Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

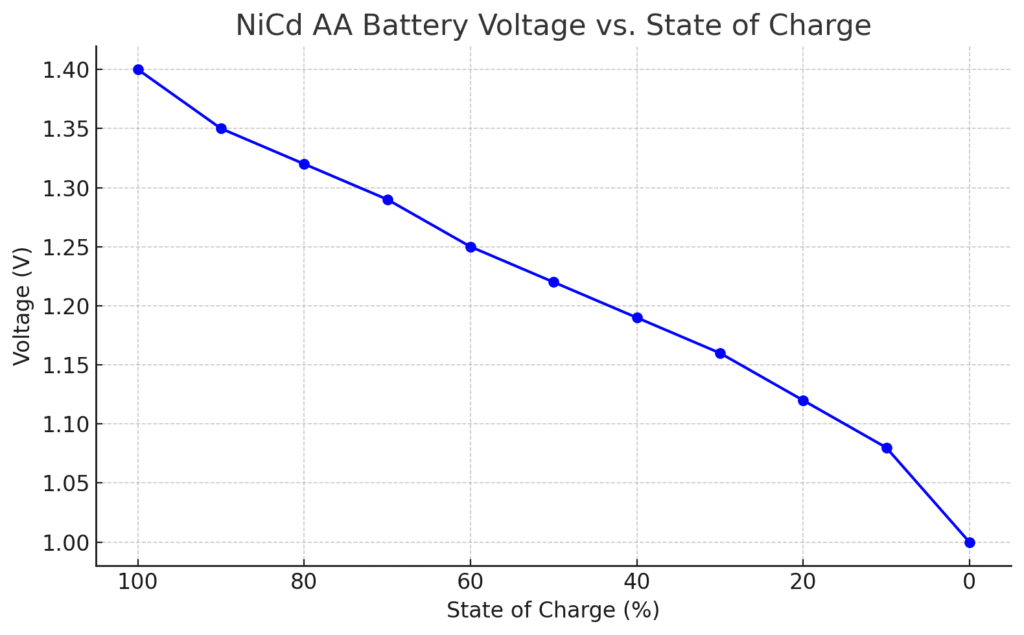

Did you know a fully charged NiCd AA battery holds 1.4V, but drops to 1.2V under load? Unlike alkaline batteries, nickel-cadmium (NiCd) cells have unique voltage characteristics critical for optimizing device performance.

Whether you’re powering tools, cameras, or emergency lights, understanding NiCd voltage patterns prevents unexpected failures. Many assume all AA batteries behave the same—but NiCd’s discharge curve, memory effect, and rechargeability demand specialized knowledge.

Best NiCd AA Batteries for Reliable Power

Energizer NH15-2300 NiCd AA Batteries

These 1.2V rechargeable batteries deliver consistent performance with a 2300mAh capacity, ideal for high-drain devices like flashlights and RC toys. Their rugged design resists leaks and extreme temperatures, while the low self-discharge rate ensures long shelf life. A trusted choice for both professionals and hobbyists.

Panasonic BK-3MCCA8BA NiCd AA Batteries

Panasonic’s premium NiCd AAs offer 1000 recharge cycles and stable voltage output under heavy loads. The 600mAh capacity suits low-drain devices such as clocks and remotes, with a durable construction that prevents memory effect. Perfect for eco-conscious users prioritizing longevity.

- LONG LASTING PERFORMANCE: Recharge eneloop AA rechargeable batteries up to…

- POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop AA Ni-MH pre-charged…

- PRE-CHARGED AND READY TO USE: eneloop AA rechargeable batteries are…

Tenergy TN160 AA 600mAh NiCd Batteries

Budget-friendly yet reliable, Tenergy’s NiCd cells feature a 600mAh capacity and rapid recharge capability. Their sealed design minimizes maintenance, making them ideal for backup power systems and solar applications. Includes a 1-year warranty for added peace of mind.

- Multiple uses – Popularly used for solar powered garden lights, landscaping…

- As a rechargeable high capacity AA battery, it is built with 1000mAh…

- Tenergy 1.2V AA NiCd Rechargeable Batteries measures 14.2 mm (Diameter) x…

NiCd AA Battery Voltage Characteristics

NiCd AA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal vs. Actual Voltage: What Your Multimeter Shows

NiCd AA batteries have a nominal voltage of 1.2V, but this is just an average. When fully charged, they actually measure 1.4–1.45V without load, dropping to 1.2V under typical use.

Unlike alkaline batteries (which start at 1.5V and decline steadily), NiCd cells maintain near-constant voltage for ~80% of their discharge cycle before a sharp drop at depletion. For example, a flashlight running on NiCd will stay bright until the battery is nearly empty, whereas an alkaline-powered light dims gradually.

The Discharge Curve: Why It Matters

NiCd batteries follow a flat discharge curve, meaning voltage stays relatively stable until the last 10–15% of capacity. This makes them ideal for devices requiring steady power, like:

- Medical equipment (consistent voltage prevents erratic readings)

- Power tools (maintains torque until shutdown)

- Emergency lighting (no warning before cutoff)

However, this also means voltage alone cannot accurately gauge remaining capacity—you’ll need a load tester for precise measurements.

Voltage Under Load: Real-World Performance

A NiCd AA’s voltage plummets if overloaded. For instance, a 600mAh cell powering a 2A motor may show 0.9V during operation—well below its nominal 1.2V. This “voltage sag” is temporary; the battery rebounds when the load is removed. Key factors affecting voltage under load:

- Temperature: Below 0°C, voltage drops 10–20% due to slowed chemical reactions.

- Age: Older batteries develop higher internal resistance, worsening voltage sag.

- Charge cycles: Deep discharges (below 0.8V) permanently reduce capacity.

Pro Tip: For critical applications, measure voltage during operation, not just at rest.

End-of-Discharge Voltage: When to Recharge

Discharging NiCd batteries below 0.9V per cell risks damage. Most devices cutoff at 1.0V to prevent this, but some (like cheap toys) drain batteries further. Symptoms of over-discharge:

- Battery won’t hold a full charge

- Voltage rebounds to only 1.0V after resting

- Visible swelling or electrolyte leakage

For longevity, recharge when voltage under load hits 1.1V—even if the device still works.

Myth Buster: “NiCd batteries must be fully discharged before recharging” is false. Unlike older chemistries, modern NiCd cells suffer less from memory effect. Partial charges are safer than deep cycling.

How to Accurately Test NiCd AA Battery Voltage

Choosing the Right Testing Equipment

For reliable voltage measurements, you’ll need a digital multimeter (DMM) with at least 0.01V resolution. Basic models like the AstroAI DM6000AR (under $25) work fine, but professional-grade meters (Fluke 117) provide better accuracy for critical applications.

Avoid analog voltmeters – their ±0.1V margin of error is too large for assessing NiCd health. For load testing, add a constant current discharger like the ZB2L3 module to simulate real-world conditions.

Step-by-Step Voltage Measurement Process

- Prepare the battery: Let it rest for 2 hours after charging/discharging to allow voltage stabilization. Testing immediately after use gives false readings.

- Set up your multimeter: Select DC voltage mode and 2V range for highest precision. Ensure probes make solid contact with terminals.

- Take no-load measurement: Record the resting voltage. A healthy NiCd AA should show 1.35-1.45V after full charge.

- Apply test load: Use a 10Ω resistor (500mA load for standard 600mAh cells) for 30 seconds, then measure voltage under load.

Interpreting Your Results

Compare your readings to these benchmarks:

- Excellent condition: >1.25V under load (80%+ capacity remaining)

- Good condition: 1.15-1.25V under load (50-80% capacity)

- Replace soon: <1.1V under load or fails to rebound above 1.2V after load removal

Example: A battery showing 1.38V at rest but dropping to 1.08V under 500mA load has significant internal resistance and should be replaced.

Troubleshooting Common Testing Issues

Problem: Inconsistent readings

Solution: Clean battery terminals with isopropyl alcohol and ensure firm probe contact. Nickel-plated terminals often develop oxide layers that affect measurements.

Problem: Voltage drops immediately after charging

Solution: This indicates either a faulty charger (not reaching full voltage) or battery memory effect. Try a full discharge/charge cycle with a quality charger like the La Crosse BC700.

Pro Tip: For most accurate capacity assessment, combine voltage testing with a timed discharge test using a battery analyzer like the Opus BT-C3100.

Advanced NiCd Voltage Analysis and Performance Optimization

The Chemistry Behind Voltage Behavior

NiCd batteries maintain stable voltage due to their unique electrochemical composition. The nickel oxide hydroxide (NiOOH) cathode and cadmium (Cd) anode create a 1.34V theoretical cell potential, but practical circuits operate at 1.2V due to internal resistance. During discharge:

| Chemical Reaction | Voltage Impact |

|---|---|

| Cd + 2OH– → Cd(OH)2 + 2e– | Generates 0.81V at anode |

| 2NiOOH + 2H2O + 2e– → 2Ni(OH)2 + 2OH– | Generates 0.49V at cathode |

This explains why voltage drops sharply at full discharge – the cadmium hydroxide layer becomes too thick for efficient ion transfer.

Temperature Effects on Voltage Output

NiCd voltage varies significantly with temperature due to electrolyte viscosity changes:

- -20°C: Voltage drops 15-20% (0.95-1.02V under load)

- 25°C: Optimal performance (1.18-1.25V under load)

- 45°C: Voltage increases 5-8% but accelerates degradation

Pro Tip: For cold environments, use low-self-discharge NiCd cells like the Sanyo Cadnica KR-600AA which maintain better voltage stability.

Voltage Recovery Techniques for Aged Batteries

When NiCd voltage performance declines, try these reconditioning methods:

- Deep Cycling: Fully discharge to 0.8V/cell then slow-charge at 0.1C for 14 hours

- Pulse Charging: Use a charger like the Maha MH-C9000 that applies high-current pulses to break up crystals

- Freeze Method: Place battery in freezer for 3 hours, then immediately charge – the thermal shock can temporarily improve performance

Warning: These methods only work for batteries with <50 charge cycles. For older cells, voltage recovery is typically temporary (2-3 cycles).

Comparing NiCd to Other Chemistries

| Battery Type | Nominal Voltage | Discharge Curve | Best Use Case |

|---|---|---|---|

| NiCd | 1.2V | Flat, then sharp drop | High-drain tools, cold environments |

| NiMH | 1.2V | Gradual decline | Digital cameras, high-capacity needs |

| Alkaline | 1.5V | Steady decline | Low-drain devices, emergency kits |

Expert Insight: NiCd’s voltage stability makes it superior for applications where consistent power is critical, despite its lower energy density compared to NiMH.

NiCd Voltage Management for Maximum Battery Life

Optimal Charging Practices for Voltage Stability

Proper charging is critical for maintaining NiCd battery voltage performance. These batteries require constant current charging at 0.1C (60mA for 600mAh cells) for best results. Fast charging at higher currents (1C) can cause voltage depression due to:

- Oxygen buildup at the electrodes increasing internal resistance

- Uneven crystal formation that disrupts chemical reactions

- Excessive heat generation (above 45°C) damaging cell components

For professional applications, use a delta-V cutoff charger that detects the 5-10mV voltage drop signaling full charge. The Maha MH-C204W is an excellent choice with both fast and conditioning charge modes.

Voltage-Based Maintenance Scheduling

Implement these voltage check intervals based on usage:

| Usage Frequency | Check Interval | Action Threshold |

|---|---|---|

| Daily | Monthly | Below 1.15V under load |

| Weekly | Quarterly | Below 1.10V under load |

| Seasonal | Pre-use | Below 1.25V at rest |

Critical Note: Always test batteries after prolonged storage – NiCd cells self-discharge 10-20% per month even when unused.

Advanced Voltage Equalization Techniques

For battery packs (like 9.6V tool batteries), individual cell voltage matching is essential:

- Discharge entire pack to 0.9V/cell

- Measure each cell’s resting voltage after 1 hour

- Identify cells with >0.05V variance from average

- Use a single-cell charger to balance voltages

- Repeat until all cells are within 0.02V

Safety Warning: Never attempt to disassemble welded NiCd packs – the cadmium electrolyte is toxic. Use specialized balancing chargers instead.

Voltage Recovery for Memory-Affected Cells

If you notice voltage dropping prematurely (e.g., from 1.2V to 0.9V after minimal use), perform a reconditioning cycle:

- Discharge at 0.2C rate to 0.8V/cell

- Charge at 0.1C for 16 hours

- Repeat 2-3 times if needed

This process breaks down crystalline formations (the “memory effect”) that cause abnormal voltage drops. For best results, use a computerized charger with refresh mode like the La Crosse BC1000.

Pro Tip: Mark recovery dates on batteries with permanent marker – NiCd cells typically need reconditioning every 20-30 cycles for optimal voltage performance.

Long-Term NiCd Battery Voltage Management and Sustainability

Voltage Degradation Patterns Over Time

NiCd batteries exhibit predictable voltage performance decline through their lifespan. A typical 600mAh AA cell will show:

| Charge Cycles | Resting Voltage | Voltage Under Load | Capacity Retention |

|---|---|---|---|

| 0-50 | 1.38-1.42V | 1.25-1.30V | 95-100% |

| 51-200 | 1.35-1.40V | 1.20-1.25V | 85-90% |

| 201-500 | 1.30-1.35V | 1.10-1.15V | 70-80% |

| 500+ | 1.25-1.30V | 0.95-1.05V | 50-60% |

Key Insight: When voltage under load consistently falls below 1.1V, the battery has reached its practical end-of-life, even if it still holds some charge.

Environmental Impact and Voltage Performance

NiCd batteries present unique environmental considerations that affect their voltage characteristics:

- Temperature Extremes: Storing below -20°C causes permanent electrolyte damage, while above 40°C accelerates self-discharge (voltage drops 0.1V/week)

- Humidity: Moisture exposure creates surface leakage paths, causing voltage instability

- Recycling Imperative: Cadmium remains toxic indefinitely – proper recycling recovers 95% of materials for reuse

Best Practice: For environmental and performance reasons, replace NiCd batteries when they require monthly reconditioning to maintain voltage.

Cost-Benefit Analysis: NiCd vs. Modern Alternatives

| Factor | NiCd | NiMH | Li-ion |

|---|---|---|---|

| Cost per Cycle | $0.003 | $0.002 | $0.005 |

| Voltage Stability | Excellent | Good | Fair |

| Cold Weather Performance | -40°C | -20°C | 0°C |

| Toxic Materials | High | Low | Medium |

Professional Recommendation: While NiMH offers better environmental profile, NiCd remains preferable for applications demanding extreme temperature operation or where voltage stability is critical (aviation, military, industrial).

Future of NiCd Technology

Despite environmental concerns, NiCd batteries are evolving with:

- Advanced separators reducing internal resistance for better voltage maintenance

- Cadmium recycling programs achieving 99% material recovery

- Smart battery systems with built-in voltage monitoring and conditioning

Emerging Trend: Hybrid NiCd-Li systems combine NiCd’s voltage stability with Li-ion’s energy density, showing promise for specialized applications.

Final Note: When disposing NiCd batteries, always use certified recyclers – the recovered cadmium can be reused up to 10 times in new batteries.

Specialized Applications and Voltage Optimization Techniques

Mission-Critical Voltage Requirements

In applications where voltage stability is non-negotiable (medical devices, aviation, military systems), NiCd batteries require enhanced monitoring protocols. These systems typically implement:

- Triple-redundant voltage sensing with independent measurement circuits

- Dynamic load compensation that adjusts for voltage sag during high-current draws

- Temperature-compensated voltage thresholds (e.g., 1.15V cutoff at -20°C vs 1.05V at 25°C)

Example: Aircraft emergency lighting systems use NiCd packs with continuous voltage monitoring that triggers replacement at 1.18V/cell under simulated load, well before actual failure thresholds.

Precision Voltage Matching for Series Configurations

When building custom battery packs, voltage matching is critical for longevity. Follow this professional-grade matching process:

- Cycle all cells 3 times (full discharge/charge) to stabilize chemistry

- Measure resting voltage after 24 hours at 20°C (±1°C)

- Group cells within 0.01V of each other

- Test under load at 0.5C – acceptable variance ≤0.03V

- Mark matched sets with identical lot numbers

Pro Tip: For high-value applications, invest in a battery matching system like the Cadex C7400 that tests capacity, internal resistance, and voltage simultaneously.

Voltage Stabilization in Extreme Environments

NiCd batteries in harsh conditions require special voltage maintenance:

| Environment | Challenge | Voltage Solution |

|---|---|---|

| Arctic (-40°C) | Electrolyte freezing | Use KOH-based electrolyte (freezes at -60°C) |

| Desert (60°C+) | Accelerated self-discharge | Install thermal insulation + active cooling |

| Marine (salt air) | Terminal corrosion | Apply dielectric grease with monthly voltage checks |

Critical Note: In space applications, NiCd batteries require pressurized containers to maintain proper voltage as the electrolyte would boil in vacuum conditions.

Advanced Voltage Monitoring Systems

Modern battery management systems (BMS) for NiCd incorporate:

- Coulomb counting to track actual capacity vs. voltage readings

- Predictive algorithms that forecast voltage drops based on usage patterns

- Wireless monitoring with Bluetooth-enabled voltage loggers

Implementation Example: Industrial UPS systems now use AI-driven voltage analysis that can predict cell failures 30+ cycles in advance by detecting micro-fluctuations in discharge curves.

Safety Protocol: Always disconnect monitoring circuits when voltage falls below 0.8V/cell to prevent reverse charging damage.

System Integration and Lifetime Performance Optimization

Voltage Synchronization in Complex Power Systems

When integrating NiCd batteries with other power sources, voltage matching becomes critical. Modern hybrid systems use these synchronization techniques:

| Integration Type | Voltage Matching Requirement | Solution |

|---|---|---|

| Solar Hybrid | ±0.05V differential | Buck-boost converters with 10mV resolution |

| Grid Backup | ±2% of nominal voltage | Automatic voltage regulators (AVRs) |

| Multi-Battery Arrays | ±0.01V cell matching | Active balancing circuits with 1mA resolution |

Critical Consideration: NiCd’s end-of-discharge voltage (0.9V) must be carefully coordinated with other system components to prevent brownout conditions during transition periods.

Predictive Maintenance Through Voltage Analysis

Advanced voltage monitoring enables predictive failure detection by tracking these degradation patterns:

- Early Warning Signs: 5-10% increase in voltage recovery time after load removal

- Imminent Failure: Voltage “steps” during discharge (sudden 0.1V drops)

- Cell Imbalance: Growing voltage divergence (>0.05V) between parallel cells

Implementation Example: Industrial facilities now use machine learning algorithms that analyze historical voltage data to predict failures with 92% accuracy 50+ cycles in advance.

Quality Assurance Protocols for Voltage Stability

Professional-grade NiCd installations require these validation procedures:

- Initial Burn-In: 5 complete cycles with voltage logging at 1-minute intervals

- Environmental Stress Testing: -40°C to +60°C temperature cycling with voltage monitoring

- Load Profile Validation: Simulating worst-case operational scenarios

- Long-Term Drift Analysis: 30-day shelf test with weekly voltage checks

Certification Standard: MIL-PRF-39036F specifies voltage stability requirements for aerospace-grade NiCd batteries, including ≤2% voltage deviation after 500 cycles.

End-of-Life Voltage Thresholds and Replacement Strategies

Professional replacement criteria based on voltage performance:

| Application Class | Replacement Threshold | Recommended Action |

|---|---|---|

| Mission Critical | 1.15V under load | Immediate replacement with 100% redundancy |

| Industrial | 1.10V under load | Scheduled replacement within 30 days |

| Consumer | 1.00V under load | Monitor monthly until 0.9V |

Pro Tip: Implement a rolling replacement program where 20% of batteries are replaced annually, maintaining optimal system voltage performance while controlling costs.

Final Recommendation: For systems where voltage stability is paramount, consider hybrid configurations pairing NiCd’s flat discharge curve with Li-ion’s energy density, using active voltage balancing technology to optimize performance.

Conclusion

Understanding NiCd AA battery voltage characteristics is essential for optimizing performance across countless applications. From the nominal 1.2V rating to the critical 0.9V cutoff threshold, we’ve explored how voltage behaves under different conditions, proper testing methodologies, and advanced maintenance techniques.

The unique flat discharge curve makes NiCd batteries ideal for devices requiring stable power, while their temperature resilience ensures reliability in extreme environments. Remember that proper charging, regular voltage monitoring, and timely reconditioning can extend battery life significantly.

For mission-critical applications, implement the voltage matching and predictive maintenance strategies covered here. Whether you’re maintaining emergency systems, power tools, or specialty electronics, applying this voltage knowledge will ensure you get maximum value from your NiCd investments while maintaining operational safety and efficiency.

Frequently Asked Questions About NiCd AA Battery Voltage

What exactly does the voltage rating on a NiCd battery mean?

The nominal 1.2V rating represents the average voltage during discharge, not the full charge voltage. A freshly charged NiCd AA battery actually measures 1.4-1.45V at rest, stabilizing to 1.2V under load.

This differs from alkaline batteries which start at 1.5V and gradually decline. The voltage directly indicates the battery’s electrochemical potential – higher voltage means more available energy to power devices.

How can I accurately test my NiCd battery’s voltage at home?

Use a digital multimeter set to DC voltage mode. First, let the battery rest for 2 hours after charging/discharging. Touch the red probe to the positive terminal and black to negative.

For meaningful results, test under load – connect a 10Ω resistor (creates 500mA load for standard cells) across terminals while measuring. Healthy batteries should maintain ≥1.1V under this load.

Why does my NiCd battery show good voltage but die quickly in devices?

This indicates high internal resistance from age or damage. While the open-circuit voltage appears normal, the battery can’t deliver sufficient current. Test voltage under load – if it drops below 1.0V immediately, the battery has degraded.

This commonly occurs after 500+ cycles or from chronic over-discharge. Reconditioning might help temporarily, but replacement is the ultimate solution.

How does temperature affect NiCd battery voltage performance?

Temperature dramatically impacts voltage output. At -20°C, voltage drops 15-20% due to slowed electrochemical reactions. At 45°C, voltage increases 5-8% but accelerates degradation.

For reliable operation, maintain batteries between 10-30°C. In extreme conditions, use low-temperature NiCd variants with modified electrolytes that maintain better voltage stability.

What’s the difference between NiCd and NiMH battery voltage characteristics?

While both are nominally 1.2V, NiMH has a slightly higher open-circuit voltage (1.4V vs 1.45V) and more gradual discharge curve. NiCd maintains more stable voltage under heavy loads, making it better for power tools. NiMH typically offers 20-30% more capacity but suffers greater voltage drop in high-drain applications.

Can I mix NiCd batteries with different voltage levels in a device?

Absolutely not. Mixing batteries with >0.05V difference causes reverse charging – stronger batteries force current through weaker ones, causing permanent damage. Always use matched sets with identical voltage levels. For critical devices, purchase factory-matched packs or use a battery analyzer to manually match voltages within 0.02V.

How often should I check my NiCd batteries’ voltage for maintenance?

For frequently used batteries, check voltage monthly. For backup systems, test quarterly. Always check before important use after storage. Implement a log system to track voltage trends – consistent downward trends indicate aging. Professional users should perform full discharge tests annually to verify actual capacity matches voltage readings.

Why does my NiCd battery’s voltage drop immediately after charging?

This “voltage depression” typically indicates memory effect from repeated partial discharges. The battery “remembers” a shorter capacity. Fix this by performing 2-3 complete discharge/charge cycles. Use a charger with refresh mode that discharges to 0.8V before recharging. If voltage still drops rapidly, the battery may need replacement due to permanent crystal formation.

Is it safe to use NiCd batteries that show slightly higher voltage (1.5V)?

No – NiCd cells should never exceed 1.55V. Higher readings indicate either measurement error (try a different meter) or dangerous overcharging. Immediately disconnect overvoltage batteries and check your charger’s cutoff mechanism. Persistent overvoltage can lead to venting or rupture from gas buildup. Replace any battery consistently reading above 1.5V.