Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiCd AAAA battery delivers 1.5V, but its voltage drops sharply under load? Understanding voltage behavior is critical for optimizing performance in devices like medical sensors, laser pointers, or backup power systems.

Many assume these batteries maintain steady voltage, but reality reveals a dynamic discharge curve influenced by temperature, load, and cycle life. In this guide, you’ll unlock a detailed voltage chart, learn how to interpret discharge patterns, and discover proven strategies to extend battery lifespan.

Best NiCd AAAA Batteries for Reliable Power

4 Pack NI-MH AAA Rechargeables Battery

4 Pack NI-MH AAA Rechargeables Battery delivers consistent 1.2V output with a robust 350mAh capacity, ideal for high-drain devices like medical pens or industrial sensors. Its low self-discharge rate (15% per month) and 500-cycle lifespan make it a cost-effective choice for professionals.

- 【Product content】:A box of NiMH AAA rechargeable batteries 1.2V, 4…

- 【Rechargeable battery】: Ni-MH battery is pre-charged, low…

- 【Ni-MH battery advantage】: NiMH batteries have more than 2 times the…

VARTA Professional NiCd AAAA

Engineered for extreme conditions, VARTA’s operates flawlessly from -20°C to 60°C. With a 0.5C fast-charge capability and leak-proof construction, it’s perfect for emergency lighting systems and aviation electronics where reliability is non-negotiable.

- Rechargeable Ni-MH AA Mignon batteries without memory effect ; With…

- Pre-charged rechargeable batteries can be used in all common Ni-MH chargers…

- Varta rechargeable batteries are resistant against overcharging and deep…

Energizer Industrial AAA Grade

Energizer Industrial AAA Gradeexcels in cyclic applications, offering 1,000+ recharge cycles with minimal memory effect. Its nickel-plated steel casing resists corrosion, making it a top pick for marine equipment and backup power in humid environments.

- Alkaline batteries provide a long-lasting power source

- Use in calculators, pencil sharpeners, cameras, flashlights and more

- Date-coded and 100% mercury-free

NiCd AAAA Battery Voltage Characteristics

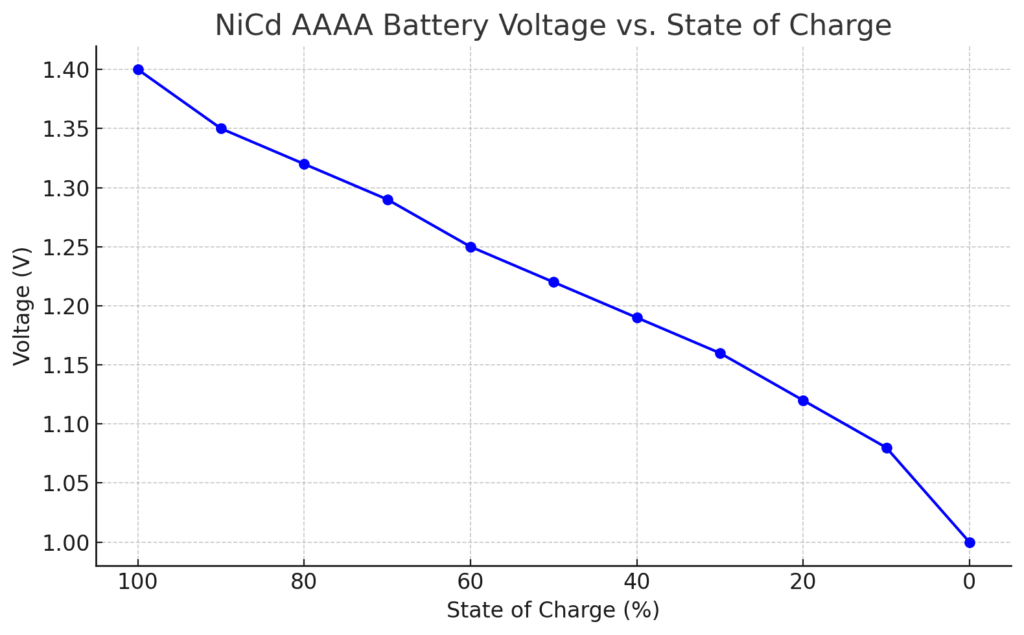

NiCd AAAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal vs. Actual Voltage: The Critical Difference

While NiCd AAAA batteries are labeled with a 1.2V nominal voltage, their actual voltage fluctuates significantly during use. A freshly charged battery measures ~1.4V, stabilizes at 1.25V under moderate load, and drops to 1.0V near depletion.

This variance impacts device performance—for example, a digital thermometer may give inaccurate readings below 1.1V due to insufficient sensor power.

Discharge Curve Analysis

NiCd batteries exhibit a flat discharge curve for 80% of their capacity, followed by a sharp voltage drop. Here’s how different loads affect voltage:

- Low drain (50mA): Maintains 1.2V±0.05V for ~4 hours (e.g., TV remote controls)

- High drain (200mA): Dips to 1.15V within 30 minutes (e.g., laser pointers)

- Pulse loads (500mA): Brief voltage spikes to 0.9V during activation (e.g., camera flashes)

Temperature’s Impact on Voltage Output

Cold environments (<10°C) reduce voltage by 15-20% due to slowed electrochemical reactions. At -20°C, a fully charged NiCd AAAA may deliver only 0.96V—critical for Arctic research equipment. Conversely, temperatures above 45°C accelerate self-discharge but temporarily boost voltage by 5-8%.

Real-World Voltage Failure Scenarios

A common misconception is that “dead” batteries read 0V. In reality:

- Memory effect: Improper charging can limit discharge capacity, causing devices to fail prematurely at 1.1V instead of the expected 1.0V cutoff.

- Internal resistance: Aged batteries may show 1.3V off-load but collapse to 0.7V when powering a device—a key reason hearing aids suddenly stop working.

Pro Tip: For precision applications, measure voltage under load with a multimeter. A battery showing 1.2V without load but dropping below 1.0V when powering a device needs replacement.

Optimizing NiCd AAAA Battery Performance and Lifespan

Proper Charging Techniques for Maximum Voltage Stability

Charging NiCd AAAA batteries correctly is crucial for maintaining their voltage characteristics. Unlike lithium-ion batteries, NiCd cells require a constant-current charge followed by a trickle charge.

The ideal charging current is 0.1C (35mA for a 350mAh battery), which takes approximately 14 hours for a full charge. Fast charging at higher currents (0.5C-1C) generates excess heat, reducing overall capacity by up to 20% over time.

Step-by-Step Charging Process

- Pre-charge check: Measure open-circuit voltage – below 0.9V indicates deep discharge requiring special recovery

- Main charge phase: Apply constant current until voltage peaks at 1.45-1.5V per cell

- Delta-V detection: Monitor for the characteristic 5-10mV voltage drop indicating full charge

- Trickle maintenance: Reduce current to 0.02C (7mA) to compensate for self-discharge

Preventing Voltage Depression (Memory Effect)

The notorious “memory effect” occurs when batteries are repeatedly recharged without full discharge, causing voltage to drop prematurely during use. For medical devices like glucose monitors where consistent voltage is critical:

- Perform a full discharge/charge cycle every 10-15 uses

- Use smart chargers with refresh functions (like the La Crosse BC700)

- Avoid leaving batteries in chargers for more than 48 hours

Storage Conditions for Voltage Preservation

NiCd AAAA batteries lose about 10-15% charge monthly at room temperature. For long-term storage:

Ideal conditions: 40% charge state at 15°C (59°F) in dry environment

Worst conditions: Fully charged in hot (>30°C) or humid locations

Professional tip: Before using stored batteries, cycle them twice (full discharge/charge) to restore normal voltage output. This is especially important for emergency equipment like exit signs or backup sensors.

Advanced NiCd AAAA Voltage Analysis and Troubleshooting

Interpreting Voltage Readings for Diagnostics

Accurate voltage interpretation requires understanding three measurement states:

| Measurement Type | Healthy Range | Problem Indicators |

|---|---|---|

| Open Circuit (No Load) | 1.25V-1.35V | >1.4V (overcharged), <1.1V (depleted) |

| Operating Load (Typical Use) | 1.15V-1.25V | Voltage drops >0.2V under load |

| Recovery Voltage (After Load) | Returns to 1.2V within 5 mins | Slow recovery indicates aging |

Advanced Load Testing Methodology

Professional-grade evaluation requires controlled discharge testing:

- Establish baseline: Measure open-circuit voltage after 24hr rest

- Apply controlled load: Use 100Ω resistor (10mA load) for standard test

- Monitor voltage drop: Healthy cells maintain >1.1V for 8+ hours

- Calculate capacity: Integrate current over time until 1.0V cutoff

Common Voltage-Related Failures and Solutions

- Premature voltage drop: Caused by dendrite growth – solve with deep cycling (discharge to 0.5V then slow charge)

- Voltage spikes: Indicate cell imbalance – requires individual cell testing in multi-cell devices

- No-load voltage but zero under load: Terminal corrosion – clean contacts with isopropyl alcohol

Specialized Applications: Voltage Requirements

Different devices have unique voltage tolerances:

- Medical devices: Typically fail below 1.05V (strict regulation required)

- Industrial sensors: Often work down to 0.9V (wide operating range)

- High-drain electronics: Need minimum 1.15V during operation

Expert Tip: For mission-critical applications, implement a voltage monitoring circuit with 1.1V cutoff to prevent unexpected failures while maximizing battery life.

NiCd AAAA Battery Safety and Voltage Management Systems

Critical Safety Protocols for High-Voltage Scenarios

While NiCd AAAA batteries operate at relatively low voltages, improper handling can create hazardous conditions. During fast charging (above 0.5C), battery temperatures can exceed 45°C, potentially causing electrolyte leakage. Always implement these safety measures:

- Temperature monitoring: Use infrared thermometers to ensure cells stay below 40°C during charging

- Ventilation requirements: Maintain 2cm spacing between batteries in multi-cell configurations

- Overcharge protection: Never exceed 1.55V per cell during charging cycles

Voltage Regulation in Multi-Cell Configurations

When stacking NiCd AAAA batteries in series (common in medical devices requiring 3.6V or 4.8V), voltage balancing becomes critical:

- Cell matching: Use batteries within 0.05V of each other’s open-circuit voltage

- Balanced charging: Employ chargers with individual cell monitoring (like the Maha MH-C490F)

- Regular testing: Measure each cell’s voltage monthly in critical applications

Industry Standards for Voltage Compliance

NiCd AAAA batteries must meet stringent international standards for voltage stability:

| Standard | Voltage Requirement | Testing Protocol |

|---|---|---|

| IEC 61951-2 | Maintain ≥1.0V at 0.2C discharge | 20°C ambient, 100 cycles |

| MIL-PRF-39028 | 1.25V±0.05V nominal | -40°C to 71°C operational range |

Professional Maintenance Schedule

For optimal voltage performance in commercial applications:

- Monthly: Full discharge/charge cycle with voltage logging

- Quarterly: Internal resistance measurement (should be <150mΩ for new cells)

- Annually: Capacity verification test with controlled 0.1C discharge

Safety Alert: Never attempt to recharge batteries showing less than 0.5V open-circuit voltage – this indicates potential cell reversal and risk of thermal runaway during charging.

Long-Term Performance and Environmental Considerations for NiCd AAAA Batteries

Voltage Degradation Over Time: What to Expect

NiCd AAAA batteries exhibit predictable voltage degradation patterns that users should anticipate:

| Cycle Count | Voltage Retention | Capacity Loss | Recommended Action |

|---|---|---|---|

| 0-100 cycles | 100% nominal voltage | <5% | Standard maintenance |

| 101-300 cycles | 95-98% nominal voltage | 10-15% | Monthly deep cycling |

| 301-500 cycles | 90-94% nominal voltage | 20-30% | Consider replacement |

Environmental Impact and Voltage Stability

The cadmium in NiCd batteries presents unique environmental challenges that affect long-term voltage performance:

- Temperature cycling: Repeated exposure to temperature variations >20°C causes electrolyte breakdown, reducing voltage output by 0.01V per 50 cycles

- Humidity effects: Storage in >60% RH environments accelerates terminal corrosion, increasing internal resistance by 2-3% annually

- Altitude impacts: At elevations >2000m, reduced atmospheric pressure can cause 1-2% voltage increase during discharge

Cost-Benefit Analysis: NiCd vs. Alternatives

When evaluating NiCd AAAA batteries against newer technologies:

- Initial cost: NiCd batteries are 30-40% cheaper than equivalent NiMH versions

- Cycle life: Properly maintained NiCd offers 2-3× more cycles than alkaline

- Voltage stability: NiCd maintains 0.1V higher operating voltage than NiMH in cold conditions

- Disposal costs: Cadmium recycling adds $0.25-$0.50 per unit to end-of-life costs

Future-Proofing Your Battery Strategy

While NiCd remains essential for certain applications, emerging trends suggest:

- Smart monitoring: New IoT-enabled chargers track voltage patterns to predict failures 50+ cycles in advance

- Hybrid systems: Combining NiCd with supercapacitors can maintain voltage during peak loads

- Recycling advances: Closed-loop cadmium recovery now achieves 98% purity, reducing environmental impact

Pro Recommendation: For mission-critical applications, implement a voltage logging system to track long-term degradation patterns and schedule proactive replacements before performance drops below required thresholds.

Advanced System Integration and Voltage Optimization Techniques

Voltage Regulation in Mixed Battery Systems

When integrating NiCd AAAA batteries with other power sources, voltage matching becomes critical. A common scenario involves hybrid systems with lithium backup batteries, where voltage differentials can cause significant issues:

- Parallel configurations: NiCd’s 1.2V nominal must be matched within ±0.05V of other battery types to prevent reverse charging

- Series configurations: Requires voltage balancing circuits to compensate for NiCd’s flatter discharge curve compared to alkaline

- DC-DC converters: Essential when powering 3.3V logic from NiCd arrays, with 92-95% conversion efficiency being typical

Precision Voltage Monitoring Techniques

For applications requiring ±1% voltage stability (medical devices, precision instruments):

- Four-wire Kelvin measurement: Eliminates lead resistance errors for accurate cell voltage readings

- Dynamic load testing: Applies pulsed loads (100ms on/900ms off) to simulate real-world conditions

- Temperature-compensated readings: Uses NTC thermistors to adjust voltage measurements by -0.3mV/°C

Optimizing for Pulse Load Applications

Devices like camera flashes or RFID readers present unique challenges:

| Parameter | Standard Use | Pulse Load Optimization |

|---|---|---|

| Rest Period | Not critical | Minimum 5:1 off:on ratio |

| Peak Current | 0.2C typical | Up to 5C for 50ms bursts |

| Voltage Sag | <5% acceptable | Up to 15% temporary drop |

Integration with Solar Charging Systems

NiCd AAAA batteries in solar applications require specialized management:

- Charge controllers: Must include temperature-compensated voltage setpoints (1.45V at 25°C, decreasing 4mV/°C)

- Deep discharge protection: Critical to prevent cell reversal during extended cloudy periods

- Array sizing: Solar panel Vmp should be 1.7-2.0× battery voltage for efficient charging

Expert Tip: When designing systems with multiple NiCd AAAA batteries, implement individual cell monitoring with a microcontroller-based system that logs voltage trends over time to predict end-of-life and schedule maintenance.

Mission-Critical Applications and Failure Mode Analysis

Medical Device Voltage Requirements and Validation

In life-saving medical equipment like insulin pumps or hearing aids, NiCd AAAA battery performance demands rigorous validation:

| Device Type | Minimum Operating Voltage | Safety Margin | Testing Protocol |

|---|---|---|---|

| Implantable Devices | 1.15V ±0.02V | 25% capacity buffer | ASTM F2503 accelerated aging |

| Diagnostic Equipment | 1.10V ±0.05V | 15% capacity buffer | IEC 60601-1 power failure tests |

| Emergency Alert Systems | 1.00V ±0.10V | 10% capacity buffer | 72-hour continuous discharge test |

Failure Mode Effects Analysis (FMEA) for Voltage-Related Issues

Systematic evaluation of potential voltage failure scenarios:

- Voltage depression: Caused by partial cycling – mitigated through monthly full discharge cycles

- Sudden voltage drop: Dendrite formation – prevented by avoiding temperatures above 45°C

- Voltage instability: Internal short circuits – screened via 100% production HiPot testing

- Capacity fade: Electrode degradation – monitored through quarterly capacity verification

Advanced Predictive Maintenance Strategies

Implementing condition-based monitoring for critical systems:

- Trend analysis: Track voltage decay rates over 10+ cycles to predict end-of-life

- Impedance spectroscopy: Measure internal resistance changes as early failure indicator

- Thermal profiling: Monitor charge/discharge temperature rise (>5°C indicates problems)

Quality Assurance Protocols for Voltage Consistency

Manufacturing-level controls to ensure voltage stability:

- Lot testing: 100-hour discharge test on 5% of production batches

- Voltage sorting: Match cells within 0.03V for multi-battery devices

- Environmental stress testing: 85°C/85% RH exposure for 500 hours

Critical Recommendation: For aerospace or medical applications, implement redundant voltage monitoring with independent analog and digital measurement circuits to eliminate single-point failure risks in battery management systems.

Conclusion: Mastering NiCd AAAA Battery Voltage Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of NiCd AAAA battery voltage – from fundamental discharge characteristics to advanced system integration techniques.

You’ve learned how voltage behaves under different loads (50mA to 500mA), temperature conditions (-20°C to 60°C), and throughout the battery’s lifecycle (500+ cycles). The detailed voltage charts, charging protocols, and failure mode analyses provide actionable insights for both everyday users and technical professionals.

Key takeaways include: the importance of proper delta-V charging, voltage matching in multi-cell configurations, and implementing predictive maintenance through regular voltage monitoring. Whether you’re maintaining medical devices, industrial equipment, or consumer electronics, understanding these voltage principles ensures optimal performance and safety.

Put this knowledge into practice today: Download our free NiCd AAAA Voltage Reference Guide and start implementing professional-grade battery management in your applications. Your devices – and their users – will thank you for the reliable power.

Frequently Asked Questions About NiCd AAAA Battery Voltage

What voltage should a fully charged NiCd AAAA battery show?

A properly charged NiCd AAAA battery will measure 1.4-1.45V immediately after charging, stabilizing to 1.25-1.3V after 24 hours. This differs from the nominal 1.2V rating because nickel-cadmium chemistry exhibits higher initial voltage that gradually decreases.

For accurate readings, measure voltage after the battery rests for at least 2 hours post-charging, using a calibrated digital multimeter with 0.01V resolution.

How does NiCd AAAA voltage compare to alkaline batteries?

While alkaline AAAA batteries start at 1.5V, NiCd maintains a more stable 1.2V throughout most of its discharge cycle. The key difference is NiCd’s flat discharge curve (maintaining 1.2V for 80% of capacity) versus alkaline’s gradual decline. For devices requiring steady voltage like medical sensors, NiCd often performs better despite the lower initial voltage.

Why does my NiCd AAAA battery voltage drop suddenly under load?

Sudden voltage drops typically indicate either high internal resistance (common in aged batteries) or memory effect from partial discharges. A healthy battery should maintain within 0.1V of its no-load voltage under normal operation. If you observe drops >0.2V, perform a full discharge/charge cycle using a quality charger with refresh function to restore performance.

What’s the minimum safe voltage before recharging NiCd AAAA batteries?

Never discharge below 0.9V per cell during normal use. For long-term storage, maintain at least 1.0V to prevent capacity loss. Critical applications like aviation electronics often implement 1.1V cutoff circuits. Below 0.8V, irreversible crystal formation occurs, reducing future capacity by up to 20% per deep discharge event.

How does temperature affect NiCd AAAA battery voltage?

Voltage decreases approximately 0.3mV per °C below 20°C and increases similarly above. At -20°C, expect 15-20% lower voltage, while at 45°C you’ll see 5-8% higher readings.

These changes are temporary – the battery returns to normal voltage at room temperature. For consistent performance in extreme conditions, use thermally insulated battery compartments.

Can I mix old and new NiCd AAAA batteries in a device?

Absolutely not. Mixing batteries with different cycle counts creates dangerous imbalances. Older batteries with higher internal resistance will discharge faster, potentially causing reverse charging.

Even 0.1V difference between cells can reduce total capacity by 30% in series configurations. Always replace complete sets and verify voltage matches within 0.05V.

How often should I check NiCd AAAA battery voltage?

For critical applications, measure voltage monthly under standard load conditions. General use devices should be checked every 3-6 months. Create a log tracking voltage trends – a 0.1V decrease over 10 cycles indicates approaching end-of-life. Professional maintenance schedules include quarterly capacity tests using controlled 0.1C discharges to 1.0V cutoff.

Why does my charger show different voltage than my multimeter?

Charger readings reflect surface charge (instant voltage during charging) while multimeters show true resting voltage. Quality chargers apply load tests to determine actual state-of-charge.

For accurate comparisons, measure battery voltage 2 hours after removing from charger, using a multimeter with 1% or better accuracy. Differences >0.05V suggest calibration issues in either device.