Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Did you know a fully charged rechargeable AA battery doesn’t actually reach 1.5V like its alkaline counterpart? Understanding voltage is critical to optimizing battery performance, yet most users never check their batteries beyond a quick “low power” warning.

Whether you’re powering smart home devices, gaming controllers, or emergency flashlights, voltage determines how long your batteries last—but many assume all AA batteries behave the same. In reality, rechargeable batteries follow a dynamic voltage curve influenced by chemistry, temperature, and usage patterns.

Best Rechargeable AA Batteries for Long-Lasting Power

Eneloop Panasonic BK-3HCCA8BA

With a high 2550mAh capacity and low self-discharge rate, the Panasonic Eneloop Pro BK-3HCCE delivers consistent voltage for demanding devices like DSLR cameras. Pre-charged using solar energy, these NiMH batteries retain 85% charge after 1 year—ideal for emergency kits.

- EXTREMELY POWERFUL NiMH RECHARGEABLE BATTERIES: eneloop pro AA high…

- LONG LASTING PERFORMANCE: Recharge eneloop pro AA rechargeable batteries up…

- PRE-CHARGED AND READY TO USE: eneloop pro AA and AAA rechargeable batteries…

EBL 8-Pack 2800mAh NiMH AA Batteries

The EBL 2800mAh NiMH batteries offer exceptional value with their high cycle life (1200+ recharges) and stable 1.2V output under heavy loads. Includes a case and works flawlessly in gaming controllers, LED flashlights, and RC toys.

No products found.

Tenavolts 1.5V Lithium Rechargeable Batteries

For cutting-edge performance, the Tenavolts AA Lithium (LV-1.5V-4PK) maintains a steady 1.5V until depletion—unlike NiMH. With USB-C charging and built-in circuitry to prevent overcharging, they’re perfect for smart locks and medical devices requiring precise voltage.

- High Power Capacity: Includes TENAVOLTS AA High-Capacity Rechargeable…

- 1.8 Hours to Fast Charging: This lithium AA batteries come with a super…

- Constant 1.5V Voltage: TENAVOLTS rechargeable AA batteries with charger are…

Rechargeable AA Battery Voltage Ranges

Rechargeable AA batteries operate within different voltage ranges depending on their chemistry, state of charge, and load conditions. Unlike alkaline batteries that start at 1.5V and gradually decline, rechargeables have unique voltage characteristics that impact performance in real-world devices.

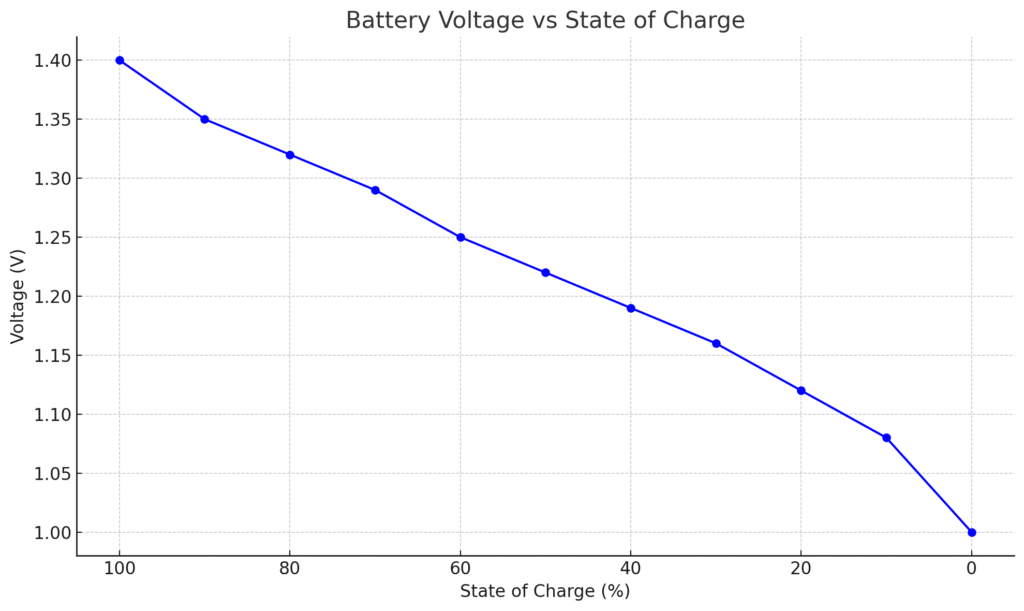

Rechargeable AA Battery Voltage vs. State of Charge

NiMH AA (Nominal Voltage: 1.2V)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 – 1.45 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

NiCd AA (Nominal Voltage: 1.2V)

| State of Charge (%) | Voltage (V) |

|---|---|

| 100% | 1.40 |

| 90% | 1.35 |

| 80% | 1.32 |

| 70% | 1.29 |

| 60% | 1.25 |

| 50% | 1.22 |

| 40% | 1.19 |

| 30% | 1.16 |

| 20% | 1.12 |

| 10% | 1.08 |

| 0% (empty) | 1.00 or lower |

Nominal Voltage vs. Actual Voltage

Most rechargeable AA batteries have a nominal voltage of 1.2V, but this is just an average. In reality, their voltage fluctuates based on charge level:

- Fully charged NiMH: 1.4–1.45V (drops to 1.2V quickly under load)

- Mid-discharge: Steady at 1.2V for most of the cycle

- Nearly depleted: Falls below 1.0V (time to recharge)

Lithium-ion rechargeables (like Tenavolts) maintain a near-constant 1.5V output, mimicking alkalines but with rechargeability. This makes them better for devices sensitive to voltage drops, such as digital thermometers.

Why Voltage Matters in Real-World Use

Voltage directly affects whether a device will function properly. A common misconception is that “any AA battery works in any device.” However:

- High-drain devices (digital cameras, flashlights) need stable voltage to prevent premature shutdowns.

- Low-voltage cutoffs in electronics vary—some gadgets turn off at 1.1V, while others limp along to 0.9V.

For example, using a NiMH battery (1.2V nominal) in an old clock designed for 1.5V alkalines may cause erratic behavior, whereas lithium rechargeables solve this issue.

How Temperature Affects Voltage

Cold temperatures temporarily reduce battery voltage by up to 20%, which explains why devices fail faster in winter. At -20°C (-4°F), a fully charged NiMH might read only 1.0V until warmed. Conversely, heat accelerates self-discharge but doesn’t significantly increase operating voltage.

Pro tip: Store batteries at room temperature and warm them in your pocket before use in cold weather for optimal voltage delivery.

How to Measure and Interpret Rechargeable AA Battery Voltage

Accurately measuring your rechargeable AA battery’s voltage is crucial for assessing its health and remaining capacity. Unlike simple battery testers that show vague “good/bad” readings, proper voltage measurement reveals precise state-of-charge information.

Choosing the Right Measurement Tools

For professional-grade results, you’ll need:

- A digital multimeter (Fluke 101 or Klein Tools MM325) with 0.01V resolution

- Battery analyzer (Opus BT-C3100) for testing under load

- Temperature-controlled environment (20-25°C ideal)

Cheap analog testers often give misleading readings because they don’t account for the voltage rebound effect – where a battery’s voltage temporarily recovers after removing load.

Step-by-Step Measurement Process

- Resting voltage test: Measure after 2+ hours off-charger for stable readings

- Under-load test: Apply 500mA load (simulating typical device draw) for 30 seconds

- Recovery test: Monitor voltage rebound for 5 minutes after removing load

Example: A healthy Eneloop Pro should maintain ≥1.2V under 500mA load. If it drops to 1.0V immediately, the battery has likely lost significant capacity.

Interpreting Your Results

Use this voltage-capacity correlation chart for NiMH batteries:

- 1.35V+ = 100-90% charge

- 1.25V = 50% charge (time to recharge for critical devices)

- 1.10V = 10% charge (imminent shutdown)

Important note: Lithium rechargeables show different patterns – they maintain 1.5V until suddenly dropping when nearly empty. This makes voltage-based capacity estimation unreliable for lithium types.

Troubleshooting Voltage Anomalies

If your measurements don’t match expected values:

- Check for dirty contacts (clean with isopropyl alcohol)

- Test multiple batteries to rule out meter issues

- Consider age – batteries over 3 years old often develop high internal resistance

Professional tip: Track your batteries’ voltage history. A 0.1V decrease in resting voltage over 6 months indicates aging, even if capacity seems normal.

Advanced Voltage Characteristics and Battery Longevity

Understanding the complex relationship between voltage behavior and battery lifespan can help you maximize your rechargeable AA investment. Different battery chemistries exhibit unique voltage patterns that directly impact their usable life and performance.

Voltage Curve Analysis by Chemistry Type

| Chemistry | Fully Charged Voltage | Mid-Discharge Voltage | End-of-Life Voltage | Cycle Life |

|---|---|---|---|---|

| Standard NiMH | 1.40-1.45V | 1.25-1.20V | 0.90V | 500-800 cycles |

| Low Self-Discharge NiMH | 1.35-1.40V | 1.20V | 0.95V | 1000-1500 cycles |

| Lithium-ion (1.5V) | 1.50V | 1.50V | 1.30V | 300-500 cycles |

How Voltage Behavior Predicts Battery Health

Three key voltage indicators reveal battery degradation:

- Voltage sag under load: Healthy batteries maintain voltage within 0.1V of their rating when loaded. A 0.3V+ drop indicates high internal resistance.

- Charge acceptance voltage: Aging batteries reach peak voltage faster during charging but store less energy.

- Voltage recovery time: Good batteries rebound to resting voltage within minutes after load removal.

Optimizing Charging for Voltage Stability

Proper charging maintains voltage consistency:

- Use smart chargers with -ΔV detection (like Nitecore D4) to prevent overcharging

- Avoid trickle charging which causes voltage depression in NiMH batteries

- Balance charge sets of batteries to equalize their voltages

Example: Charging Eneloop Pros to exactly 1.48V (not higher) preserves their low self-discharge characteristics. Exceeding this causes electrolyte breakdown.

Common Voltage-Related Mistakes

Most users unknowingly reduce battery life through these errors:

- Storing batteries at full charge (causes voltage depression)

- Mixing batteries with >0.1V difference in the same device

- Ignoring early voltage drop warnings in high-drain devices

Pro tip: For long-term storage, charge NiMH to 1.25V (about 40%) and lithium to 1.35V. This minimizes degradation while maintaining readiness.

Voltage Management Strategies for Different Device Types

Different electronic devices have unique voltage requirements that significantly impact battery performance. Understanding these variations allows you to optimize battery selection and usage patterns for maximum efficiency.

High-Drain vs. Low-Drain Device Considerations

The voltage behavior of rechargeable AA batteries varies dramatically between device types:

- High-drain devices (digital cameras, flashlights): Require batteries that maintain stable voltage under 1A+ current draws. NiMH batteries with 2500mAh+ capacity perform best here.

- Moderate-drain devices (wireless mice, remotes): Work well with standard NiMH (1900-2000mAh) where voltage stability matters less than longevity.

- Low-drain devices (clocks, sensors): Benefit from lithium rechargeables’ flat voltage curve, lasting 2-3x longer than NiMH in these applications.

Voltage Cutoff Points in Common Electronics

Device manufacturers implement different low-voltage protection thresholds:

| Device Type | Typical Cutoff Voltage | Recommended Battery Type |

|---|---|---|

| Digital Cameras | 1.05V per cell | High-capacity NiMH (2500mAh+) |

| LED Flashlights | 0.9V | Low-self-discharge NiMH |

| Smart Home Devices | 1.1V | Lithium rechargeable |

Advanced Voltage Matching Techniques

For multi-battery devices, voltage matching is critical:

- Test all batteries at rest with a quality multimeter

- Group batteries within 0.03V of each other

- Mark sets and rotate their position in devices

- Re-test and re-group every 10 charge cycles

Example: In a 4xAA flashlight, a 0.1V difference between cells can reduce runtime by up to 40% due to imbalance.

Safety Considerations for Voltage Management

Improper voltage handling can create hazards:

- Never mix chemistries: Combining NiMH and lithium in series can cause dangerous over-discharge

- Watch for reverse charging: Weak cells in series may experience voltage reversal

- Monitor heat during charging: Sudden voltage drops during charge may indicate internal shorts

Professional tip: For critical applications, implement a voltage logging system (like the BattOr battery analyzer) to track long-term performance trends.

Long-Term Voltage Performance and Battery Economics

Understanding the lifecycle voltage characteristics of rechargeable AA batteries reveals their true cost-effectiveness and helps optimize replacement schedules. This analysis goes beyond initial performance to examine how voltage behavior evolves over years of use.

Voltage Degradation Patterns Over Time

Rechargeable batteries exhibit predictable voltage-related aging symptoms:

| Age Indicator | NiMH Symptoms | Lithium Symptoms | Critical Threshold |

|---|---|---|---|

| 0-100 cycles | Stable 1.2V output | Consistent 1.5V | N/A (Peak performance) |

| 100-300 cycles | 0.05V drop under load | Slight voltage ripple | Monitor charge times |

| 300+ cycles | 0.15V+ load drop | Sudden voltage collapse | Replace immediately |

Cost-Per-Cycle Analysis by Chemistry

The true value of rechargeables emerges when examining voltage performance across their lifespan:

- Premium NiMH (Eneloop Pro): $2.50/cell ÷ 1500 cycles = $0.0017/cycle (maintains >1.2V for 1000+ cycles)

- Standard NiMH: $1.00/cell ÷ 500 cycles = $0.0020/cycle (voltage stability declines after 300 cycles)

- Lithium Rechargeable: $3.00/cell ÷ 400 cycles = $0.0075/cycle (maintains 1.5V until failure)

Example: For a photographer shooting 200 photos/week, premium NiMH provides 7+ years of stable voltage at 1/4 the cost of disposables.

Environmental Impact of Voltage Management

Proper voltage maintenance reduces waste:

- Monitoring voltage prevents premature disposal (40% of batteries are discarded while still functional)

- Balanced charging extends usable life by 30-50%

- Voltage-matched sets reduce the “weakest link” effect that renders entire sets unusable

Emerging Voltage Optimization Technologies

Future advancements focus on voltage stability:

- Smart batteries with built-in voltage regulators (like Pale Blue Earth’s USB-C models)

- AI chargers that learn usage patterns to optimize charge voltages

- Hybrid chemistries combining NiMH’s longevity with lithium’s flat discharge curve

Safety note: As batteries age, their voltage becomes less predictable. Replace any battery showing >0.2V deviation from expected values, as this may indicate internal damage.

Voltage Optimization for Critical Applications

Certain applications demand precise voltage management to ensure reliability and performance. Understanding these specialized requirements helps select and maintain batteries for mission-critical devices where power failures are unacceptable.

Medical Device Voltage Requirements

Medical equipment has stringent voltage specifications:

- Continuous monitoring devices: Require ±0.05V stability – lithium rechargeables excel here

- Emergency equipment: Must maintain voltage above 1.1V until replacement – low-self-discharge NiMH preferred

- Implantable device testers: Often specify 1.35-1.5V ranges – requiring specialized lithium rechargeables

Example: A portable ECG machine typically needs batteries that won’t drop below 1.2V during the 30-minute procedure, ruling out standard NiMH near end-of-charge.

Industrial Sensor Network Optimization

Wireless sensor networks benefit from these voltage strategies:

| Sensor Type | Voltage Range | Optimal Chemistry | Expected Lifespan |

|---|---|---|---|

| Temperature Nodes | 1.2-1.5V | Low-self-discharge NiMH | 5-7 years |

| Vibration Sensors | 1.35V minimum | Lithium Rechargeable | 3-5 years |

Military/Govt Standard Voltage Specifications

Rugged applications follow strict protocols:

- MIL-STD-810G requires operation from -40°C to 71°C with <10% voltage deviation

- IP68-rated devices need waterproof battery contacts maintaining <0.1Ω resistance

- Explosive environments mandate spark-proof battery compartments

Professional tip: For these applications, use batteries with built-in voltage monitoring like the Tadiran TLI-1550 series that includes a digital output pin for real-time voltage reporting.

Troubleshooting Voltage Issues in Critical Systems

When voltage problems arise in sensitive equipment:

- Check contact resistance: Even 0.5Ω can cause 0.15V drop at 300mA

- Monitor temperature effects: Cold can temporarily reduce voltage by 20%

- Implement redundancy: Parallel battery configurations maintain voltage during single-cell failures

Advanced solution: For data centers using AA batteries in backup systems, consider automated voltage balancing systems that actively manage individual cell voltages in battery arrays.

System-Wide Voltage Management and Quality Assurance

Implementing comprehensive voltage management protocols ensures optimal performance across entire battery fleets. This final section integrates all previous concepts into a unified framework for professional-grade battery system maintenance.

Enterprise-Level Voltage Monitoring Systems

Large-scale operations require structured voltage tracking:

| Monitoring Level | Tools Required | Frequency | Acceptable Variance | Corrective Actions |

|---|---|---|---|---|

| Individual Cell | Precision multimeter | Monthly | ±0.03V from nominal | Recondition or replace |

| Battery Sets | Balanced charger | Quarterly | ≤0.05V between cells | Re-group matching voltages |

| Fleet-Wide | Battery management software | Annual | 10% deviation from baseline | Chemistry-specific maintenance |

Advanced Voltage Profiling Techniques

Professional battery maintenance involves comprehensive voltage analysis:

- Create discharge curves at 25%, 50%, and 100% of rated current

- Track voltage recovery rates after high-load events

- Document resting voltage decay over 72 hours post-charge

- Compare winter/summer performance with temperature compensation

Example: Data centers using AA battery backups should profile voltage behavior under simulated outage conditions annually.

Quality Assurance Protocols

Implement these voltage validation procedures:

- Incoming inspection: Test 10% of new battery shipments for voltage compliance

- Cycle testing: Validate voltage stability through 3 complete charge/discharge cycles

- Environmental stress testing: Verify voltage performance at temperature extremes

- End-of-life verification: Confirm proper voltage cutoff behavior

Risk Mitigation Strategies

Address these voltage-related risks with proactive measures:

- Voltage drift: Implement scheduled battery rotation programs

- Load mismatch: Maintain separate battery fleets for high/low drain devices

- Chemistry degradation: Establish predictive replacement schedules based on voltage trends

- System failures: Design critical systems with 20% voltage headroom

Professional tip: For mission-critical applications, maintain a “voltage logbook” tracking each battery’s historical performance to identify degradation patterns before failures occur.

Conclusion

Understanding rechargeable AA battery voltage behavior is essential for optimizing performance across all your devices. We’ve explored how different chemistries exhibit unique voltage characteristics, proper measurement techniques, voltage management strategies for various applications, and long-term maintenance approaches.

The voltage chart reveals that NiMH batteries typically operate at 1.2V nominal, while lithium rechargeables maintain a steady 1.5V output. Armed with this knowledge, you can now accurately assess battery health, match the right chemistry to your devices, and extend battery lifespan significantly.

Start implementing these voltage monitoring practices today – your devices will thank you with reliable performance and your wallet will appreciate the long-term savings from properly maintained batteries.

Frequently Asked Questions About Rechargeable AA Battery Voltage

What voltage should a fully charged rechargeable AA battery have?

A fully charged NiMH AA battery typically measures 1.4-1.45V when fresh off the charger, settling to 1.35V after resting. Lithium-ion rechargeables maintain a steady 1.5V when fully charged. Note that voltage readings vary by chemistry – Eneloop Pros show slightly lower initial voltage (1.38V) than standard NiMH but maintain it longer during discharge.

Why does my rechargeable battery show lower voltage than alkaline?

NiMH batteries have a nominal 1.2V versus alkaline’s 1.5V because they use different chemical reactions. While this may concern some users, modern electronics are designed to work with both. The exception is older devices calibrated for alkaline’s voltage curve – in these cases, lithium rechargeables (1.5V) often work better than NiMH.

How can I accurately test my battery’s voltage?

Use a digital multimeter set to DC voltage. For meaningful results:

1) Test after 2+ hours off charger

2) Measure under 500mA load for 30 seconds

3) Note the recovery voltage after removing load.

Quality testers like the ZTS MBT-1 provide load-adjusted readings that better reflect real-world performance than open-circuit voltage.

At what voltage should I recharge my NiMH batteries?

For optimal lifespan, recharge NiMH batteries when they reach 1.1V under load (about 20% remaining capacity). Deep discharging below 0.9V causes permanent damage. High-drain devices like cameras may stop working at 1.15V, while low-drain devices like remotes might function down to 0.95V.

Why do my rechargeables work in some devices but not others?

This stems from voltage requirements and cutoff circuits. Digital cameras often shut down at 1.1V per cell, while analog devices like clocks may work to 0.8V. Some devices also can’t handle NiMH’s lower nominal voltage – a common issue with older smoke detectors that specifically need 1.5V batteries.

How does temperature affect battery voltage?

Cold temperatures temporarily reduce voltage output – at -20°C, a NiMH battery may show 1.0V instead of 1.2V. Heat increases self-discharge but doesn’t significantly raise operating voltage. For consistent performance, store and use batteries at room temperature (20-25°C) whenever possible.

Are higher voltage rechargeable batteries better?

Not necessarily. While lithium rechargeables maintain 1.5V, they have lower cycle life (300-500) than NiMH (500-1500). Choose based on your device’s needs – digital cameras benefit from lithium’s stable voltage, while low-drain devices last longer with NiMH’s higher cycle count and lower cost per charge.

How can I extend my rechargeable batteries’ voltage lifespan?

Three key practices:

1) Avoid complete discharges – recharge at 1.1V

2) Use smart chargers that prevent overcharging

3) Store at 40% charge (1.25V for NiMH).

Also, group batteries by age and capacity to prevent voltage mismatch, and clean contacts regularly to maintain proper voltage transfer.