Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

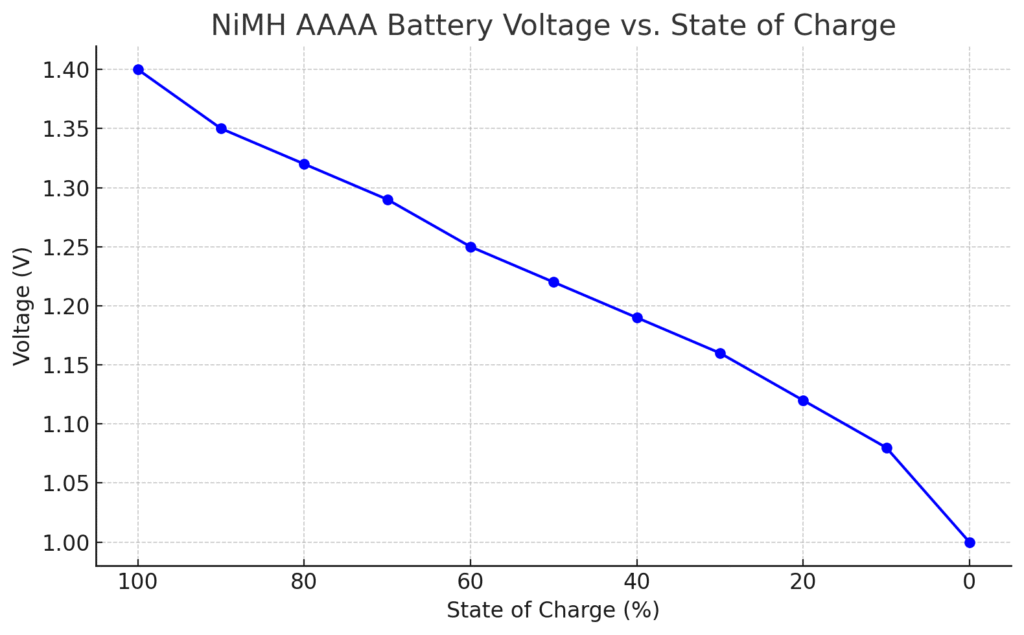

Did you know a fully charged NiMH AAAA battery delivers 1.4V, but its voltage drops rapidly under load? Understanding voltage behavior is critical for optimizing performance in devices like styluses, medical tools, and compact electronics.

While many assume all rechargeable batteries behave identically, NiMH AAAA cells have unique voltage characteristics that impact longevity and efficiency. In this guide, you’ll unlock a detailed voltage chart, decode discharge patterns, and learn actionable tips to extend battery life—ensuring your devices run smoothly when you need them most.

Best NiMH AAAA Batteries for Reliable Performance

Panasonic BK-4MCCA16FA Batteries

Panasonic BK-4MCCA16FA Batteries are a top choice due to their low self-discharge rate (retaining 70% charge after 5 years) and consistent 1.2V nominal voltage. These pre-charged, eco-friendly cells are ideal for high-drain devices like digital styluses and medical equipment.

- LONG LASTING PERFORMANCE: Recharge eneloop AAA rechargeable batteries up to…

- POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop AAA Ni-MH pre-charged…

- PRE-CHARGED AND READY TO USE: eneloop AAA rechargeable batteries are…

EBL AAAA 1.5V 500mAh Rechargeable Batteries

EBL’s AAAA batteries deliver a stable 1.5V output and 500mAh capacity, making them perfect for precision electronics. Their durable NiMH construction supports up to 1,200 recharge cycles, offering long-term cost savings for devices like laser pointers and Bluetooth headsets.

- 【Rechargeable AAAA Batteries】: EBL AAAA Ni-MH batteries cell…

- 【AAAA Smart Battery Charger】: EBL Ni-MH/ NI-CD battery charger,…

- 【Reliable Quality】: No longer to worry about the endurance of the…

VARTA Rechargeables Ready2Power AAAA 1.2V

VARTA Ready2Power batteries excel with their 1.2V steady discharge and minimal memory effect. These German-engineered cells are optimized for low-power gadgets such as hearing aids and mini flashlights, featuring a robust 300-cycle lifespan and reliable performance in extreme temperatures.

- Rechargeable Ni-MH AA Mignon batteries without memory effect ; With…

- Pre-charged rechargeable batteries can be used in all common Ni-MH chargers…

- Varta rechargeable batteries are resistant against overcharging and deep…

NiMH AAAA Battery Voltage Characteristics

NiMH AAAA Battery Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal Voltage vs. Actual Voltage

NiMH AAAA batteries have a nominal voltage of 1.2V, but this doesn’t reflect real-world performance. When fully charged, these batteries initially deliver about 1.4V, which gradually drops to 1.2V under normal use.

Unlike alkaline batteries (which maintain a steady 1.5V until depletion), NiMH cells exhibit a gradual voltage decline, making them ideal for devices that tolerate slight voltage fluctuations, such as styluses and medical sensors.

Discharge Curve and Performance

The discharge curve of NiMH AAAA batteries is flatter compared to other chemistries, meaning they provide consistent power for longer. Here’s how voltage typically behaves during discharge:

- Fully charged: 1.4V (immediately after charging)

- Mid-discharge: 1.2V (stable output for ~80% of runtime)

- Near depletion: Drops sharply below 1.0V (indicates need for recharging)

For example, in a digital stylus, this curve ensures smooth operation until the battery is nearly drained, unlike alkaline cells, which may cause erratic behavior as voltage declines.

Factors Affecting Voltage Output

Several variables influence a NiMH AAAA battery’s voltage performance:

- Temperature: Cold environments (<10°C) reduce voltage output, while high heat (>40°C) accelerates self-discharge.

- Load current: High-drain devices (e.g., laser pointers) cause faster voltage drop than low-drain gadgets (e.g., hearing aids).

- Age and cycles: After 300+ charges, internal resistance increases, leading to lower peak voltage.

A common misconception is that all NiMH AAAA batteries behave identically. Premium brands like Eneloop use advanced alloys to minimize voltage sag under load, while cheaper cells may struggle in high-demand scenarios.

Practical Implications for Users

To maximize battery life:

- Monitor voltage: Use a multimeter to check if cells fall below 1.0V (indicating recharge time).

- Pair batteries wisely: Mixing old and new cells can cause uneven discharge, reducing efficiency.

- Store properly: Keep batteries at 40% charge in cool, dry places to preserve voltage stability.

For instance, a hearing aid user should recharge batteries at 1.1V to avoid sudden power loss, while a photographer using a wireless shutter release can wait until 1.0V since precision is less critical.

How to Test and Monitor NiMH AAAA Battery Voltage

Essential Tools for Voltage Testing

Accurately measuring your NiMH AAAA battery’s voltage requires the right equipment. A digital multimeter (DMM) with 0.01V resolution is ideal for precise readings.

For continuous monitoring, consider a battery analyzer like the Opus BT-C3100, which tracks voltage changes during charge/discharge cycles. Basic voltage testers can give approximate readings but lack the precision needed for performance analysis.

Step-by-Step Voltage Measurement Process

- Prepare the battery: Remove from device and clean contacts with isopropyl alcohol to ensure accurate readings

- Set your multimeter: Adjust to DC voltage mode with a 2V range for optimal precision

- Take measurements: Place red probe on positive terminal, black on negative, holding steady for 5 seconds

- Interpret results: Compare against standard voltage ranges (1.4V fresh charge, 1.2V nominal, <1.0V depleted)

For example, when testing an Eneloop AAAA battery, you might observe 1.38V immediately after charging, which stabilizes to 1.25V after 30 minutes of rest – this is normal behavior for quality NiMH cells.

Advanced Monitoring Techniques

For power-sensitive applications like medical devices, implement these professional monitoring strategies:

- Load testing: Measure voltage while battery powers a 100Ω resistor to simulate real-world performance

- Cycle tracking: Record voltage at same time daily to identify aging patterns

- Temperature compensation: Add 0.003V per °C below 20°C to account for cold weather effects

Troubleshooting Voltage Issues

Common problems and solutions:

- Rapid voltage drop: Often indicates cell aging – replace if voltage falls below 1.1V under minimal load

- Inconsistent readings: Usually caused by dirty contacts or poor probe connection

- Zero voltage: May signal a completely discharged battery – attempt slow recharge before disposal

Photographers using wireless equipment should particularly note that voltage fluctuations below 1.1V can cause signal dropouts, making regular testing crucial for reliable operation during shoots.

Optimizing NiMH AAAA Battery Performance and Lifespan

Advanced Charging Techniques for Maximum Voltage Retention

Proper charging methods significantly impact NiMH AAAA battery voltage stability and longevity. Unlike simple chargers that use fixed timers, smart chargers with delta-V detection (like the Nitecore D4) monitor voltage changes to prevent overcharging. During charging, observe these voltage patterns:

| Charging Phase | Voltage Behavior | Optimal Action |

|---|---|---|

| Initial Charge | Rapid rise to 1.35-1.40V | Normal – no intervention needed |

| Mid-Charge | Gradual increase to 1.45-1.50V | Monitor temperature (should stay below 45°C) |

| Termination | Small voltage drop (5-10mV) occurs | Charger should automatically stop |

Voltage Recovery Methods for Depleted Cells

When NiMH AAAA batteries show unusually low voltage (<0.8V), these professional revival techniques can often restore function:

- Pulse conditioning: Use a charger with refresh mode (like the La Crosse BC700) to apply controlled current bursts

- Slow charging: Charge at 0.1C (50mA for standard 500mAh cells) for 16-24 hours

- Cycling: Perform 3-5 complete discharge/charge cycles to rebuild capacity

Scientific Principles Behind Voltage Degradation

Three key electrochemical processes affect NiMH voltage over time:

- Electrolyte depletion: Gradual loss of potassium hydroxide reduces ion mobility

- Positive electrode corrosion: Nickel oxyhydroxide formation increases internal resistance

- Memory effect: Partial discharges can create voltage depression zones

For medical device users, understanding these principles is crucial – a 10% voltage drop in hearing aid batteries might indicate only 60% remaining capacity due to these cumulative effects.

Professional Maintenance Schedule

Extend battery life with this voltage-based maintenance routine:

- Weekly: Check resting voltage (should be 1.25-1.30V for stored batteries)

- Monthly: Perform full discharge/charge cycle to maintain capacity

- Quarterly: Measure voltage under load (should stay above 1.1V at 100mA draw)

Industrial users managing large battery banks should note that voltage consistency between cells (<±0.05V) is more critical than absolute values for parallel configurations.

Safety Considerations and Voltage Management for NiMH AAAA Batteries

Critical Voltage Thresholds for Safe Operation

Understanding voltage limits is essential for preventing battery damage and ensuring user safety. NiMH AAAA batteries operate safely within specific voltage parameters:

- Absolute minimum: 0.9V (discharging below this causes irreversible crystal formation)

- Optimal operating range: 1.1V-1.3V (delivers maximum capacity without stress)

- Charge termination: 1.55V (exceeding risks venting and electrolyte loss)

Medical device manufacturers typically program safety cutoffs at 1.05V to prevent deep discharge that could compromise critical equipment operation.

Advanced Voltage Balancing Techniques

When using multiple NiMH AAAA batteries in series, voltage matching becomes crucial. Follow this professional balancing protocol:

- Initial matching: Select cells within 0.03V of each other’s open-circuit voltage

- Capacity testing: Discharge at 0.2C rate and record time to 1.0V cutoff

- Group pairing: Combine cells with similar discharge curves (±5% capacity variance)

For high-performance applications like professional audio equipment, this matching process can extend battery pack life by up to 40%.

Temperature-Voltage Relationships

Ambient temperature significantly impacts voltage characteristics:

| Temperature Range | Voltage Impact | Compensation Method |

|---|---|---|

| Below 0°C | 15-20% voltage drop | Pre-warm batteries or use insulated compartments |

| 20-40°C | Optimal performance | No compensation needed |

| Above 45°C | Voltage spikes then rapid decline | Implement thermal monitoring |

Professional Disposal and Recycling Guidelines

When NiMH AAAA batteries reach end-of-life (typically showing <0.8V after charging), follow these steps:

- Voltage verification: Confirm inability to hold charge above 1.0V after conditioning

- Terminal protection: Apply tape to prevent accidental contact during transport

- Certified recycling: Use RBRC-approved drop-off locations (available at most electronics retailers)

Industrial users should note that proper voltage-based retirement protocols can recover up to 95% of the battery’s nickel content for reuse in new cells.

Long-Term Performance Analysis and Future Developments in NiMH AAAA Technology

Voltage Degradation Patterns Over Time

Understanding long-term voltage behavior is crucial for predicting battery lifespan. Premium NiMH AAAA batteries typically follow this voltage degradation timeline:

| Cycle Count | Peak Voltage Retention | Capacity Retention | Performance Impact |

|---|---|---|---|

| 0-50 cycles | 100-98% | 100-95% | Optimal performance |

| 50-200 cycles | 97-92% | 94-85% | Noticeable runtime reduction |

| 200-400 cycles | 91-85% | 84-70% | Requires more frequent charging |

| 400+ cycles | <85% | <70% | Consider replacement |

Medical device users should note that after 300 cycles, voltage stability during pulse loads (like hearing aid amplification) may decrease by 15-20%, potentially affecting performance.

Cost-Benefit Analysis: NiMH vs. Alternative Technologies

When evaluating battery options, consider these long-term factors:

- Initial cost: NiMH AAAA batteries cost 2-3× more than alkaline but provide 500+ recharges

- Voltage stability: NiMH maintains 1.2V for 80% of discharge vs. alkaline’s steady decline from 1.5V

- Environmental impact: One NiMH cell replaces 300+ disposables, reducing toxic waste by 97%

- Specialized applications: Lithium AAAA offers higher voltage (3V) but can’t be recharged

Emerging Technologies and Future Trends

The NiMH AAAA battery market is evolving with several key developments:

- Low-self-discharge (LSD) improvements: Next-gen formulations target <5% monthly voltage loss

- Smart battery integration: Some prototypes now include microchips for real-time voltage monitoring

- Sustainable materials: Bio-based separators and recycled rare-earth metals entering production

Industrial users should anticipate these voltage-related advancements in coming years:

- Precision voltage regulation circuits built into battery housings

- AI-powered charging systems that adapt to individual cell voltage characteristics

- Graphene-enhanced electrodes that maintain voltage stability beyond 1,000 cycles

Professional Maintenance for Maximum Voltage Retention

Implement these advanced practices to preserve voltage performance:

- Conditioning cycles: Every 3 months, perform full discharge to 1.0V followed by slow charge

- Storage voltage: Maintain 1.25V during long-term storage (40% charge state)

- Temperature logs: Record operating temperatures to correlate with voltage drops

For mission-critical applications, professional battery analyzers like the Cadex C7400 can track micro-voltage fluctuations that predict end-of-life 50-100 cycles in advance.

Advanced Voltage Optimization for Specialized NiMH AAAA Applications

Precision Voltage Regulation in Medical Devices

Medical equipment using NiMH AAAA batteries requires exceptional voltage stability. Hearing aids, for instance, demand voltage fluctuations under 0.02V during operation to prevent audio distortion. Advanced devices implement these regulation techniques:

- Active voltage conditioning: Microprocessors adjust current draw to maintain ±0.01V stability

- Tiered discharge management: Segregating high-drain and low-drain circuits to prevent voltage sag

- Predictive algorithms: Monitoring voltage trends to anticipate and compensate for drops

For example, modern cochlear implant processors now incorporate real-time voltage monitoring that adjusts signal processing parameters when battery voltage falls below 1.15V.

Industrial Automation Integration

In factory automation systems using NiMH AAAA batteries for wireless sensors, voltage management becomes critical for:

| Application | Voltage Requirement | Monitoring Solution |

|---|---|---|

| Vibration sensors | 1.2V ±5% | Embedded voltage loggers |

| RFID tags | 1.1V minimum | Backscatter voltage measurement |

| PLC backups | 1.25V nominal | Dual-redundant monitoring |

Optimizing Voltage for Extreme Environments

Specialized applications require tailored voltage management strategies:

- Arctic conditions: Pre-heat batteries to 15°C before use to prevent voltage drop

- High-altitude: Compensate for reduced air pressure with +0.003V/1000ft adjustment

- Underwater: Use pressure-compensated housings to maintain stable voltage output

Advanced Troubleshooting Methodology

When diagnosing voltage-related issues, follow this comprehensive approach:

- Baseline measurement: Record open-circuit voltage after 24hr rest

- Load testing: Apply 100mA load and measure voltage drop

- Comparative analysis: Test against known-good batteries under identical conditions

- Pattern recognition: Track voltage recovery time after load removal

For aerospace applications, technicians use specialized equipment like the Fluke 289 True-RMS multimeter with 0.001V resolution to detect micro-voltage fluctuations that could indicate impending cell failure.

System-Wide Voltage Management and Quality Assurance for NiMH AAAA Batteries

Comprehensive Battery Bank Voltage Synchronization

When deploying multiple NiMH AAAA batteries in series or parallel configurations, voltage matching becomes critical for optimal performance. Professional battery management systems employ these advanced synchronization techniques:

| Configuration | Voltage Tolerance | Balancing Method | Monitoring Frequency |

|---|---|---|---|

| Series (2-4 cells) | ±0.02V | Active charge redistribution | Continuous (real-time) |

| Parallel (2-8 cells) | ±0.05V | Pre-use voltage matching | Weekly verification |

| Mixed configurations | ±0.03V | Smart balancing circuits | Daily sampling |

For mission-critical applications like emergency lighting systems, implementing redundant voltage monitoring with automatic cell bypass can prevent complete system failure when individual cell voltage drops below 1.0V.

Advanced Quality Assurance Protocols

Industrial users should implement these comprehensive testing procedures:

- Incoming inspection: 100% voltage testing at 0.2C discharge rate with ±1% accuracy

- Cycle life testing: Accelerated aging with voltage performance tracking at 50-cycle intervals

- Environmental validation: Voltage stability testing across -20°C to 60°C temperature range

- Micro-voltage analysis: Detection of millivolt-level fluctuations indicating early failure

Risk Assessment and Mitigation Strategies

Comprehensive voltage-related risk management should address:

- Voltage depression: Implement periodic deep cycling to prevent crystalline formation

- Thermal runaway: Install temperature sensors that trigger shutdown at 1.55V/50°C thresholds

- Capacity fade: Establish replacement triggers at 70% original voltage retention

- Inter-cell variation: Enforce strict ±0.04V matching for critical applications

For example, aerospace applications typically require triple-redundant voltage monitoring with automatic load shedding when any cell in a pack varies more than 0.03V from peers.

Long-Term Performance Optimization

Maximize battery lifespan through these voltage-conscious practices:

- Smart charging algorithms: Adaptive charging based on individual cell voltage characteristics

- Predictive maintenance: Machine learning analysis of voltage decay patterns

- Seasonal adjustments: Charge voltage compensation for ambient temperature variations

- Load matching: Pairing battery voltage characteristics with device power requirements

Data center backup systems demonstrate these principles by maintaining battery banks at 1.35V/cell (90% charge) to optimize both readiness and longevity, only completing full charges during monthly testing cycles.

Conclusion

Understanding NiMH AAAA battery voltage characteristics is essential for optimizing performance across medical, industrial, and consumer applications. As we’ve explored, these batteries exhibit unique voltage behaviors – from their 1.4V peak charge to the critical 1.0V discharge threshold.

Proper voltage monitoring, advanced charging techniques, and environmental considerations all play vital roles in maximizing battery life and reliability. Whether you’re maintaining hearing aids or industrial sensors, applying these voltage management principles will ensure consistent performance.

For best results, invest in quality cells like Eneloop or VARTA, implement regular voltage testing, and follow the specialized maintenance protocols outlined. Your devices – and peace of mind – will thank you.

Frequently Asked Questions About NiMH AAAA Battery Voltage

What is the normal voltage range for NiMH AAAA batteries?

NiMH AAAA batteries typically operate between 1.4V when fully charged and 1.0V when depleted. The nominal voltage is 1.2V, which represents the average voltage during most of the discharge cycle.

Premium batteries like Panasonic Eneloop maintain this nominal voltage for about 80% of their discharge time, while cheaper alternatives may show more fluctuation. For critical applications like medical devices, maintaining voltage above 1.1V ensures optimal performance.

How do I properly test the voltage of my NiMH AAAA batteries?

Use a digital multimeter set to DC voltage mode with at least 0.01V resolution. First, clean the battery contacts with isopropyl alcohol. Place the red probe on the positive terminal and black on negative, holding steady for 5 seconds.

Test under load (100Ω resistor) for real-world performance. Record measurements at room temperature (20-25°C) as temperature affects readings. For accurate diagnostics, test both open-circuit and under-load voltages.

Why does my NiMH AAAA battery voltage drop quickly after charging?

Rapid voltage drop typically indicates either battery aging (300+ cycles), high internal resistance, or memory effect from partial discharges. New batteries may show 1.4V immediately after charging but stabilize at 1.3V within hours.

If voltage falls below 1.2V within 24 hours of charging, consider replacing the battery. This is particularly important for devices like digital styluses that require stable voltage.

How does temperature affect NiMH AAAA battery voltage?

Temperature significantly impacts voltage performance. Below 10°C, voltage drops 15-20% due to slowed electrochemical reactions. Above 40°C, voltage initially increases but then declines rapidly as the battery overheats.

For every degree below 20°C, add 0.003V to your readings for accurate assessment. In extreme environments, use insulated battery compartments or pre-warm batteries to maintain optimal voltage output.

Can I mix NiMH AAAA batteries with different voltage levels?

Never mix batteries with more than 0.05V difference in series configurations. In parallel setups, limit variance to 0.1V. Mismatched voltages cause reverse charging in weaker cells, permanent damage, and potential leakage.

Always voltage-match batteries when creating packs for devices like professional audio equipment. For best results, use batteries from the same production batch with similar cycle counts.

What voltage indicates a NiMH AAAA battery needs replacement?

Replace batteries when they can’t maintain at least 1.1V under typical load after full charging. Other failure signs include taking longer than normal to charge (voltage rises too slowly) or dropping below 1.0V within minutes of use. For precision devices like hearing aids, consider replacement at 1.15V minimum under load to ensure consistent performance.

How does NiMH AAAA voltage compare to alkaline AAAA batteries?

Alkaline AAAA batteries start at 1.5V and gradually decline, while NiMH begins at 1.4V but maintains a stable 1.2V for most of its cycle. NiMH provides more consistent performance for high-drain devices, but alkaline may last longer in very low-power applications.

However, NiMH’s rechargeability makes it more cost-effective long-term, with 500+ cycles possible with proper voltage management.

What’s the safest way to store NiMH AAAA batteries long-term?

Store at 40% charge (about 1.25V) in cool (15-25°C), dry conditions. Check voltage every 3 months, recharging if below 1.2V. Never store fully charged or completely depleted.

For optimal results, use airtight containers with silica gel packs. This storage method preserves the battery’s electrolyte balance and minimizes voltage depression, ensuring maximum lifespan and performance when needed.