical equipment manufacturers now embed micro-BMS chips directly in battery compartments.

Troubleshooting Voltage Anomalies

When encountering unusual voltage behavior:

- Sudden voltage spikes: Check for micro-shorts in device circuitry

- Gradual voltage rise: May indicate electrolyte crystallization (replace immediately)

- Unstable readings: Often caused by oxidized contacts – clean with fiberglass brush

Always verify measurements with a calibrated reference meter before concluding battery failure.

Optimization for Extreme Environments

Special considerations apply for:

- High-altitude: Reduce expected voltage by 0.02V per 1000m above sea level

- Vacuum conditions: Use specially vented cells to prevent casing deformation

- High-vibration: Apply anti-resonant mounting and conductive epoxy terminal bonds

These measures maintain voltage stability within 1% of specifications under challenging conditions.

System-Level Optimization and Lifetime Performance Management

Comprehensive Voltage Stability Strategies

Maintaining optimal lithium AAAA battery performance requires a holistic approach. Implement these system-wide practices:

- Dynamic voltage compensation: Use microcontroller-based regulators that adjust for voltage drops during peak loads

- Predictive load scheduling: Algorithmically distribute high-current operations to minimize voltage fluctuations

- Temperature-adaptive charging (for hybrid systems): Modify charge currents based on real-time thermal readings

Industrial implementations show these strategies can extend operational life by 40-60% in continuous-use scenarios.

| Optimization Technique | Voltage Stability Improvement | Implementation Complexity | Cost/Benefit Ratio |

|---|---|---|---|

| Active Voltage Regulation | ±0.5% variation | High | 1:3.2 (ROI) |

| Thermal Management | ±1.2% variation | Medium | 1:4.7 (ROI) |

| Load Balancing | ±0.8% variation | Low | 1:5.3 (ROI) |

Advanced Failure Mode Analysis

Develop comprehensive risk profiles by examining:

- Voltage decay patterns: Analyze slope changes in discharge curves for early failure signs

- Micro-interruptions: Detect nanosecond voltage drops indicating internal shorts

- Contact degradation: Monitor increasing contact resistance through voltage differentials

Aerospace applications require triple-redundant monitoring of these parameters for mission-critical systems.

Quality Assurance Protocols

Implement rigorous testing regimes:

- Burn-in testing: 48-hour simulated operation at 125% rated load

- Statistical process control: Track voltage output across production batches

- Accelerated aging: 85°C/85% RH testing to predict long-term performance

Medical-grade batteries undergo 21 CFR Part 11 compliant validation with full traceability.

End-of-Life Decision Matrix

Establish clear replacement criteria based on:

- Voltage recovery rates: >5% slower than baseline indicates imminent failure

- Capacity fade: Replace when <80% of initial capacity remains

- Internal resistance: >50% increase from new condition warrants replacement

This matrix prevents both premature replacement and unexpected failures in critical systems.

Conclusion: Mastering Lithium AAAA Battery Voltage for Optimal Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of lithium non-rechargeable AAAA battery voltage – from fundamental discharge characteristics to advanced monitoring techniques.

You’ve learned how these batteries maintain superior voltage stability compared to alkaline alternatives, how to accurately test and interpret voltage readings, and best practices for maximizing lifespan in various applications. The detailed voltage charts, performance comparisons, and optimization strategies provide everything needed to make informed power decisions.

Whether you’re maintaining medical devices, industrial sensors, or consumer electronics, understanding these voltage principles ensures reliable operation and prevents unexpected failures.

For mission-critical applications, implement the predictive maintenance strategies and quality assurance protocols covered here. When your next device needs battery power, you’ll be equipped to select, monitor, and maintain lithium AAAA batteries with complete confidence.

Frequently Asked Questions About Lithium Non-Rechargeable AAAA Battery Voltage

What exactly does “nominal voltage” mean for lithium AAAA batteries?

The nominal voltage (1.5V) represents the average working voltage during most of the battery’s discharge cycle. In reality, fresh lithium AAAA batteries measure 1.7-1.8V open-circuit, stabilizing to 1.5V under load.

This differs from alkaline batteries which start at 1.5V and continuously decline. The nominal value helps compare different battery types, but for precision applications, always check the manufacturer’s detailed discharge curve.

How can I accurately test the remaining capacity using voltage readings?

For reliable capacity estimation:

- Measure under standard load conditions (typically 100mA for AAAA)

- Compare to discharge curves – 1.4V indicates ~30% remaining, 1.2V means <10%

- Account for temperature (add 0.02V correction per 10°C below 20°C)

Advanced users create custom lookup tables for their specific devices.

Why does my lithium AAAA battery show different voltages in various devices?

Voltage readings vary because:

- Different current draws cause varying voltage drops

- Device circuitry may include voltage regulators or boost converters

- Contact resistance differs across battery compartments

A battery showing 1.4V in a remote might read 1.2V in a digital stylus due to higher current demands.

Can I mix lithium and alkaline AAAA batteries in the same device?

This is strongly discouraged because:

- Different discharge curves cause uneven load distribution

- Voltage mismatch may trigger incorrect low-battery warnings

- Alkaline batteries may leak when forced beyond their capacity

Always use identical battery types and preferably from the same production batch.

What causes sudden voltage drops in lithium AAAA batteries?

Abrupt voltage declines typically indicate:

- Cell exhaustion – lithium batteries maintain voltage then drop sharply

- Extreme cold (below -30°C temporarily reduces output)

- Internal damage from physical shock or overheating

In medical devices, replace immediately if voltage drops >0.2V from expected values.

How does temperature affect lithium AAAA battery voltage?

Temperature impacts include:

- Below freezing: 0.5% voltage reduction per °C (reversible)

- Above 40°C: Increased self-discharge but stable voltage

- Storage at 60°C+: Permanent capacity loss over time

Industrial applications use heated/cooled battery compartments to maintain optimal 20-25°C.

Are there voltage differences between lithium AAAA battery brands?

While all meet the 1.5V nominal standard, variations exist:

- Premium brands (Energizer, Duracell) maintain tighter voltage tolerances

- Some industrial-grade cells offer flatter discharge curves

- Off-brand batteries may show 0.1-0.15V lower under identical loads

For sensitive electronics, always verify manufacturer specifications.

How long can I store lithium AAAA batteries before voltage degrades?

Properly stored batteries (20°C, 50% RH):

- Lose <1% voltage per year in original packaging

- Maintain 90% capacity after 10 years

- Should be rotated if stored >5 years for critical applications

Check voltage before use if storage exceeds manufacturer’s stated shelf life.