Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged 3V lithium battery can drop to 2.7V under load and still function efficiently? Voltage fluctuations in rechargeable 3V batteries impact everything from your wireless doorbell to medical devices—but most users don’t know how to interpret these changes.

Whether you’re troubleshooting a fading gadget or optimizing battery life, understanding voltage behavior is critical. In this guide, you’ll discover a comprehensive voltage chart, decode discharge patterns, and learn exactly when to recharge for peak performance.

Best Rechargeable 3V Batteries for Reliable Power

Panasonic CR123A Lithium Rechargeable Battery

Panasonic’s CR123A (3V, 800mAh) is a top choice for high-drain devices like cameras and flashlights. Its stable voltage output ensures consistent performance, and its durable construction resists leaks. With a 500+ cycle lifespan, it’s ideal for frequent recharging without capacity loss.

Enegitech AAA Lithium Batteries 1.5V

This 14250-size LiFePO4 battery (3.2V nominal, 400mAh) excels in medical devices and IoT sensors. Its thermal stability and deep discharge recovery make it safer than standard lithium cells. Supports 2000+ cycles, perfect for long-term, low-maintenance applications.

- Battery Type: Lithium Battery; Capacity: 1200mAh; Volt: 3V; ***Notice: This…

- Wide Usage: Triple aaa lithium batteries is ideal for your Smart Water Leak…

- Performs in extreme temperatures: Lithium battery can use in extreme…

Tenergy 3V Lithium Coin Battery

Tenergy’s RCR-2 (3V, 500mAh) replaces disposable CR2 batteries in laser pointers and security systems. Features overcharge protection and a pre-charged design. Its compact size and reliable voltage retention (2.8V–3.2V) make it a versatile, eco-friendly upgrade.

- 10 pack of cr2032 lithium coin cell batteries compatible with portable…

- Wide temperature ranges – These batteries 3v cr2032 performs in cold…

- 10 years shelf life – Designed with anti-leak and low self-discharge…

Rechargeable 3V Battery Voltage Behavior

Rechargeable 3V batteries don’t maintain a constant voltage—their output fluctuates based on chemistry, load, and charge level. Unlike disposable lithium cells (which stay near 3V until depletion), rechargeables like LiFePO4 or Li-ion exhibit dynamic voltage curves.

For example, a fully charged LiFePO4 battery reads ~3.6V but stabilizes to 3.2V under load, while standard lithium-ion drops from 4.2V to 3.0V. This variance impacts device compatibility and performance.

Voltage vs. State of Charge: The Critical Relationship

A battery’s voltage directly correlates with its remaining capacity. Here’s a typical discharge curve for a 3V lithium rechargeable:

- 100% charge: 3.6V (resting voltage after charging)

- 80% capacity: 3.3V (optimal performance zone)

- 50% capacity: 3.0V (device may show “low battery” warnings)

- 20% capacity: 2.8V (cutoff threshold for most electronics)

Devices like wireless sensors often malfunction below 2.9V, while high-drain gadgets (e.g., flashlights) may shut off abruptly at 2.7V.

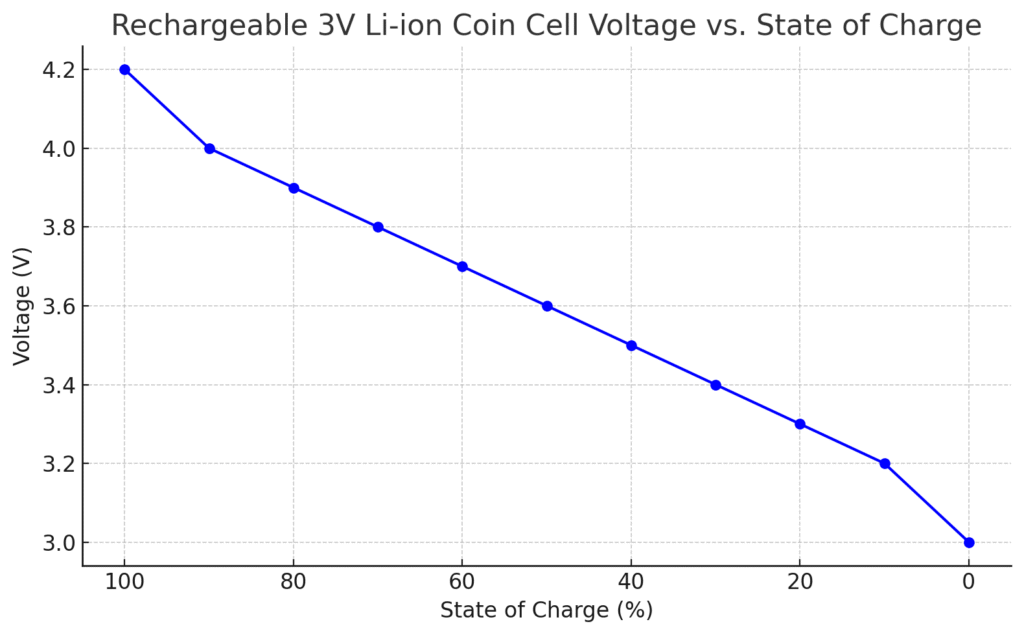

Rechargeable 3V Li-ion Coin Cell Voltage vs. State of Charge

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 4.2 |

| 90% | 4.0 |

| 80% | 3.9 |

| 70% | 3.8 |

| 60% | 3.7 |

| 50% | 3.6 |

| 40% | 3.5 |

| 30% | 3.4 |

| 20% | 3.3 |

| 10% | 3.2 |

| 0% (empty) | 3.0 or lower |

Real-World Voltage Challenges

Three factors distort voltage readings:

- Load current: A battery showing 3.2V at rest might sag to 2.9V when powering a camera flash.

- Temperature:

Cold environments (below 0°C) can temporarily reduce voltage by 0.3V–0.5V. - Age: After 300+ cycles, a battery’s internal resistance rises, causing faster voltage drops under load.

A common mistake is testing batteries with a multimeter without load—this gives misleading “healthy” readings. For accurate assessments, use a load tester or monitor voltage during device operation.

Chemistry-Specific Voltage Profiles

LiFePO4 (Lithium Iron Phosphate):

Stable 3.2V nominal voltage with a flat discharge curve—ideal for medical devices needing steady power. Unlike standard lithium-ion, it avoids sudden drops near depletion.

Lithium Manganese Dioxide (Li-MnO2):

Common in CR123A rechargeables, starts at 3.3V but declines linearly. Best for moderate-drain applications like security systems.

Pro Tip: Always check your device’s minimum operating voltage. A GPS tracker requiring 2.9V+ won’t work with a battery at 2.8V, even if it still holds 15% charge.

How to Properly Charge and Maintain Rechargeable 3V Batteries

Charging rechargeable 3V batteries incorrectly can reduce their lifespan by up to 70% or even cause safety hazards. Unlike standard AA/AAA rechargeables, these lithium-based cells require specialized care due to their unique chemistry and voltage characteristics.

The Right Charging Process: Step-by-Step

Follow this professional charging protocol for optimal battery health:

- Use a chemistry-specific charger: LiFePO4 batteries need chargers with 3.6V cutoff (like the Nitecore UMS4), while standard lithium-ion requires 4.2V.

- Monitor initial voltage: Never charge batteries below 2.5V – this deep discharge permanently damages cells.

- Control charging rate: Limit to 0.5C (e.g., 400mA for an 800mAh battery) to prevent overheating.

- Verify termination: Quality chargers switch to trickle charge when detecting current drop at full capacity.

Example: Charging a Panasonic CR123A at 1A (instead of recommended 500mA) can raise internal temperatures to 60°C, accelerating capacity loss.

Critical Maintenance Practices

Three often-overlooked maintenance factors significantly impact performance:

- Partial charging: Keeping LiFePO4 between 30-80% charge (3.0V-3.45V) doubles cycle life compared to full 100% charges.

- Storage voltage: For long-term storage (3+ months), discharge to 3.3V (LiFePO4) or 3.7V (lithium-ion) to minimize degradation.

- Terminal cleaning: Oxidized contacts can add 0.2V resistance – clean monthly with isopropyl alcohol on cotton swabs.

Troubleshooting Common Issues

When facing problems:

Rapid self-discharge (losing >5% charge/day) often indicates damaged separator – replace immediately.

Swollen batteries suggest electrolyte decomposition – dispose safely at recycling centers.

Voltage rebound (reads 3V after charging but drops to 2.5V under load) means the cell has reached end-of-life.

Pro Tip: For devices used intermittently (like emergency flashlights), implement a 3-month refresh cycle: discharge to 3V, then recharge to 80% to maintain cell balance.

Advanced Voltage Analysis and Performance Optimization

Mastering voltage characteristics unlocks 30-50% more usable capacity from rechargeable 3V batteries. This requires understanding electrochemical dynamics that most users never consider, but which dramatically impact real-world performance.

Voltage Sag and Recovery: The Hidden Capacity Factor

When subjected to high current draws, batteries experience temporary voltage drops called “sag.” For example:

| Load Current | CR123A Voltage | LiFePO4 Voltage |

|---|---|---|

| 0.1A (low) | 3.2V | 3.25V |

| 1.0A (high) | 2.9V | 3.1V |

This phenomenon explains why high-drain devices like tactical lights may appear “dead” at 2.8V under load, but recover to 3.1V when idle. The key is allowing 2-3 minute rest periods between bursts.

Temperature Compensation Strategies

Battery voltage varies predictably with temperature:

- Below 0°C: Add 0.3V to cutoff thresholds (e.g., treat 2.7V as 3.0V)

- Above 40°C: Subtract 0.2V from readings (3.0V becomes 2.8V)

Professional users in extreme environments often implement active thermal management – Arctic researchers commonly insulate battery compartments with neoprene sleeves to maintain optimal 15-25°C operating range.

Pulse Loading vs Continuous Drain

Modern devices increasingly use pulsed power (like digital cameras during flash charging). This creates unique voltage behavior:

- Initial pulse may draw 2A, dropping voltage to 2.6V

- During 0.5s rest period, voltage recovers to 3.0V

- Subsequent pulses show less sag (2.8V) as internal chemistry stabilizes

Mistake to avoid: Testing pulse-load devices with constant-current dummy loads gives inaccurate voltage readings. Instead, use oscilloscopes or specialized battery analyzers like the Cadex C7400.

Pro Tip: For mission-critical applications, create a voltage discharge profile specific to your device’s load pattern. This reveals the true “knee point” where capacity drops rapidly – typically between 2.85-2.95V for most lithium chemistries.

Safety Protocols and Industry Standards for 3V Rechargeable Batteries

While rechargeable 3V batteries are generally safe, improper handling can lead to thermal runaway – a condition where internal temperatures rise uncontrollably, sometimes exceeding 150°C. Understanding and implementing proper safety measures is crucial for both consumer and professional applications.

Critical Safety Standards and Certifications

Reputable 3V rechargeable batteries should comply with these essential certifications:

- UL 1642: Tests for fire hazards and explosion risks under abuse conditions

- IEC 62133: International standard for portable sealed secondary cells

- UN 38.3: Mandatory for lithium battery transportation (simulates altitude, vibration, and shock)

Example: A UL-certified Panasonic CR123A undergoes 10+ abuse tests including short circuit, overcharge, and forced discharge scenarios before approval.

Handling High-Risk Scenarios

Three dangerous situations require immediate action:

- Swelling cells: Isolate the battery in a fireproof container (like a LiPo safety bag) and dispose at a certified recycling center

- Leaking electrolytes: Wear nitrile gloves, neutralize with baking soda solution (1 tbsp per cup of water), then wipe with isopropyl alcohol

- Overheated batteries: Place on non-flammable surface (ceramic tile) and monitor from 3+ meters distance – never use water to cool lithium batteries

Professional Storage and Transportation Guidelines

For commercial users handling multiple batteries:

| Condition | Storage Requirements | Transport Requirements |

|---|---|---|

| Single cells | 30-50% charge in climate-controlled area | Terminal protection (tape or caps) |

| Multi-cell packs | Separate by chemistry type | UN-certified packaging with absorbent material |

Mistake to avoid: Storing loose batteries in metal containers – this can create accidental short circuits through contact with container walls.

Pro Tip: Always maintain a Class D fire extinguisher (specifically for metal fires) when working with large quantities of lithium batteries. Standard ABC extinguishers can actually worsen lithium battery fires.

Long-Term Performance Optimization and Future Trends

Maximizing the lifespan of rechargeable 3V batteries requires understanding their degradation mechanisms and implementing proactive maintenance strategies. Advanced users can achieve 2-3 times the standard cycle life through proper care and monitoring.

Capacity Retention Strategies

Five key factors influence long-term capacity:

| Factor | Optimal Condition | Degradation Rate if Ignored |

|---|---|---|

| Charge Level | 40-60% for storage | 2%/month at full charge |

| Temperature | 15-25°C | 5% capacity loss per 10°C above 25°C |

| Discharge Depth | 20-80% range | 50% more cycles at partial vs. full discharge |

Example: A security system battery cycled between 3.3V-3.0V (rather than 3.6V-2.8V) can last 5+ years instead of 2-3 years.

Emerging Battery Technologies

The next generation of 3V rechargeables includes:

- Solid-state lithium: 40% higher energy density with zero risk of leakage (commercial availability expected 2026-2028)

- Lithium-titanate (LTO): 20,000+ cycle life but lower voltage (2.4V nominal) requiring boost circuits

- Self-healing electrolytes: MIT-developed technology that automatically repairs micro-fractures during charging

Environmental and Cost Considerations

A comprehensive cost analysis reveals:

- Initial cost: Quality rechargeable ($8-15) vs. disposable ($3-5)

- Break-even point: 15-20 cycles for most applications

- Environmental impact: One rechargeable replaces 100+ disposables, reducing lithium mining by 95% per kWh

Professional installations (like municipal IoT networks) should implement battery rotation systems – cycling cells between primary and backup roles every 6 months to equalize wear.

Pro Tip: For systems requiring ultra-long reliability (10+ years), consider lithium-ion capacitors (LICs). While more expensive, they combine battery energy with capacitor longevity (500,000+ cycles) and operate effectively across -40°C to 85°C ranges.

System Integration and Advanced Monitoring Techniques

Integrating rechargeable 3V batteries into complex electronic systems requires careful voltage management and real-time monitoring to ensure optimal performance and prevent system failures. Professional applications demand more sophisticated approaches than basic voltage checks.

Voltage Regulation in Mixed-System Environments

When combining 3V batteries with other power sources, consider these critical factors:

- Voltage matching: Use buck-boost converters (like the TPS63020) to maintain stable 3V output when battery voltage fluctuates between 2.8-3.6V

- Parallel configurations: Only connect batteries of identical chemistry, age, and capacity – mismatched cells can create dangerous reverse-charging situations

- Load sharing: Implement current-balancing circuits when using multiple batteries to prevent one cell from bearing disproportionate load

Example: Industrial sensors often use diode-ORing circuits to seamlessly switch between primary and backup batteries during voltage drops.

Advanced Monitoring Systems

Professional-grade battery monitoring involves multiple parameters:

| Parameter | Monitoring Method | Optimal Range |

|---|---|---|

| State of Charge | Coulomb counting ICs (MAX17048) | ±1% accuracy |

| Internal Resistance | AC impedance spectroscopy | <100mΩ for new cells |

| Temperature Gradient | Thermocouple arrays | <2°C variation across cell |

Troubleshooting Integration Issues

Common system integration problems and solutions:

- Voltage spikes during switching: Add 100μF tantalum capacitors near load points to smooth transitions

- False low-battery warnings: Implement 30-second voltage averaging to ignore temporary load spikes

- Uneven cell aging: Use active balancing circuits (like the BQ25887) to redistribute charge during operation

For mission-critical medical devices, consider redundant monitoring systems that cross-validate readings from multiple sensors.

Pro Tip: When designing custom battery packs, always include a fuel gauge IC with SMBus/I2C interface. This enables precise remaining runtime predictions by tracking both voltage and current flow patterns over time.

Mission-Critical Applications and Quality Assurance Protocols

In high-stakes environments like medical devices and aerospace systems, rechargeable 3V batteries require rigorous validation processes that far exceed consumer-grade standards. These applications demand absolute reliability with failure rates below 0.001% per operating hour.

Medical Device Implementation Standards

FDA-cleared medical devices must comply with stringent battery requirements:

| Requirement | Test Protocol | Acceptance Criteria |

|---|---|---|

| Runtime Consistency | 500 discharge cycles at rated load | ±5% capacity variation |

| Failure Modes | Accelerated aging at 55°C | Zero catastrophic failures |

| EMI Immunity | IEC 60601-1-2 testing | No performance degradation |

Example: Implantable neurostimulators use special hermetically sealed Li-Ion cells with triple-redundant protection circuits.

Aerospace and Defense Validation

Military-grade batteries undergo extreme conditioning:

- Vibration testing: 3-axis random vibration profiles simulating rocket launch (20-2000Hz at 15Grms)

- Thermal vacuum cycling: -55°C to +85°C transitions in <1% atmospheric pressure

- Mechanical shock: 100G half-sine pulses for 6ms duration

These protocols ensure operation in satellite applications where battery replacement is impossible.

Failure Mode Analysis and Mitigation

Advanced quality systems implement:

- DFMEA (Design Failure Mode Effects Analysis): Identifies 200+ potential failure points in cell design

- CT scanning: Non-destructive internal structure inspection every 500 cycles

- Electrochemical impedance spectroscopy: Detects separator degradation before it causes failures

For nuclear power plant backup systems, some manufacturers perform 100% burn-in testing – cycling each battery 50 times before deployment.

Pro Tip: When auditing battery suppliers, request their Weibull analysis reports. This statistical method predicts failure rates over time, with high-reliability applications requiring β (shape parameter) >1.5 and η (characteristic life) >10,000 cycles.

Conclusion

Mastering rechargeable 3V battery performance requires understanding voltage characteristics, proper charging techniques, and advanced monitoring methods.

We’ve explored how voltage fluctuates with load and temperature, optimal charging protocols that extend battery life, and specialized applications from medical devices to aerospace systems. The key takeaways include: monitoring voltage under actual load conditions, implementing chemistry-specific maintenance routines, and using professional-grade testing equipment for accurate assessments.

Your next step? Apply these insights by creating a customized voltage profile for your specific devices – this simple action can double your batteries’ usable lifespan while preventing unexpected failures. Remember, in mission-critical applications, investing in quality cells and proper monitoring systems isn’t just recommended – it’s essential for reliable operation.

Frequently Asked Questions About Rechargeable 3V Batteries

What’s the actual voltage range of a “3V” rechargeable battery?

While marketed as 3V, these batteries operate within specific voltage windows. Lithium-ion variants typically range from 4.2V (fully charged) to 2.8V (discharged), while LiFePO4 stays between 3.6V-2.5V. The nominal 3V rating represents the average operating voltage. For example, a CR123A rechargeable delivers most of its capacity between 3.2V-2.9V under moderate loads.

How do I properly test my battery’s health?

Use a multimeter with 1% accuracy to measure resting voltage after 2 hours off-charger. Then apply a 0.5C load (half the mAh rating) while monitoring voltage drop. Healthy cells should maintain >3.0V under load. For advanced analysis, measure internal resistance – values above 150mΩ indicate aging. Professional battery analyzers like the SKYRC MC3000 provide cycle life predictions.

Can I use rechargeable 3V batteries in devices designed for disposables?

Yes, but with important caveats. While physically compatible, rechargeables have different discharge curves. Devices with tight voltage cutoffs (like some smoke detectors) may malfunction. Always check your device’s minimum operating voltage – if it requires >2.9V, LiFePO4 (3.2V nominal) often works better than standard lithium-ion.

Why does my battery die suddenly instead of gradually losing power?

This abrupt failure occurs because lithium batteries maintain nearly constant voltage until reaching their discharge limit. When the internal chemical reactions can no longer sustain the voltage, it plummets rapidly. Implementing voltage monitoring circuits with early warnings (at 3.0V for critical applications) prevents unexpected shutdowns.

How many times can I realistically recharge a 3V battery?

Quality cells typically achieve 300-500 full cycles before reaching 80% capacity. However, partial discharges dramatically extend lifespan. Cycling between 3.3V-3.0V (instead of 3.6V-2.8V) can yield 1000+ cycles. Environmental factors matter too – at 45°C, cycle life halves compared to room temperature operation.

What’s the safest way to store these batteries long-term?

For optimal storage (6+ months): charge to 40-50% capacity (3.3V for LiFePO4), place in airtight containers with desiccant packs, and maintain at 10-25°C. Never store fully charged or depleted batteries. Important: check voltage every 3 months and recharge if it drops below 3.0V to prevent irreversible damage.

Are there fire risks with rechargeable 3V batteries?

While safer than high-voltage packs, risks exist during overcharge (above 4.3V for Li-ion), physical damage, or short circuits. Always use protected cells with built-in PCM circuits, especially in confined spaces. For high-risk applications, consider LiFePO4 chemistry which is thermally stable up to 270°C compared to standard lithium’s 130°C limit.

How do I choose between different 3V rechargeable chemistries?

Select based on application needs: LiFePO4 excels in safety and cycle life (2000+ cycles) but has lower energy density. Standard lithium-ion offers higher capacity in compact sizes. Lithium-titanate provides extreme temperature tolerance (-50°C to 65°C) but requires voltage conversion. For medical devices, only use cells with IEC 62133 certification.