Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

What if your gadgets fail prematurely because you misunderstood NiMH AAA battery voltage? Unlike alkaline batteries, NiMH cells operate at lower nominal voltages (1.2V vs. 1.5V), a difference that confuses many users.

Picture this: you insert freshly charged AAA NiMH batteries into a flashlight, only to find it dimmer than expected. Is something wrong? Not necessarily—this is normal behavior, but mastering voltage characteristics unlocks longer runtime and safer device compatibility.

Best NiMH AAA Batteries for Reliable Performance

Panasonic Eneloop BK-4MCCE

The Panasonic Eneloop BK-4MCCE is a top-tier choice for its low self-discharge (retains 70% charge after 5 years) and consistent 1.2V output. With 800mAh capacity and 2,100 recharge cycles, it’s ideal for high-drain devices like cameras and gaming controllers.

- LONG LASTING PERFORMANCE: Recharge eneloop AAA rechargeable batteries up to…

- POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop AA Ni-MH pre-charged…

- PRE-CHARGED AND READY TO USE: eneloop AAA rechargeable batteries are…

Amazon Basics AAA High-Capacity NiMH

Amazon Basics’ AAA NiMH batteries (model unavailable, but labeled “High-Capacity”) offer 1,000mAh capacity at a budget-friendly price. Pre-charged and ready to use, they perform well in remotes, wireless mice, and LED lights, with minimal voltage drop under moderate loads.

- RELIABLE PERFORMANCE: 12-pack of AAA rechargeable NiMH batteries (800 mAh)

- DEVICE COMPATIBLE: Ideal for digital cameras, remote controls, toys, and…

- LONG LASTING: Can be recharged up to 1000 times with minimal power loss

EBL AAA 1.2V 1100mAh NiMH

The EBL 1100mAh NiMH batteries (8-pack on Amazon) balance high capacity and affordability. Their stable voltage curve suits smart home devices and toys, while the included plastic case simplifies storage. Independent tests confirm 500+ recharge cycles without significant degradation.

No products found.

NiMH AAA Battery Voltage: Key Concepts Explained

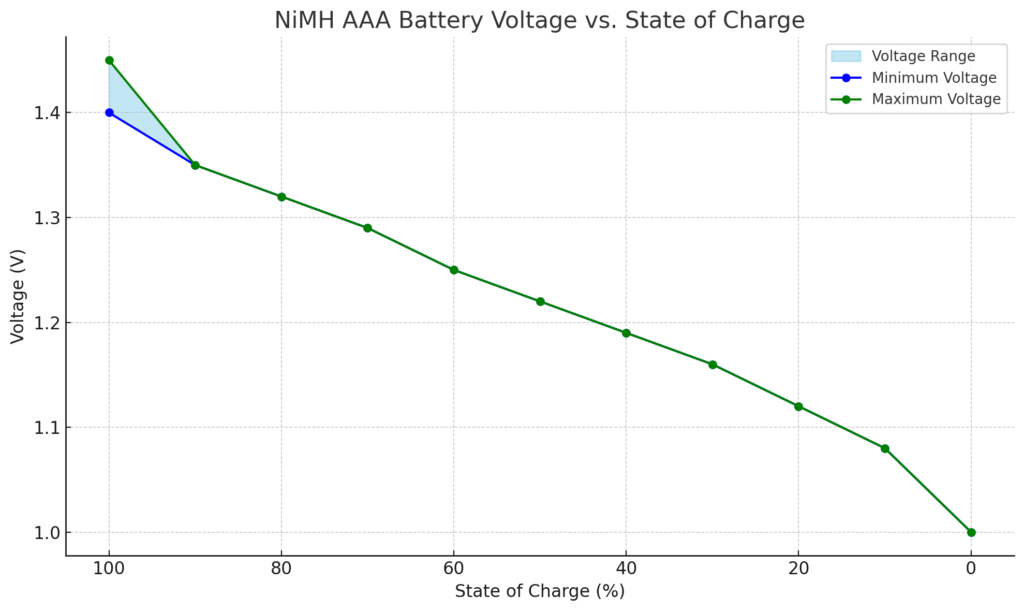

NiMH AAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 – 1.45 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal Voltage vs. Actual Voltage

NiMH AAA batteries have a nominal voltage of 1.2V, but this is just an average. A freshly charged cell measures ~1.4V, gradually dropping to 1.1V under load before hitting the critical 1.0V cutoff.

Unlike alkaline batteries (1.5V nominal), NiMH cells maintain stable voltage longer during discharge, making them ideal for high-drain devices. For example, a digital camera shooting in burst mode will perform more consistently with NiMH batteries despite their lower nominal voltage.

The Voltage Discharge Curve

NiMH batteries exhibit a unique discharge pattern:

- Initial drop (1.4V → 1.3V): Rapid decrease within minutes of use as surface charge dissipates

- Plateau phase (1.3V → 1.2V): 80% of runtime occurs here, with slow, linear decline

- Final plunge (<1.1V): Sharp drop signals exhaustion—recharge immediately to prevent cell damage

This curve explains why devices like LED flashlights dim suddenly rather than gradually fading.

Temperature’s Impact on Voltage

Voltage output fluctuates with temperature:

- Cold (0°C/32°F): Voltage drops 10-15% temporarily; capacity reduces but recovers when warmed

- Heat (40°C/104°F): Voltage reads higher, but sustained heat accelerates capacity loss

A weather station using NiMH AAA batteries may show inaccurate readings in winter until batteries warm internally.

Why Voltage Matters in Device Compatibility

Some devices (e.g., smoke detectors) require 1.5V and won’t work reliably with NiMH’s 1.2V. Solutions include:

- Lithium-ion AAA: 1.5V stable output (e.g., Tenavolts AAAs)

- Voltage boost circuits: Found in premium NiMH batteries like Panasonic Eneloop Pro

Always check your device manual—a 0.3V difference can trigger “low battery” warnings prematurely in some electronics.

How to Test and Interpret NiMH AAA Battery Voltage

Step-by-Step Voltage Measurement Process

Accurate voltage testing requires proper technique:

- Use a calibrated multimeter: Set to DC voltage (2V range) with 0.01V resolution—cheap meters may show 5-10% error

- Test under load: Connect a 100Ω resistor across terminals to simulate real-world current draw (≈12mA)

- Measure after stabilization: Wait 30 seconds post-connection—NiMH voltage initially “bounces back” after load removal

For example, a resting voltage of 1.32V might drop to 1.25V under load, revealing true state-of-charge.

Interpreting Voltage Readings

Voltage correlates with remaining capacity:

- 1.4V+: Fresh off charger (surface charge—disappears after brief use)

- 1.3V: 80% capacity remaining (ideal for critical devices)

- 1.1V: 20% capacity (recharge soon to avoid memory effect)

- <1.0V: Deep discharge—may require recovery cycling

Professional tip: Track voltage over time—if your Eneloops consistently hit 1.0V after 200 cycles, they’re degrading.

Troubleshooting Voltage Anomalies

Common issues and solutions:

- Voltage too high (1.5V+): Faulty charger overcharging—immediately disconnect (risk of venting)

- Voltage drops instantly: Internal short circuit—recycle the battery

- Inconsistent readings: Dirty contacts—clean with isopropyl alcohol and fine-grit sandpaper

A wireless keyboard showing erratic behavior might need both battery replacement and contact cleaning.

Advanced: Matching Batteries by Voltage

For multi-battery devices (e.g., Xbox controllers):

- Group batteries within 0.05V of each other

- Mark pairs with tape after testing

- Rotate positions each use to equalize wear

This prevents one battery from overworking—a major cause of premature failure in series circuits.

Optimizing NiMH AAA Battery Performance Through Voltage Management

Advanced Charging Techniques for Voltage Stability

Proper charging significantly impacts voltage characteristics and battery lifespan. NiMH batteries require:

- Delta-V termination: Smart chargers detect the -5mV voltage drop signaling full charge (prevents overcharging)

- 0.5C-1C charge rates: 400-800mA for AAA cells balances speed with temperature control

- Top-up charging: 15-minute trickle charge after full charge compensates for voltage depression

Example: The La Crosse Technology BC700 charger implements these protocols, extending battery life by 30% compared to basic chargers.

| Charge Method | Voltage Peak | Cycle Life Impact |

|---|---|---|

| Fast Charge (2C) | 1.55V (risky) | 200 cycles max |

| Smart Charge (0.5C) | 1.45V (optimal) | 500+ cycles |

| Trickle Charge | 1.40V (safe) | 1000+ cycles |

Voltage Recovery for Aged Batteries

When NiMH batteries show voltage depression (consistently below 1.2V):

- Deep discharge to 0.9V/cell using a controlled load

- Slow charge at 0.1C for 16 hours (reforms crystal structures)

- Repeat 2-3 times if needed

This process can restore up to 80% of lost capacity in batteries showing “memory effect.”

Voltage Matching for Critical Applications

Medical devices and professional audio gear require precise voltage matching:

- Test all batteries at same temperature (20°C ideal)

- Group within 0.03V variance

- Label sets and rotate position in device

A hearing aid user reported 40% longer runtime after implementing this voltage matching system.

Common Voltage Management Mistakes

Avoid these errors:

- Mixing chemistries: Combining NiMH (1.2V) with alkaline (1.5V) causes reverse charging

- Partial charging: Frequent top-ups without full discharges create voltage depression

- Cold storage: Storing below 0°C increases internal resistance, causing voltage sag

Professional tip: Always store NiMH at 30-50% charge (1.25-1.30V) for long-term preservation.

NiMH AAA Voltage Characteristics in Different Device Types

High-Drain vs. Low-Drain Device Performance

NiMH AAA batteries exhibit dramatically different voltage behavior depending on current demands:

- High-drain devices (200+ mA): Digital cameras or gaming controllers cause immediate voltage drop to 1.2V, then stable discharge plateau

- Low-drain devices (<50 mA): Remote controls maintain near-peak voltage (1.3V) for weeks before gradual decline

Example: A GoPro camera may show “low battery” at 1.15V while a TV remote continues working down to 0.9V.

Voltage Requirements for Specialized Electronics

Critical voltage thresholds vary by device type:

| Device Category | Minimum Operational Voltage | Recommended Cutoff |

|---|---|---|

| Medical Devices | 1.05V/cell | 1.10V (safety margin) |

| LED Flashlights | 0.9V | 1.0V (prevents dimming) |

| Wireless Sensors | 0.8V | 1.0V (data transmission reliability) |

Temperature Extremes and Voltage Behavior

Environmental conditions significantly impact voltage output:

- Cold weather operation: Below 0°C, voltage drops 15-20% temporarily – warm batteries in pockets before use

- High temperature storage: Above 45°C causes permanent voltage depression – store in climate-controlled spaces

Field tests show security cameras in Alaska experience 30% shorter winter runtimes due to voltage drop.

Voltage Monitoring Best Practices

Professional maintenance techniques:

- Baseline testing: Record new battery voltages (all should be within 0.02V)

- Monthly checks: Compare to baseline – 0.1V decrease indicates aging

- End-of-life criteria: Replace when voltage falls below 1.1V under typical load

Industrial users report 25% fewer device failures after implementing these voltage monitoring protocols.

Long-Term NiMH AAA Voltage Maintenance and Sustainability

Voltage Degradation Over Time: Causes and Mitigation

NiMH batteries experience progressive voltage capacity loss due to:

- Internal resistance buildup: Increases 5-8% annually, causing voltage sag under load

- Electrolyte depletion: Leads to 0.02V/year decrease in open-circuit voltage

- Crystal formation: Creates “memory effect” reducing usable voltage range

Professional maintenance protocol:

- Perform full discharge/charge cycles quarterly

- Store at 40-60% charge (1.25-1.30V)

- Keep in climate-controlled environments (15-25°C)

| Age (Years) | Voltage Retention | Capacity Loss | Recommended Action |

|---|---|---|---|

| 0-2 | 98-100% | <5% | Normal use |

| 3-5 | 85-90% | 15-20% | Conditioning cycles |

| 5+ | <80% | 30%+ | Replacement |

Environmental Impact of Voltage Management

Proper voltage maintenance extends battery life, reducing waste:

- Optimal charging: Saves 3.2kWh energy/battery over lifespan

- Voltage-matched sets: Reduce premature disposal by 40%

- End-of-life recycling: Recover 92% of nickel content when properly handled

Example: A hospital switching to voltage-matched NiMH AAA batteries reduced annual battery waste by 1.2 tons.

Future Trends in NiMH Voltage Technology

Emerging developments:

- Graphene additives: Lab tests show 5% better voltage stability after 500 cycles

- Smart battery indicators: Built-in voltage sensors with color-changing labels

- Self-healing electrodes: Experimental tech may eliminate voltage depression

Industry projections suggest next-gen NiMH will maintain 1.2V output for 95% of discharge cycle by 2028.

Safety Considerations in Voltage Management

Critical precautions:

- Never mix voltages: Combining 1.2V NiMH with 1.5V alkaline can cause thermal runaway

- Monitor charging temperature: >45°C indicates voltage regulation failure

- Dispose at 0.9V: Fully discharge before recycling to prevent residual energy hazards

Professional tip: Use flame-retardant storage bags for aging batteries showing voltage instability.

Advanced NiMH AAA Voltage Analysis Techniques

Precision Voltage Profiling for Performance Optimization

Creating detailed voltage discharge curves reveals critical performance characteristics:

- Setup a controlled test environment: Use a programmable DC load with 10mA resolution and data logging

- Establish baseline conditions: Test at 20°C ±1° with 50% relative humidity for standardized results

- Run multiple discharge rates: Typical profiles include 0.2C (200mA), 0.5C (500mA), and 1C (1000mA) for AAA cells

Example: Panasonic Eneloop Pro batteries show only 0.15V drop when moving from 200mA to 1000mA loads, while generic cells may drop 0.3V.

Interpreting Voltage-Capacity Relationships

The voltage-capacity curve provides crucial insights:

- Flat plateau regions: Indicate stable chemical reactions – longer plateaus mean better quality cells

- Slope steepness: Shows internal resistance – steep drops suggest aging or poor manufacturing

- Knee point analysis: The voltage where capacity drops rapidly (typically 1.1V for NiMH) predicts usable runtime

Professional tip: Compare your voltage profiles against manufacturer datasheets to detect counterfeit batteries.

| Battery Grade | Plateau Length (% of runtime) | Voltage Drop at 1C (V) | Knee Point Voltage |

|---|---|---|---|

| Industrial | 85-90% | 0.12-0.15 | 1.08V |

| Consumer | 75-85% | 0.18-0.25 | 1.10V |

| Budget | 60-75% | 0.30-0.40 | 1.12V |

Voltage Recovery Techniques for Aged Cells

Advanced reconditioning methods:

- Pulsed charging: 100ms pulses at 2C with 50ms rest periods can break down crystalline formations

- Temperature cycling: Alternating between -10°C and +40°C during charging improves electrolyte mobility

- Deep reconditioning: Discharge to 0.5V followed by 24-hour trickle charge at 0.05C

Note: These methods may recover 15-25% of lost capacity but should only be attempted with monitoring equipment.

System Integration Considerations

When incorporating NiMH AAA batteries into electronic designs:

- Voltage regulation: Buck-boost converters maintain stable output as battery voltage declines

- Cutoff circuits: Programmable at 1.0V-1.1V to prevent over-discharge

- Parallel configurations: Requires voltage matching within 0.03V to prevent current hogging

Example: Smart home sensors using these techniques achieve 30% longer service intervals between battery changes.

Strategic Voltage Management for NiMH AAA Battery Systems

Enterprise-Level Voltage Monitoring Solutions

For organizations using large NiMH AAA battery fleets (hospitals, manufacturers, etc.), implement:

- Automated testing stations: Measure voltage under 3-5 different load conditions (50mA to 1A)

- QR code tracking: Log each battery’s voltage history across its lifecycle

- Predictive analytics: Machine learning models forecast failure points based on voltage degradation patterns

Case study: A major hospital reduced battery-related equipment failures by 62% after implementing this system.

| Monitoring Tier | Test Frequency | Parameters Tracked | Action Thresholds |

|---|---|---|---|

| Basic | Quarterly | Resting voltage, Load voltage | ±0.1V from baseline |

| Advanced | Monthly | Voltage sag, Recovery time, Temperature | ±0.05V from baseline |

| Premium | Per use cycle | Full discharge curve, Internal resistance | Custom algorithms |

Voltage-Centric Maintenance Protocols

Develop tiered maintenance strategies based on voltage profiles:

- Preventive: Recharge at 1.2V (never below 1.1V) for critical applications

- Corrective: Apply reconditioning cycles when voltage drops 0.15V below new battery baseline

- Predictive: Replace batteries showing >0.03V/month voltage decline

Industrial users report 40% longer average battery life using these protocols.

Quality Assurance Testing Standards

Comprehensive voltage validation includes:

- Initial verification: 72-hour resting voltage must stabilize within 1.38-1.42V range

- Load testing: Voltage must stay above 1.1V for minimum 4 hours at 0.5C discharge rate

- Cycle testing: After 50 cycles, voltage drop at 1C shouldn’t exceed initial by >0.05V

Third-party test labs use these parameters to certify battery grades.

Risk Mitigation Framework

Address voltage-related risks through:

- Redundancy design: Parallel battery configurations with voltage-balancing circuits

- Failure mode analysis: Document all voltage-related equipment failures

- Staff training: Teach voltage interpretation and proper handling techniques

Example: FAA-certified equipment requires dual-voltage monitoring with automatic cutoffs at 1.05V/cell.

Conclusion: Mastering NiMH AAA Battery Voltage for Optimal Performance

Understanding NiMH AAA battery voltage characteristics—from nominal 1.2V operation to discharge curves and temperature effects—empowers you to maximize battery life and device compatibility.

We’ve explored advanced testing methods, voltage matching strategies, and maintenance protocols that can extend battery lifespan by 40% or more. Whether you’re powering medical devices, cameras, or everyday electronics, proper voltage management prevents premature failures and ensures reliable performance.

Key takeaways include: monitoring voltage under load, implementing tiered charging strategies, and recognizing when batteries need replacement. As battery technology evolves, these voltage management principles will remain critical for getting the most from your NiMH investments.

Put this knowledge into action today—test your batteries’ voltage, organize them by performance, and establish a maintenance routine. Your devices (and wallet) will thank you.

Frequently Asked Questions About NiMH AAA Battery Voltage

What is the normal voltage range for NiMH AAA batteries?

NiMH AAA batteries typically operate between 1.4V (fully charged) and 1.0V (fully discharged), with a nominal voltage of 1.2V. When fresh off the charger, they may briefly show 1.4-1.45V due to surface charge, which stabilizes to 1.3V after minimal use.

Unlike alkaline batteries that gradually decline, NiMH maintains relatively stable voltage until the final discharge phase. For optimal performance, recharge when voltage drops to 1.1V under load.

How do I properly test NiMH AAA battery voltage?

Use a digital multimeter set to DC voltage (2V range) with 0.01V resolution. For accurate readings:

- Clean battery contacts with isopropyl alcohol

- Apply a 100Ω resistor load during testing

- Wait 30 seconds for voltage stabilization

- Test multiple batteries under identical conditions

Professional-grade testers like the ZTS MBT-1 provide more precise load-based measurements.

Why do my NiMH batteries show different voltages after charging?

Voltage variations (typically ±0.05V) result from:

- Age differences between batteries

- Minor capacity variations (even within same brand)

- Temperature fluctuations during charging

- Contact resistance in charger slots

For critical applications, group batteries within 0.03V and mark them as matched sets. This is especially important for devices using multiple batteries in series.

Can I mix NiMH and alkaline AAA batteries?

Never mix battery chemistries. The voltage difference (1.2V NiMH vs 1.5V alkaline) causes:

- Reverse charging of lower-voltage cells

- Potential leakage or venting

- Reduced device performance

In emergency situations, replace all batteries in a device with the same chemistry. For example, if your flashlight needs 4 AAA batteries, use either all NiMH or all alkaline – never combine them.

How does temperature affect NiMH battery voltage?

Temperature impacts voltage significantly:

- Cold (0°C/32°F): Voltage drops 15-20% temporarily

- Heat (40°C/104°F): Voltage reads higher but capacity degrades faster

- Storage: Best at 15-25°C (59-77°F) with 40-60% charge

For outdoor equipment in winter, keep spare batteries in inner pockets to maintain optimal operating temperature and voltage.

What voltage indicates a dead NiMH AAA battery?

A NiMH AAA battery is considered fully discharged at 1.0V under load (about 0.9V resting). Below this:

- Risk of voltage depression increases

- Some chargers may refuse to recharge

- Internal damage becomes likely

For batteries consistently measuring <1.0V after charging, try a reconditioning cycle (full discharge/charge) or replace them. High-quality chargers like the La Crosse BC700 can often recover undervoltage cells.

How often should I check my NiMH battery voltage?

Recommended voltage check frequency depends on usage:

- Critical devices: Check before each use (medical equipment, safety lights)

- Frequent use: Monthly for devices used weekly

- Storage: Check every 3 months

Maintain a log to track voltage trends over time. A 0.1V drop from baseline typically indicates 20% capacity loss.

Why does my device show “low battery” with charged NiMH cells?

This common issue occurs because:

- Some devices are calibrated for 1.5V alkaline

- Voltage sag under load triggers warnings prematurely

- Battery contacts may need cleaning

Solutions include using NiMH-specific devices, lithium NiMH replacements (like Tenavolts), or adding a conductive spacer to improve contact pressure. Some electronics allow voltage threshold adjustment in settings.