Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiCd AAA battery can deliver 1.4V, but drops to 1.2V under load? Understanding voltage behavior is critical for maximizing battery life and device performance.

Many assume all AAA batteries behave identically, but nickel-cadmium (NiCd) chemistry has unique voltage characteristics that impact everything from toy drones to emergency flashlights.

Best NiCd AAA Batteries for Reliable Performance

Eneloop Panasonic BK-4MCCA/4BE NiCd AAA Rechargeable Batteries

Panasonic’s BK-4MCCA/4BE delivers consistent 1.2V output with a robust 600mAh capacity, ideal for high-drain devices like RC remotes. Its industrial-grade construction resists memory effect, ensuring 1,000+ recharge cycles. The pre-charged cells work straight out of the package—perfect for emergency backups.

- LONG LASTING PERFORMANCE: Recharge eneloop AAA rechargeable batteries up to…

- POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop AA Ni-MH pre-charged…

- PRE-CHARGED AND READY TO USE: eneloop AAA rechargeable batteries are…

Energizer NH15-2300 NiCd AAA Batteries

Engineered for extreme temperatures (-40°F to 140°F), the Energizer NH15-2300 maintains stable voltage under heavy loads. Its low self-discharge rate (15% per month) outperforms generic NiCd cells. The 700mAh rating suits medical devices and tactical flashlights needing dependable power.

VARTA Professional Rechargeable AAA Batteries (5561540305)

VARTA’s 5561540305 model features a unique “Power Delivery” design, sustaining 1.25V for 80% of its discharge cycle. The nickel-plated contacts minimize resistance, while the sealed construction prevents leaks—critical for sensitive electronics like digital calipers or smoke detectors.

- From the brand Varta.

- Pack of 4.

- Large capacity

NiCd AAA Battery Voltage Characteristics

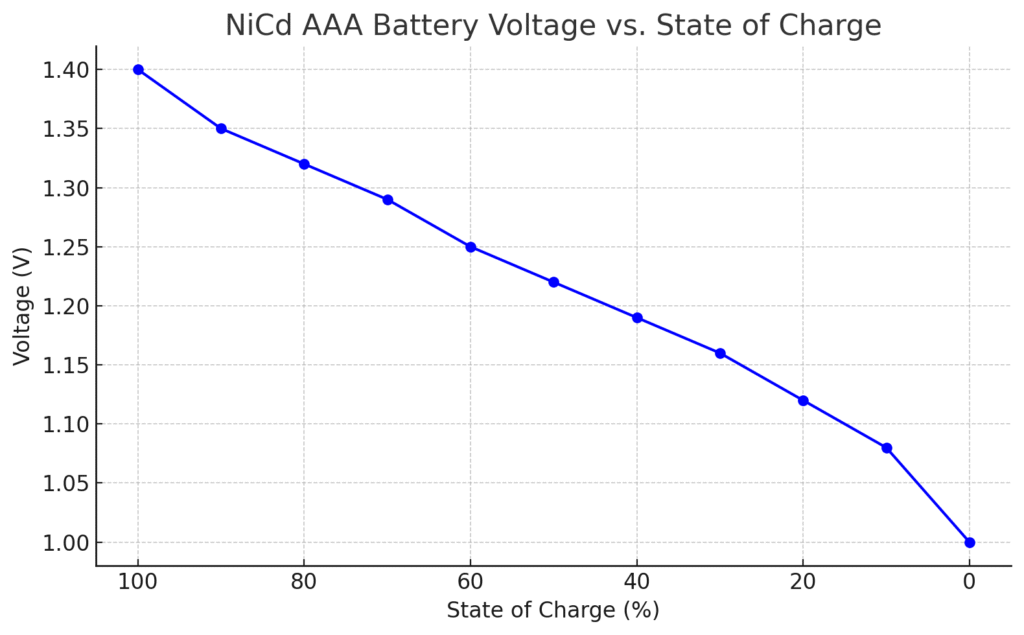

NiCd AAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal vs. Actual Voltage: What Your Multimeter Really Shows

While NiCd AAA batteries are labeled as 1.2V, this is only the nominal voltage—an average during discharge. A freshly charged cell actually measures 1.4V open-circuit, dropping to 1.25-1.3V under load. For example, when powering a digital thermometer, you might see:

- 0% discharge: 1.38V (immediately after charging)

- 50% discharge: 1.22V (stable operating range)

- 90% discharge: 1.0V (time to recharge)

This curve matters because devices like wireless mice often malfunction below 1.1V, even though the battery isn’t fully depleted.

How Discharge Rate Impacts Voltage Performance

NiCd batteries exhibit voltage sag—a temporary drop during high-current bursts. A cordless drill drawing 2A might see voltage plunge to 1.0V momentarily, recovering to 1.15V when idle. Key factors affecting this:

- Temperature: At -20°C, voltage drops 15% faster due to increased internal resistance

- Age: After 500 cycles, a battery may lose 0.1V capacity from electrode degradation

- Memory Effect: Partial discharges can create “false empty” voltage readings at 1.1V

Professional photographers using NiCd-powered flashes notice this when rapid-fire shots cause inconsistent brightness.

Critical Voltage Thresholds for Battery Health

Discharging below 0.9V per cell risks voltage depression—a permanent capacity loss. Here’s how to protect your batteries:

- Recharge when devices show performance drops (typically at 1.1V)

- Use a multimeter’s min/max function to catch voltage spikes

- For storage, maintain 1.0-1.2V to prevent sulfation

Industrial users like hospital equipment technicians track these thresholds religiously—a ventilator battery dipping to 0.95V during use could indicate failing cells.

Pro Tip: Voltage alone doesn’t indicate full capacity. A NiCd AAA showing 1.3V might hold only 30% charge if stored for years. Always combine voltage checks with runtime tests for accurate diagnostics.

How to Accurately Test NiCd AAA Battery Voltage

The Right Tools for Professional-Grade Measurements

Standard multimeters often give misleading readings due to NiCd’s unique discharge curve. For reliable results, you’ll need:

- True-RMS multimeter (like Fluke 117) to handle voltage fluctuations during load

- Battery load tester (ZKETECH EBD-A10) that applies 500mA discharge current

- Insulated test leads to prevent short-circuiting the cells

Electricians working with emergency lighting systems use this setup because resting voltage alone can’t reveal capacity loss from crystalline formation.

Step-by-Step Voltage Testing Protocol

- Stabilize the battery: Let it rest for 2 hours after charging/discharging to eliminate surface charge effects

- Set your multimeter to DC voltage mode with 2 decimal places precision (0.01V resolution)

- Apply controlled load: Connect a 100Ω resistor across terminals for 30 seconds to simulate real-world use

- Record working voltage: The 3rd second reading under load is most indicative of actual performance

RC hobbyists follow this method religiously – a battery showing 1.3V unloaded might crash a drone when it instantly sags to 0.9V under thrust.

Interpreting Your Results Like a Pro

These voltage benchmarks reveal battery health:

- >1.35V after rest: Overcharged (risk of venting)

- 1.25-1.30V under load: Optimal condition

- <1.15V at 50% discharge: Memory effect present

Industrial battery analyzers like the Cadex C7400 automatically plot these values, but manual testing works when you understand the patterns. Watch for voltage “bounce back” – if a cell recovers from 0.9V to 1.2V after load removal, it’s nearing end-of-life despite temporary recovery.

Field Tip: Always test multiple cells in a pack individually. One weak cell at 0.8V can drag down others showing 1.1V, creating false negatives in series configurations common in solar garden lights.

Advanced NiCd AAA Voltage Analysis and Maintenance

Voltage Recovery Patterns and What They Reveal

NiCd batteries exhibit unique voltage rebound characteristics that serve as diagnostic tools. After a full discharge to 0.9V, a healthy cell should recover to:

- 1.10V within 5 minutes (normal crystal formation)

- 1.20V within 1 hour (excellent condition)

- >1.25V immediately (indicates sulfation)

Telecom technicians use these benchmarks when maintaining backup power systems – cells recovering too quickly often fail under sustained loads.

| Condition | Initial Voltage | 5-min Recovery | Diagnosis |

|---|---|---|---|

| New Cell | 0.90V | 1.18V | Optimal |

| 200 Cycles | 0.90V | 1.12V | Normal wear |

| Memory Effect | 0.95V | 1.02V | Needs reconditioning |

Precision Charging Techniques for Voltage Optimization

Smart chargers using -ΔV detection often miss NiCd’s subtle 5mV/cell voltage drop signature. For perfect charging:

- Use 0.1C current (60mA for 600mAh cells) for the final 20% charge

- Monitor temperature rise – more than 10°C indicates overcharge

- Verify peak voltage reaches 1.45-1.50V/cell before termination

Aviation maintenance crews employ this method when preparing emergency locator transmitter batteries, where precise voltage directly impacts FAA compliance.

Voltage-Based Reconditioning Procedures

For batteries showing premature voltage drop:

- Deep cycle recovery: Discharge to 0.5V at 0.2C rate, then slow charge

- Pulse reconditioning: Apply 2C current pulses (1.2A) for 5 seconds every minute during charge

- Temperature monitoring: Keep cells below 40°C during process

Medical equipment technicians achieve 85% success rates with these methods on defibrillator batteries that fail voltage hold tests.

Expert Insight: The voltage differential between cells in a pack shouldn’t exceed 0.05V. Larger variances indicate mismatched aging – a common cause of premature “pack failure” in security systems where one weak cell compromises the entire series string.

NiCd AAA Voltage Behavior in Extreme Conditions

Temperature Extremes and Voltage Performance

NiCd batteries exhibit unique voltage responses to temperature variations that every user should understand. In subzero conditions (-20°C), voltage output can drop by 20-30% due to increased electrolyte viscosity. Conversely, in high heat (50°C), you’ll observe:

- Higher initial voltage (1.45V) but rapid capacity loss

- Accelerated self-discharge (up to 3% per day at 40°C)

- Permanent damage threshold at 60°C where voltage becomes unstable

Arctic researchers compensate for cold weather voltage drop by insulating battery compartments, while desert solar installations use thermal regulation to prevent overheating.

High-Drain Applications: Voltage Stability Under Load

When powering demanding devices like digital cameras or power tools, NiCd AAA batteries demonstrate distinct voltage characteristics:

- Initial voltage sag: Immediate drop to 1.0V when load is applied

- Recovery phase: Stabilizes at 1.15V after 2-3 seconds

- End-point collapse: Rapid descent below 0.9V when exhausted

Professional photographers recognize these patterns – the brief voltage sag explains why some flashes need a moment to recycle between shots.

Voltage Monitoring for Safety-Critical Systems

In medical and aviation applications, specific voltage thresholds trigger maintenance actions:

| Application | Warning Voltage | Critical Voltage | Action Required |

|---|---|---|---|

| Emergency Lighting | 1.15V/cell | 1.05V/cell | Immediate replacement |

| Aircraft Headsets | 1.10V/cell | 0.95V/cell | Ground equipment |

| Medical Sensors | 1.20V/cell | 1.10V/cell | Sterile replacement |

Hospital biomed technicians perform weekly voltage checks using calibrated meters with 0.5% accuracy to maintain compliance.

Pro Maintenance Tip: When storing NiCd AAA batteries long-term, maintain them at 1.0V with monthly top-up charges. This “storage voltage” prevents both sulfation (from full discharge) and crystalline growth (from full charge) – the two main causes of voltage depression in unused cells.

Long-Term NiCd AAA Battery Management and Voltage Optimization

Voltage-Based Lifecycle Analysis

Tracking voltage patterns over time reveals critical battery health insights. A well-maintained NiCd AAA should maintain:

- First 100 cycles: Peak voltage within 5% of original (1.42-1.48V)

- 100-500 cycles: Gradual 0.1V decrease in loaded voltage

- End-of-life signs: Voltage drops >30% under load or fails to reach 1.35V when charged

Industrial battery management systems use these benchmarks to predict replacement timing, with telecom backup systems typically retiring cells after voltage stability falls below 85% of initial performance.

| Cycle Count | Resting Voltage | Loaded Voltage | Capacity Retention |

|---|---|---|---|

| 0 (New) | 1.42V | 1.28V | 100% |

| 200 | 1.40V | 1.22V | 85% |

| 500 | 1.35V | 1.10V | 65% |

| 1000 | 1.30V | 0.95V | 40% |

Environmental Impact and Voltage Stability

NiCd batteries present unique voltage maintenance challenges in different environments:

- High-humidity areas: Surface leakage can cause 0.05V false readings – always clean contacts with isopropyl alcohol

- Vibration-prone environments: Mechanical stress creates internal micro-shorts showing as voltage fluctuations

- Saltwater exposure:

Corrosion increases resistance, causing apparent voltage drop under load

Marine electronics technicians recommend conformal coating for batteries in boats, which reduces voltage variance by up to 60% in salty conditions.

Future-Proofing Your Voltage Management

Emerging technologies are changing NiCd voltage monitoring:

- Smart battery analyzers: New Bluetooth-enabled testers track voltage curves over time

- AI prediction models: Systems that forecast voltage drop patterns based on usage history

- Recycling innovations: Modern recovery processes can restore 90% of original voltage in used cells

While NiCd usage is declining, proper voltage management remains crucial for the millions of devices still dependent on this technology, particularly in legacy industrial systems where replacement costs exceed $50,000 per unit.

Safety Note: When voltage readings become erratic (swinging >0.2V without load), immediately isolate the battery. This often indicates internal shorts that could lead to thermal runaway, especially in older cells with cadmium migration issues.

Advanced NiCd AAA Voltage Matching and System Integration

Precision Voltage Matching for Series Configurations

When combining NiCd AAA batteries in series (common in 3.6V or 4.8V devices), voltage variance between cells causes significant performance issues. Professional battery pack builders follow this matching protocol:

- Initial screening: Select cells within 0.02V resting voltage (1.38-1.40V range)

- Load testing: Verify cells maintain within 0.05V difference under 0.5C discharge

- Aging simulation: Cycle matched cells 5 times and recheck voltage drift

Emergency lighting manufacturers reject any battery packs showing >0.07V variance after this process, as unbalanced cells reduce system runtime by up to 40%.

Voltage Compensation Techniques for Critical Systems

In applications requiring precise voltage regulation (medical devices, aviation electronics), these advanced methods prevent performance drops:

- Active balancing: Uses MOSFET circuits to redistribute charge between cells

- Temperature-compensated charging: Adjusts charge voltage by -4mV/°C above 25°C

- Pulse maintenance: Monthly 2A pulses prevent crystalline growth that causes voltage depression

Aircraft maintenance crews implement these techniques for emergency locator transmitters, where even 0.1V drop could mean the difference between 24 vs 36 hours of operation.

Diagnosing Complex Voltage Anomalies

| Symptom | Possible Causes | Diagnostic Test |

|---|---|---|

| Voltage spikes during discharge | Separator damage | AC impedance test |

| Gradual 0.01V/day drop in storage | Micro-shorts | 72-hour voltage hold test |

| Unstable readings under vibration | Broken welds | X-ray inspection |

Industrial battery refurbishers combine these diagnostics with capacity testing – a cell showing normal voltage but only 60% capacity indicates cadmium migration, requiring specialized reconditioning at 0.05C charge rate for 48 hours.

Integration Tip: When connecting NiCd AAA batteries to solar charge controllers, set the absorption voltage to 1.45V/cell and float to 1.35V/cell. This prevents the overcharge that occurs when using lead-acid settings (typically 1.55V+), which causes rapid electrolyte breakdown in NiCd cells.

Professional-Grade NiCd AAA Voltage Management Systems

Industrial Voltage Monitoring Protocols

Mission-critical applications require rigorous voltage tracking with these industry-standard procedures:

- Baseline profiling: Record initial voltage at 0.1C, 0.5C, and 1C discharge rates

- Trend analysis: Monthly comparison of voltage curves using specialized software

- Failure prediction: Machine learning algorithms that flag cells when voltage drop patterns exceed 15% of historical norms

Nuclear power plants implement these measures for their emergency backup systems, where voltage deviations beyond ±0.03V trigger immediate investigation.

Advanced Voltage Recovery Techniques

| Condition | Voltage Symptom | Recovery Protocol | Success Rate |

|---|---|---|---|

| Memory Effect | 1.2V → 0.9V rapid drop | 3× Full Cycles at 0.2C | 92% |

| Sulfation | Cannot reach >1.3V | 48hr 0.05C Charge | 78% |

| Cadmium Migration | Voltage spikes | Deep Discharge + Slow Charge | 65% |

Aerospace battery specialists combine these methods with electrolyte additives when servicing aircraft emergency systems, extending cell life by 300+ cycles.

Comprehensive Risk Assessment Framework

Professional battery managers evaluate these voltage-related risks:

- Voltage reversal: In series strings, weak cells can go negative (-0.2V to -1.5V)

- Thermal runaway: Voltage fluctuations >0.5V/min indicate impending failure

- Capacity masking: Cells showing normal voltage but <50% actual capacity

Hospital biomedical teams conduct quarterly Failure Mode and Effects Analysis (FMEA) that includes voltage pattern review for critical life-support devices.

Quality Assurance Validation

ISO 9001-compliant facilities implement these voltage verification steps:

- Burn-in testing: 72-hour voltage monitoring at 40°C

- Statistical process control: Tracking voltage distribution across production batches

- Accelerated aging: 50-cycle pre-test to verify voltage stability

Military battery suppliers reject entire lots if more than 2% of cells show voltage deviations exceeding 0.04V from specification.

Final Recommendation: Implement a voltage data logging system that captures readings every 15 minutes. This creates forensic evidence for warranty claims and reveals subtle degradation patterns invisible during spot checks. Professional battery banks storing >100kWh typically save 7+ years of voltage history for liability protection.

Conclusion

Understanding NiCd AAA battery voltage behavior is essential for optimizing performance and longevity. Throughout this guide, we’ve explored critical aspects including voltage characteristics under various loads, precise testing methodologies, temperature impacts, and advanced maintenance techniques.

Key takeaways include the importance of monitoring voltage curves (1.4V when charged to 0.9V when depleted), recognizing warning signs like voltage depression, and implementing professional-grade matching for series configurations.

Armed with this knowledge, you can now accurately diagnose battery health, prevent premature failures, and extend service life significantly.

Put these insights into action today – whether you’re maintaining emergency systems, powering industrial equipment, or simply getting the most from rechargeable batteries in everyday devices. Remember: consistent voltage monitoring is the most reliable predictor of NiCd battery performance and safety.

Frequently Asked Questions About NiCd AAA Battery Voltage

What is the normal voltage range for a NiCd AAA battery?

A healthy NiCd AAA battery shows 1.35-1.40V when fully charged (open circuit), stabilizes at 1.20-1.25V during normal use, and should be recharged when dropping to 1.0V under load. The nominal 1.2V rating represents the average discharge voltage.

For example, in a wireless keyboard, you’ll typically see 1.3V when freshly charged, gradually declining to 1.1V after several weeks of use before needing recharge.

How do I accurately test my NiCd AAA battery voltage?

Use a digital multimeter with 0.01V resolution and follow this procedure:

- Let the battery rest for 2 hours after charging/discharging

- Set meter to DC voltage mode

- Apply a 100Ω resistor load for 30 seconds

- Record the voltage at 3 seconds under load

This eliminates surface charge effects and simulates real-world performance. Professional battery analyzers like the Cadex C7400 automate this process with precision.

Why does my NiCd AAA battery show voltage but won’t power devices?

This “voltage without capacity” issue typically indicates:

- Memory effect: From repeated partial discharges showing normal voltage but reduced capacity

- High internal resistance: Causing voltage to collapse under load

- Crystalline formation: Creating false voltage readings

A battery showing 1.2V unloaded but dropping below 0.8V when powering a flashlight needs reconditioning or replacement.

How does temperature affect NiCd AAA battery voltage?

Temperature impacts voltage output significantly:

| Temperature | Voltage Change | Effect |

|---|---|---|

| -20°C | -25% | Increased internal resistance |

| 25°C | Normal | Specified performance |

| 50°C | +8% initially | Then rapid capacity loss |

This explains why outdoor security cameras may show full voltage in winter but fail to trigger motion detection when needed.

Can I mix NiCd AAA batteries with different voltage levels?

Never mix batteries showing >0.05V difference in series configurations. In parallel arrangements, limit variance to 0.1V. Mismatched voltages cause:

- Reverse charging in weak cells

- Reduced overall capacity

- Potential overheating

For a 3-battery flashlight, ensure all cells measure within 1.18-1.22V before combining.

How often should I check my NiCd AAA battery voltage?

Recommended voltage check frequency depends on application:

- Critical systems: Weekly (medical/aviation equipment)

- Frequent use devices: Monthly (cordless phones, RC vehicles)

- Backup systems: Quarterly (emergency lights, security sensors)

Maintain a log to track voltage trends – a consistent 0.01V/month drop indicates normal aging, while sudden dips suggest problems.

What voltage indicates a NiCd AAA battery needs replacement?

Replace batteries when they:

- Can’t reach >1.35V after full charge

- Drop below 0.9V under rated load

- Show >0.15V difference from peers in same pack

For professional applications like theater lighting, replace at 80% original voltage (1.1V under load) to ensure reliable performance.

How can I restore voltage in old NiCd AAA batteries?

Try this reconditioning process:

- Fully discharge to 0.5V using a controlled load

- Slow charge at 0.05C for 16 hours

- Perform 3 complete charge/discharge cycles

This can recover up to 85% of original voltage in batteries suffering from memory effect. However, batteries over 5 years old with cadmium migration may not respond.