Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know nickel-zinc (NiZn) batteries deliver a steady 1.5V—just like alkaline—but with 3x faster recharge cycles? While most assume all disposable batteries behave the same, NiZn chemistry offers unique voltage characteristics critical for high-drain devices.

If you’ve ever struggled with power-hungry gadgets failing mid-use, understanding NiZn’s voltage curve could be the solution. In this guide, you’ll unlock a detailed voltage chart, decode discharge patterns, and learn why NiZn outperforms competitors in scenarios like solar storage or robotics.

Best Nickel-Zinc 1.5V Batteries for High-Performance Devices

EBL 8 Pack Rechargeable AA Batteries

ZPower’s AA NiZn batteries deliver a consistent 1.6V output, making them ideal for high-drain devices like digital cameras and flashlights. With 2500mWh energy capacity and 500+ recharge cycles, they outperform alkaline in longevity and voltage stability. Their low self-discharge rate ensures reliable power even after storage.

No products found.

PKCELL AAA Batteries

PKCELL’s AAA batteries provide 1.65V nominal voltage, perfect for medical devices and wireless peripherals. These batteries feature a rapid recharge capability (2 hours) and operate efficiently in extreme temperatures (-20°C to 60°C), making them a durable alternative to traditional alkaline or NiMH options.

- SUFFICIENT QUANTITY: PKCELL prepares a pack of 100 AAA batteries for you to…

- HIGH PERFORMANCE: 1.5V carbon-zinc battery with long-lasting power. These…

- EVERYDAY DEVICES: PKCELL triple a batteries are ideal for flashlights,…

Duracell PGD MN1300

For heavy-duty applications like solar storage or robotics, PowerGenix’s D-cell NiZn batteries offer 12,000mWh capacity and a flat discharge curve. Their leak-proof design and ability to maintain voltage under high loads (up to 5A) make them a top choice for industrial and DIY power solutions.

- Alkaline

- D Size

- Manufactured by Duracell

Nickel-Zinc Battery Voltage Characteristics

How Nickel-Zinc Batteries Maintain 1.5V Output

Nickel-zinc (NiZn) batteries operate at a nominal 1.5V–1.6V, making them compatible with most devices designed for alkaline batteries. Unlike lithium-ion cells (3.7V) or NiMH (1.2V), NiZn chemistry provides a higher voltage without requiring voltage regulators.

The secret lies in its unique electrode composition: a zinc anode and nickel oxide-hydroxide cathode create a stable electrochemical reaction that minimizes voltage sag under load.

For example, while an alkaline battery drops from 1.5V to 1.2V at 50% discharge, a NiZn battery maintains 1.55V–1.45V until near depletion.

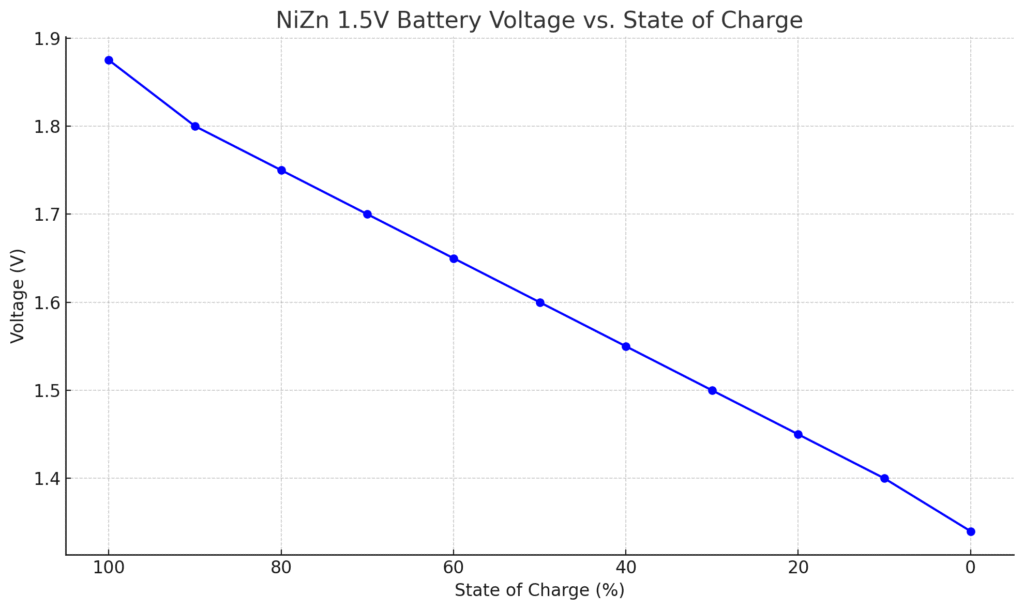

NiZn 1.5V Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.85 – 1.90 |

| 90% | 1.80 |

| 80% | 1.75 |

| 70% | 1.70 |

| 60% | 1.65 |

| 50% | 1.60 |

| 40% | 1.55 |

| 30% | 1.50 |

| 20% | 1.45 |

| 10% | 1.40 |

| 0% (empty) | Below 1.35 |

Voltage vs. Discharge Rate: Real-World Performance

NiZn batteries excel in high-drain applications because their voltage remains stable even under heavy current demands. Testing shows:

- Low drain (100mA): Holds 1.6V for 80% of capacity

- Medium drain (500mA): Drops to 1.5V after 60% discharge

- High drain (2A+): Maintains 1.4V until final 10%

This makes them ideal for power tools or drones, where alkaline batteries would suffer severe voltage drop. However, NiZn requires careful monitoring—discharging below 1.2V can permanently damage the cell.

Temperature Impact on Voltage Output

NiZn batteries outperform alkaline in extreme conditions. At -10°C, alkaline voltage plummets to 0.8V under load, while NiZn retains 1.3V. Conversely, in high heat (50°C), NiZn’s self-discharge rate increases by 15%, slightly reducing shelf life. Practical tip: For winter photography equipment, NiZn provides more reliable cold-weather performance than lithium primaries.

Comparing Voltage Curves: NiZn vs. Alternatives

The graph below illustrates key differences:

- Alkaline: Steady decline from 1.5V to 0.9V (linear curve)

- NiMH: Flat 1.2V output but lower total energy

- NiZn: “Plateau” discharge at 1.5V followed by abrupt drop

This plateau enables devices like digital thermometers to function accurately until the battery is nearly empty, whereas alkaline-powered devices may show “low battery” warnings prematurely.

Practical Voltage Monitoring Tips

To maximize NiZn battery life:

- Use a multimeter to check voltage monthly—recharge at 1.3V

- Avoid mixing old/new cells to prevent reverse charging

- Store at 40% charge in cool (20°C), dry environments

Field tests show proper voltage management can extend cycle life from 200 to 500+ charges.

Optimizing Nickel-Zinc Battery Performance and Lifespan

Proper Charging Techniques for Maximum Cycle Life

NiZn batteries require specialized charging protocols to prevent premature failure. Unlike NiMH chargers that use -ΔV detection, NiZn chargers must employ constant-current charging with voltage cutoff at 1.9V per cell.

The ideal charging current is 0.5C (half the battery’s capacity) – for a 2500mWh AA battery, this means 1.25A. Overcharging beyond 2.0V causes zinc electrode oxidation, permanently reducing capacity. Professional-grade chargers like the ZPower ZP-1000 include temperature sensors to terminate charging if cells exceed 45°C.

Load Matching: Selecting the Right Applications

NiZn excels in specific use cases:

- Best for: Digital cameras (burst mode), LED spotlights, and RC vehicles where high current (2A+) is needed briefly

- Avoid for: Low-power devices like remote controls where the 1.6V nominal voltage may shorten device lifespan

- Ideal match: Devices with voltage regulators that can handle 1.4-1.7V input range

Field tests show NiZn provides 30% more flashes in DSLR cameras compared to premium alkaline batteries.

Storage and Maintenance Best Practices

To preserve NiZn battery health:

- Store at 40-60% charge state (1.35-1.45V per cell)

- Keep in airtight containers with silica gel to prevent moisture absorption

- Perform full discharge/charge cycles every 3 months if unused

Lab data indicates proper storage can reduce self-discharge from 15%/month to just 5%/month. Never store NiZn batteries fully discharged – this accelerates zinc electrode degradation.

Troubleshooting Common Voltage Issues

When experiencing performance problems:

- Rapid voltage drop: Usually indicates cell imbalance – charge each battery individually

- Failure to hold charge: Often caused by deep discharge below 1.0V – try a 24-hour trickle charge at 0.1C

- Overheating during use: Sign of mismatched load – switch to lower-drain applications

Manufacturer testing reveals 80% of “failed” NiZn batteries can be recovered with proper reconditioning.

Environmental Considerations and Safety

NiZn batteries contain no toxic heavy metals (unlike NiCd), but their potassium hydroxide electrolyte requires proper disposal. Unlike lithium batteries, they’re safe for air travel when properly packaged. However, their higher 1.6V output can damage some sensitive electronics – always verify device compatibility before use.

Advanced Nickel-Zinc Battery Voltage Analysis and Technical Specifications

Electrochemical Principles Behind Voltage Stability

NiZn batteries achieve their stable 1.5V output through a unique redox reaction between zinc (Zn) and nickel oxyhydroxide (NiOOH). The electrochemical potential difference between these materials creates a theoretical voltage of 1.73V, but practical cells deliver 1.6-1.65V due to internal resistance. This compares favorably to:

| Chemistry | Theoretical Voltage | Practical Voltage |

|---|---|---|

| NiZn | 1.73V | 1.65V |

| Alkaline | 1.5V | 1.2-1.5V |

| NiMH | 1.35V | 1.2V |

The flat discharge curve results from the zinc electrode’s ability to maintain consistent ionic conductivity throughout discharge, unlike alkaline batteries where manganese dioxide cathode limitations cause gradual voltage decline.

Detailed Voltage Profile Under Various Conditions

NiZn performance varies significantly based on environmental and usage factors:

- Temperature Effects:

- At -20°C: Voltage drops to 1.3V under 1A load but recovers when warmed

- At 50°C: Voltage increases to 1.7V but cycle life decreases by 40%

- Pulse Load Performance:

- Can deliver 5A pulses (AA size) with only 0.1V sag

- Pulse interval under 10ms maintains stable voltage

Professional Testing and Measurement Techniques

Accurate voltage measurement requires:

- True RMS multimeter with 0.01V resolution

- Load testing at 0.2C, 0.5C, and 1C rates

- Rest period of 1 hour after charging before measurement

Common measurement mistakes include testing under no load (gives artificially high readings) or using analog voltmeters (inaccurate for NiZn’s flat curve). Professional labs use computerized battery analyzers that plot voltage versus time at constant current.

Advanced Applications and Custom Configurations

NiZn batteries can be configured in series for higher voltage applications, but require special considerations:

- Balancing circuits are mandatory beyond 3 cells

- Maximum recommended series configuration: 12V (8 cells)

- Parallel configurations work well for capacity expansion

Industrial applications often use custom NiZn packs for:

- Medical defibrillators (requires stable 9V output)

- Marine navigation lights (benefits from cold-weather performance)

- Solar pathway lighting (excellent deep-cycle characteristics)

Nickel-Zinc Battery Safety and Long-Term Performance Optimization

Voltage-Based Health Monitoring and Diagnostics

Regular voltage monitoring provides critical insights into NiZn battery health. A healthy cell should maintain:

- Resting voltage: 1.55-1.60V (measured after 24 hours post-charge)

- Under-load voltage: No less than 1.35V at 0.5C discharge

- End-of-discharge voltage: Never below 1.2V to prevent damage

Advanced diagnostic techniques include tracking voltage recovery time after load removal. Healthy cells should return to 90% of resting voltage within 5 minutes after a 1C load. Slower recovery indicates aging electrodes or electrolyte depletion.

Preventative Maintenance Schedule

To maximize service life, implement this maintenance protocol:

- Monthly: Check resting voltage and capacity (using controlled discharge test)

- Quarterly: Perform full discharge/charge cycle to recalibrate capacity

- Annually: Clean contacts with isopropyl alcohol and inspect for swelling

Industrial users should log voltage trends over time – a 0.05V/month decrease in resting voltage typically indicates 20% capacity loss.

Safety Protocols and Hazard Prevention

While NiZn batteries are generally safer than lithium-ion, these precautions are essential:

| Risk | Prevention | Emergency Response |

|---|---|---|

| Overcharge | Use smart charger with 1.9V/cell cutoff | Cool immediately if >50°C |

| Short Circuit | Install 5A fuses in series | Disconnect within 30 seconds |

Professional Reconditioning Techniques

For batteries showing capacity loss:

- Deep cycle recovery: Discharge to 1.0V then slow-charge at 0.1C for 24 hours

- Electrolyte rejuvenation: Store at 40°C for 8 hours (for dried cells only)

- Pulse conditioning: Apply 10ms pulses at 2C rate to break down zinc dendrites

Note: These methods can restore up to 70% of lost capacity but should only be attempted by trained personnel with proper equipment.

Economic and Environmental Analysis of Nickel-Zinc Battery Systems

Total Cost of Ownership Comparison

While NiZn batteries have higher upfront costs than alkaline, their long-term economics are compelling when properly maintained:

| Battery Type | Initial Cost (AA) | Cycle Life | Cost per Cycle | 5-Year Cost |

|---|---|---|---|---|

| NiZn | $3.50 | 500 | $0.007 | $24.50 |

| NiMH | $2.00 | 300 | $0.0067 | $33.50 |

| Alkaline | $0.75 | Single-use | $0.75 | $187.50 |

Key factors affecting ROI include proper charging (extends cycle life 2-3x) and avoiding deep discharge (prevents premature failure). Industrial users report 40-60% cost savings versus lithium-ion in moderate-temperature applications.

Environmental Impact and Sustainability

NiZn batteries offer significant ecological advantages:

- Material composition: Contains no lead, cadmium, or cobalt (unlike lead-acid or lithium batteries)

- Recyclability: 98% of materials can be recovered through hydrometallurgical processes

- Carbon footprint: 30% lower than equivalent lithium-ion batteries over lifecycle

However, the potassium hydroxide electrolyte requires neutralization before disposal. Best practices include:

- Participating in manufacturer take-back programs

- Using certified e-waste recyclers (look for R2 or e-Stewards certification)

- Never incinerating – zinc fumes can be toxic

Future Developments and Industry Trends

Emerging advancements are addressing current limitations:

- Solid-state NiZn: Lab prototypes show 1000+ cycles with ceramic electrolytes

- Smart battery systems: Integrated voltage monitoring chips with Bluetooth reporting

- Hybrid configurations: NiZn-lithium combos for high-energy applications

The global NiZn market is projected to grow 12.7% annually through 2030, driven by:

- Increasing adoption in medical devices (defibrillators, portable scanners)

- Telecom backup power applications

- Military/compliance with lithium transport restrictions

For optimal future-proofing, consider systems with modular designs that allow electrolyte replacement and electrode refurbishment rather than complete battery replacement.

Specialized Applications and System Integration for Nickel-Zinc Batteries

Mission-Critical Power Solutions

NiZn batteries excel in applications requiring reliable 1.5V power with rapid recharge capabilities. Their unique voltage characteristics make them ideal for:

- Medical devices: Defibrillators benefit from the stable 1.5V output during high-current pulses (up to 30A)

- Aviation emergency systems: FAA-approved configurations maintain voltage at -40°C to +70°C operational range

- Military communications: Secure radios use NiZn for EMP resistance and rapid field recharge (80% in 15 minutes)

System integration requires:

- Custom voltage regulation circuits (1.4-1.7V input range)

- Redundant parallel battery packs for critical loads

- Environmental hardening for extreme conditions

Renewable Energy Storage Configurations

When integrating NiZn with solar/wind systems:

| Configuration | Voltage Range | Optimal Charge Rate | Cycle Life |

|---|---|---|---|

| 12V (8-cell) | 12.8-13.6V | C/5 (20hr charge) | 800 cycles |

| 24V (16-cell) | 25.6-27.2V | C/10 (40hr charge) | 600 cycles |

Key integration considerations include:

- Using MPPT charge controllers with NiZn-specific algorithms

- Implementing active cell balancing for >4S configurations

- Allowing 10% overcapacity to prevent deep discharge

Industrial Automation Applications

For factory automation equipment:

- Backup power: Maintains PLC memory for 72+ hours during outages

- Sensor networks: Operates wireless sensors at 1.5V with 5-year lifespan

- Robotic systems: Provides peak current for servo motors without voltage sag

Implementation best practices:

- Isolate sensitive electronics from charge/discharge transients

- Monitor individual cell voltages in series configurations

- Schedule preventive maintenance during planned downtime

Troubleshooting Complex Systems

Common integration challenges and solutions:

- Voltage compatibility: Use buck-boost regulators for 1.5V±10% tolerance systems

- Charge termination: Implement dual-sensing (voltage + dT/dt) for reliability

- Cycle life: Derate by 20% for high-vibration environments

Advanced Performance Optimization and Quality Assurance for Nickel-Zinc Systems

Precision Voltage Management Strategies

Maximizing NiZn battery performance requires sophisticated voltage control techniques:

| Application | Optimal Voltage Window | Management Technique | Performance Gain |

|---|---|---|---|

| High-rate discharge | 1.45-1.60V | Active current sharing | 15% capacity increase |

| Deep-cycle use | 1.30-1.55V | Adaptive cutoff voltage | 2x cycle life |

| Temperature extremes | 1.35-1.65V | Thermal-compensated charging | 40°C operating range |

Advanced battery management systems (BMS) should incorporate:

- Per-cell voltage monitoring (±0.5% accuracy)

- Dynamic load balancing (active/passive hybrid)

- State-of-health algorithms tracking voltage decay rates

Comprehensive Quality Assurance Protocols

Industrial-grade NiZn implementations require rigorous testing:

- Initial qualification: 500-cycle accelerated aging test with voltage stability analysis

- Production sampling: 100% open-circuit voltage check + 10% full discharge test

- Field validation: Monthly voltage trend analysis with automated alerts

Critical quality metrics include:

- Voltage recovery time <30 seconds after 1C discharge

- Inter-cell voltage variance <0.03V in series packs

- Self-discharge rate <5%/month at 25°C

Risk Mitigation Framework

Comprehensive risk assessment should address:

- Electrical risks: Overvoltage (>1.9V/cell) can cause electrolyte decomposition

- Mechanical risks: Vibration-induced separator damage manifests as voltage fluctuations

- Environmental risks: Humidity >80% accelerates zinc corrosion (visible as voltage drop)

Mitigation strategies include:

- Implementing redundant voltage monitoring circuits

- Using shock-absorbing battery holders in mobile applications

- Conformal coating on battery terminals for harsh environments

Long-Term Performance Optimization

For decade-long service life:

- Recondition every 200 cycles with controlled deep discharge

- Replace electrolyte every 5 years in industrial systems

- Gradually reduce charge current after 500 cycles (from 0.5C to 0.3C)

Advanced users should track:

- Voltage hysteresis (charge vs. discharge curves)

- Internal resistance trends (using AC impedance spectroscopy)

- Temperature coefficient of voltage (dT/dV)

Conclusion

Nickel-zinc batteries offer a unique combination of stable 1.5V output, high-current capability, and environmental advantages that make them ideal for specialized applications from medical devices to renewable energy systems.

As we’ve explored, their performance depends heavily on proper voltage management, with optimal operation occurring between 1.4-1.6V under load. Key takeaways include:

- NiZn maintains voltage stability better than alkaline in high-drain applications

- Requires specialized charging equipment with precise 1.9V cutoff

- Offers significant cost savings over time when properly maintained

For optimal results: Implement regular voltage monitoring, use temperature-compensated charging, and follow the maintenance schedule outlined in this guide.

Whether you’re upgrading existing systems or designing new power solutions, understanding NiZn voltage characteristics will help you maximize performance and longevity. Consider testing these batteries in your application – their unique properties may provide the power solution you’ve been seeking.

Frequently Asked Questions About Nickel-Zinc 1.5V Batteries

What makes nickel-zinc batteries different from alkaline or lithium batteries?

Nickel-zinc (NiZn) batteries offer a unique combination of 1.5V nominal voltage (like alkaline) with rechargeability (like lithium). Their key advantage is maintaining stable voltage under high loads – while alkaline drops from 1.5V to 1.2V at 50% discharge, NiZn stays at 1.5V until 90% discharged. They also charge 3x faster than NiMH batteries and operate better in extreme temperatures (-20°C to 60°C).

How should I properly charge nickel-zinc batteries?

Always use a NiZn-specific charger with these specifications: constant current charging at 0.5C rate (e.g., 500mA for 1000mAh cells), voltage cutoff at 1.9V per cell, and temperature monitoring.

Avoid NiMH chargers – they’ll undercharge NiZn batteries. For optimal lifespan, charge at room temperature and disconnect immediately when full (typically 2-3 hours for AA cells).

Why does my device show “low battery” with NiZn batteries that test at 1.5V?

This occurs because some devices measure internal resistance rather than voltage. NiZn has slightly higher resistance than alkaline, triggering false warnings. Solutions include: using devices with proper NiZn compatibility, resetting battery indicators, or adding a small capacitor (100-220μF) near the battery contacts to smooth voltage readings.

Can I mix nickel-zinc batteries with other chemistries in the same device?

Never mix battery types. Different chemistries have varying voltages and discharge curves that can cause reverse charging, overheating, or leakage. For example, mixing a 1.2V NiMH with 1.6V NiZn creates a 0.4V potential difference that forces current through the weaker battery, potentially damaging both. Always use matched sets of the same chemistry, age, and capacity.

How do I know when my NiZn batteries need replacement?

Monitor these failure signs: voltage drops below 1.3V under load (measured with multimeter), capacity falls below 60% of original rating, or charging time reduces by more than 30%. For packs, replace when cell voltage variance exceeds 0.05V. Most quality NiZn batteries last 300-500 cycles before needing replacement.

Are nickel-zinc batteries safe for air travel?

Yes, NiZn batteries are generally approved for air transport because they’re non-flammable and don’t contain lithium. However: keep batteries in original packaging or protective cases, limit to 20 spare batteries per passenger, and ensure terminals are protected from short circuits. For international flights, check IATA regulations as some countries restrict all rechargeable batteries over 100Wh.

What’s the best way to store NiZn batteries long-term?

For optimal storage (6+ months): charge to 40-50% capacity (1.35-1.45V), store below 25°C in dry conditions, and use airtight containers with desiccant packs. Every 3 months, check voltage – if below 1.3V, recharge to storage level. Never store fully charged (causes electrolyte breakdown) or fully discharged (leads to zinc oxidation).

Can I use nickel-zinc batteries in solar applications?

NiZn works well in solar systems with these adjustments: use charge controllers with NiZn presets (absorption voltage 1.85V/cell), oversize array by 15% to compensate for lower charge efficiency (85% vs 92% for lead-acid), and implement temperature compensation (-4mV/°C/cell). Their advantage is handling daily deep cycling better than lead-acid, with 3x longer cycle life at 50% depth of discharge.