Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged NiMH AA battery doesn’t actually reach 1.5V like alkaline batteries? If you’ve ever wondered why your rechargeable batteries behave differently—or how to maximize their lifespan—you’re not alone.

NiMH (Nickel-Metal Hydride) batteries power everything from cameras to solar lights, but their voltage characteristics are often misunderstood. Unlike disposable batteries, their voltage fluctuates significantly during use, impacting performance.

Best NiMH AA Batteries for Reliable Performance

Eneloop Pro AA HR-3UWXB

Panasonic’s Eneloop Pro AA (HR-3UWXB) is a top-tier NiMH battery with a 2550mAh capacity and low self-discharge, retaining 85% charge after a year. Ideal for high-drain devices like cameras and flashlights, its consistent voltage output ensures stable performance even under heavy use.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro AA high…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AA rechargeable batteries up…

- PRE-CHARGED AND READY TO USE: eneloop pro AA rechargeable batteries are…

AmazonBasics Pre-Charged Rechargeable AA Batteries

These budget-friendly NiMH AA batteries offer 2000mAh capacity and come pre-charged, making them ready to use out of the box. With a long cycle life (1000+ recharges), they’re perfect for everyday electronics like remotes, wireless mice, and kids’ toys.

- RELIABLE PERFORMANCE: 8-pack of AA rechargeable NiMH batteries (2,000 mAh)

- DEVICE COMPATIBLE: Ideal for remote controls, flashlights, clocks, and more

- LONG LASTING: Can be recharged up to 1000 times with minimal power loss

EBL 2800mAh AA Batteries (8-Pack)

EBL’s high-capacity (2800mAh) NiMH AA batteries deliver extended runtime for power-hungry devices like gaming controllers and LED lanterns. Their low self-discharge rate and included storage case make them a practical choice for both casual and heavy users.

No products found.

NiMH AA Battery Voltage Characteristics

NiMH (Nickel-Metal Hydride) AA batteries operate differently from alkaline or lithium counterparts, with unique voltage behaviors that impact performance. Unlike alkaline batteries that start at 1.5V and gradually decline, NiMH cells begin at 1.4V when fully charged and maintain a relatively stable voltage until depletion.

This “flat discharge curve” makes them ideal for devices requiring consistent power, such as digital cameras or flashlights, where sudden voltage drops would cause malfunctions.

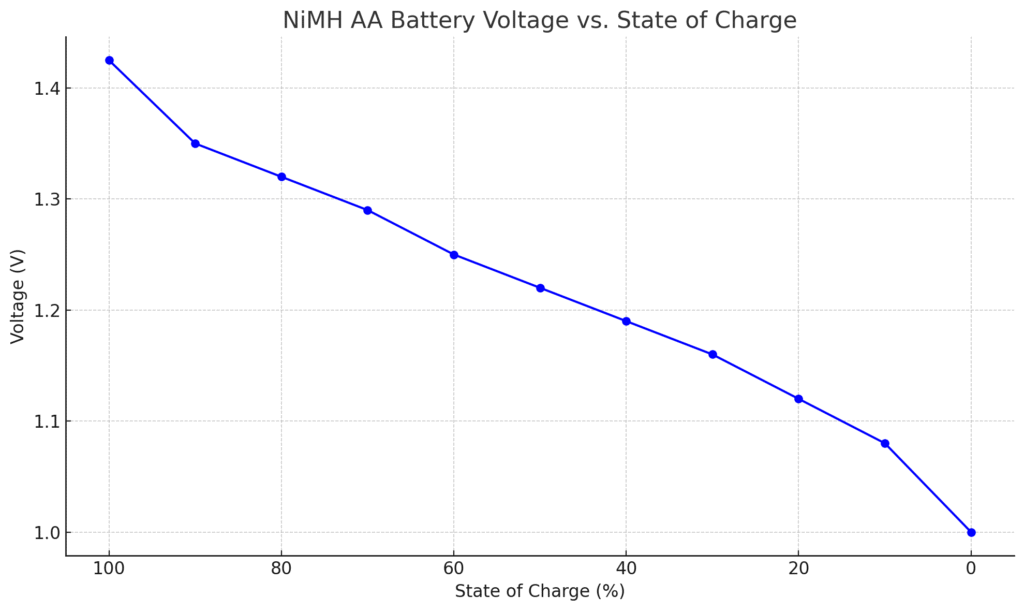

NiMH AA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 – 1.45 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Key Voltage Benchmarks

A NiMH AA battery’s voltage changes predictably during use:

- Fully charged: 1.4V–1.45V (measured immediately after charging)

- Nominal voltage: 1.2V (the standard rating during most of the discharge cycle)

- Depleted: 0.9V–1.0V (point where most devices stop functioning)

For example, a wireless gaming controller might shut off at 1.0V despite the battery still holding some charge—this is a safety cutoff to prevent over-discharge damage.

Why Voltage Matters in Real-World Use

Voltage directly affects device compatibility and runtime. A common misconception is that NiMH batteries are “weaker” than alkalines because of their lower nominal voltage (1.2V vs. 1.5V). However, their ability to sustain this voltage under load—unlike alkalines that sag quickly—often makes them more effective in high-drain devices. For instance:

- Digital cameras: Require stable voltage to maintain autofocus and flash cycles.

- RC toys: Need sustained voltage for consistent motor speed.

Temperature and Load Impact

Voltage readings can vary based on external factors:

- Cold weather: May temporarily reduce voltage by 0.1V–0.2V, causing devices to misread battery levels.

- High loads: Drawing 2A+ (e.g., in a drone) can cause voltage to “sag” by 0.3V during operation.

This explains why a battery showing 1.3V on a multimeter might fail under heavy load—always test under realistic conditions.

Pro Tip: To check true capacity, use a capacity tester that discharges the battery while measuring voltage drop over time. This reveals how long the battery stays above your device’s cutoff voltage.

How to Accurately Measure NiMH AA Battery Voltage

Proper voltage measurement is critical for assessing battery health, but most people make crucial mistakes that lead to inaccurate readings. Unlike simple “battery testers” that give rough estimates, professional-grade methods reveal the true state of your NiMH cells.

Essential Tools for Voltage Testing

You’ll need:

- Digital multimeter (DMM): A Fluke 101 or ANENG AN8008 provides ±0.5% accuracy (avoid analog meters)

- Battery holder with leads: Ensures stable contact during measurement

- Load tester (optional): Simulates real-world current draw

Step-by-Step Measurement Process

- Prepare the battery: Let it rest for 2 hours after charging (removes surface charge that inflates voltage)

- Set your multimeter: DC voltage mode, 2V range for highest precision

- Connect probes: Red to positive terminal, black to negative (use alligator clips for stability)

- Record readings: Note both open-circuit voltage and voltage under 500mA load (if possible)

Example: A healthy Eneloop Pro AA shows 1.32V at rest but drops to 1.25V under load – this <10% drop indicates good condition. If voltage collapses below 1.1V under load, the battery needs replacement.

Interpreting Your Results

Voltage alone doesn’t tell the whole story. Combine measurements with:

- Capacity testing: Discharge fully while tracking mAh output

- Internal resistance: Higher than 150mΩ signals aging

Pro Tip: Create a battery log tracking voltage over time. A cell that loses 0.1V/month faster than others is failing.

Common Measurement Mistakes

- Testing while charging: Gives artificially high readings

- Dirty contacts: Adds 0.05-0.1V error – clean with isopropyl alcohol

- Ignoring temperature: Voltage drops 0.003V/°C below 20°C

For critical applications like medical devices, use a battery analyzer (e.g., Opus BT-C3100) that graphs voltage vs capacity during discharge cycles.

Advanced NiMH Voltage Analysis: Interpreting Discharge Curves and Performance Metrics

Understanding discharge characteristics separates casual users from power professionals. NiMH batteries exhibit unique voltage behavior patterns that reveal their true health and capacity – information critical for applications like professional photography or emergency equipment.

Reading Discharge Curves Like an Expert

A typical NiMH discharge curve has three distinct phases:

| Phase | Voltage Range | Duration | Significance |

|---|---|---|---|

| Initial Drop | 1.4V → 1.3V | First 5-10% | Normal surface charge dissipation |

| Plateau | 1.3V-1.2V | 80-85% | Usable power delivery period |

| Knee Drop | <1.1V | Final 5-10% | Imminent depletion warning |

Performance Degradation Indicators

As NiMH batteries age, their discharge curves reveal telltale signs:

- Shortened plateau: A curve that drops below 1.2V before 50% discharge indicates capacity loss

- Voltage sag: >0.15V drop under load suggests rising internal resistance

- Early knee: When the final drop occurs above 1.1V, the cell can no longer hold full charge

Real-World Application Examples

Professional Photography: Camera flashes need consistent 1.2V+ during rapid cycling. A battery showing 1.18V during testing will cause recycle delays.

Solar Applications: In solar lights, a battery that drops to 1.0V at 40°C will cut runtime in half compared to 25°C operation.

Advanced Testing Methodology

- Charge at 0.5C rate (half battery capacity – e.g., 1000mA for 2000mAh cell)

- Rest 1 hour to stabilize

- Discharge at 0.2C rate while logging voltage every 2 minutes

- Plot results against manufacturer specs

Pro Tip: For mission-critical uses, test new batteries and establish a baseline curve before deployment. Re-test every 50 cycles to predict failure points.

Optimizing NiMH Battery Performance: Charging Strategies and Maintenance Protocols

Proper charging and maintenance can double the lifespan of NiMH batteries, yet most users unknowingly degrade their cells through common handling mistakes. This section reveals professional-grade techniques used in industrial applications that you can implement at home.

Smart Charging Techniques for Maximum Longevity

The charging process significantly impacts battery health. Follow these scientifically-validated methods:

- Delta-V Termination: Advanced chargers detect the -ΔV voltage drop (typically 5-10mV per cell) that signals full charge, preventing overcharging

- Temperature Monitoring: Maintain cells below 45°C during charging – heat is the primary cause of capacity loss

- Trickle Charge Rates: After full charge, reduce to 0.05C (e.g., 100mA for 2000mAh cells) to maintain without damage

Cycle Maintenance for Battery Health

NiMH batteries benefit from periodic conditioning:

- Deep Discharge: Every 10 cycles, discharge to 0.9V/cell to prevent voltage depression

- Capacity Refresh: Use charger’s refresh mode to discharge/charge 3 times consecutively

- Equalization Charge: For battery packs, charge individually to balance cell voltages

Storage Best Practices

Proper storage preserves capacity when batteries aren’t in use:

| Storage Duration | Recommended Charge Level | Temperature |

|---|---|---|

| <1 month | 40-60% | Room temperature |

| 1-6 months | 30-50% | 15-20°C |

| >6 months | 20-30% | 0-10°C |

Troubleshooting Common Issues

Problem: Battery won’t hold charge

Solution: Perform 3 full discharge/charge cycles – may revive cells suffering from “memory effect”

Problem: Overheating during charge

Solution: Reduce charge current to 0.3C and ensure proper ventilation

Professional Insight: Industrial users often implement battery rotation systems, labeling cells with purchase dates and cycle counts. This allows predictive replacement before failures occur in critical equipment.

NiMH Battery Economics and Environmental Impact: A Lifecycle Analysis

While NiMH batteries offer excellent performance, understanding their total cost of ownership and environmental footprint requires examining their complete lifecycle from production to disposal. This analysis reveals why they remain a sustainable choice despite newer technologies.

Cost-Per-Cycle Breakdown

A comprehensive economic comparison shows NiMH’s long-term value:

| Battery Type | Initial Cost | Cycle Life | Cost/Cycle | 10-Year Cost |

|---|---|---|---|---|

| NiMH AA | $2.50 | 500-1000 | $0.0025-$0.005 | $12.50 |

| Alkaline AA | $0.75 | Single-use | $0.75 | $150+ |

| Li-ion AA | $6.00 | 300-500 | $0.012-$0.02 | $30+ |

Key Insight: While NiMH batteries have higher upfront costs, their 50-100x lower cost-per-cycle makes them dramatically more economical for regular users.

Environmental Considerations

NiMH batteries present several ecological advantages:

- Recyclability: 95% of materials (nickel, steel, rare earth metals) can be recovered through proper recycling

- Toxicity: Contains no lead or cadmium (unlike NiCd batteries), meeting RoHS standards

- Energy Density: 80Wh/kg rating provides better material efficiency than alkaline batteries

Safety Protocols and Handling

While generally safe, NiMH batteries require proper handling:

- Thermal Management: Never charge above 45°C – can cause electrolyte breakdown

- Venting: Modern NiMH have pressure relief valves, but avoid physical damage

- Transportation: For bulk shipping, maintain state-of-charge below 30% per IATA regulations

Future Developments

Emerging advancements in NiMH technology include:

- High-Energy Variants: New formulations reaching 300Wh/kg (vs current 100Wh/kg)

- Fast-Charge Improvements: 15-minute full charge capabilities without capacity loss

- Recycling Innovations: Hydrometallurgical processes recovering 99% of rare earth metals

Professional Recommendation: For environmentally-conscious users, pair NiMH batteries with solar chargers. This combination reduces grid dependence while maintaining reliable performance across thousands of cycles.

Advanced System Integration: Optimizing NiMH Batteries for Specific Applications

Different electronic devices demand unique power profiles from NiMH batteries. Understanding these requirements allows for customized optimization that maximizes both battery life and device performance.

Application-Specific Voltage Requirements

Various devices have distinct voltage thresholds that affect NiMH performance:

| Device Type | Minimum Operating Voltage | Optimal Voltage Range | Recommended Battery Configuration |

|---|---|---|---|

| Digital Cameras | 2.4V (2 cells) | 2.6-3.0V | High-capacity (2500mAh+) in series |

| LED Flashlights | 0.9V/cell | 1.1-1.3V | Low-self-discharge cells in parallel |

| RC Vehicles | 4.8V (4 cells) | 5.2-6.0V | High-discharge (10A+) matched packs |

Battery Pack Configuration Strategies

For multi-cell applications, follow these professional guidelines:

- Cell Matching: Use batteries within 0.02V and 5% capacity variance for series connections

- Parallel Arrangement: Ideal for increasing capacity while maintaining voltage

- Thermal Management: Allow 2mm spacing between cells in high-current applications

Voltage Regulation Solutions

When devices require stable voltage despite battery discharge:

- Buck-Boost Converters: Maintain constant output from varying input voltage (e.g., 3.3V from 1.0-1.5V cells)

- Low-Dropout Regulators: For minimal voltage overhead in sensitive electronics

- Capacitor Buffering: Smooths voltage during high-current pulses

Specialized Charging Solutions

Advanced charging systems for specific applications:

- Solar Chargers: Must include MPPT controllers for optimal NiMH charging

- Vehicle Chargers: Require voltage stabilization to handle 12V system fluctuations

- Fast-Charge Stations: Need temperature monitoring and ΔV detection for safe 2C charging

Professional Tip: For mission-critical systems, implement redundant battery banks with automatic switching when voltage drops below threshold. This provides uninterrupted power while allowing for battery maintenance.

Troubleshooting Note: If experiencing premature low-voltage cutoff in devices, measure voltage under load – a battery showing 1.2V at rest might sag to 0.9V when powering motors, triggering early shutdown.

Professional-Grade NiMH Battery Management Systems

For industrial and commercial applications, advanced battery management extends beyond basic voltage monitoring to comprehensive performance optimization. These systems maximize battery lifespan while ensuring reliable power delivery in critical operations.

Advanced Monitoring Parameters

Professional battery management tracks multiple performance metrics simultaneously:

| Parameter | Measurement Method | Optimal Range | Corrective Action Threshold |

|---|---|---|---|

| Internal Resistance | AC impedance at 1kHz | <150mΩ (new cell) | >250mΩ |

| Charge Efficiency | Energy in/Energy out | 85-95% | <80% |

| Self-Discharge Rate | 72h open-circuit loss | <5%/month | >10%/month |

Predictive Maintenance Framework

Implement these professional maintenance protocols:

- Baseline Testing: Record initial capacity, internal resistance, and discharge curve for each cell

- Cyclic Performance Tracking: Log capacity fade rate and resistance increase every 50 cycles

- Condition-Based Replacement: Schedule replacement at 80% of original capacity or 200% resistance increase

Quality Assurance Procedures

Industrial users should implement these validation steps:

- Incoming Inspection: 100% capacity verification for critical applications

- Cycle Testing: Sample testing to 300% of rated cycle life

- Environmental Stress Testing: -20°C to 60°C operational verification

Risk Mitigation Strategies

Address these common failure modes with proactive measures:

- Thermal Runaway: Install temperature sensors with >5°C/minute rate-of-rise detection

- Cell Reversal: Use blocking diodes in series configurations

- Capacity Mismatch: Implement automatic cell balancing during charging

Professional Insight: For large battery banks, consider impedance spectroscopy testing every 6 months. This advanced technique detects early electrolyte breakdown before capacity degradation becomes apparent in standard tests.

Validation Protocol: Before deploying new battery systems, conduct a 72-hour burn-in test including:

• Full discharge/charge cycle

• Load testing at maximum rated current

• Recovery voltage measurement after 24h rest

Conclusion: Mastering NiMH Battery Performance

Throughout this comprehensive guide, we’ve explored the critical aspects of NiMH AA battery voltage characteristics – from fundamental voltage benchmarks to advanced management systems.

You’ve learned how to accurately measure voltage, interpret discharge curves, optimize charging strategies, and integrate batteries into various applications. The detailed voltage charts, performance metrics, and maintenance protocols provided here give you professional-grade tools to maximize battery lifespan and reliability.

Remember that proper NiMH battery management combines science and practice: understanding voltage behavior informs better usage decisions, while regular maintenance prevents premature failure. Whether you’re powering household devices or industrial equipment, applying these principles will ensure you get maximum value from your rechargeable batteries.

Frequently Asked Questions About NiMH AA Battery Voltage

What voltage indicates a fully charged NiMH AA battery?

A freshly charged NiMH AA battery typically shows 1.4-1.45V when measured immediately after charging, settling to 1.35-1.4V after resting for 2 hours. This differs from alkaline batteries’ 1.5V nominal voltage.

The higher initial reading comes from surface charge, which dissipates quickly. For accurate measurement, use a digital multimeter and test after the battery has rested. Professional chargers detect full charge by monitoring temperature and voltage drop (-ΔV) rather than just absolute voltage.

Why does my NiMH battery show 1.2V when fully charged?

This is completely normal. NiMH batteries have a nominal voltage of 1.2V during most of their discharge cycle, unlike alkalines that start at 1.5V. The 1.2V reading indicates the battery has settled after charging.

What matters more is voltage under load – a healthy NiMH should maintain at least 1.1V when powering devices. The consistent 1.2V output is actually an advantage for stable device performance.

How low can I safely discharge a NiMH AA battery?

Never discharge below 0.9V per cell under load. Deep discharge below this threshold causes irreversible damage by creating crystalline formations in the electrodes.

Most devices automatically shut off around 1.0V to prevent this. For battery packs, ensure all cells discharge evenly – one weak cell dropping below 0.9V can ruin the entire pack. Use protected chargers with discharge prevention circuits for safety.

Why do my NiMH batteries lose charge so quickly when not in use?

All NiMH batteries self-discharge, but rates vary significantly. Standard NiMH can lose 1-2% charge daily (30% monthly), while low-self-discharge (LSD) versions like Eneloops lose just 15-20% annually.

High temperatures accelerate discharge – store at 15°C or below. If experiencing excessive discharge, test for voltage drops over 72 hours – more than 5% indicates aging cells needing replacement.

Can I mix old and new NiMH batteries in devices?

Strongly discouraged. Mixing batteries with different charge levels or capacities causes reverse charging and reduces overall performance. In series connections, weaker batteries drain first, then get forced into negative voltage by stronger cells.

Always use matched sets with similar cycle counts, and replace all batteries in a device simultaneously. For critical applications, purchase pre-matched battery packs.

How accurate are battery testers for NiMH voltage measurement?

Most consumer battery testers are optimized for alkalines and give misleading NiMH readings. They often interpret 1.2V as “low” when it’s actually normal. For accurate assessment, use a digital multimeter measuring to 0.01V precision, and test under load.

Professional battery analyzers like the Opus BT-C3100 provide the most reliable results by performing full discharge tests while monitoring voltage curves.

Why does voltage drop when I put batteries in my device?

This voltage “sag” occurs due to internal resistance – higher current draw causes greater voltage drop. A battery showing 1.3V at rest might drop to 1.1V under load. Excessive sag (below 1.0V at moderate loads) indicates aging batteries.

High-drain devices like digital cameras require low-resistance NiMH cells (often labeled “high current” or “ultra low impedance”) to minimize this effect.

How does temperature affect NiMH battery voltage?

Voltage decreases about 0.003V per °C below 20°C, so at 0°C you’ll see roughly 0.06V lower readings. Conversely, high temperatures temporarily increase voltage but accelerate degradation.

In freezing conditions, voltage may drop below device cutoff even with remaining capacity – warm batteries briefly to restore function. For consistent performance, operate NiMH batteries between 10°C and 30°C when possible.